i

TABLE OF CONTENTS

Section Title Page

1. SAFETY.............................................................................................................................................1

1.1. Safety Headings........................................................................................................................1

1.2. Training .....................................................................................................................................1

1.3. Safety Summary .......................................................................................................................1

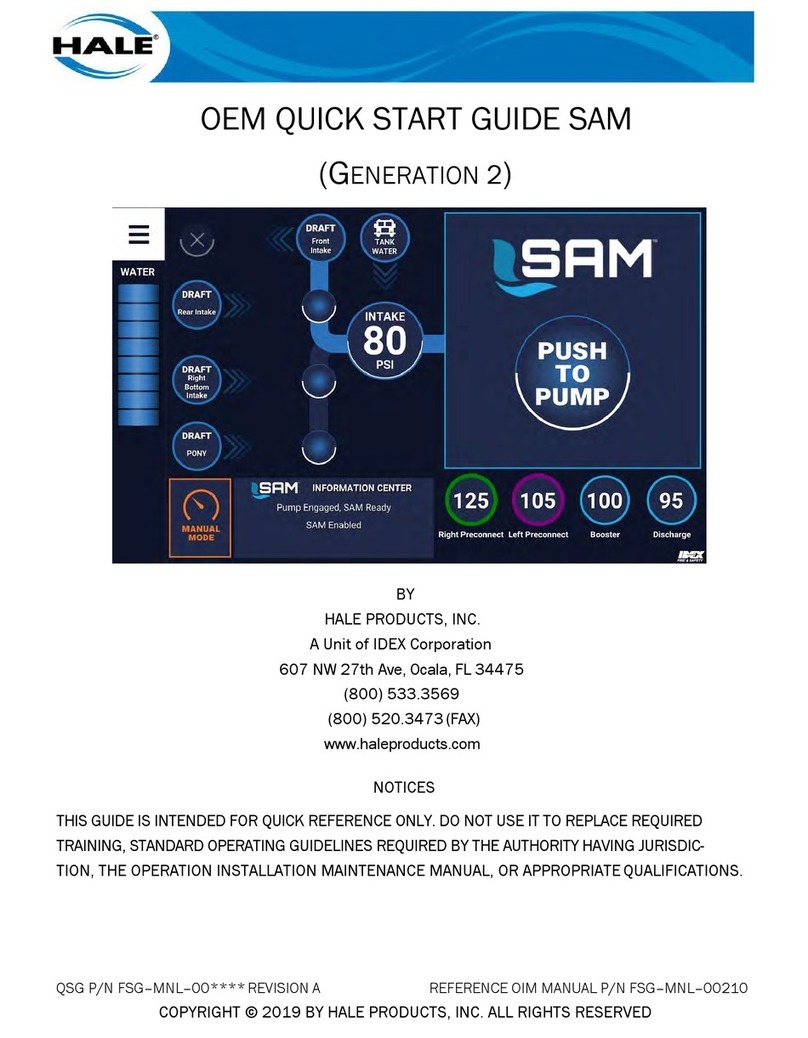

2. GENERAL INSTRUCTIONS ...............................................................................................................5

2.1. Overview....................................................................................................................................5

2.2. Pump Specifications and Numbering......................................................................................5

2.2.1 Optional Pump Panel Identification Plates.......................................................................5

2.2.2 Identification Plate.............................................................................................................6

3. TRANSPORT AND STORAGE ...........................................................................................................7

3.1. Shipping, Movement, And Installation Preparations..............................................................7

3.2. Pump Gearbox Shipped Without Fluid ....................................................................................7

3.3. Storage......................................................................................................................................7

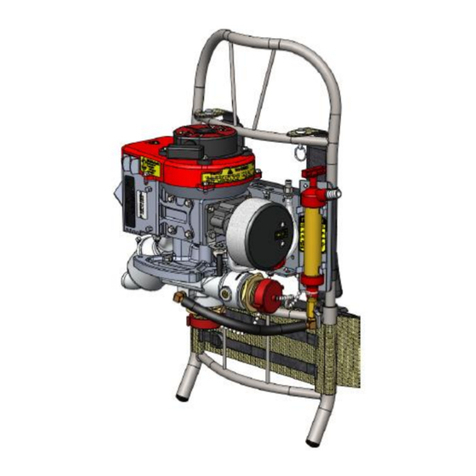

4. PUMP OVERVIEW ............................................................................................................................9

5. INSTALLATION .............................................................................................................................. 11

5.1. Warnings And Cautions......................................................................................................... 11

5.2. Risk Assessment ................................................................................................................... 11

5.3. Special Tools.......................................................................................................................... 11

5.4. Mounting A Hale Booster Pump ........................................................................................... 11

5.4.1 Hardware Requirements ................................................................................................ 13

5.4.1.1 Mounting Hardware.................................................................................................. 13

5.4.1.2 Thread Lock, Bonding, Or Sealant Compound ....................................................... 14

5.4.1.3 Driveshaft Hardware ................................................................................................ 14

5.4.2 Inlet And Discharge Connections................................................................................... 14

5.4.3 Booster Pump Drains...................................................................................................... 14

5.4.4 Priming Connections....................................................................................................... 14

6. COMMISSIONING, STARTUP, OPERATION, AND SHUTDOWN.................................................... 15

6.1. Installation Verification ......................................................................................................... 15

6.2. Performance Verification ...................................................................................................... 15

6.3. Initial Startup ......................................................................................................................... 15

6.4. Draft Operation Notes ........................................................................................................... 17

6.5. Hydrant Or Relay Operation .................................................................................................. 18