1 General information

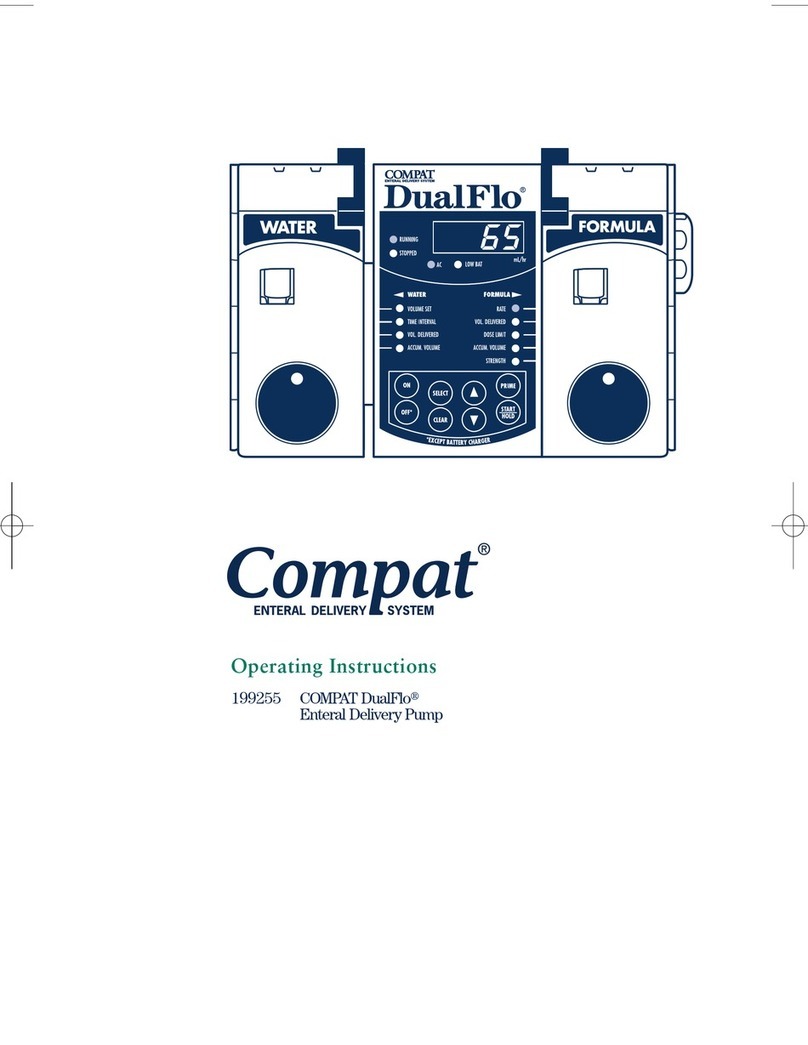

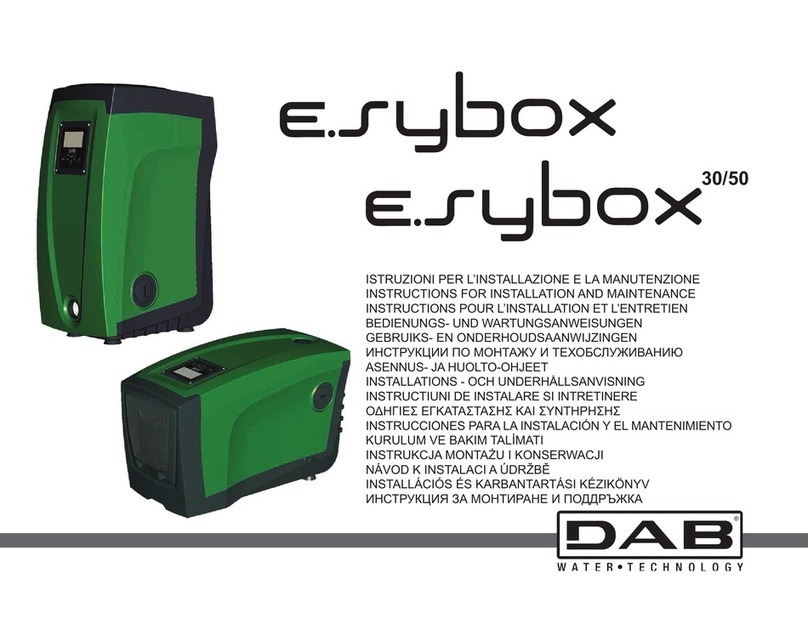

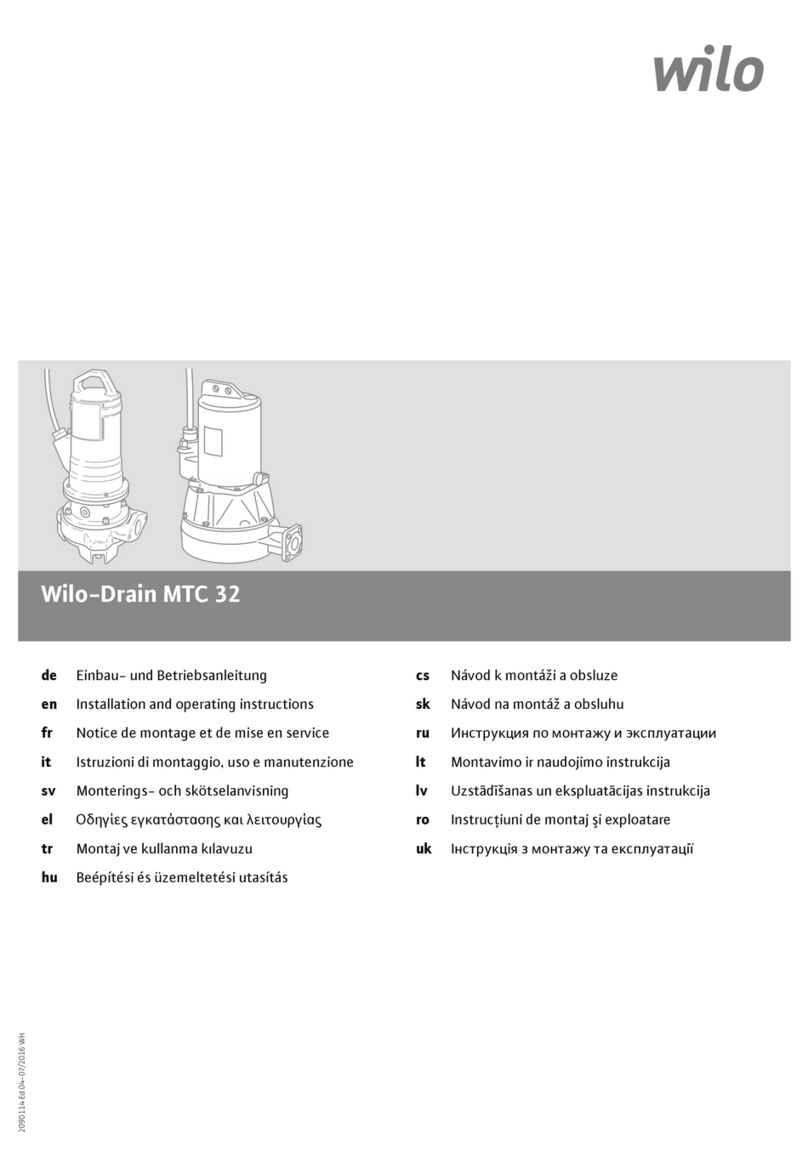

0DNO0201 Installation-Operation ST1 Solar Pump Station 3

Contents

1General information.........................................................................................................4

1.1 About these instructions...............................................................................................4

1.2 About this product........................................................................................................4

