URLHAKKO Document Portal

HAKKO Document Portal

Instruction manual in the language of Japanese, English, Chinese, French, German, and

Korean can be downloaded from the HAKKO Document Portal.

(Please note that some languages may not be available depending on the product.)

https://www.hakko.com/english/support/doc/

Table of Contents

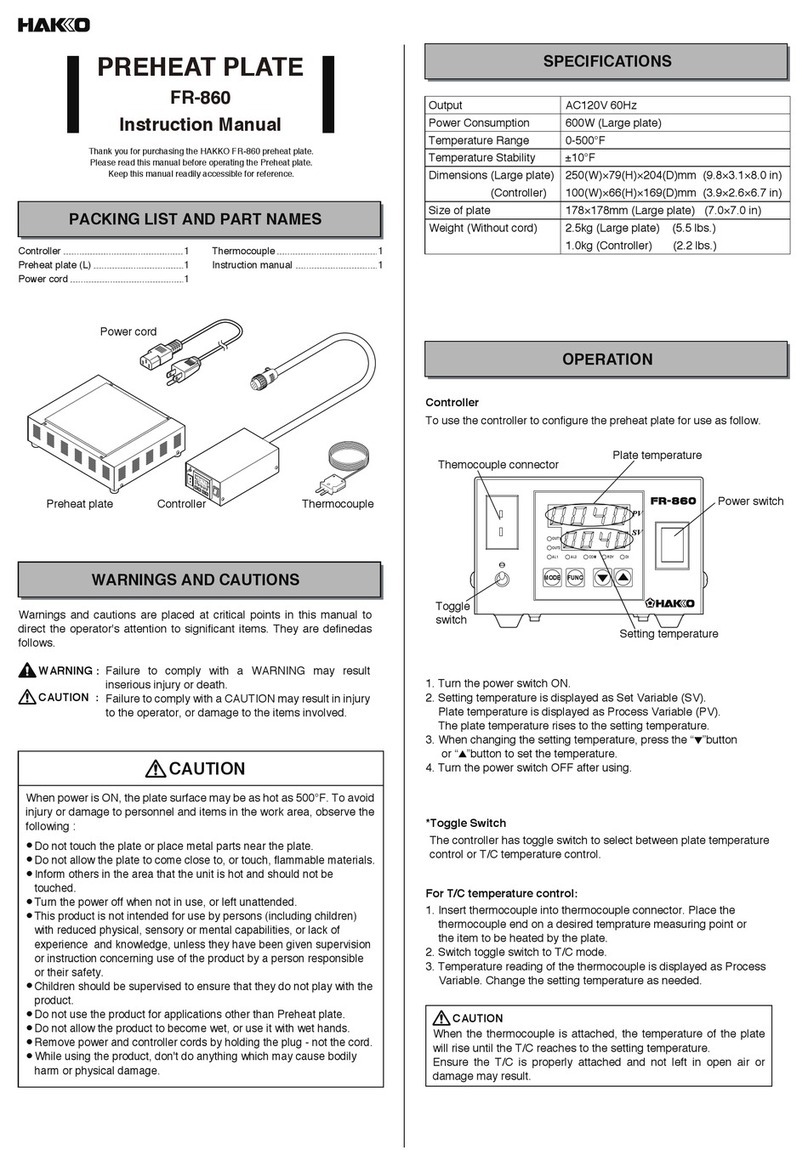

1. PACKING LIST AND PART NAMES....................................................... 1

2. SPECIFICATIONS ................................................................................... 1

3. WARNINGS, CAUTIONS AND NOTES .................................................. 2

4. INITIAL SETUP........................................................................................ 3

4-1 Blades ..............................................................................................3

4-1-1 Attaching blades ....................................................................3

4-1-2 Removing blades ...................................................................3

4-1-3 Blade holder...........................................................................3

4-2 Station ..............................................................................................4

5. HOW TO USE ..........................................................................................4

5-1 Operation and display (switch and operation buttons) .....................4

5-2 Setting/changing output....................................................................4

5-3 Handle ..............................................................................................5

5-3-1 Attaching the lead adjuster ....................................................5

5-3-2 How to use the lead adjuster .................................................6

5-3-3 Stripping a wire ......................................................................6

6. SETTING PARAMETERS ........................................................................7

6-1 Parameter setting table ....................................................................7

6-2 Parameter setting procedure............................................................8

7. MAINTENANCE .....................................................................................12

8. INSPECTION..........................................................................................12

9. TROUBLESHOOTING ...........................................................................13

10. PART NUMBER .....................................................................................13