– 4 –

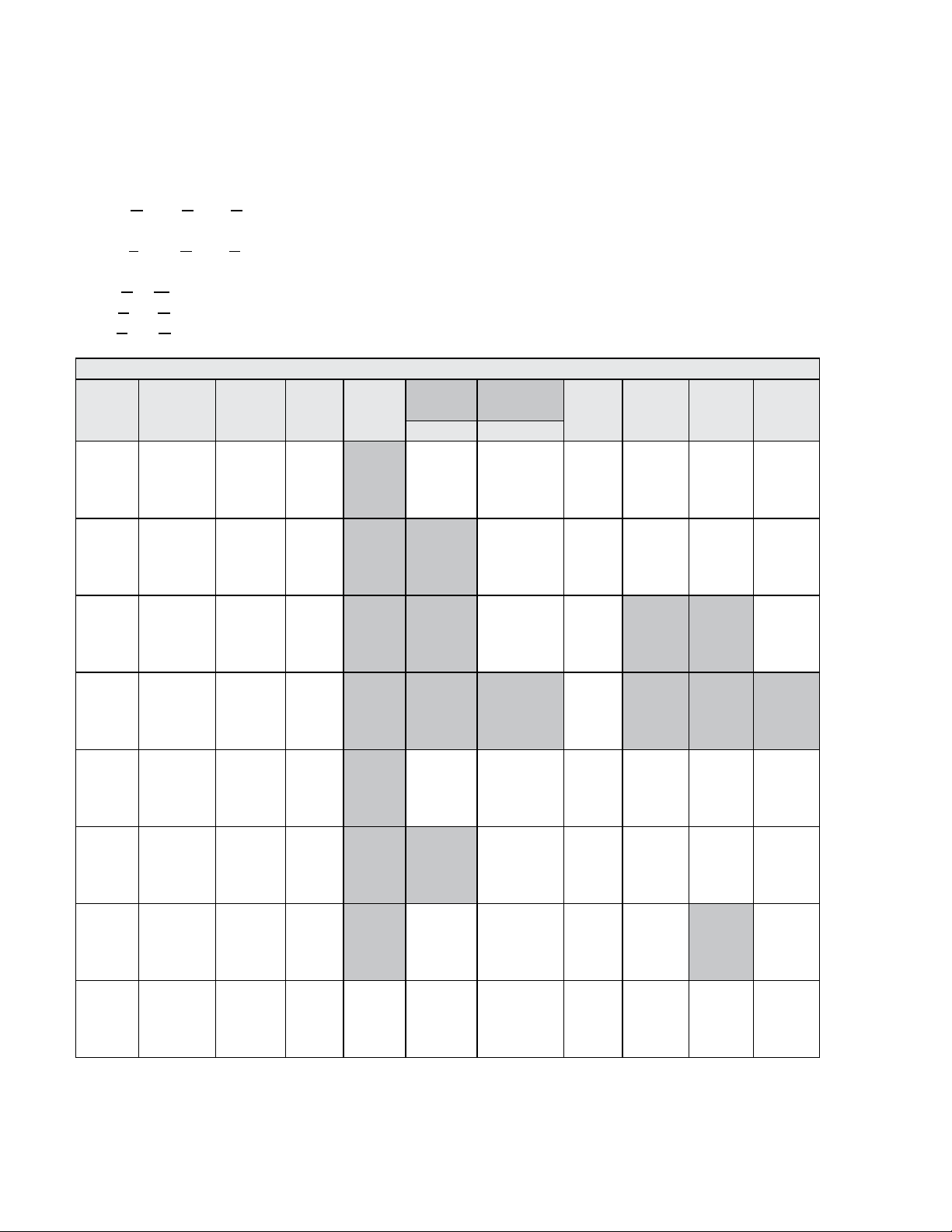

Circulation Diagnostics .........................................................................................................26

No Circulation ......................................................................................................................27

Circulation Motor and Pump Assembly.................................................................................28

Main Conduit ........................................................................................................................29

Middle Conduit......................................................................................................................29

Spray Arms ...........................................................................................................................29

Upper Rack...........................................................................................................................30

Lower Rack...........................................................................................................................30

Tub Gasket ...........................................................................................................................31