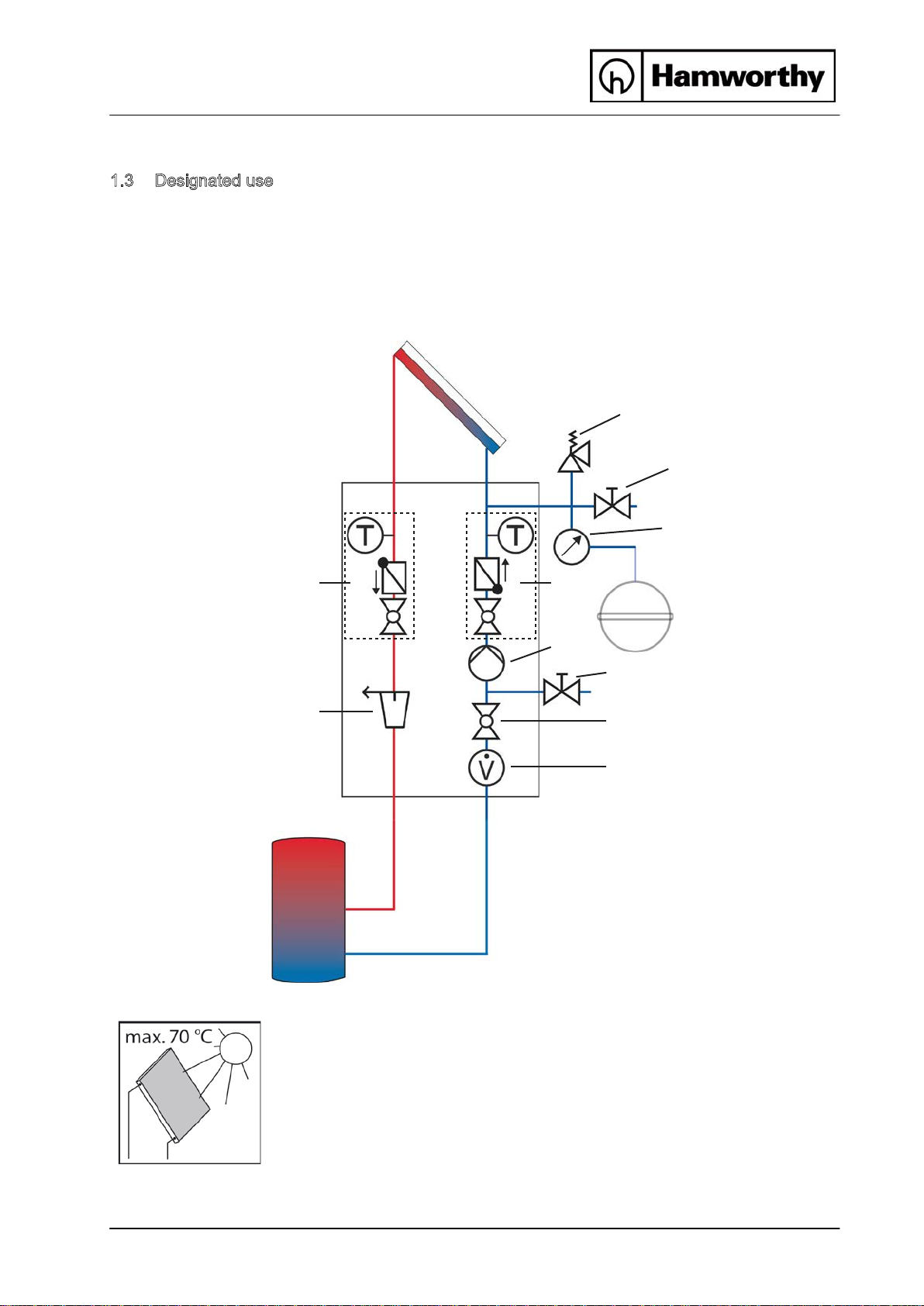

1.3 Designated use............................................................................................................5

2Safety instructions...........................................................................................................6

