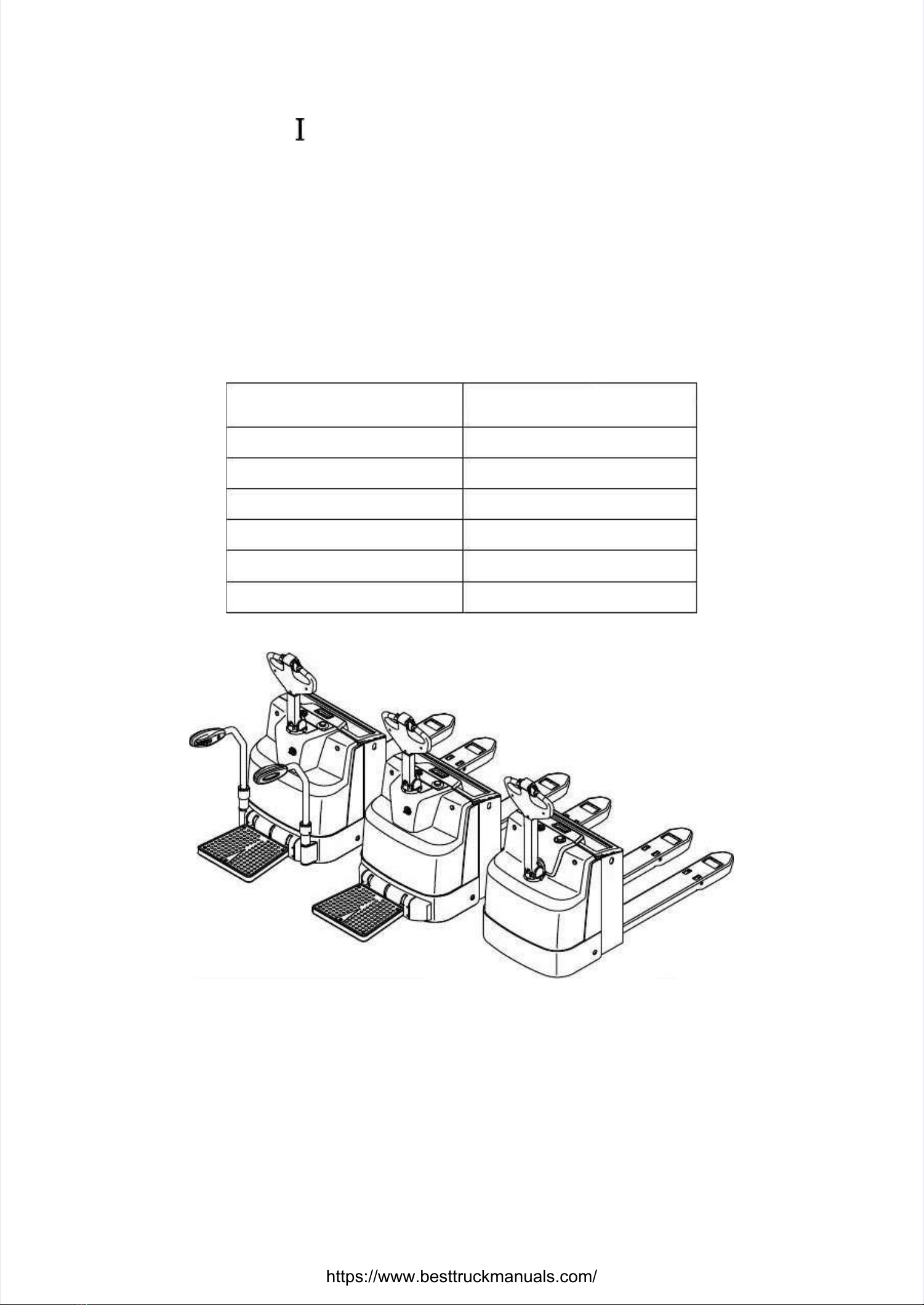

HANGCHA CBD20-AEC1 User manual

ELECTRIC PAELECTRIC PALLET TRUCKLLET TRUCK CBD20-AEC1CBD20-AEC1

CBD20-AEC1SCBD20-AEC1S

OPERATION AND MAINTENANCE MANUALOPERATION AND MAINTENANCE MANUAL

Original InstructionOriginal Instruction

HANGCHA GROUP CO., LTD.HANGCHA GROUP CO., LTD.

