2 / 48

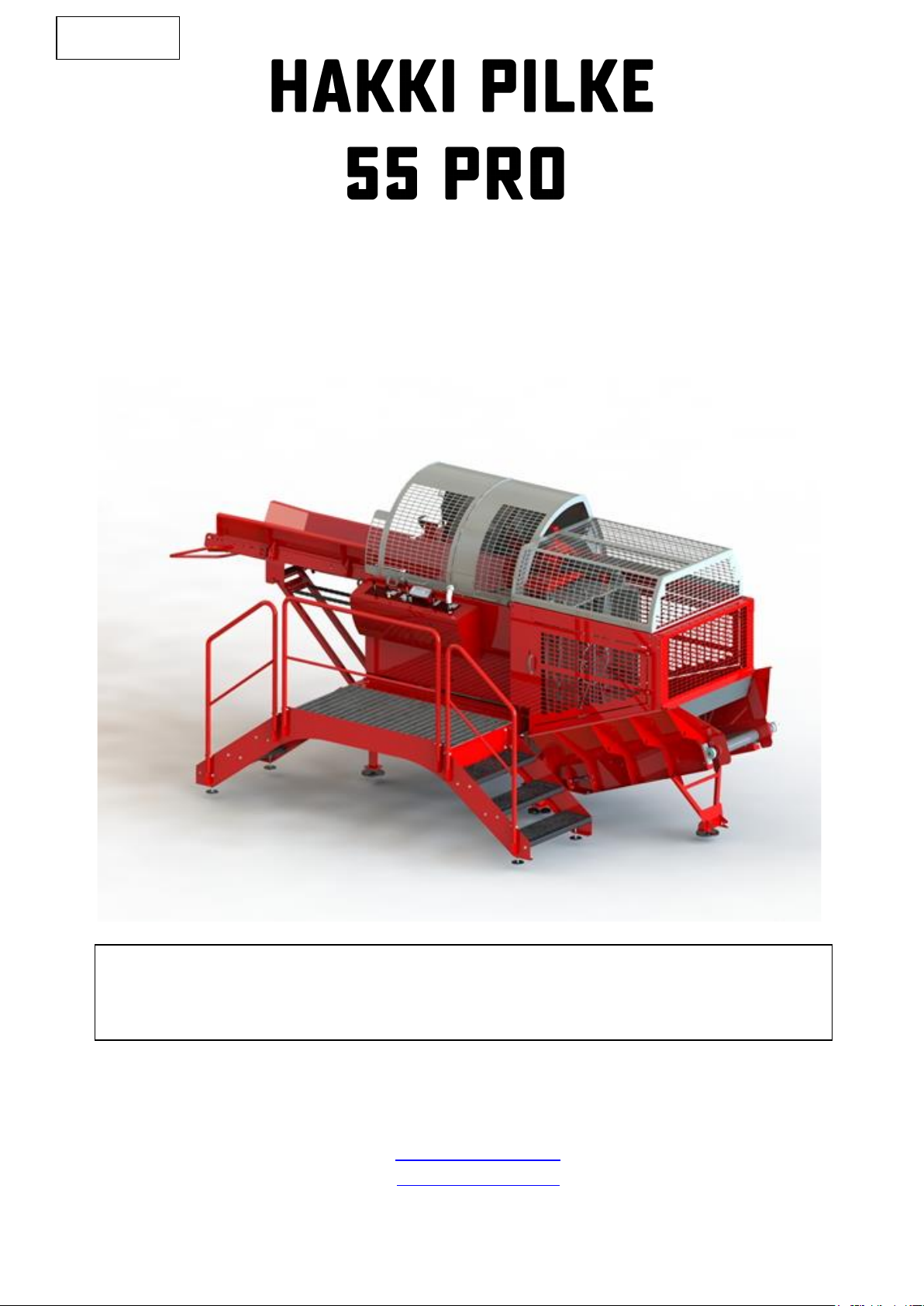

Hakki Pilke 55 Pro Translation Version 3-2022

Table of contents

1. General information.................................................................................................................... 4

1.1. Introduction...................................................................................................................................... 4

1.2. Purpose of use .................................................................................................................................. 4

1.3. Machine models and basic information........................................................................................... 4

1.4. Operating conditions ........................................................................................................................ 4

1.5. Safety instructions ............................................................................................................................ 5

1.6. Noise and vibration........................................................................................................................... 5

1.7. Warning symbols .............................................................................................................................. 5

2. Receipt and assembly.................................................................................................................. 7

2.1. Delivery inspection ........................................................................................................................... 7

2.2. Lifting and moving the machine ....................................................................................................... 7

