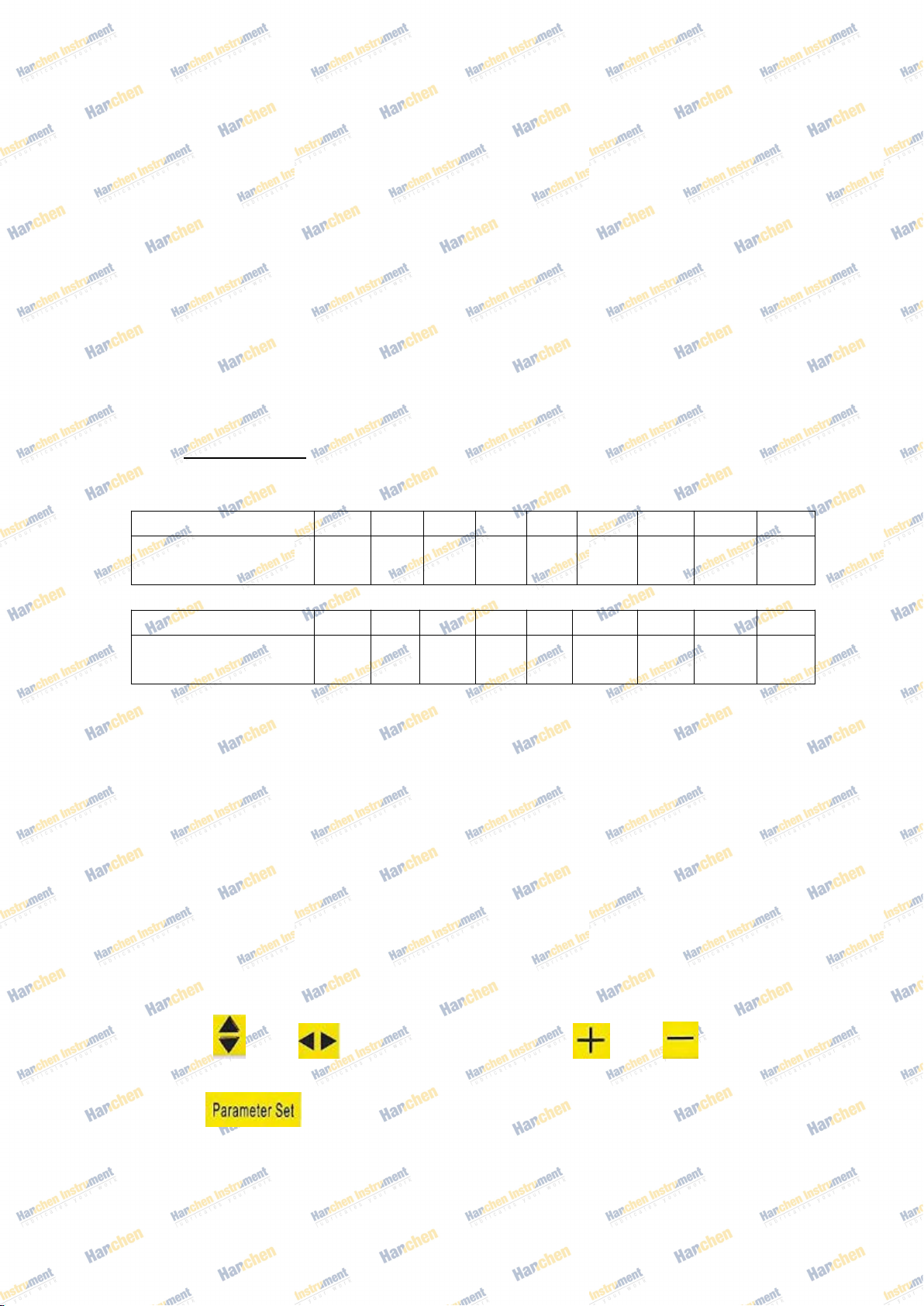

3. Selecting data group from 0-6.

I. When editing group “0”, the cursor will automatically appear.

II. When editing group “1-6”, please press to choose the group you want, and then long

press for about 3 seconds until there is a beep, and cursor will appear on the

screen. Then you can edit the parameters of them.

