DUAL DRYER SYSTEM

INSTALLATION/SERVICE

MANUAL (L31279)

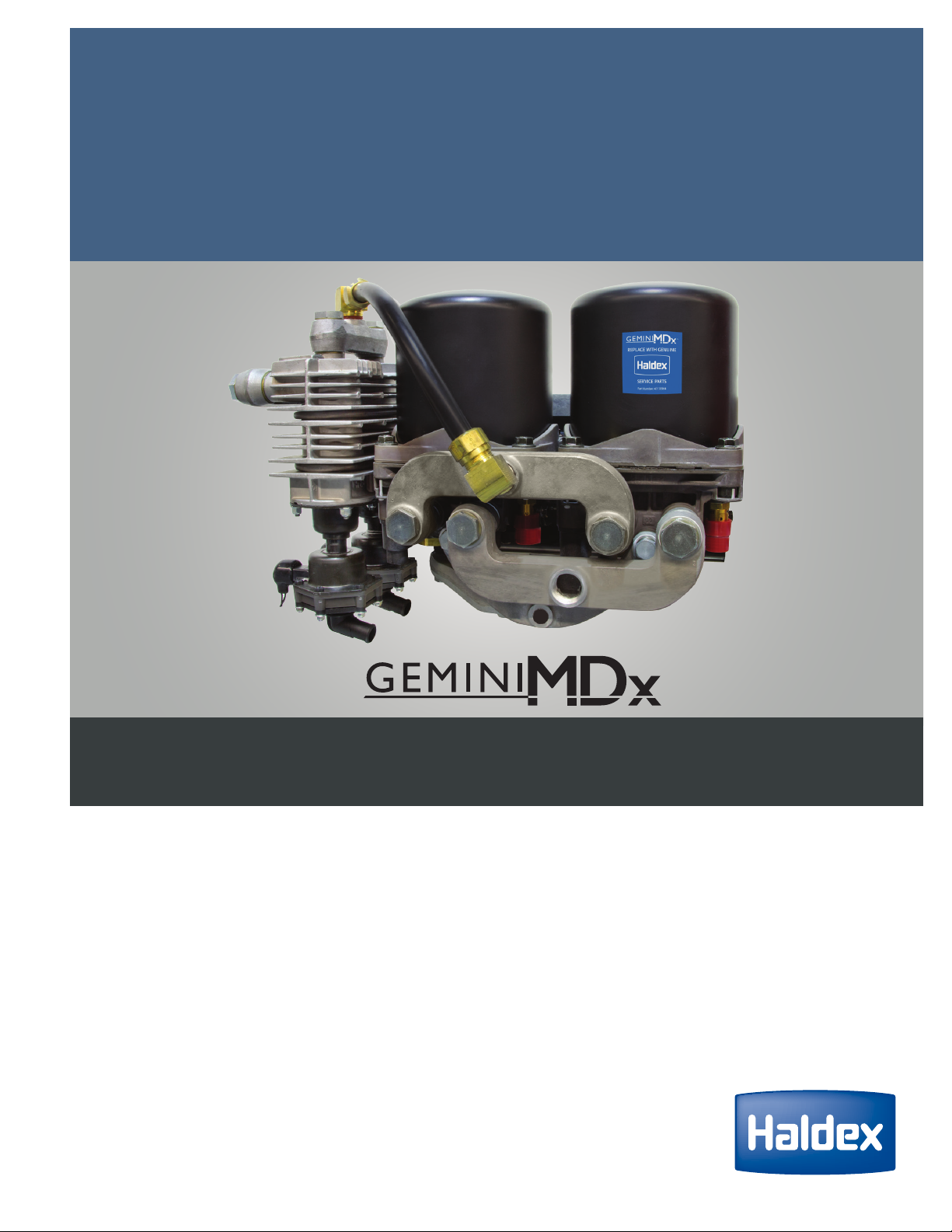

General

This manual has been designed to assist personnel

in satisfactory installation, maintenance and

troubleshooting of the Haldex GeminiMDx High

Capacity Dual Air Dryer System. The intention

has been to provide guidance on certain aspects

of the product. It is expected that this manual

will be in possession of the appropriate person

throughout the install, maintenance and/or

troubleshooting process.

Safety and Important Precautions

• All company and vehicle manufacturer’s safety

procedures must be followed when installing

the GeminiMDx Dryer.

• Always wear proper personal protective

equipment, including approved eye glasses.

• Never work on or under a vehicle unless it is

parked on a level surface and its wheels are

blocked to prevent it from moving.

• Never work on a vehicle air brake system

when the engine is running. Where

circumstances require that the engine be in

operation, extreme caution should be used to

prevent personal injury resulting from contact

with moving, rotating, leaking, heated or

electrically charged components.

• Drain all air pressure from the air system

before beginning any installation, service or

repair.

• Never connect or disconnect a hose or

line containing pressure. Never remove a

component plug unless it is certain that all

system pressure has been depleted.

• Never exceed recommended component or

system pressures.

• Do not attempt to install, remove,

disassemble or assemble a component until all

recommended procedures have been read and

are fully understood. Use only the proper tools

and observe all precautions pertaining to the

use of those tools.

• Components with stripped threads or

damaged parts should be replaced rather

than repaired. Repairs requiring machining

or welding should not be attempted unless

specifically approved and stated by the

vehicle or component manufacturer.

• Prior to returning the vehicle to service,

make certain all components and systems are

restored to their proper operating condition.

Mounting and Installation Precautions

• The GeminiMDx uses a 4-bolt mounting

pattern. See “Dimensions and Port

Identification” on Page 8.

• If the GeminiMDx is to be bolted directly to

the frame or other support member, check

the vehicle manufacturers recommendations.

• At a minimum use grade 5, 1/2” bolts and

nuts.

• The GeminiMDx must not incline in any

direction more than 15° from vertical.

• Mount in a space to avoid excessive heat

sources (175°F maximum).

• Mount with the exhaust port oriented

downward.

• Mount in an area where it is protected from

wheel or road splash.

Replacement Parts/Retrot Components

Use appropriate spare parts documentation

when obtaining spare parts. Only use Genuine

Haldex replacement parts in the repair process.

See a complete listing on Page 15.

Questions?

If you have any questions on this product or

any of the innovative products offered by

Haldex, contact your local distributor for

complete details. Technical Service or

Troubleshooting help can be obtained by

calling Haldex Technical Services Department

at 800.643.2374, follow prompts.

Important Notices

DUAL DRYER SYSTEM

INSTALLATION/SERVICE

GUIDE (L31279)