5

SUMMARY

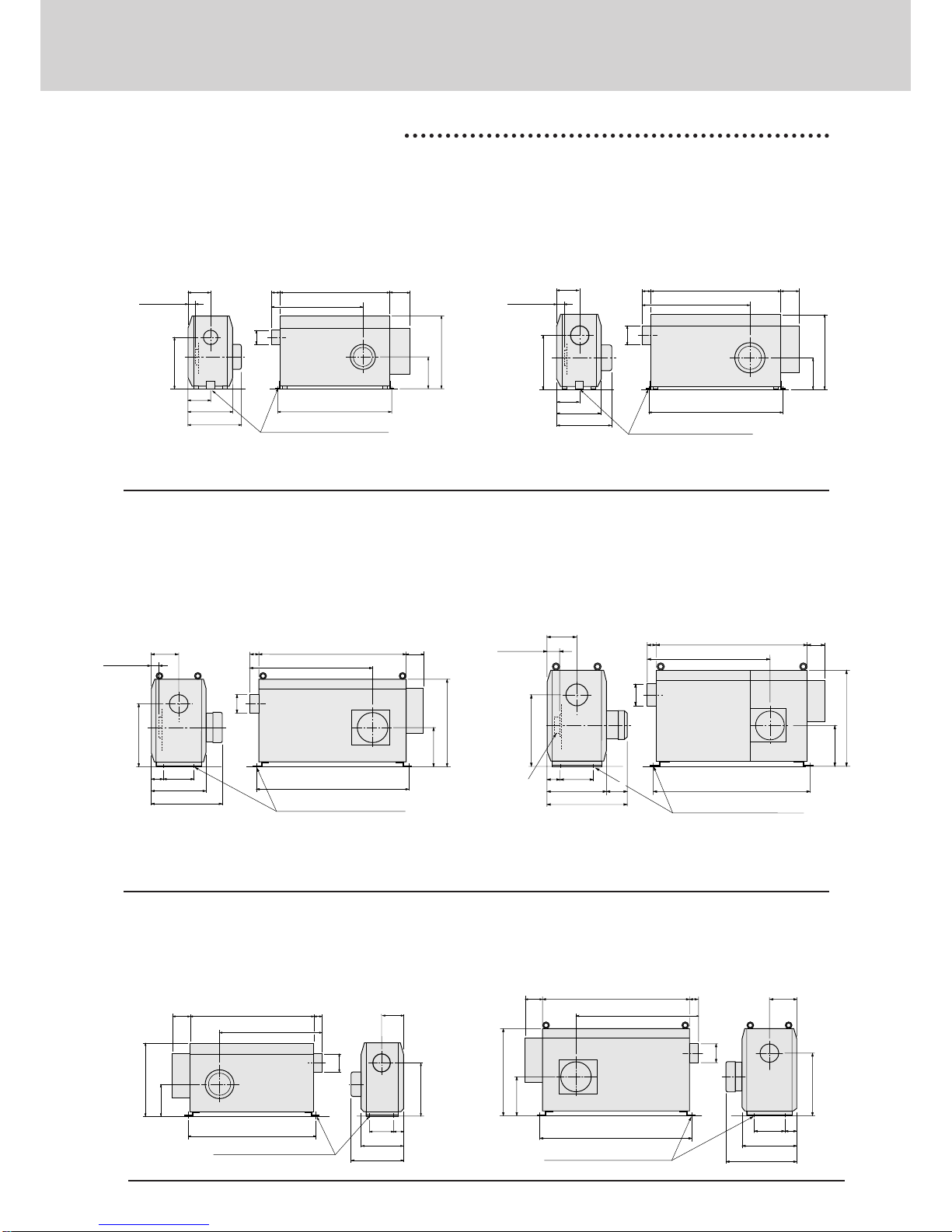

《MAINSPECIFICATION》HAP2000SERIES

HAP2000SERIES

ModelNo. HAP2031 HAP2051 HAP2076 HAP2081 HAP2101

ProductCode 00700210 00700220 00700230 00700240 00700250

PowerSource 3-phase200V(50/60Hz)

TotalWattage 3.2kW 5.2kW 7.7kW 8.3kW 10.3kW

HeaterWattage 3kW 5kW 7.5kW 8kW 10kW

AirTemp.RangeofOutlet roomtemp.〜350 ℃*

Max.AirFlow(50/60Hz)

4.0/ 4.8裙/min(damperfullopen)

3.2/ 3.8裙/min(damper2/3open)

2.0/ 2.4裙/min(damper1/3open)

6.7/ 7.8裙/min(damperfullopen)

5.7/ 6.6裙/min(damper2/3open)

3.6/ 4.3裙/min(damper1/3open)

AirFlowAdjustmentType Adjustswithair-intakeadjustmentplate

SuctionDiameter φ75㎜(withair-intakeadjustmentplate) φ100㎜(

withair-intakeadjustmentplate

)

OutletDiameter φ73㎜ (stainlesspipe) φ98㎜ (stainlesspipe)

SuctionAirTemperature −10℃〜230℃

Blower

Specific

-ation

Max.AirFlow

5.4/ 6.2裙/min

(50/60Hz)

8.8/ 10.4裙/min

(50/60Hz)

Max.StaticPressuer

0.63/ 0.91kPa(50/60Hz) 0.95 /1.35kPa(50/60Hz)

Wattage 3phase200V 0.15kW 3phase200V 0.3kW

NoiseatMax.AirFlow

55/ 59dB(50/60Hz) 64 /66dB(50/60Hz)

PowerSourceElectricWire 4core×3.5袿×3m

4core

×

5.5袿

×

3m 4core

×

5.5袿

×

3m 4core

×

8袿

×

3m

Weight 28kg 34kg 35kg

ModelNo. HAP2151 HAP2201 HAP2301

ProductCode 00700260 00700270 00700280

PowerSource 3-phase200V(50/60Hz)

TotalWattage 16.5kW 21.5kW 31.5kW

HeaterWattage 15kW 20kW 30kW

AirTemp.RangeofOutlet roomtemp.〜350 ℃*

Max.AirFlow(50/60Hz)

13.4/ 15.5裙/min(damperfullopen)

11.8/ 14.0裙/min(damper2/3open)

7.9/ 9.2裙/min(damper1/3open)

21/ 25裙/min(damperfullopen)

19/ 22裙/min(damper2/3open)

13/ 15裙/min(damper1/3open)

AirFlowAdjustmentType Adjustswithair-intakeadjustmentplate

SuctionDiameter φ125㎜(withair-intakeadjustmentplate) φ148 ㎜(damperwithflange)

OutletDiameter φ123㎜ stainlesspipe

SuctionWindTemperature −10℃〜230℃

Blower

Specific

-ation

Max.WindFlow

20/ 22.6裙/min

(50/60Hz)

30/ 36裙/min

(50/60Hz)

Max.StaticPressuer

1.61/ 2.32kPa

(50/60Hz)

1.96/ 2.85kPa

(50/60Hz)

Wattage 3-phase200V 1.5kW

NoiseatMax.AirFlow

68/ 72dB

(50/60Hz)

72/ 75dB

(50/60Hz)

PowerSourceElectricWire

4core

×

14袿

×

3m 4core

×22袿×3m

4core

×38袿×3m

Weight 73kg 76kg 108kg

HAP2402

00700292

41.5kW

40kW

200kg

φ148㎜ stainlesspipe

*Airtemperaturevariesdependonusageconditions.Usewithconditionsofundermaximumtemperature.

*Airtemperaturevariesdependonusageconditions.Usewithconditionsofundermaximumtemperature.

《

MAINSPECIFICATION

》