1

GENERAL DATA

ENGINE DATA

Engine ................................................................... Honda BF45A (Modified)

Configuration ....................................................... 3-cylinder 4-stroke, OHC vertical crankshaft

Bore and Stroke .................................................... 70 mm x 70 mm

Capacity ................................................................ 808cc (49.4 cu.in.)

Rated Power ......................................................... 6600 r.p.m. max.*

Idle Speed ............................................................. 950+/–50 r.p.m.

Valve Clearance – Inlet (COLD) ......................... 0.13 – 0.17 mm

– Exhaust (COLD) .................... 0.21 – 0.25 mm

Battery (Low-Maintenance) ................................. 12 Volt 18 Amp Hr, Neg. Earth

Ignition Timing Range ......................................... 5° – 32° BTDC

Spark Plug – Type ................................................ N.G.K. D7EA or equivalent

– Gap ................................................. 0.6 – 0.7mm

Fuel Tank Capacity .............................................. 14 litres

Fuel Pump ............................................................ Diaphragm-type driven from camshaft.

Carburettors (Three) ............................................. Constant-vacuum type

Lubrication System .............................................. Pressure-feed and splash

Oil Sump Capacity (With Filter) .......................... 2.6 litres

(Without Filter) .................... 2.0 litres

Oil Pressure (Engine at 80°C) .............................. 1.5 bar at 950+/–50 r.p.m.

Oil Filter ............................................................... Honda screw-on disposable cartridge

Cooling System .................................................... Water circulation by engine pump with

thermostat, heat exchanger, oil cooler and

header tank.

Cooling Water Capacity ....................................... 5.0 litres

Operating Temperature ........................................ 72°C

Anti-Freeze ........................................................... Ethylene Glycol-base

Starter – Electric ................................................... Electric starter 0.9kw (Inertia-type)

– Manual ................................................... Rope-wrap on flywheel

* Full throttle r.p.m.

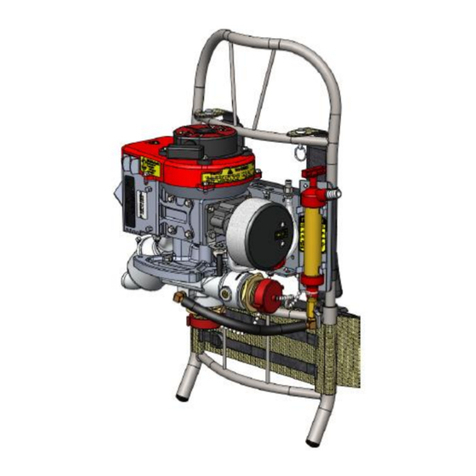

PUMP DATA

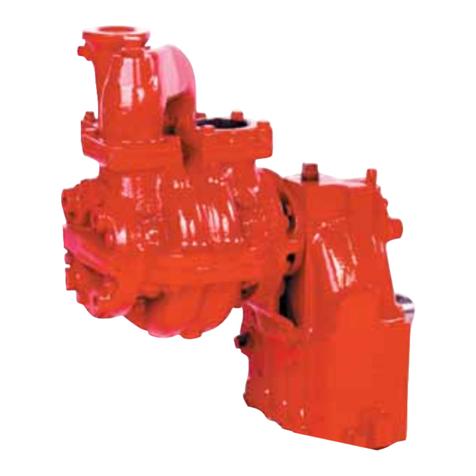

Pump – Model ...................................................... GPl0/l0

– Type ........................................................ Single-stage, centrifugal.

Rated Output ........................................................ 1,000 litres at 10 bar and 3 m lift.

Pump Shaft Seal ................................................... Spring-loaded, self-adjusting, carbon-faced

gland with silicon-carbide counterface.

Delivery Valves .................................................... Screw-down DIN-type (2-OFF).

Priming ................................................................. Exhaust-gas ejector and automatic priming

valve.

Thermal Relief Valve (Optional)

Operating Temperature .......................... 42°C

Length (Cradle Handles Closed) .......................... 680 mm

Width .................................................................... 495 mm

Height (Complete Unit) ........................................ 605 mm

Weight (With Battery, Oil Coolant and Fuel) ...... 112 kg