ADJUSTMENTS

AND

TESTING

ANTEA 50 BT – BTS - BTO

Doc. 10059284

Issued 12/201

Ver. AC

Page 2 of 25

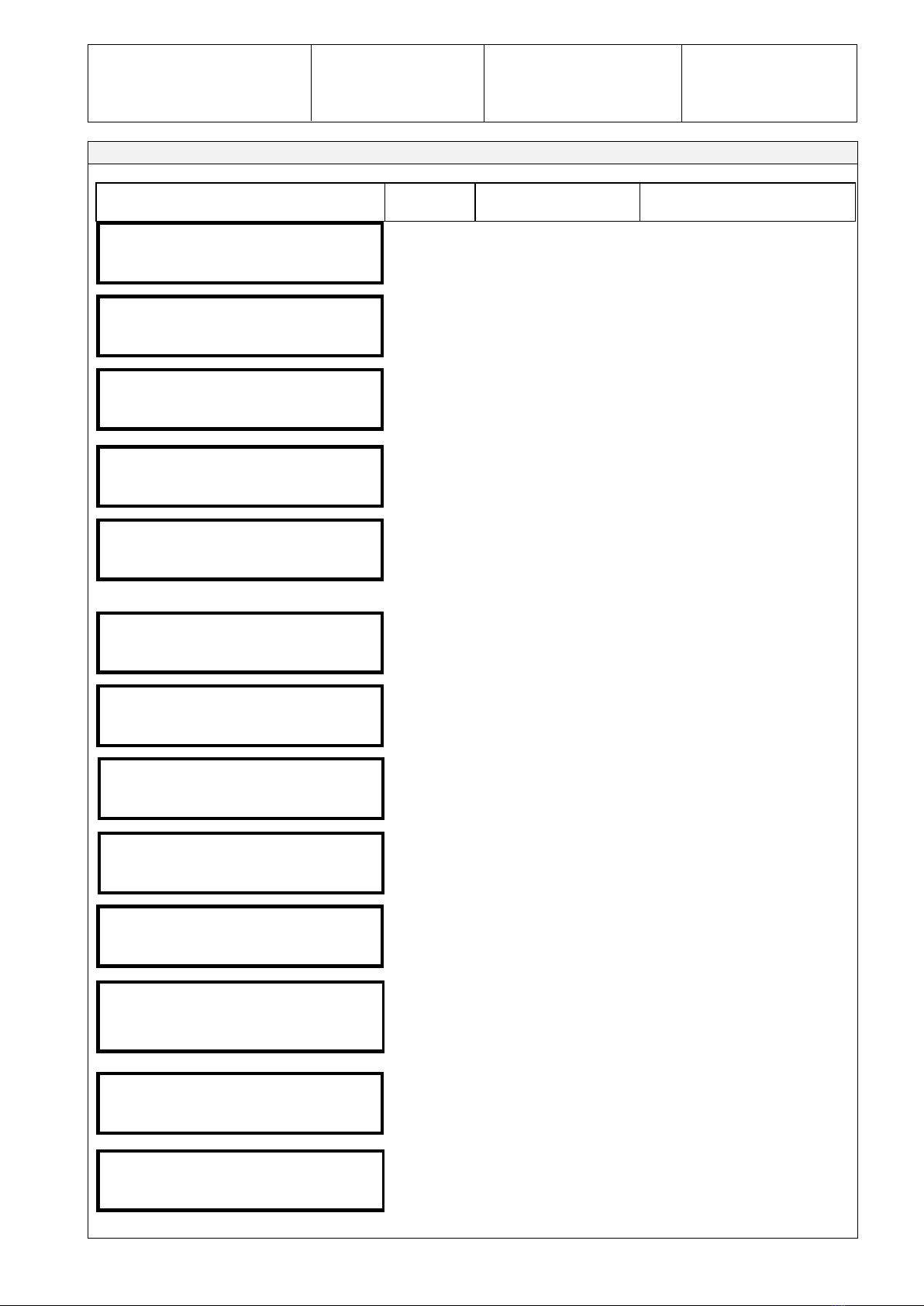

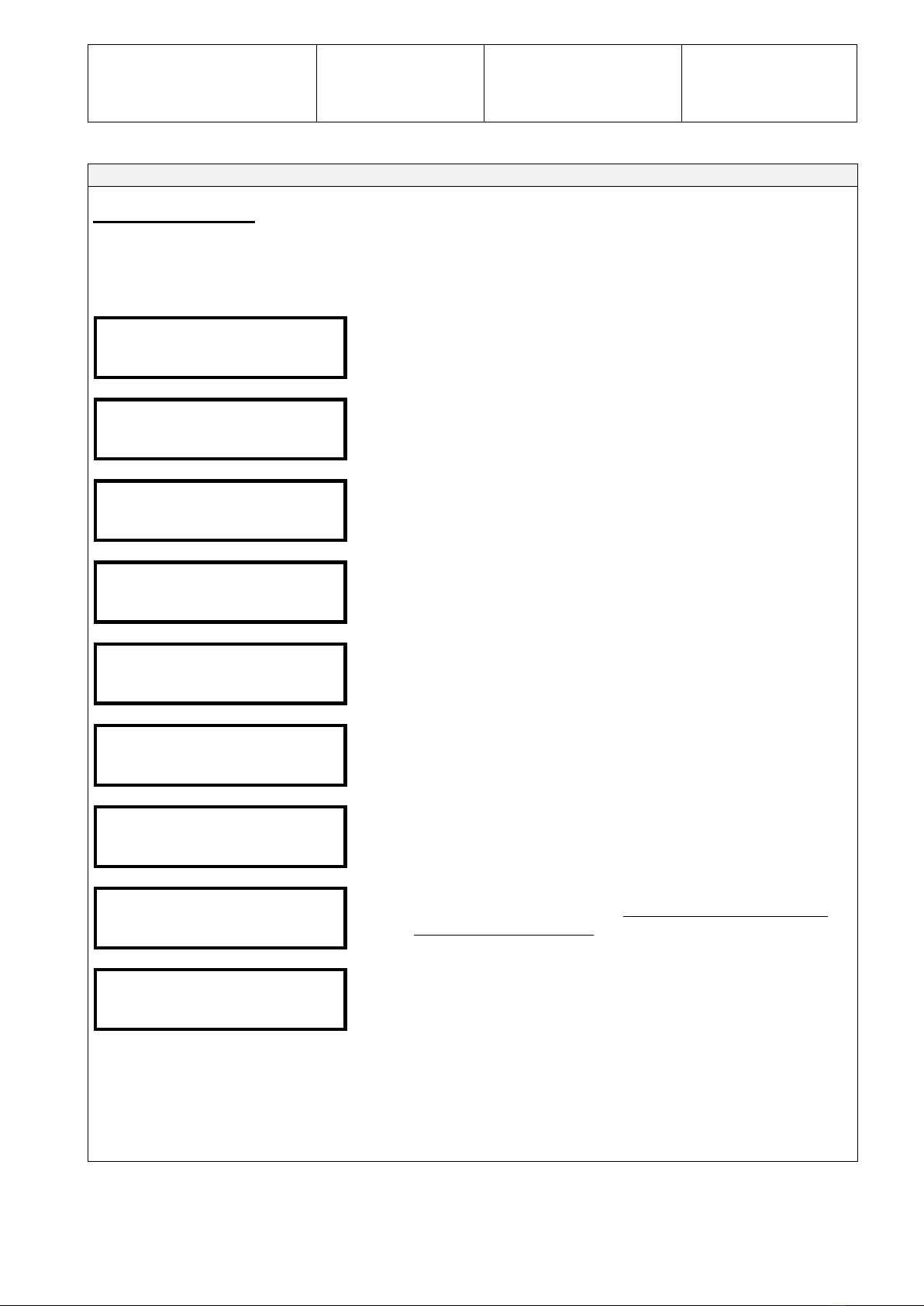

Display function – Alarm Ta le

The display shows the possible alarms of the machine.

Alarms are shown on the first line of the display and it alternates between the alarm id and a

short alarm description.

Here below the alarm table.

Allarm id. Alarm Description What to do

AL_1: Function Brushes Current

Protection

High current consumption detected. Check

the brush motor absorption and utilization.

Brushes Ammeter

AL_2: Function Vacuum Current

Protection

High current consumption detected. Check

the vacuum motor absorption and

utilization.

Vacuum Ammeter

AL_3: Function Damaged powerstage Brush or vacuum power stage damaged.

Replace the electronic card.

Powerstage Fail

AL_4: Function Brush or Vacuum

overcurrent

Short circuit on brush or vacuum motor

output. Check motor cables and conditions.

Overcurrent

AL_5: Function Thermal protection on

brush or vacuum

motor

Over temperature on brush or vacuum

stage. Wait 5 minutes and check the motor

absorption rate.

Overtemperature

AL_10: Function Batteries not

connected

Check the connections of the batteries

cables and the related connections

electronic card.

Batt. Connection

AL_13: Traction Lever fault

Check connections and functionality of

potentiometer.

Lever Failure

AL_14: Traction Pressed lever during

turning on

Forward Micro Switch pressed at

Release the lever.

Release lever

AL_15: Traction Thermal protection on

traction motor

Over temperature on traction stage. Wait 5

minutes and check the motor absorption.

Overtemperature

AL_1 : Traction Damaged powerstage Traction power stage damaged. Replace

the electronic card.

Powerstage fail

AL_17: Traction Traction overcurrent Short circuit on traction motor output.

Check motor cables and conditions.

Overcurrent