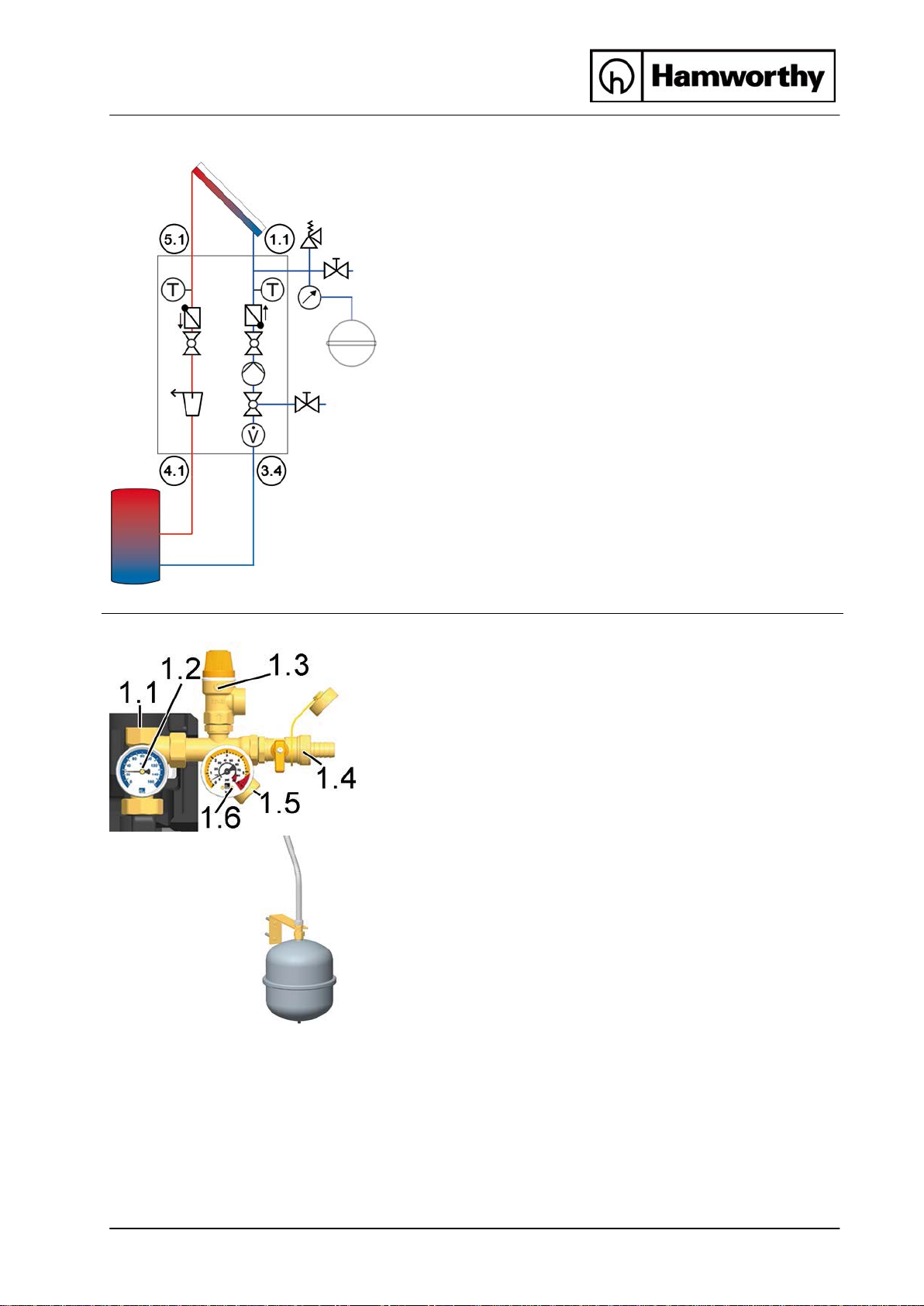

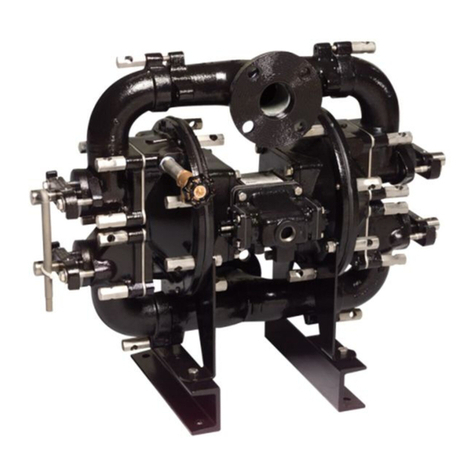

3Assembly and installation [installer]..................................................................................8

4Commissioning [installer]...............................................................................................11

4.1 Flushing and filling the solar circuit.............................................................................12

4.2 Preparations before flushing.......................................................................................14

4.3 Flushing and filling .....................................................................................................14

4.4 Setting the solar installation (only for standard solar pumps)......................................17

5Maintenance [installer]...................................................................................................18

5.1 Draining the solar installation .....................................................................................18

5.2 Disassembly...............................................................................................................18

6Spare parts [installer].....................................................................................................19

6.1 ST1 Solar Pump Station.............................................................................................19

Controller extension..............................................................................................................20

720

Technical data

...............................................................................................................

7.1 Pressure drop characteristics ST1 Solar Pump Station..............................................21

8Function check valves [installer].....................................................................................22

9Commissioning report....................................................................................................

24