Document#101-0008 2 11/11/05

TABLE OF CONTENTS

I. INTRODUCTION...................................................................................................4

Compatibility .................................................................................................................................. 4

Validator..................................................................................................................................... 4

Operation ....................................................................................................................................... 4

II. INSTALLATION...................................................................................................5

FrontLoadCabinet........................................................................................................................ 5

RearLoad Cabinet ........................................................................................................................ 5

III. STACKER REMOVAL .......................................................................................6

FrontLoadCabinet........................................................................................................................ 6

RearLoad Cabinet ........................................................................................................................ 6

IV. BILL REMOVAL...................................................................................................7

FrontLoadCabinet........................................................................................................................ 7

RearLoad Cabinet ........................................................................................................................ 7

V. MAINTENANCE ...................................................................................................8

Monthly Maintenance ................................................................................................................... 8

AnnualMaintenance ..................................................................................................................... 8

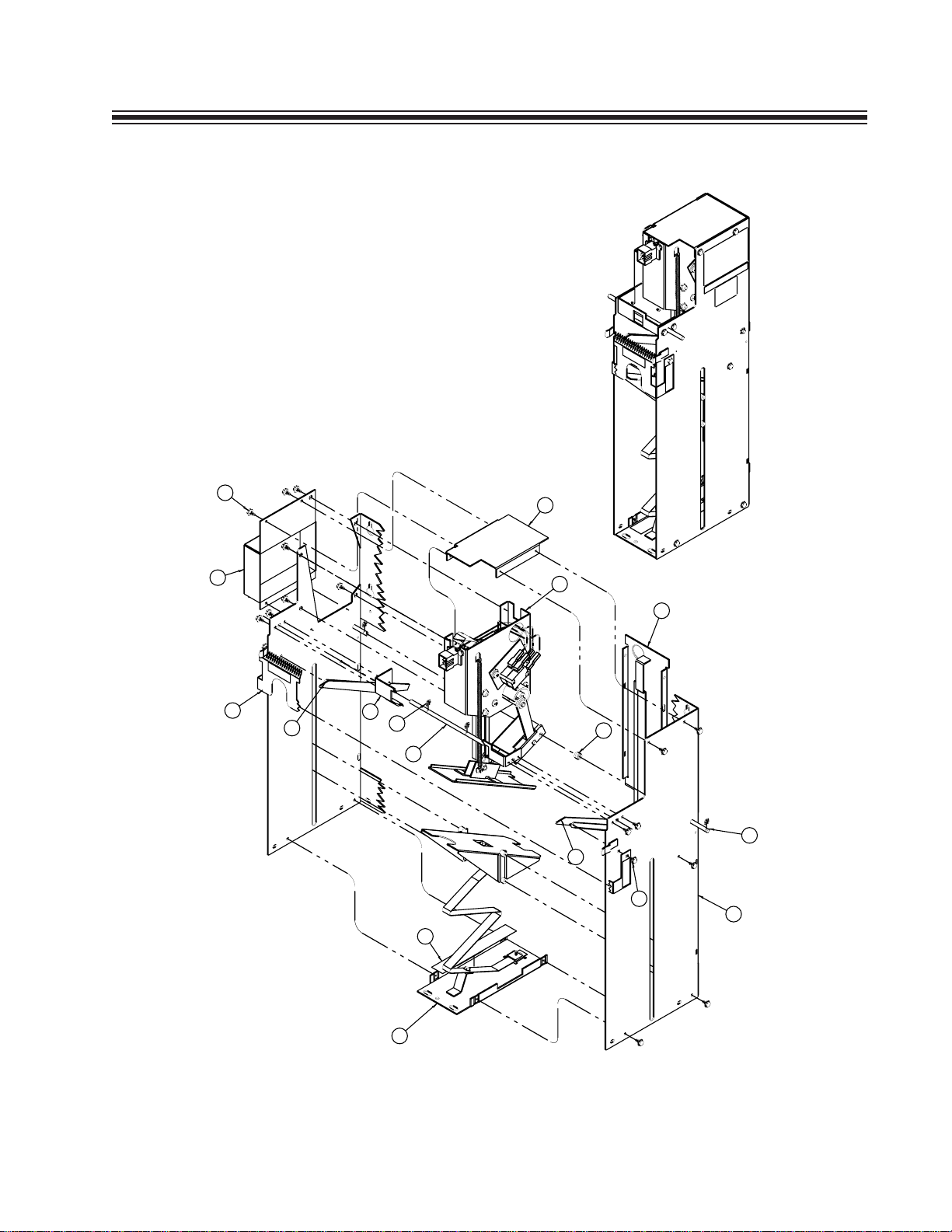

VI. PARTS....................................................................................................................9

Single Stacker ........................................................................................................... 9

SingleStackerBillOfMaterials .............................................................................. 10

Motor Assembly ..................................................................................................... 11

MotorAssembly Bill Of Materials .......................................................................... 12

Bottom PlateAssmebly........................................................................................... 13

APPENDIXA ......................................................................................................... 14

APPENDIX B......................................................................................................... 15