4. Start filling.

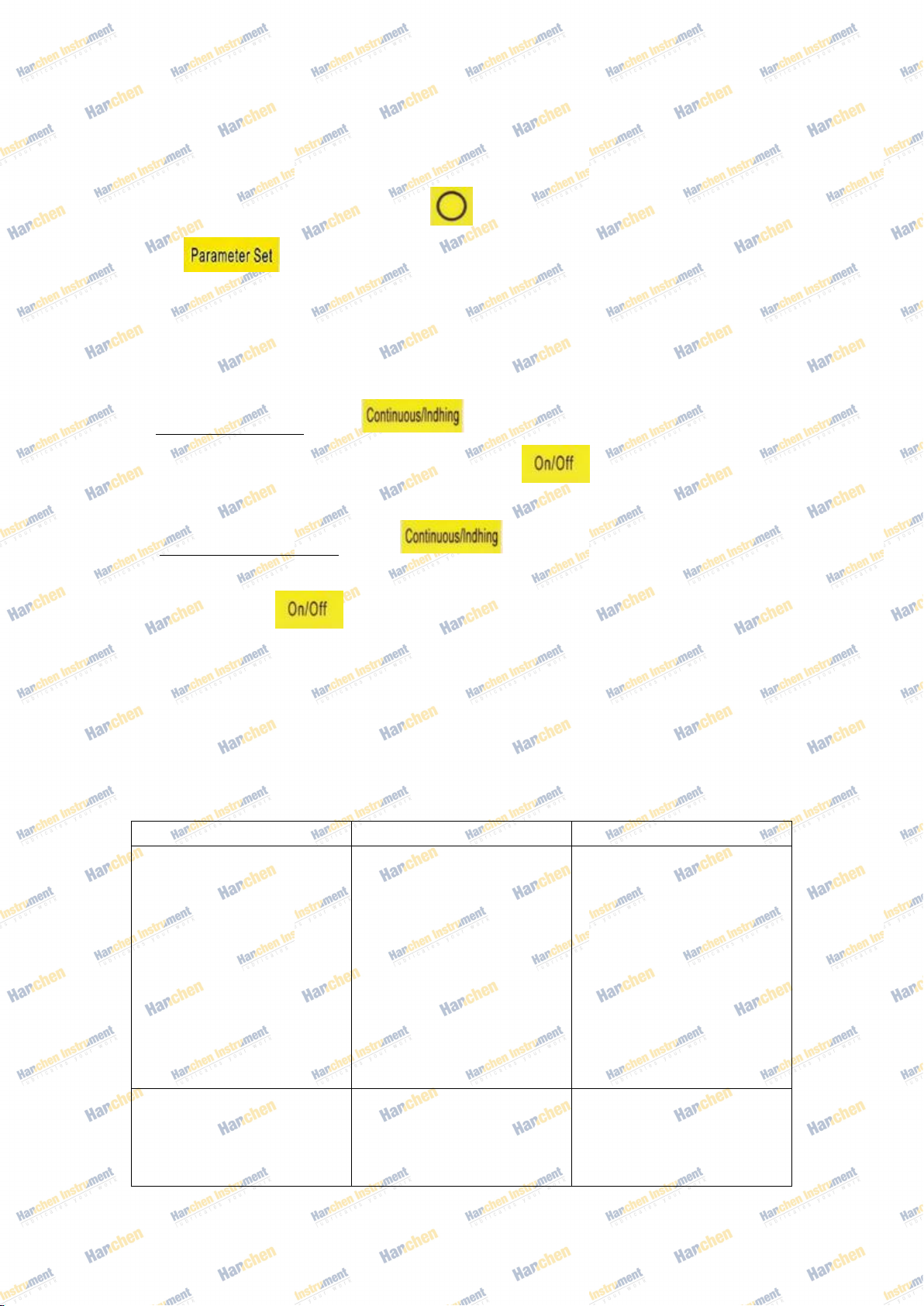

I. Choose inching mode: press to switch to “Inching mode”, set “S.P”(filling

speed) and “W.T”(filling time), then save setting. Press , and filler machine is under

“Work Status”. Press red button to finish each filling process.

II. Choose continuous mode: press to switch to “Continuous mode”, set

“S.P”(filling speed), “W.T”(filling time), and “S.T”(waiting time between two filling process”, then

save setting. Press , and filler machine is under “Work Status”. Press red button to

finish each filling process.

Troubleshooting

Machine cannot pump

water, but the sound of

pump can be heard

Pump is not broken, it

cannot pump water

because it is dry inside.

1. Use machine fill water

for several times.

2. If issue cannot be

solved, remove mesh filter

and use a cartridge to

manually add water into

tube. Start machine to

check whether it can work,

if not, please repeat the

second step.

Machine cannot pump

water, and the sound of

pump cannot be heard

1. Inner connection of

pump and control board is

disconnected

2. Pump is broken

1. Open the machine and

connect the wires.

2. Replace the pump.