ARQ1000A

ERROR

CORRECTION

TERMINAL

CONTENTS:

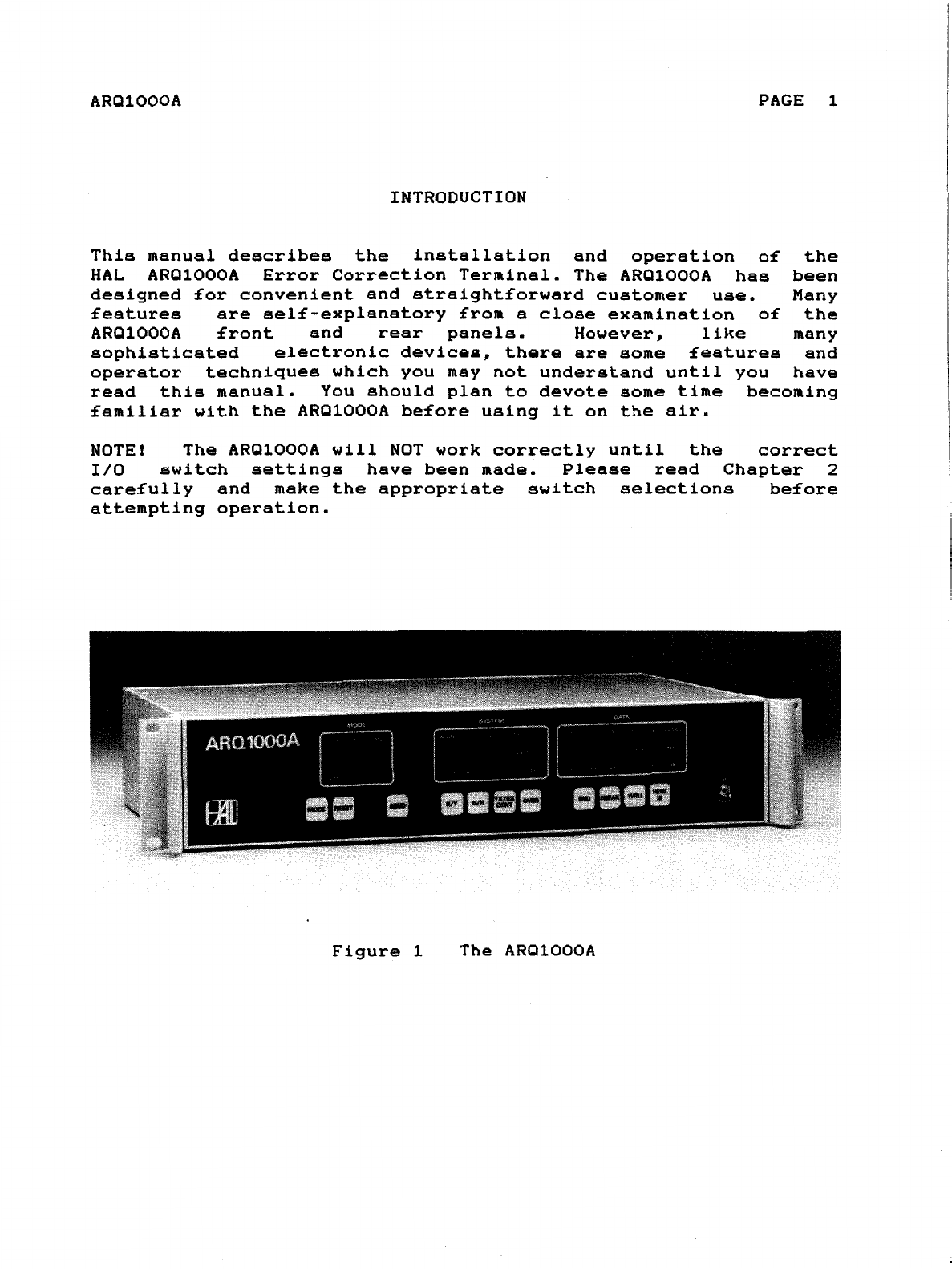

INTRODUCTION

. • • • • . . . . . . . . . . . . . . 1

CHAPTER

1.

UNPACKING

AND

INSPECTION 2

CHAPTER

2.

INSTALLATION . • • • • • • • • • • • • • • • • • • 5

2.1

PRELIMINARY INSTALLATION CONSIDERATIONS • • • 5

2.1.1

MECHANICAL

REQUIREMENTS

• • • • . • • 5

2.1.2

ELECTRICAL

REQUIREMENTS

• • • • • • • 5

2.1.3

REAR

PANEL

CONNECTIONS

• • • • • • • • 6

2.2

TTY

TERMINAL

INTERFACE • • • . • • • • .

••

12

2.2.1

SELECTION

OF

TTY

TERMINAL

••••••

12

2.2.2

TERMINAL

CONNECTIONS

•••.•••••

15

2.2.3

CONNECTION

TO

HAL

DS3200

••.•..•

17

2.3

DEMODULATOR

CONNECTIONS

• • • • • • • . • • •

18

2.3.1

SWITCH

SELECTION

•••••••••••

18

2.3.2

CONNECTIONS

TO

HAL

DEMODULATORS

•••

19

2.4

TRANSMITTER

AND

RECEIVER CONSIDERATIONS • • •

21

CHAPTER

3.

OPERATING

THE

ARQ1000A • • • • • • . • • • •

•••

25

3.1

ARQ1000A

FRONT

PANEL

•••.••••••••

25

3.1.1

MODE

CONTROL

•••••••••••••

25

3.1.2

TRANSMISSION

CONTROL

SWITCHES

••••

26

3.1.3

SYSTEM

INDICATION

AND

CONTROL

••••

26

3.1.4

DATA

INDICATORS

••••••.••••

28

3.1.5

WRU

AND

HERE

IS

SWITCHES

.••••••

29

3.2

PROGRAMMABLE

FEATURES

OF

THE

ARQ1000A • • • •

30

3.2.1

ENTERING

PROGRAM

MODE

••••••••

30

3.2.2

PROGRAMMING

COMMANDS

AND

FORMAT

• • •

31

3.2.3

PROGRAMMING

THE

HERE

IS

MESSAGE

•.•

32

3.2.4

PROGRAMMING

THE

IDENTIFIER

CODES

• • •

32

3.2.5

CS

X/1

CONTROL

SIGNAL

PARAMETER

• • •

33

3.2.6

EC

ON/OFF

TERMINAL

ECHO

PARAMETER

.•

34

3.2.7

TIME

OUT

<TO>

PARAMETER

••••.••

35

3.2.8

WRU

CONTROL

COMMAND

• • . • • • • • •

35

3.2.9

DEFAULT

AFTER

RESET

PARAMETERS

• • • •

35

3.2.10

CONVERSATIONAL

FEC

<CF:>

••••.••

36

3.2.11

TRANSMIT

DELAY

<TO:>

.••.•••••

37

3.2.12

CONTROL

DELAY

<CD:>

•••••••••

38

3.2.13

AUDIO

DELAY

<AD:>

•.••••••••

39

3.2.14

BUFFER

CLEAR

<BC:>

•.•••••.•.

39

3.2.15

ST:

LIST

STATUS

COMMAND

••••..•

40

3.2.16

EX: EXIT

PROGRAMMING

COMMAND

•••••

40