7/20157/2015

Basic RangeBasic Range

https://www.besttruckmanuals.com/

FOREWORDFOREWORD

Thank you very much for purchasing the A series basic range electric pallet truck of Hangcha

Thank you very much for purchasing the A series basic range electric pallet truck of Hangcha

Group .Group .

A series A series basic basic range electric range electric pallet truck pallet truck is is a a newly developed newly developed product for product for warehouwarehouse se logistic, itlogistic, it

owns characteristics as advanced performance, comfort operation, safety and security, lowowns characteristics as advanced performance, comfort operation, safety and security, low

maintenance cost, and is an ideal tool for handling goods in warehouse, supermarket andmaintenance cost, and is an ideal tool for handling goods in warehouse, supermarket and

workshop.workshop.

Before use the truck, relative persons must read and understand the manual, get to know how toBefore use the truck, relative persons must read and understand the manual, get to know how to

safely operate and maintain the truck.safely operate and maintain the truck.

Part one of this manual is about the brief introduction and correct operation of thePart one of this manual is about the brief introduction and correct operation of the basic range

basic range

electric pallet truck, which will tell you how to operate safely and maintain preventively; part twoelectric pallet truck, which will tell you how to operate safely and maintain preventively; part two

will tell you the will tell you the structure, working principstructure, working principle and maintenance of the electric pallet truck.le and maintenance of the electric pallet truck.

Because of the update and improvements of our products, there may be some differencesBecause of the update and improvements of our products, there may be some differences

between this operation manual contents and your forklift between this operation manual contents and your forklift truck.truck.

If you have any questions, please contact Hangcha Group Co., Ltd. sales company or the agent.If you have any questions, please contact Hangcha Group Co., Ltd. sales company or the agent.

©©7/2015 7/2015 HANGCHA HANGCHA GROUP GROUP CO., CO., LLTDTD

https://www.besttruckmanuals.com/

ContentContent

Part Part : : Operation Operation and and maintenancmaintenance e ........................................................................................................................................................... ........................... 11

1 1 Truck Truck Introduction....Introduction........................................................................................................................................................................................................................... ......... 11

1.1 1.1 General General ....................................................................................................................................................................................................................................... ................................. 11

1.2 1.2 Use occasion and Use occasion and condition condition ...................................................................................................................................................................................................... 1.... 1

1.3 1.3 Main paMain part name rt name ............................................................................................................................................................................................................................ .................... 11

1.4 1.4 Display Display and contrand control ol ..................................................................................................................................................................................................................... ............... 33

1.4.1 1.4.1 Display ................Display .......................................................................................................................................................................................................................................... ................ 44

1.4.2 1.4.2 Control ..................................Control ....................................................................................................................................................................................................... ................................. 55

1.4.3 1.4.3 Others .................Others ........................................................................................................................................................................................................................................... ................ 77

1.5 1.5 StaStandard technndard technical datical data a ............................................................................................................................................................................................................. 9......... 9

1.6 1.6 Product plates and warning labProduct plates and warning labels location els location ................................................................................................................................................ ........ 1111

2 2 Safety Safety Rules Rules ........................................................................................................................................................................................................................... ......................... 1313

3 3 TranspoTransport rt ............................................................................................................................................................................................................................... ............................... 1616

3.1 3.1 Lifting Lifting by by crane...............crane............................................................................................................................................................................................................................ ... 1616

3.2 3.2 Securing Securing the truck the truck during trduring transport ansport ..................................................................................................................................................... ......................... 1717

3.3 3.3 How to remove a How to remove a broken truck broken truck ............................................................................................................................................................... ............................... 1818

4 4 Battery Battery ....................................................................................................................................................................................................................................... ............................... 1919

4.1 4.1 Attention for usinAttention for using battery g battery .......................................................................................................................................................................................................... 19.. 19

4.2 4.2 Dimension/SerDimension/Service vice Weight Weight ...................................................................................................................................................................................................... .. 2121

4.3 4.3 Charging Charging the battethe battery ry ............................................................................................................................................................................................................... ............. 2222

4.4 4.4 Replacing thReplacing the battery e battery ............................................................................................................................................................................................................ .............. 2626

5 5 Truck Truck breaking-in breaking-in ......................................................................................................................................................................................................................... ............. 2727

6 6 Operation Operation ............................................................................................................................................................................................................................... ............................... 2828

6.1 6.1 Check beCheck before ofore operation peration ........................................................................................................................................................................................................... ....... 2828

6.2 6.2 StaStart up rt up ....................................................................................................................................................................................................................................... ............................... 3030

