2 / 40

Hakki Pilke 38 Pro Translation Version 3

Table of contents

1. General information.....................................................................................................................4

1.1. Introduction..............................................................................................................................................4

1.2. Purpose of use..........................................................................................................................................4

1.3. Machine models and basic information...................................................................................................4

1.4. Operating conditions................................................................................................................................4

1.5. Safety instructions....................................................................................................................................5

1.6. Noise and vibration ..................................................................................................................................5

1.7. Warning symbols ......................................................................................................................................5

2. Receipt and assembly...................................................................................................................7

2.1. Delivery inspection ...................................................................................................................................7

2.2. Lifting and moving the machine...............................................................................................................7

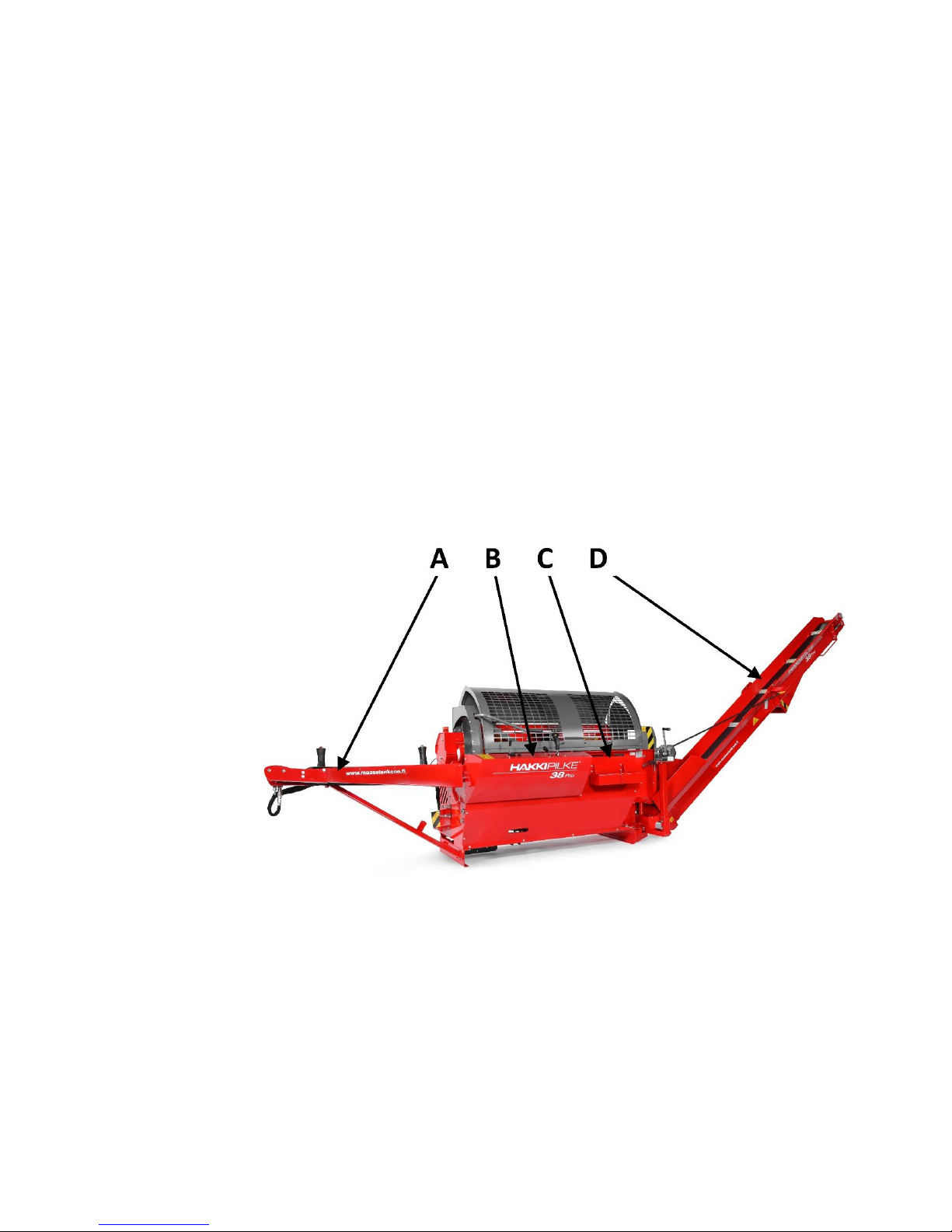

2.3. Main components of the machine ...........................................................................................................8

2.4. Preparing the machine for operation......................................... Virhe. Kirjanmerkkiä ei ole määritetty.

