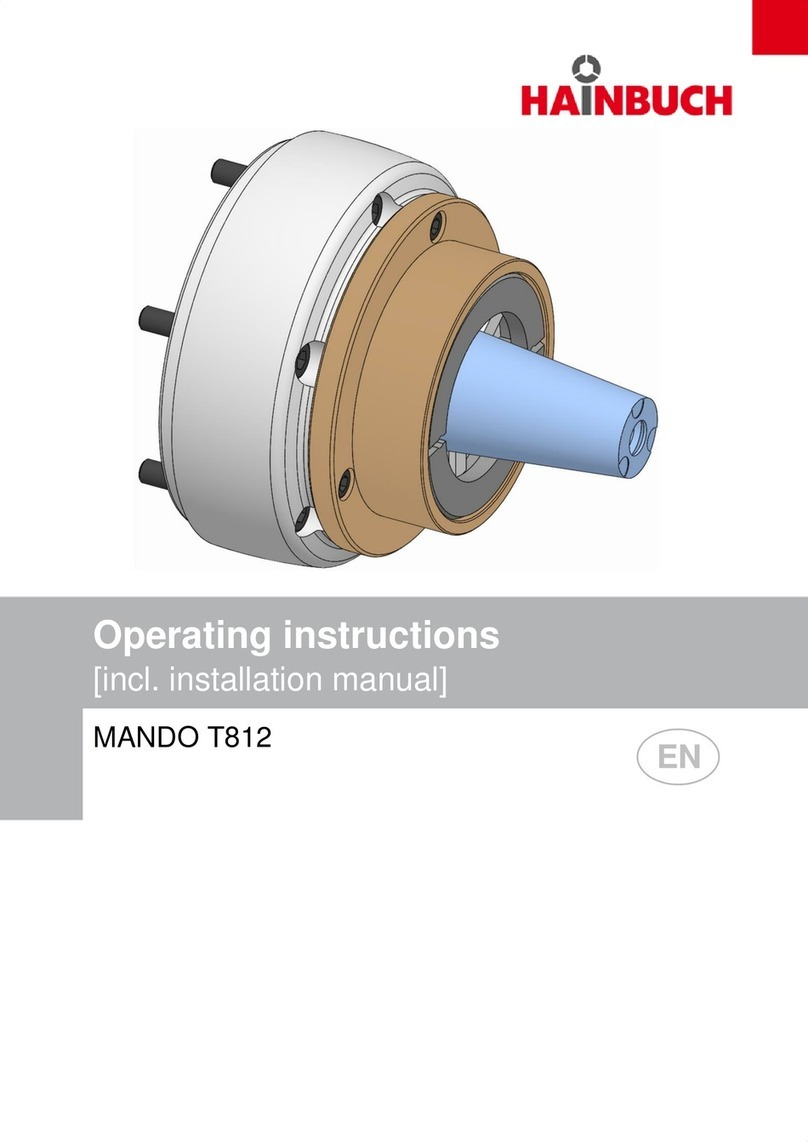

Segmented mandrel T812. english

5.4 Unpacking and inner-company transport......................................................26

5.5 Packaging..................................................................................................27

5.6 Storing.......................................................................................................28

6 Assembly...............................................................................................................29

6.1 Pre-consideration........................................................................................30

6.2 Preparations...............................................................................................30

6.3 Assembling of the clamping device...............................................................32

6.3.1 Assembling the draw tube adapter....................................................34

6.3.2 Assembling the flange......................................................................34

6.3.3 Assembling the quick-change machine adapter..................................37

6.3.4 Assembly of the segmented mandrel..................................................37

6.3.5 Assembly of the segmented mandrel [bayonet]...................................38

6.3.6 Assembly of the segmented mandrel [quick change-over interface].......39

6.3.7 Checking and adjusting the face run and the concentricity...................39

6.3.8 Assembly of the segmented clamping bushing RD...............................41

6.3.9 Assembling of the work piece end-stop..............................................42

6.4 Work piece................................................................................................43

6.5 Inspections.................................................................................................44

6.6 Control of the stroke position........................................................................45

6.7 Activities after production is concluded.........................................................45

7 Disassembly, subsequent storage, disposal...............................................................46

7.1 Safety........................................................................................................46

7.2 Disassembling the clamping device...............................................................48

7.2.1 Disassembling the work piece end-stop..............................................48

7.2.2 Disassembling the segmented clamping bushing [RD/SE]....................48

7.2.3 Disassembling the segmented mandrel [machine spindle]....................49

7.2.4 Disassembly of the segmented mandrel [bayonet]...............................49

7.2.5 Disassembly of the segmented mandrel [quick-change interface]..........50

7.2.6 Disassembling the flange..................................................................50

7.2.7 Disassembly of the quick-change machine adapter [optional]..............51

7.2.8 Disassembling the draw tube adapter................................................51

7.3 Subsequent storage of the clamping device...................................................51

7.4 Disposal.....................................................................................................52

8 Maintenance..........................................................................................................53

8.1 General.....................................................................................................53

8.2 Cleaning....................................................................................................55

8.3 Preservation...............................................................................................56

8.4 Use of lubricant..........................................................................................56

8.5 Maintenance schedule.................................................................................57

8.6 Bolt torque.................................................................................................59

Order Hotline +49 [0]7144. 907-333 3