6.3 6.3 TravelliTravelling........................ng..................................................................................................................................................................................................................................... ... 3131

6.4 6.4 Braking Braking ....................................................................................................................................................................................................................................... ............................... 3333

6.5 6.5 SteerSteering ing ..................................................................................................................................................................................................................................... ............................... 3333

6.6 6.6 StoppStopping ing ................................................................................................................................................................................................................................... ............................... 3333

6.7 6.7 Loading Loading ..................................................................................................................................................................................................................................... ............................... 3333

6.8 6.8 Unloading Unloading ............................................................................................................................................................................................................................... ............................... 3434

6.9 6.9 Parking Parking ....................................................................................................................................................................................................................................... ............................... 3535

7 7 Deposit Deposit the the truck truck ......................................................................................................................................................................................................................... ............. 3636

7.1 7.1 Deposit the Deposit the truck for lontruck for long time g time ............................................................................................................................................................... ............................... 3636

7.2 7.2 StaStart running rt running after deafter deposit for a posit for a long time long time ............................................................................................................................................ .............. 3636

8 8 Maintenance Maintenance ........................................................................................................................................................................................................................... ......................... 3737

8.1 8.1 Maintenance Maintenance general general ............................................................................................................................................................................................................ .............. 3737

8.2 8.2 Periodic Periodic maintenance maintenance schedule.......schedule............................................................................................................................................................... .................... 3838

8.3 8.3 Truck used Truck used oil and luoil and lubrication brication ................................................................................................................................................................. ............................... 4242

8.4 8.4 Replace hydrauReplace hydraulic oil lic oil ............................................................................................................................................................................................................... 43............. 43

8.5 8.5 Replace Replace wheels wheels ........................................................................................................................................................................................................................ .................. 4444

8.5.1 8.5.1 Replace Replace drive drive wheel ..wheel ................................................................................................................................................................................................................... ....... 4444

8.5.2 8.5.2 Replace Replace load load wheels ......wheels .................................................................................................................................................................................................................. .. 4646

8.5.3 8.5.3 Replace Auxiliary Replace Auxiliary Wheels Wheels .......................................................................................................................................................................................................... .. 4747

8.6 8.6 Replace the key Replace the key safe parts pesafe parts periodically riodically ..................................................................................................................................................... 48............. 48

9 9 Relevant Relevant safety safety directive directive or or standard standard (CE) (CE) ............................................................................................................................................... ....... 4949

Part Part : : Structure, Structure, Priciple Priciple and and Maintenance Maintenance ............................................................................................................................................... ....... 5151

1 1 Drive Drive Unit Unit ............................................................................................................................................................................................................................... ............................... 5151

1.1 1.1 Drive unit strDrive unit structure and ucture and principle principle ............................................................................................................................................................. ......................... 5151

1.2 1.2 Assemble Assemble and uand use nose notice tice .......................................................................................................................................................................................................... .. 5353

1.3 1.3 Fault and Fault and troubleshotroubleshooting oting .......................................................................................................................................................................................................... 53.. 53

1.4 1.4 Drive Drive motor motor ............................................................................................................................................................................................................................... ......................... 5454

1.5 1.5 ElectromagneElectromagnetic brake tic brake ............................................................................................................................................................................................................... ....... 5757

1.5.1 Electromagnetic brake 1.5.1 Electromagnetic brake working principle ....................................working principle ................................................................................................................. 58....... 58

1.5.2 1.5.2 ElectromagnElectromagnetic etic brake brake installatioinstallation ....................................................n ......................................................................................................................... ... 5959

https://www.besttruckmanuals.com/

1.5.3 1.5.3 Maintenance .......Maintenance ............................................................................................................................................................................................................................... .............. 6060

1.5.4 Adjust the 1.5.4 Adjust the Air Air Gap of Gap of the the Brake Brake ........................................................................................................................................................... 61............................... 61

1.5.5 1.5.5 Common fault Common fault and and troubleshotroubleshooting .oting ......................................................................................................................................................... 62.................... 62

2 2 Hydraulic Hydraulic system system ......................................................................................................................................................................................................................... ............. 6363

2.1 2.1 Hydraulic syHydraulic system worstem working princking principle iple ..................................................................................................................................................... ......................... 6464

2.2 2.2 Hydraulic Hydraulic unit unit .............................................................................................................................................................................................................................. .................... 6666

2.3 2.3 Hydraulic Hydraulic unit unit dismantle dismantle ....................................................................................................................................................................................................... ......... 6868