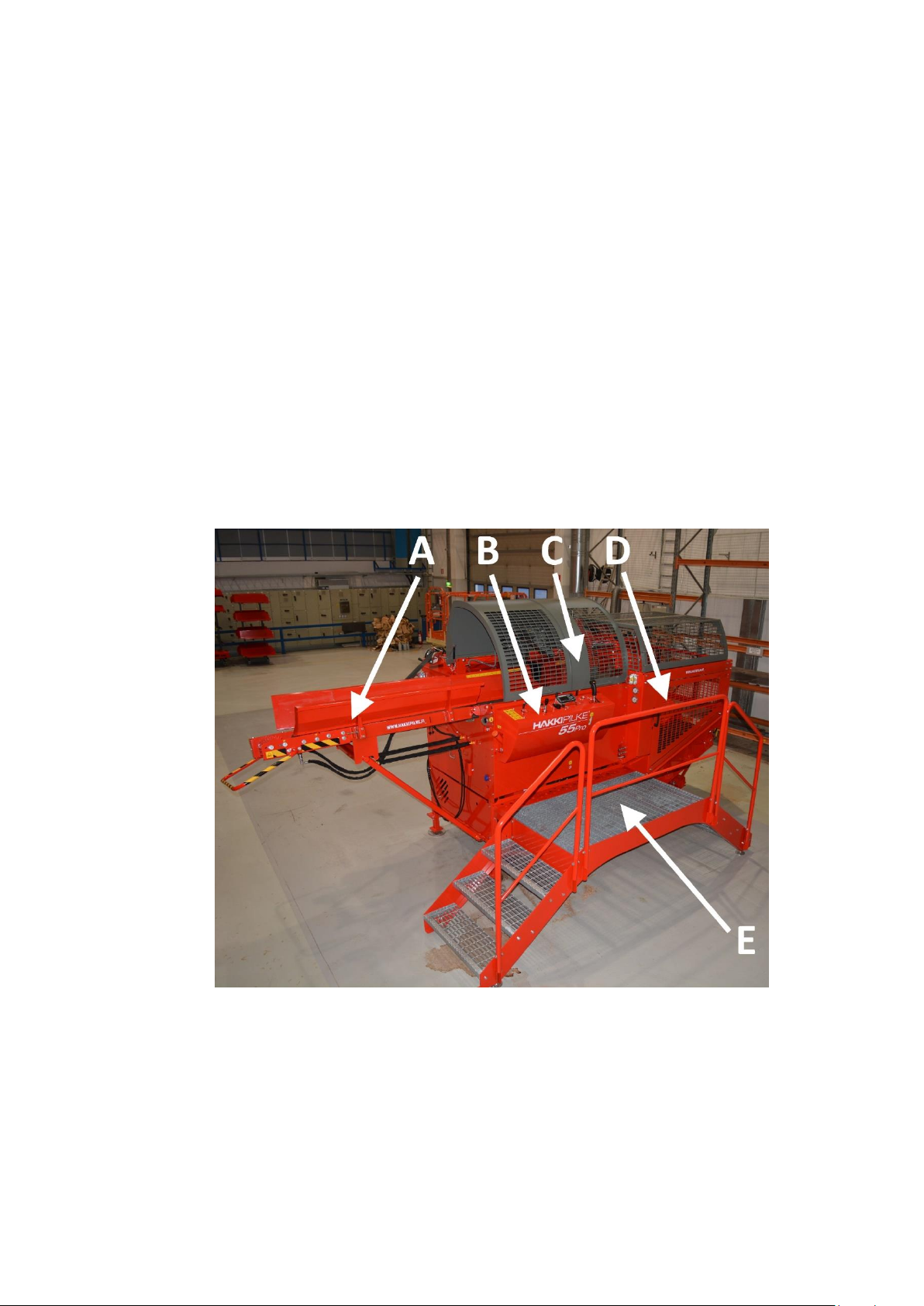

2.3. Main components of the machine ................................................................................................... 8

3. Control functions and setting up the machine............................................................................ 9

3.1. Preparing the machine for operation and transport........................................................................ 9

3.1.1. Placing the in-feed conveyor in the operating or storage position .......................................... 9

3.2. Controls........................................................................................................................................... 11

3.2.1. Using the machine’s monitor .................................................................................................. 13

3.2.2. Tractor drive ............................................................................................................................ 14

3.2.3. Electrical drive ......................................................................................................................... 15

3.2.4. Adjusting the log length .......................................................................................................... 16

3.2.5. Using the XL Conveyor out-feed conveyor (accessory)........................................................... 17

3.2.6. Adjusting and using the splitting knife.................................................................................... 18

3.2.7. Using the sawdust blower (accessory).................................................................................... 20

4. Operating the machine.............................................................................................................. 21

4.1. Performing a test run on the machine ........................................................................................... 21

4.2. Placing logs on the in-feed conveyor.............................................................................................. 22

4.3. Feeding and sawing wood .............................................................................................................. 22

4.3.1. Hydraulic log press .................................................................................................................. 22

4.3.2. Jamming of the cutting blade.................................................................................................. 23

4.3.3. Guide plates for falling wood pieces....................................................................................... 23

4.3.4. Sawing the last log................................................................................................................... 24

4.3.5. Using the quick couplings of the additional hydraulics........................................................... 24

4.3.6. Connecting a log table’s in-feed rollers to the in-feed conveyor............................................ 24

4.4. Log splitting..................................................................................................................................... 25

4.4.1. Jamming of wood on the splitting knife.................................................................................. 25

4.4.2. Resplitting or splitting without cutting ................................................................................... 25

4.4.1. Adjusting the stroke length of the splitting motion................................................................ 25