2

Table of Contents

1 Page 3

2 Page 3

3 Page 4

Page 4

Page 5

Page 5

Page 6

4 Page 6

Page 7

Page 7

Page 9

Page 8

5 Page 9

Page 10

6 Page 10

Page 11

Page 11

Page 12

Page 12

Page 13

7 Page 13

Page 13

Page 13

Page 14

Page 14

8 Page 15

Page 15

Page 15

Page 15

Page 16

9 Page 16

10 Page 17

11 Page 18

Page 18

Page 19

Page 20

Page 20

Page 21

Page 23

12 Page 23

Page 23

Page 24

Page 24

13 Page 25

Page 26

14 Page 27

15 Page 27

16 Page 28

17

Warnings

General Information

Maintenance Intervals

3.1 System Maintenance K (Customer)

3.2 System Maintenance I (125 hours of operation) 3.3

System Maintenance II (250 hours of operation) 3.4

Hammerhead System Maintenance S

(500 hrs of operation, at least yearly)

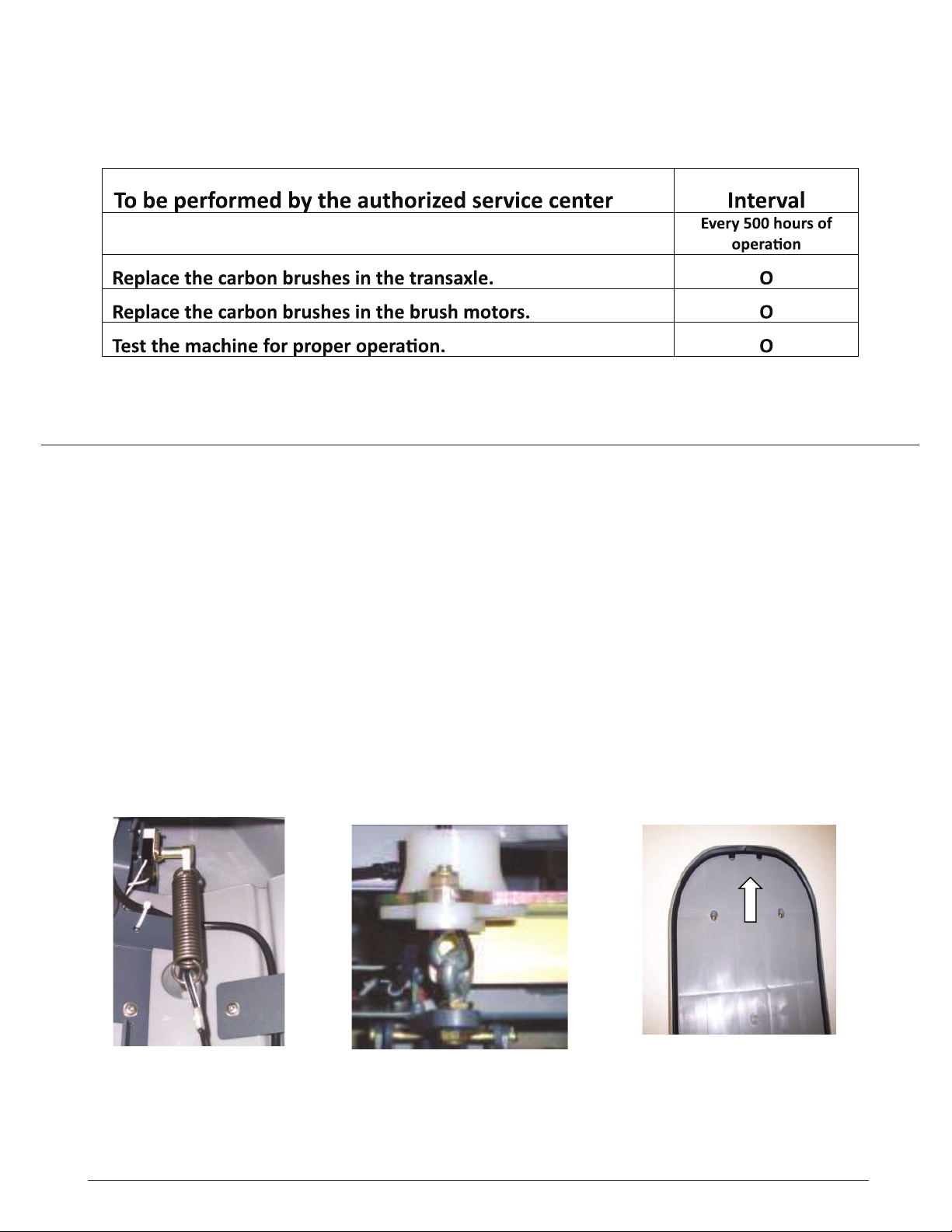

Squeegee Cable and Recovery Tank Gasket

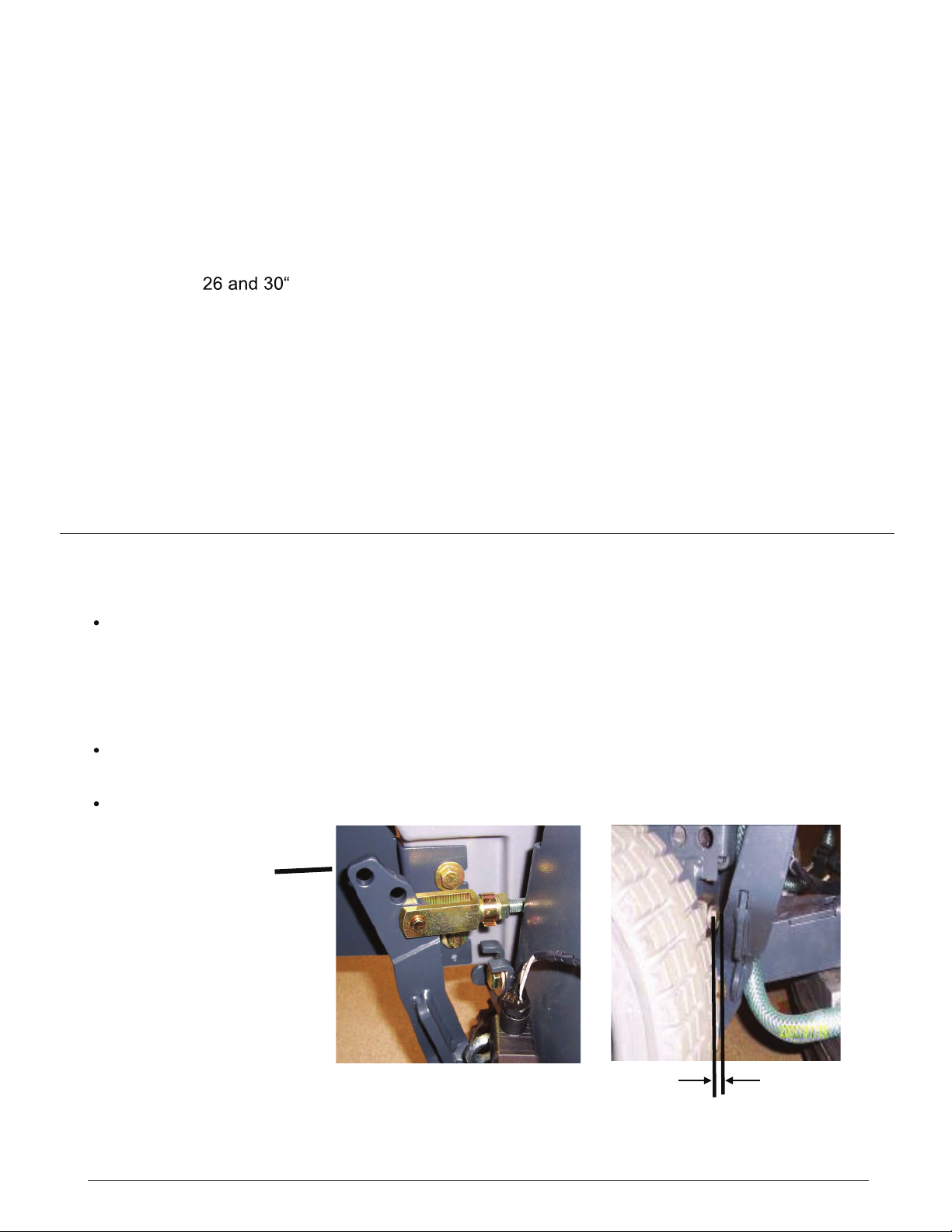

4.1 Squeegee Adjustment (First Version)

4.2 Squeegee Adjustment (new Style)

4.3 Squeegee Lift Cable, Micro Switch, Vacuum Motor

4.4 Squeegee Wheel Adjustment

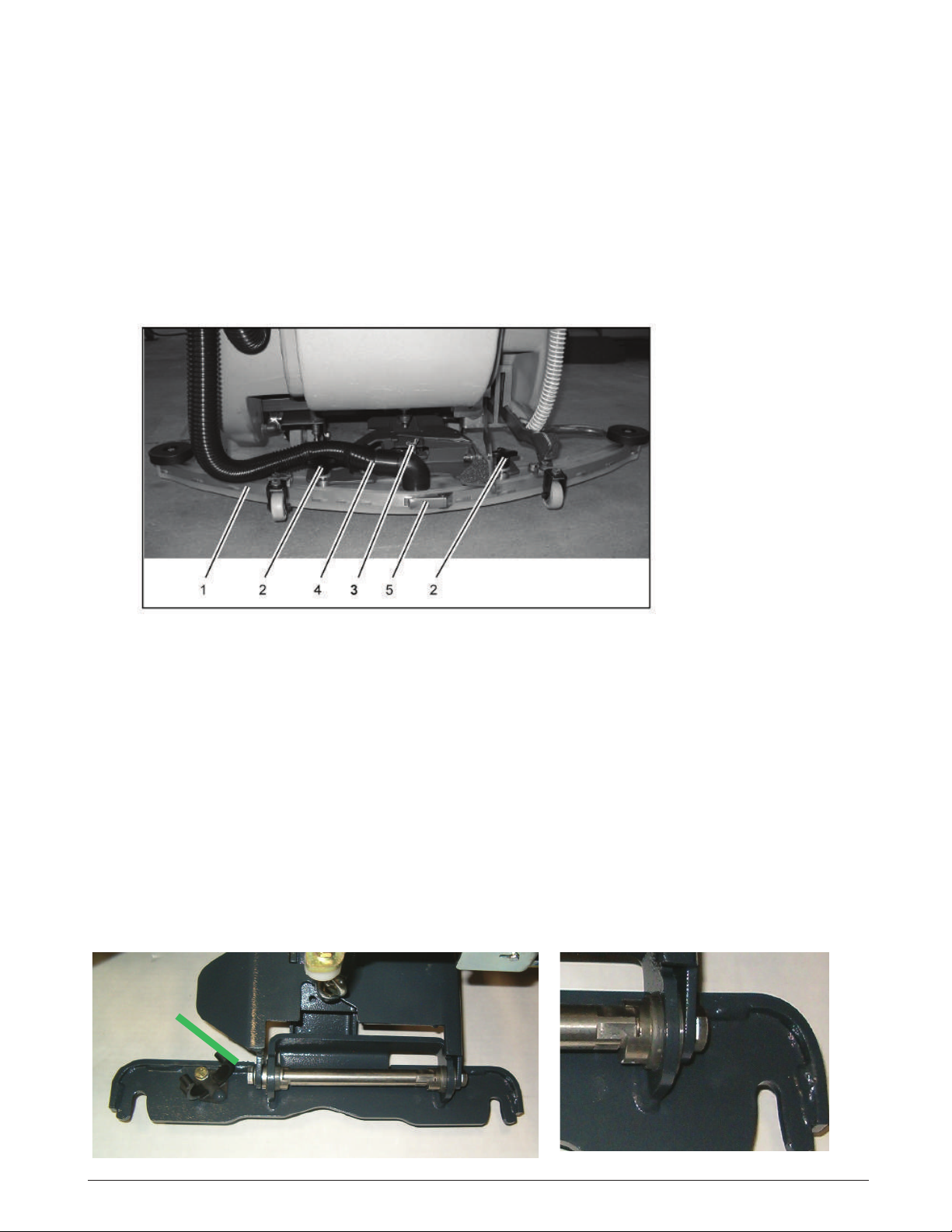