2.4 2.4 Dismantle the Dismantle the lifting cylifting cylinder from linder from the truck othe truck or replace r replace ......................................................................................... ......................... 6969

2.5 2.5 Hydraulic systeHydraulic system fault diam fault diagnosis angnosis and correctiod correction n .................................................................................................................................... 72.. 72

3 3 Electric Electric system system .......................................................................................................................................................................................................................... .................. 7373

3.1 3.1 Electrical scheElectrical schematic diagramatic diagram m ................................................................................................................................................................... ............................... 7474

3.2 3.2 AC motor coAC motor controller ntroller ................................................................................................................................................................................................................... ............. 7575

3.2.1 3.2.1 Maintenance .......Maintenance ............................................................................................................................................................................................................................... .............. 7575

3.2.2 3.2.2 Diagnosis Diagnosis and and troubleshootintroubleshooting g ............................................................................................................................................................. 76............................... 76

3.2.3 3.2.3 LED LED StStatus atus Indicator Indicator ............................................................................................................................................................................................................... ............. 8080

3.2.4 3.2.4 Fault Fault code code table table ........................................................................................................................................................................................................................ 81.................. 81

AttachmentAttachment::Table for bolt’s tightening torqueTable for bolt’s tightening torque............................................................................................................................................... ............. 8787

https://www.besttruckmanuals.com/

11

Part Part : : Operation Operation and and maintenancemaintenance

1 1 TTruck ruck IntroductionIntroduction

1.1 General1.1 General

A seriesA series basic range electric pallet truck

basic range electric pallet truckdescribed in this manual should work under moderatedescribed in this manual should work under moderate

intensity working strength.intensity working strength.

According to differeAccording to different operation waynt operation way, it has two types as, it has two types aspedestrianpedestrian type and stand-on type. Usestype and stand-on type. Uses

can get relevant information as rated load from the product model.can get relevant information as rated load from the product model.

CBD20-AEC1CBD20-AEC1

CBD20-AEC1SCBD20-AEC1S Mode

Mode

CBD CBD Electric Electric pallet pallet trucktruck

2020 Rated load capacity×100kg

Rated load capacity×100kg

A A Product seriProduct serial numberal number

EE Basic Range

Basic Range

C1 C1 Controller Controller typetype

S S Stand-on Stand-on typetype

https://www.besttruckmanuals.com/

22

Truck body systemTruck body system

–– Beautiful and compact outline, concise and fluent Beautiful and compact outline, concise and fluent line.line.

–– High strength steel frame structure High strength steel frame structure chassis provide larger residual load capability and longerchassis provide larger residual load capability and longer

working life.working life.

–– Chassis adopts 5-wheel structure, including one central driving wheel, two lateral auxiliaryChassis adopts 5-wheel structure, including one central driving wheel, two lateral auxiliary

wheels as stabilization and two load wheels. It can make sure stable and safe driving.wheels as stabilization and two load wheels. It can make sure stable and safe driving.

Auxiliary whAuxiliary wheel gets dameel gets damping desigping design.n.

–– Hanging foldable damping pedal.Hanging foldable damping pedal.

Driving systemDriving system

–– Drive unit adopts wheel type, Drive unit adopts wheel type, with compact and simple integral structure.with compact and simple integral structure.

–– The adopted unique floating supension system ensures good driving wheels`s grip andThe adopted unique floating supension system ensures good driving wheels`s grip and

excellent stability.excellent stability.

–– AC travelling motor applied to provide excellent acceleration, good gradeabilityAC travelling motor applied to provide excellent acceleration, good gradeability, low heat, , low heat, nono

carbon brush and carbon brush and maintenance free.maintenance free.

–– High performance electromagnetic brake.High performance electromagnetic brake.

Braking systemBraking system

–– It owns three emergency braking functions as release brake, reverse brake andIt owns three emergency braking functions as release brake, reverse brake and

electromagnetic brake to ensure travelling safety.electromagnetic brake to ensure travelling safety.

–– It owns slope anti-slide function to ensure safety.It owns slope anti-slide function to ensure safety.

Operation steering systemOperation steering system

–– New ergonomics designed control handle owns acceleration, reversing, horn, braking,New ergonomics designed control handle owns acceleration, reversing, horn, braking,

lifting/lowering, emergency reverse functions, thus makes operation easier.lifting/lowering, emergency reverse functions, thus makes operation easier.