3. Control functions and setting up the machine ............................................................................9

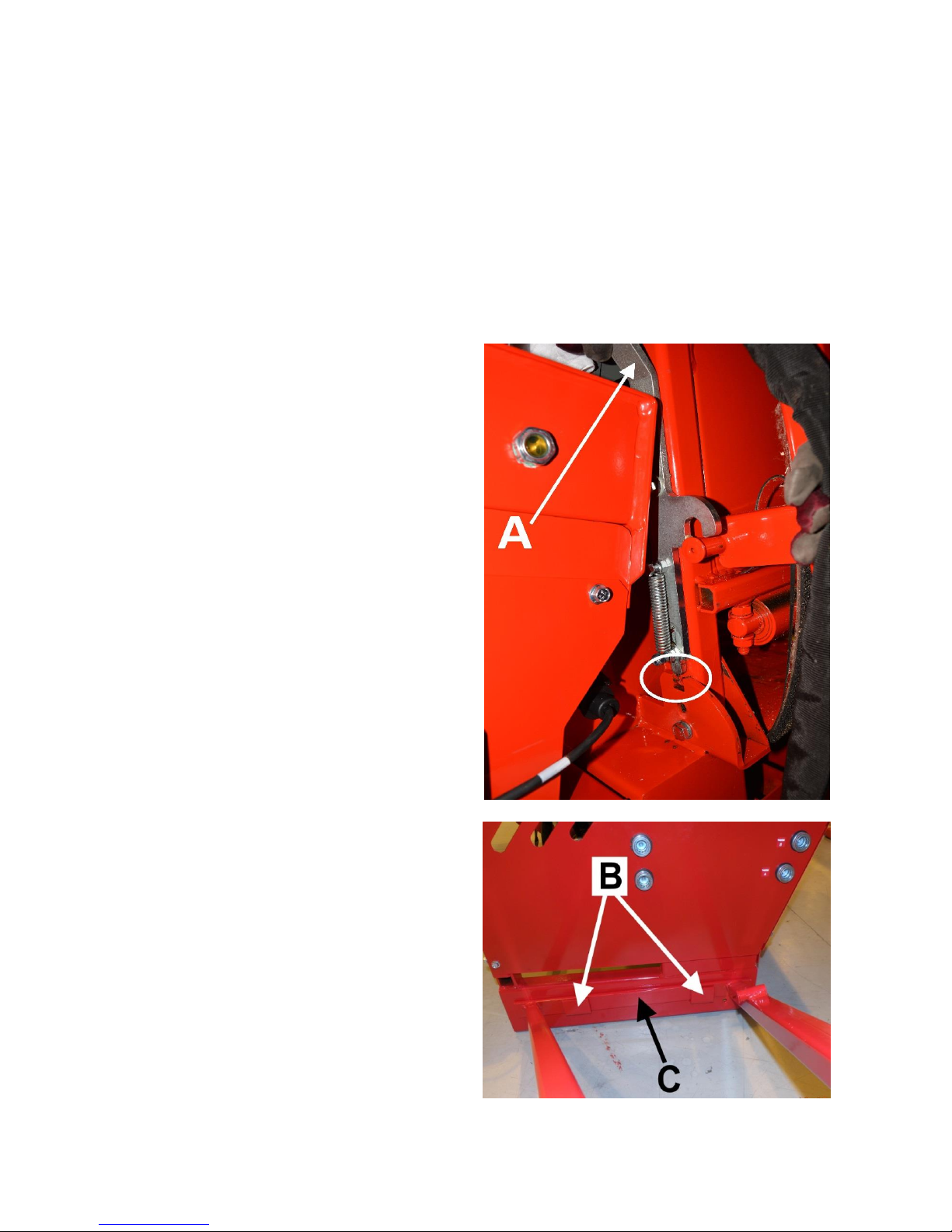

3.1. Arranging the machine for operation and transport ...............................................................................9

3.1.1. Placing the in-feed conveyor in the operating or transport position ...............................................9

3.1.2. Placing the out-feed conveyor in the operating or transport position ..........................................10

3.2. Controls ..................................................................................................................................................11

3.2.1. Tractor drive....................................................................................................................................12

3.2.2. Electrical drive.................................................................................................................................13

3.2.3. Adjusting the log length ..................................................................................................................15

3.2.4. Using the out-feed conveyor ..........................................................................................................15

3.2.5. Splitting blade adjustment..............................................................................................................17

3.2.6. Using a sawdust removal device.....................................................................................................17

4. Operating the machine ..............................................................................................................17

4.1. Performing a test run on the machine ...................................................................................................17

4.2. Placing logs on the in-feed conveyor .....................................................................................................18

4.3. Feeding and sawing wood ......................................................................................................................18

4.3.1. Jamming of the cutting blade .........................................................................................................19

4.3.2. Sawing the last log ..........................................................................................................................19

4.3.3. Using the quick couplings of the additional hydraulics ..................................................................19

4.3.4. Using the quick couplings of the auxiliary feed rollers ...................................................................19

4.4. Log splitting ............................................................................................................................................20

4.4.1. Jamming of wood on the splitting blade.........................................................................................20