Halton Max Ultra Circular (MUC) - Quick guide for commissioning

All rights reserved ©Halton

Contents

1Introduction ................................................................................................................................................................. 3

1.1 About this document........................................................................................................................................... 3

1.2 Copyright and disclaimers .................................................................................................................................. 3

1.3 Summary of changes ......................................................................................................................................... 3

1.4 Contact information ............................................................................................................................................ 3

2Product description ..................................................................................................................................................... 4

2.1 Overview ............................................................................................................................................................ 4

3Commissioning ........................................................................................................................................................... 5

3.1 Before you start .................................................................................................................................................. 5

3.1.1 Commissioning process............................................................................................................................. 5

3.1.2 Commissioning information........................................................................................................................ 5

3.1.3 Airflow control panel................................................................................................................................... 6

3.1.4 Airflow control panel: start-up views .......................................................................................................... 7

3.1.5 Modbus RTU communication..................................................................................................................... 8

3.1.6 Self-diagnosis function............................................................................................................................... 8

3.2 Step by step instructions .................................................................................................................................... 9

3.2.1 Configuring basic controller settings in analog mode ................................................................................ 9

3.2.2 Configuring basic controller settings in Modbus mode .............................................................................. 9

3.2.3 Configuring basic controller settings in console mode (service or testing) .............................................. 10

3.2.4 Calculating the airflow control and feedback signals ............................................................................... 10

3.2.5 Rebooting the controller........................................................................................................................... 11

3.2.6 Configuring the scheduled restart function .............................................................................................. 11

4Troubleshooting ........................................................................................................................................................ 11

5Technical reference data .......................................................................................................................................... 12

5.1 Controller connections...................................................................................................................................... 12

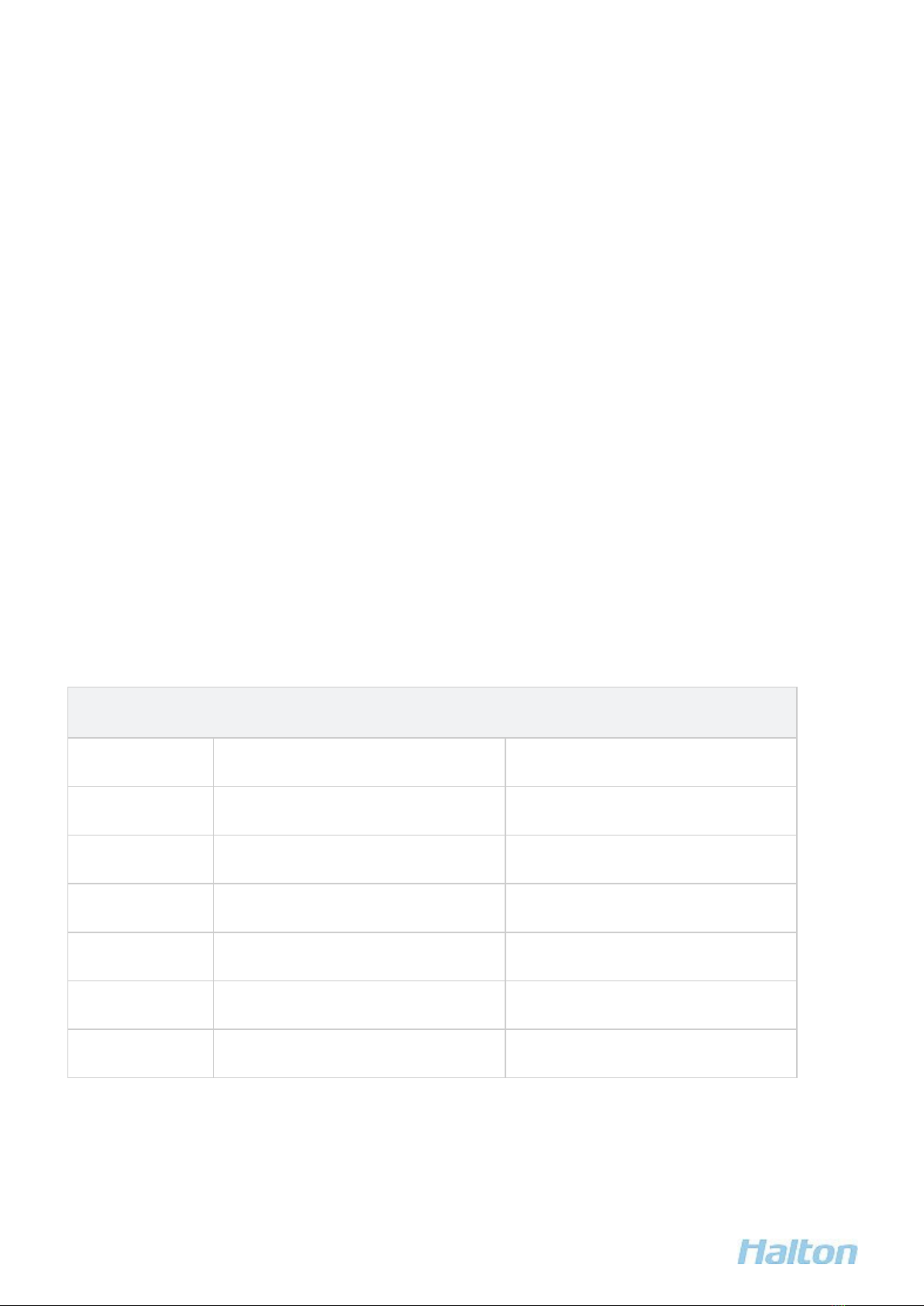

5.2 Parameters ....................................................................................................................................................... 13

5.2.1 Halton Max Ultra Circular (MUC) installation cases................................................................................. 13