–– Emergency reversing button on the control handle head can prevent driver from hurt whenEmergency reversing button on the control handle head can prevent driver from hurt when

encountering emergency in backward driving.encountering emergency in backward driving.

–– Turtle speed function can keep the slow move when the tiller is vertical direction, the truckTurtle speed function can keep the slow move when the tiller is vertical direction, the truck

can stack goods even in narrow space.can stack goods even in narrow space.

–– Steering angle +/- 90°.Steering angle +/- 90°.

Hydraulic systemHydraulic system

–– Modularization hydraulic power unit owns low noise, low vibration, stable and reliable liftingModularization hydraulic power unit owns low noise, low vibration, stable and reliable lifting

and lowering.and lowering.

Electric systemElectric system

–– 24V Electric system24V Electric system

–– CURTIS latest AC control system provides accurate and CURTIS latest AC control system provides accurate and atable control to work more atable control to work more efficient.efficient.

–– Multi-function meter, has the power display, timing and fault self-diagnosis function.Multi-function meter, has the power display, timing and fault self-diagnosis function.

–– Emergency stop switch.Emergency stop switch.

–– The standard equipped electronic lifting limitation and soft landing system protect workingThe standard equipped electronic lifting limitation and soft landing system protect working

motor and loads from motor and loads from damaging.damaging.

https://www.besttruckmanuals.com/

11

1.2 1.2 Use Use occasion occasion and and conditioncondition

Truck in this manual is only for Truck in this manual is only for lifting and transporting loads.lifting and transporting loads.

It must be It must be used, operated and maintainused, operated and maintained according to the information in this manual. Any othered according to the information in this manual. Any other

uses are outside the design envelope and can lead to injury to persons or damage to equipmentuses are outside the design envelope and can lead to injury to persons or damage to equipment

and property.and property.

Only used in Only used in specified place and conditionspecified place and condition::

–– Use in specified rated load.Use in specified rated load.

–– Used in specified area as factory, tourist attraction and recreation place.Used in specified area as factory, tourist attraction and recreation place. 。。

–– Used on the flat ground, that is fixed and owns enough carrying capacity.Used on the flat ground, that is fixed and owns enough carrying capacity.

–– It is prohibtted to pass the bulge or cavity as the small wheel diameter may cause truckIt is prohibtted to pass the bulge or cavity as the small wheel diameter may cause truck

tipping over.tipping over.

–– Used on the road with good vision and equipment use license.Used on the road with good vision and equipment use license.

–– Max. uphill grade when driving is 6%.Max. uphill grade when driving is 6%.

–– It is prohibited to travel crosswise or obliquely. When go uphill with loads, keep the loads inIt is prohibited to travel crosswise or obliquely. When go uphill with loads, keep the loads in

front; when go downhill, keep people in front.front; when go downhill, keep people in front.

For truck operation, the

For truck operation, the following normal climatic conditions apply:following normal climatic conditions apply:

–– Average

Average ambient tempambient temperature for coerature for continuous duntinuous duty:ty: ++2525℃℃;;

–– Maximum ambient temperatur

Maximum ambient temperature, short term e, short term (up to (up to 1h):1h): ++4040℃℃;;

–– Lowest ambient temperature for trucks intended for use Lowest ambient temperature for trucks intended for use in normal indoor conditions:in normal indoor conditions:++55℃℃;;

–– Lowest ambient temperature for trucks intended for

Lowest ambient temperature for trucks intended for use in use in normal outdoor conditionormal outdoor conditions:ns:--2020℃℃;;

–– Altitude:

Altitude: up to 2000m.up to 2000m.

Please read others safety rules in this Please read others safety rules in this manual, it is important to your personal safety, working staffmanual, it is important to your personal safety, working staff

and goods safety.and goods safety.

WARNINGWARNING

Do not carry people.Do not carry people.

Do not over load.Do not over load.

