6

HAZARD PRECAUTIONS

Unplug electrical plug from the power point before conducting repair, service, maintenance

or equipment cleaning.

Electrical

Do not handle electrical plug or machine with wet hands and power connected.

Do not run vacuum motor when wet scrubbing or stripping.

Do not use machine for wet scrubbing without skirt in place.

Do not store machine outdoors or expose to rain.

Do not wash or hose down the machine.

Do not clean the machine by spraying it with water, detergent or cleaning solutions.

Do not use machine if water has been picked up by the vacuum system, without electrical

inspection by a qualified person.

Do not pull on the Power Cord.

Work away from the Power Cord to avoid entanglement with the rotating brush/pad mechanism.

Plan work path based on layout and work area using a systematic approach.

Machine Control and Property Damage

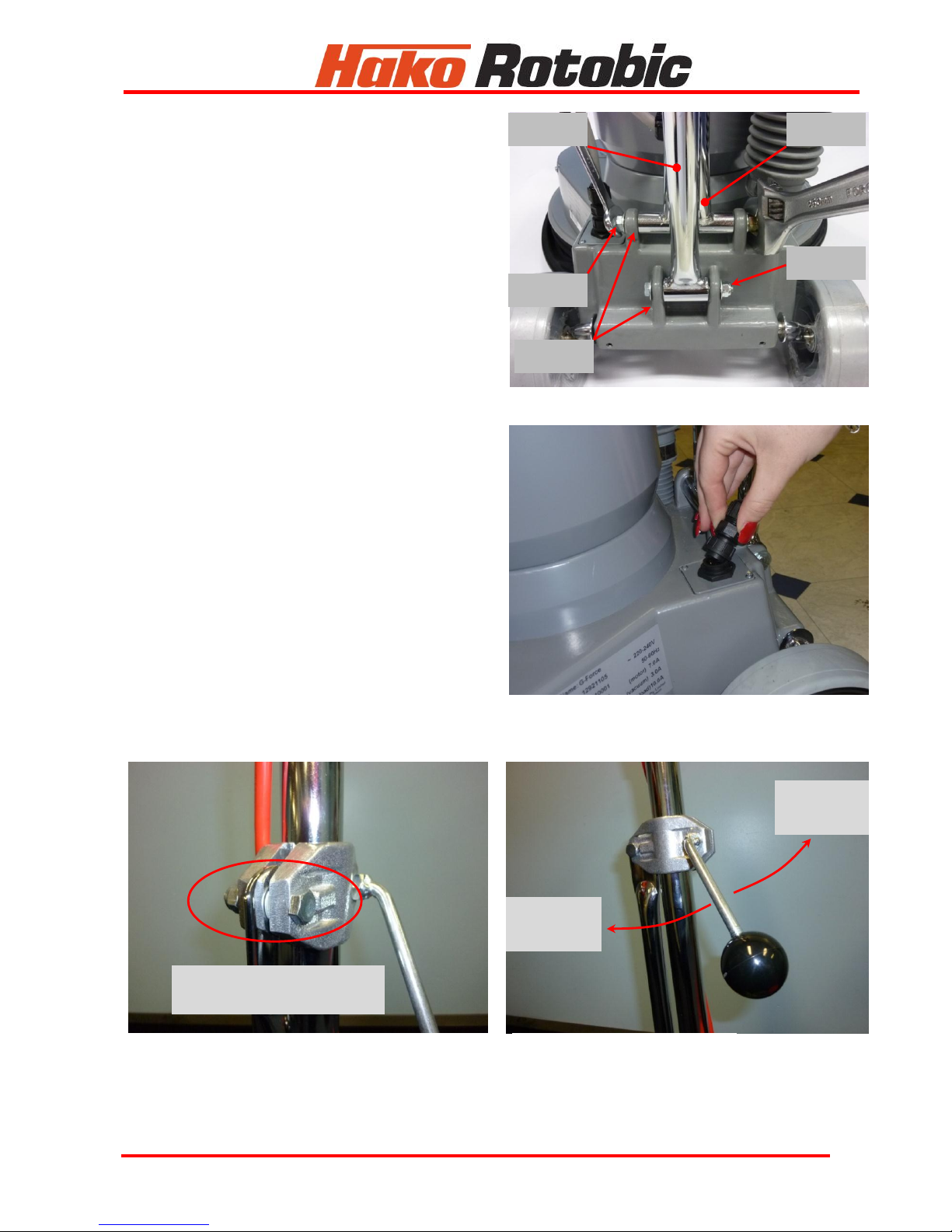

Ensure correct handle height adjustment for control.

Violent handle movement by operator will cause rapid sideways movement and may cause

operator to lose control.

Fit quality brushes and pads, correctly sized, to suit application.

Ensure floor is uniformly wetted when wet scrubbing, and that floor surface is uniform, to

minimize rapid sideways movement of the machine.

Ensure the rear wheels are UP when in use.

Ensure the machine is in constant motion over the floor area. Keeping the machine in a

localized spot may result in friction burns to the floor.

Trips, Slips and Falls

Do not wear open top footwear when using this equipment.

Wear slip resistant footwear at all times. Wear chemical resistant footwear when wet

scrubbing or stripping.floors.

Ensure electrical cord is clear of machine and operators feet.

Use appropriate signage and barriers e.g. ‘Cleaning in Progress’ to alert public to cleaning

activity.

Burns, Fire, or Explosion

Do not vacuum anything that is burning or smoking such as cigarettes, matches or hot ash.

Do not use machine in areas where flammable or combustible liquids, vapors or gases are

present.

Do not operate near explosive materials such as solvents, thinners, fuels or grain dust.

Muscloskeletal Injury

Change brushes and pads using correct posture.

Adjust handle to correct height and operate machine using correct posture.

Hold handle firmly at start, relax grip and maintain a straight wrist when machine is running.

Do not twist at the waist when slewing the machine or turning, turn using your feet.

Using mechanical aids or team lifting, when lifting the machine

Do not pull machine upstairs.

Do not heel the machine to the point where the machine is on its edge, this can cause injury,

damage to the handle, or damage to the floor.

Respiratory Damage/Illness due to Irritant Dust.

Do not use machine for vacuuming hazardous dust/particulates as defined in clause 50,

WorkCover NSW, Occupational Health and Safety Regulation 2001.

Filtration efficiency, vacuum airflow, particulate size and quantity must be considered in the

assessment of emissions.