Latch System........................................................................................................................32

Dry System ...........................................................................................................................33

Heat Element Removal.........................................................................................................34

Heater Components .............................................................................................................35

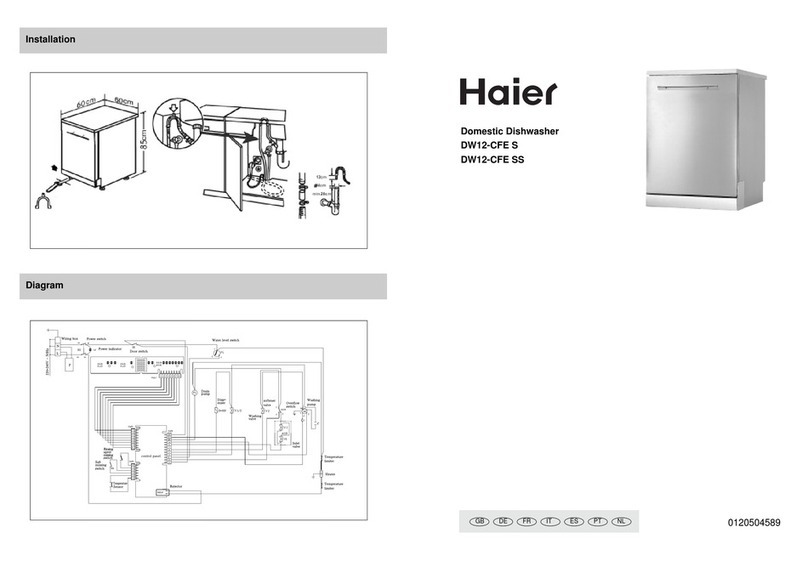

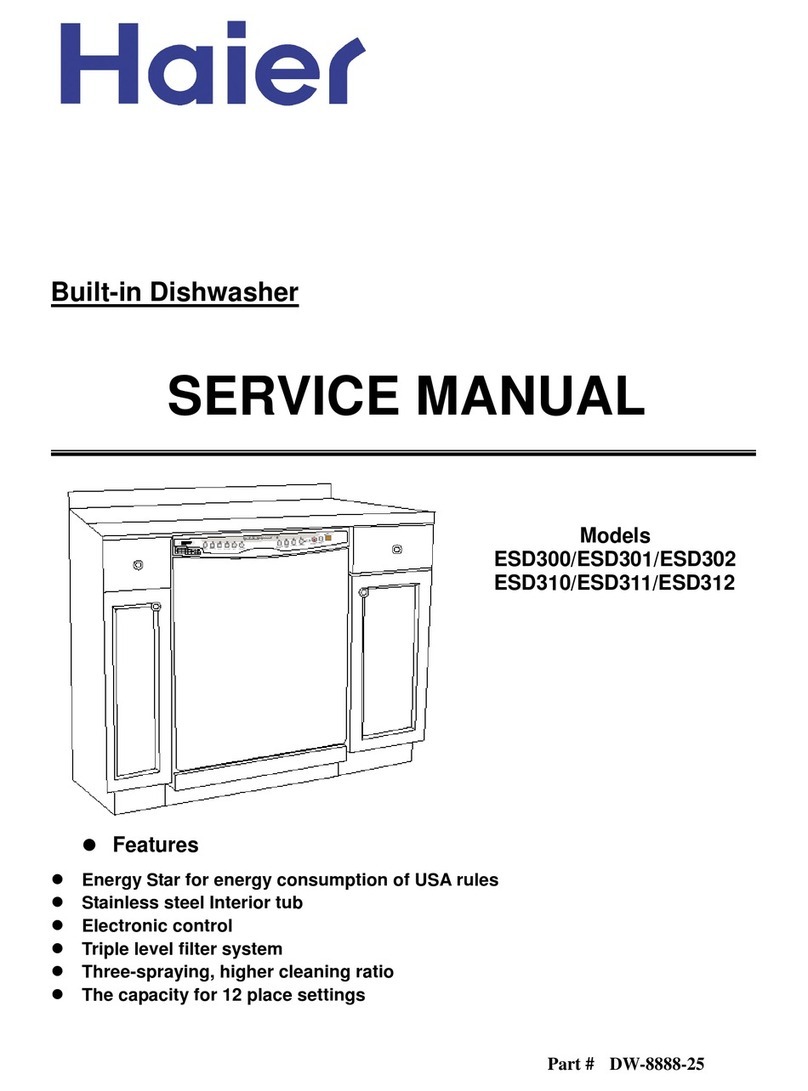

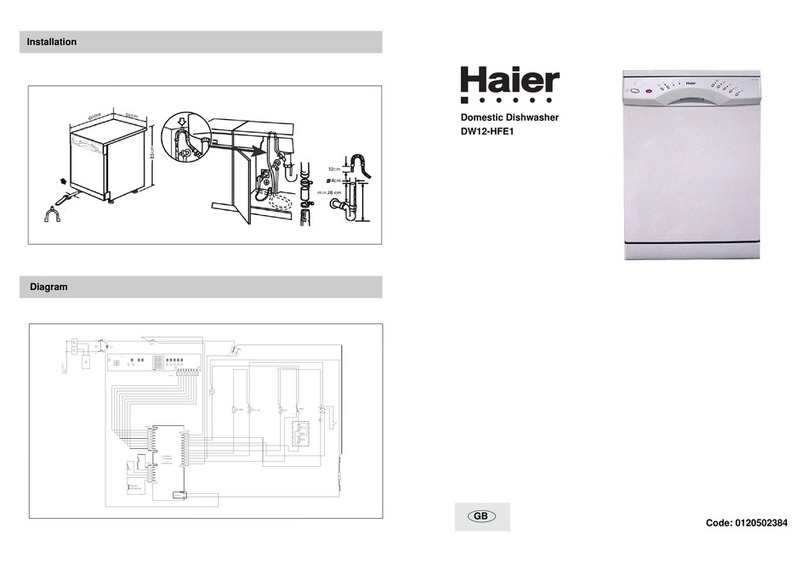

Structure.......................................................................................................................................37

Toe Kick ................................................................................................................................37

Junction Box and House Wiring Connection ........................................................................37

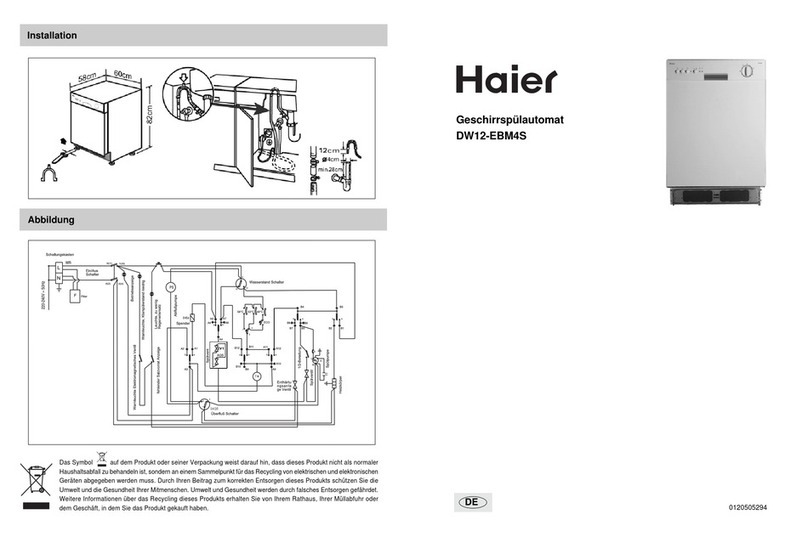

Leveling Legs .......................................................................................................................38

Right Door Balance System .................................................................................................38

Left Door Balance System....................................................................................................38

Fill System ............................................................................................................................39

Water Level...........................................................................................................................39

Pressure Sensor...................................................................................................................39

Fill Funnel and Hose.............................................................................................................40

Fill Valve ...............................................................................................................................41

No Fill Diagnostics................................................................................................................42

Main Control Board...............................................................................................................43

To Access Main Control Board .............................................................................................44

Thermistor.............................................................................................................................44

Current Sensor Module (CSM) .............................................................................................45

Drain System ........................................................................................................................46

Failure to Drain Flowchart ....................................................................................................47

Drain Pump...........................................................................................................................48

(Continued next page)