Do not push and pull loads.Do not push and pull loads.

https://www.besttruckmanuals.com/

11

1.3 1.3 Main Main part part namename

11

22

33

44

55

66

55

77

88

99

1212

1111

1010

CBD20-AECBD20-AEC1(PedestriC1(Pedestrian an type)type)

11

22

33

44

55

1313 66 55

77

88

1111

1212

1010 99

CBD20-AEC1S(Stand-on type)CBD20-AEC1S(Stand-on type)

https://www.besttruckmanuals.com/

22

1414

Item

ItemDescriptionDescriptionItemItem DescriptionDescription

1 1 Control Control handle handle 8 8 ForkFork

2 2 Control Control lever lever 9 9 Load Load wheelwheel

3 3 Key Key switch switch 10 10 Battery Battery covercover

4 4 Hood Hood 11 11 InstrumenInstrumentt

5 Auxiliary 5 Auxiliary wheel wheel 12 12 Emergency Emergency stop stop switchswitch

6 6 Drive Drive wheel wheel 13 13 PedalPedal

7 7 Rear Rear frame frame 1414 Fence(optional)

Fence(optional)

https://www.besttruckmanuals.com/

33

1.4 1.4 Display Display and and controlcontrol

11

33

1111

1212

1616 1717

1919

1919

2222

2121 2020 2121

2222

1818

https://www.besttruckmanuals.com/

44

1.4.1 Display1.4.1 Display

Instrument [11]Instrument [11]

Dot-matrix LCD displayDot-matrix LCD display

The display screen is 8 alphanumericThe display screen is 8 alphanumeric

characters, dot-matrix LCD liquid crystalcharacters, dot-matrix LCD liquid crystal

display, can display vehicles fault code,display, can display vehicles fault code,

battery soc and total running time.battery soc and total running time.

Vehicles when the normal operation of theVehicles when the normal operation of the

display shows the battery remaining power.display shows the battery remaining power.

Service indicator(red LED)Service indicator(red LED)

When the controller to detect When the controller to detect fault information,fault information,

the red LED indicator light flashing, at thethe red LED indicator light flashing, at the

same time LCD display shows two digits ofsame time LCD display shows two digits of

the fault code.When there are multiple faultthe fault code.When there are multiple fault

fault code alternates between interval of 2fault code alternates between interval of 2

seconds.Fault code corresponding faultseconds.Fault code corresponding fault

information to view in this paper, the fault codeinformation to view in this paper, the fault code

table.table.

BDI indicator(yellow LED)BDI indicator(yellow LED)

When battery remaining power less than 20%,When battery remaining power less than 20%,

the yellow LED indicator lights flashing,the yellow LED indicator lights flashing,

warned "depleted", at the same time LCDwarned "depleted", at the same time LCD

display shows "20%" for 1 seconds after intodisplay shows "20%" for 1 seconds after into

"Low BDI"."Low BDI".

When the yellow LED indicator lights flashing,When the yellow LED indicator lights flashing,

vehicle lifting by automatic locking function,vehicle lifting by automatic locking function,

running speed is reduced.At this time shouldrunning speed is reduced.At this time should

be immediately available for vehiclesbe immediately available for vehicles

recharged.recharged.

Hourmeter indicator(green LED)Hourmeter indicator(green LED)

Said when the green LED light is normally onSaid when the green LED light is normally on

the timer is timing, the smallest unit of time forthe timer is timing, the smallest unit of time for

0.1 hours.0.1 hours.

Every time when starting the vehicle LCDEvery time when starting the vehicle LCD

screen will display the vehicle's total run time,screen will display the vehicle's total run time,

this time is for regular maintenance on thethis time is for regular maintenance on the

basis of the basis of the vehicle.vehicle.

Low speed indicator [18]Low speed indicator [18]

When the indicator light shows that the truckWhen the indicator light shows that the truck

is in low is in low speed operation mode.speed operation mode.