Brush Head (Disk Brushes) Connections

5.1 Brush Motor Information

Brush Head Transport Position

6.1 Brush Switch

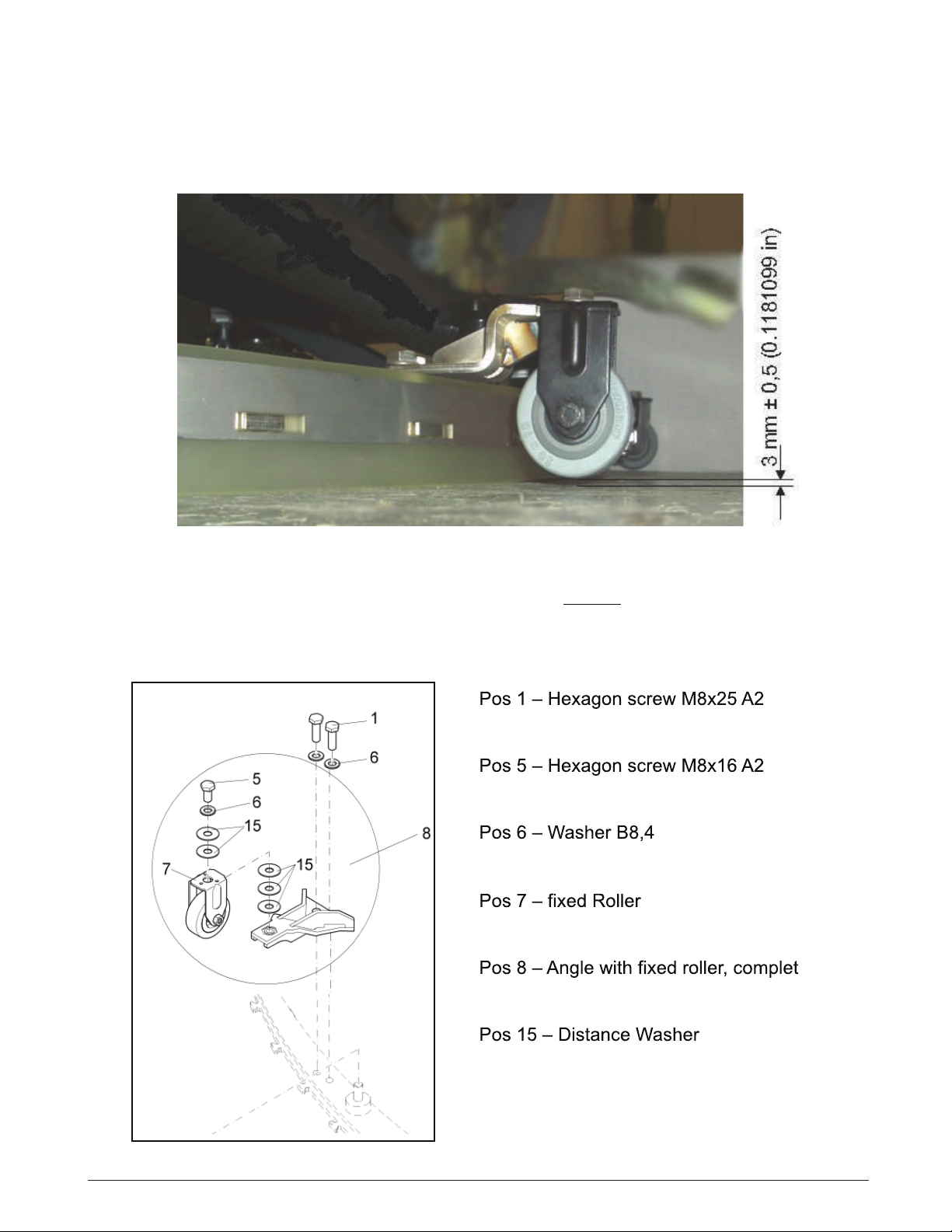

6.2 Brush Pressure Adjustment on the Disk Models

6.3 Brush Pressure (Disk Decks)

6.4 Cylindrical Brush Head Electrical Connections

6.5 Cylindrical Brush Head Adjustment

Drive and Wheels - General Data

7.1 Electric Brake

7.2 Transaxle Motor

7.3 Carbon Brushes

7.4 Drive Potentiometer

Water Supply

8.1 Solenoid

8.2 Solution Filter

8.4 Solution Flow Rates

8.5 Water Pump

The Last Error

Table of Error Codes and Information

Battery Charger

11.1 Operating Instructions

11.2 Charger Error Codes

11.3 Charger Trouble Shooting

11.4 Charger Maintenance Points

11.5 Programming The Charger

11.6 Replacing The Charger Harness

Batteries

12.1 Maintaining Wet Lead Acid Batteries

12.2 Load Testing Batteries

12.3 Hydrometer Testing

Fuse Locations Version 2

13.1 Controller Version 3

Controller Connections

Trouble Shooting Controller

Contactor Harness

Contactor Wiring Page 29

Page 6

HAMMERHEAD