Table of Contents

1. Introduction ............................................................................................................................................ 1

2. Safety instructions.................................................................................................................................. 1

2.1. General Precautions ..................................................................................................................... 1

2.2. Definition of equipment and document symbols and designations............................................... 2

2.3. Laser Information .......................................................................................................................... 3

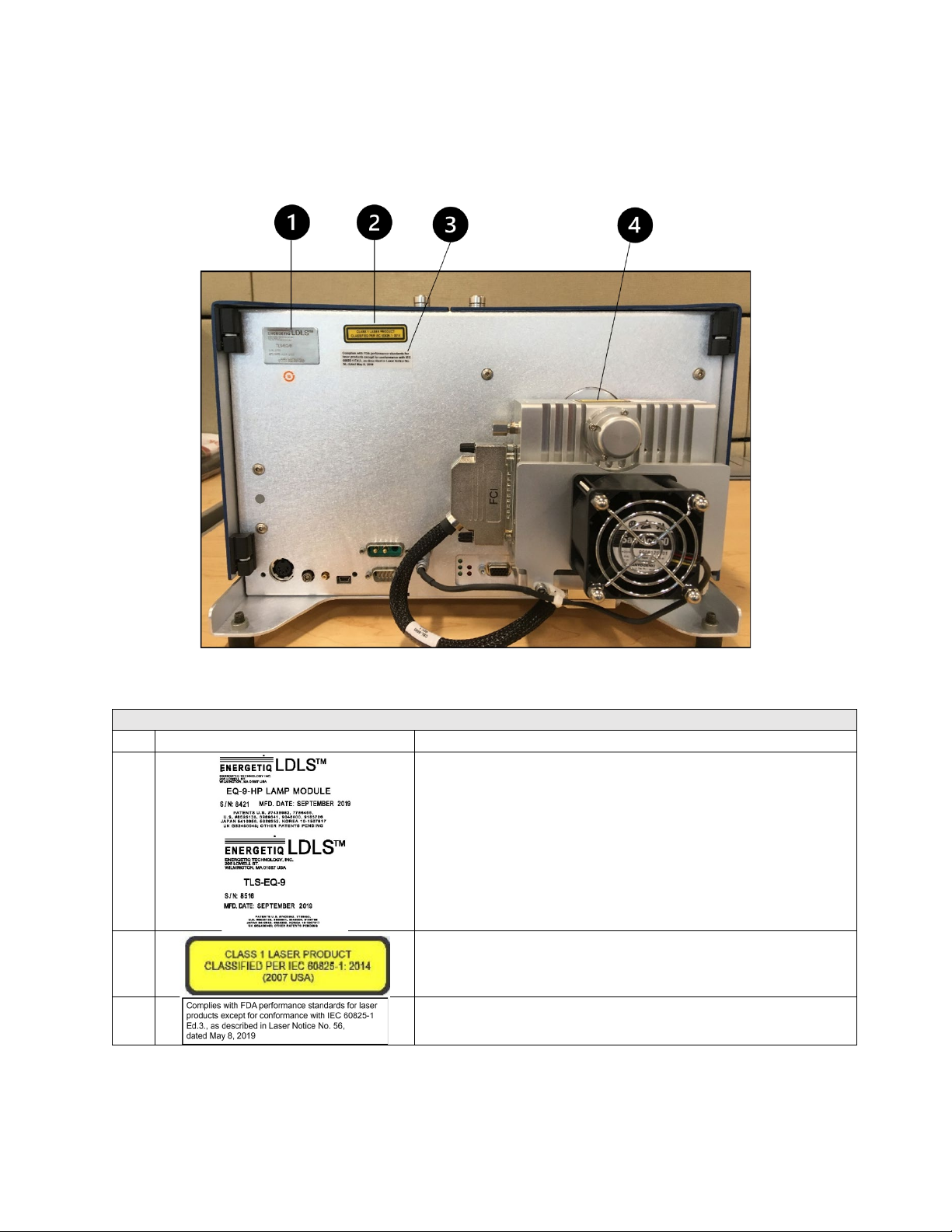

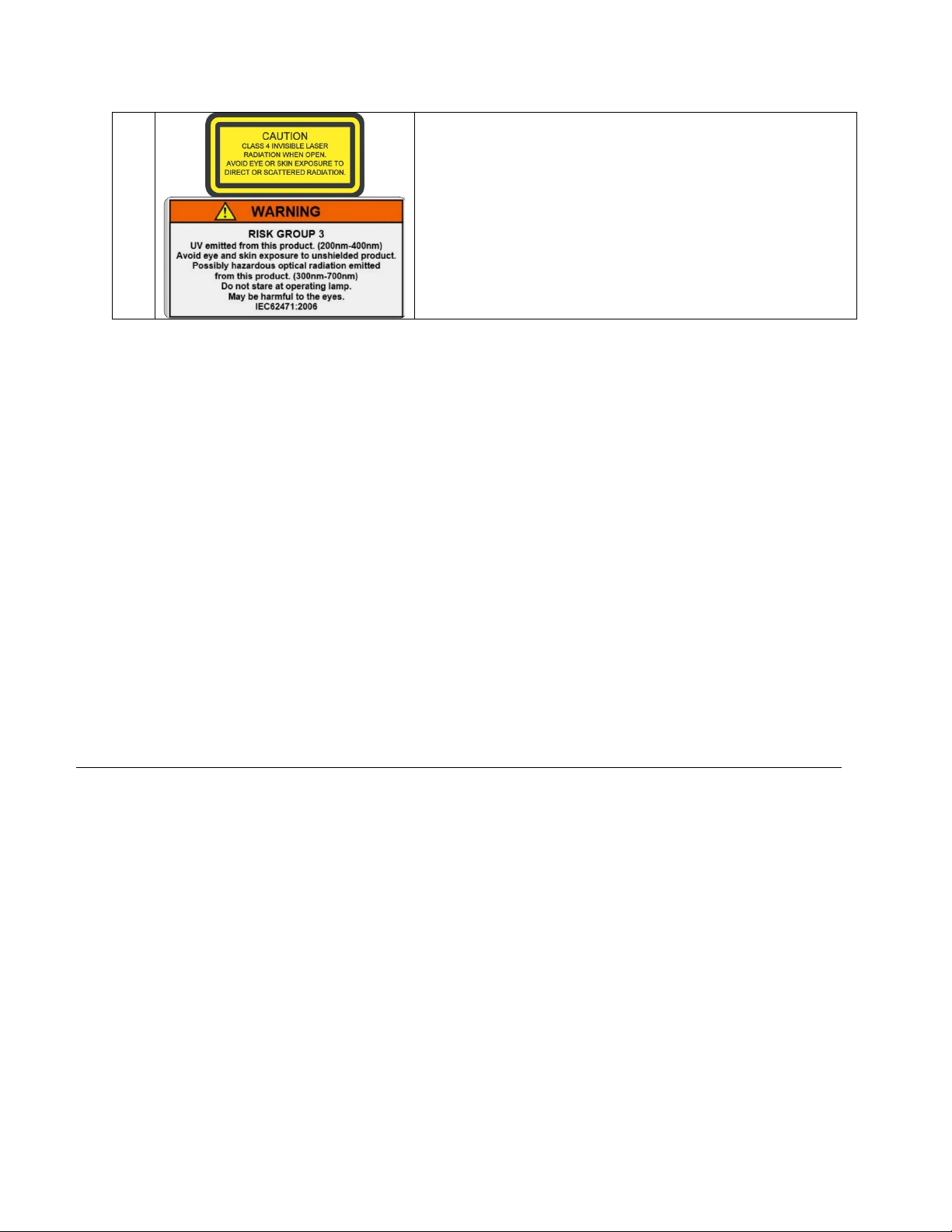

2.4. Labels and Safety Notification....................................................................................................... 4

2.5. Safety Interlocks............................................................................................................................ 5

2.6. External Interlocks......................................................................................................................... 5

2.7. Correct disposal of the unit ........................................................................................................... 5

3. Preparation of System ........................................................................................................................... 5

3.1. Unpacking guide ........................................................................................................................... 5

3.2. System Description ....................................................................................................................... 6

3.2.1 TLS-EQ-9 Main Housing ........................................................................................................... 6

3.2.2 Internal Components ................................................................................................................. 8

3.3. Optical Performance ..................................................................................................................... 9

3.4. Physical Specifications.................................................................................................................. 9

3.5. Utility requirements ....................................................................................................................... 9

3.6. Remote Interface........................................................................................................................... 9

3.7. External interlock connection ...................................................................................................... 10

4. TLS-EQ-9 Setup .................................................................................................................................. 10

4.1. Connections ................................................................................................................................ 10

4.1.1 Electrical Power....................................................................................................................... 10

4.1.2 Purge Gas ............................................................................................................................... 10

4.1.3 RS-485 Interface ..................................................................................................................... 10

4.2. Installation Procedure ................................................................................................................. 11

5. TLS-EQ-9 Operation ............................................................................................................................ 12

5.1. Startup......................................................................................................................................... 12

5.2. Stopping ...................................................................................................................................... 12

5.3. Monochromator Interface ............................................................................................................ 12

5.4. Changing Monochromator slits ................................................................................................... 13

6. Service Requirements.......................................................................................................................... 13

7. Maintenance and Troubleshooting Guide............................................................................................ 14

7.1. Maintenance................................................................................................................................ 14

7.1.1 Optical Alignment .................................................................................................................... 14