https://www.besttruckmanuals.com/

55

1.4.2 Control1.4.2 Control

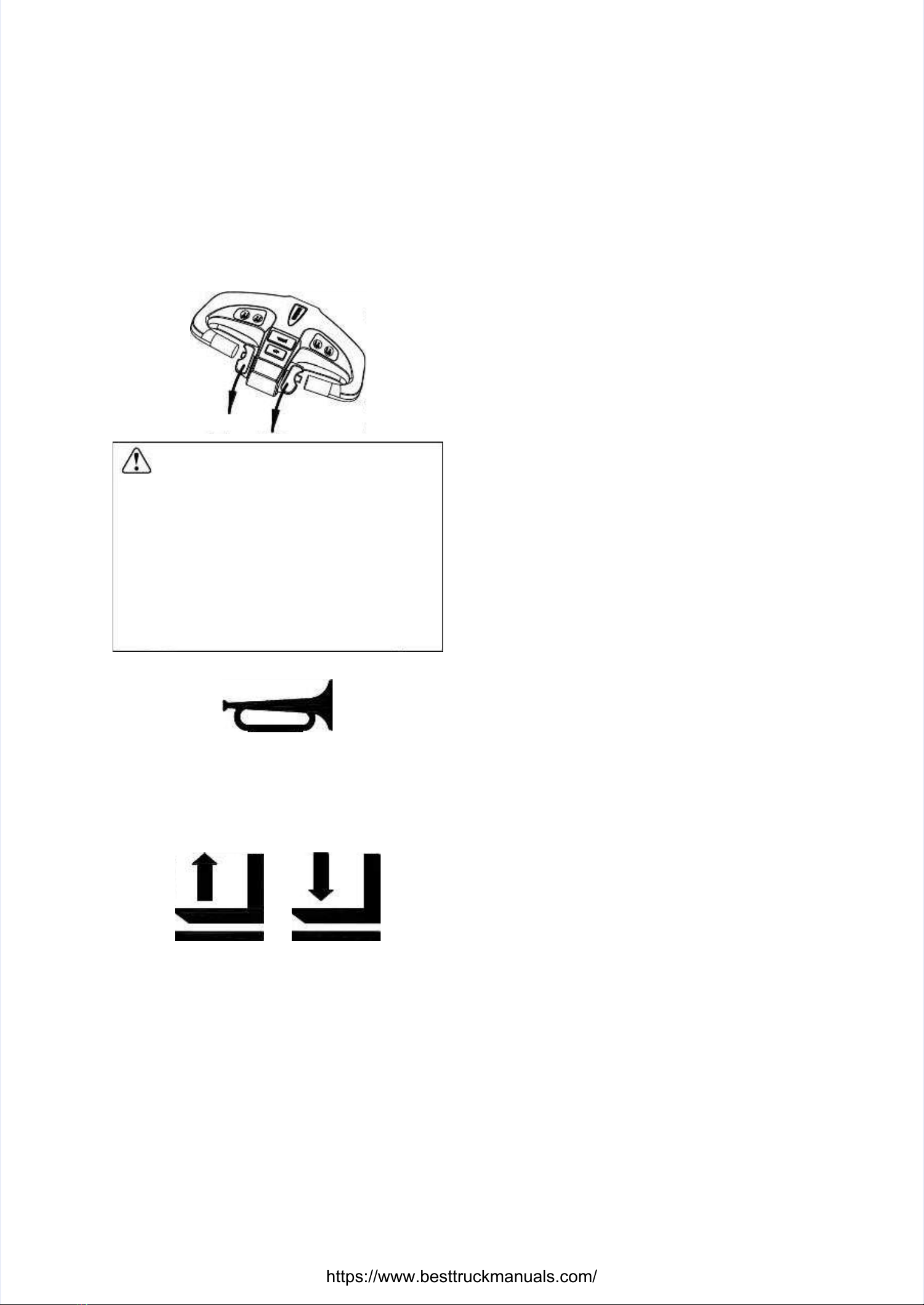

Control handle[1]Control handle[1]

Control truck steering and braking.Control truck steering and braking.

When turn the control handle right and left, itWhen turn the control handle right and left, it

can realize the truck right and left turncan realize the truck right and left turn。。TheThe

max turning angle of this handle is max turning angle of this handle is about 175°.about 175°.

When press the handle to horizontal positionWhen press the handle to horizontal position

or push up to vertical position, it can realizeor push up to vertical position, it can realize

the truck brake. These two positions are setthe truck brake. These two positions are set

by brake inching switch. Normal is open circuit,by brake inching switch. Normal is open circuit,

working status is closed, brake inching switchworking status is closed, brake inching switch

at horizontal or vertical position at horizontal or vertical position is normal.is normal.

Key switch [3]Key switch [3]

Turn on the key switch, and the power is on. TurnTurn on the key switch, and the power is on. Turn

off the switch, and the power is off. Turn off theoff the switch, and the power is off. Turn off the

key switch before charging.key switch before charging.

Emergency stop switch [12]Emergency stop switch [12]

Press this switch, power is off. Press it whenPress this switch, power is off. Press it when

emergency or no ise. If re-start needed, pullemergency or no ise. If re-start needed, pull

upward.upward.

Emergency reverse button [Emergency reverse button [16

16]]

This switch is at the head of control lever,This switch is at the head of control lever,

once touch this button, the truck movesonce touch this button, the truck moves

forward. It is used to protect people fromforward. It is used to protect people from

being clamped by the control handle.being clamped by the control handle.

This switch is This switch is also called belly switch.also called belly switch.

Low speed travel button [Low speed travel button [17

17]]

Press this button, the maximum speed of the

Press this button, the maximum speed of the

truck to reduce to 2.4 km/h.truck to reduce to 2.4 km/h. Release thisRelease this

button, the truck travels in button, the truck travels in normal speed.normal speed.

Direction and speed control button[Direction and speed control button[19

19]]

This button is at both sides of control leverThis button is at both sides of control lever

head, one linkage per left and right. It is tohead, one linkage per left and right. It is to

control travelling direction and travellingcontrol travelling direction and travelling

speed.speed.

Truck travels to the fork sideTruck travels to the fork side

–– Press this Press this control handle downwards.control handle downwards.

–– Turn this button from the side of body toTurn this button from the side of body to

outside gradually with thumb.outside gradually with thumb.

–– Truck travels to the fork side.Truck travels to the fork side.

https://www.besttruckmanuals.com/

66

Truck travels to the handle side(or pedal)Truck travels to the handle side(or pedal)

–– Press this control handle downwards.Press this control handle downwards.

Turn this button towards the side of bodyTurn this button towards the side of body

gradually with thumb.gradually with thumb.

–– Truck travels to the handle side(orTruck travels to the handle side(or

platform).platform).

CautionCaution

After the finger is released, theAfter the finger is released, the

direction and speed button willdirection and speed button will

reset itself and the truck will stopreset itself and the truck will stop

by brake. So do not loosen theby brake. So do not loosen the

knob when the truck is requested toknob when the truck is requested to

continue driving.continue driving.

Horn button [20]Horn button [20]

The button is located on the front of theThe button is located on the front of the

control handle upper surface. Press down thecontrol handle upper surface. Press down the

button, and the horn sounds.button, and the horn sounds.

Lifting button[21], lowering Lifting button[21], lowering button[22]button[22]

The lifting button and the lowering button areThe lifting button and the lowering button are

located on both side surface of the middlelocated on both side surface of the middle

control handle. Press the lifting button, andcontrol handle. Press the lifting button, and

the forks move up; press the lowering button,the forks move up; press the lowering button,

the forks go down.the forks go down.

When battery power less than 20%, lifting

When battery power less than 20%, lifting

function will be locked up, at this time shouldfunction will be locked up, at this time should

be recharged as soon as possible.be recharged as soon as possible.

https://www.besttruckmanuals.com/

77

1.4.3 Others1.4.3 Others

Hood [4]Hood [4]

There install main parts as hydraulic unit, main drive unit and There install main parts as hydraulic unit, main drive unit and electric system etc. under the hood.electric system etc. under the hood.

When check or maintan, please take down the protective shield and then open the rear hood.When check or maintan, please take down the protective shield and then open the rear hood.

Fork [8]Fork [8]

Forks can be lifted or lowered to fetch goods. Because of four-bar mechanism, forks assembly willForks can be lifted or lowered to fetch goods. Because of four-bar mechanism, forks assembly will

move horizontally a distance when forks lift or lower.move horizontally a distance when forks lift or lower.

CAUTIONCAUTION

It is forbidden to put hands, feet or any part of the body between lift assy and truckIt is forbidden to put hands, feet or any part of the body between lift assy and truck

frame when lifting or lowering.frame when lifting or lowering.

Load wheel [9]Load wheel [9]

There is one load wheel under each front outrigger to ensure longitudinal stability.There is one load wheel under each front outrigger to ensure longitudinal stability.

Check the load wheel to find if there is disrepair or abnormal wear according to necessity. If there isCheck the load wheel to find if there is disrepair or abnormal wear according to necessity. If there is

disrepair on the load wheel or its inner bearing, suspend the truck off the ground or jack the frontdisrepair on the load wheel or its inner bearing, suspend the truck off the ground or jack the front

outrigger off the ground, replace the worn load wheel or the worn bearing, and renew sufficientoutrigger off the ground, replace the worn load wheel or the worn bearing, and renew sufficient

multi-purpose grease on the bearing.multi-purpose grease on the bearing.

Battery cover [10]Battery cover [10]

There is a handle in the There is a handle in the front of the battery cover, and you can front of the battery cover, and you can open the battery cover by pushingopen the battery cover by pushing

this handle.this handle.

When check battery, take out the plug, charge or replace the battery, you can easily open theWhen check battery, take out the plug, charge or replace the battery, you can easily open the

battery cover.battery cover.

CAUTIONCAUTION

When closing the When closing the battery coverbattery cover, protect , protect your fingers from being your fingers from being clamped.clamped.

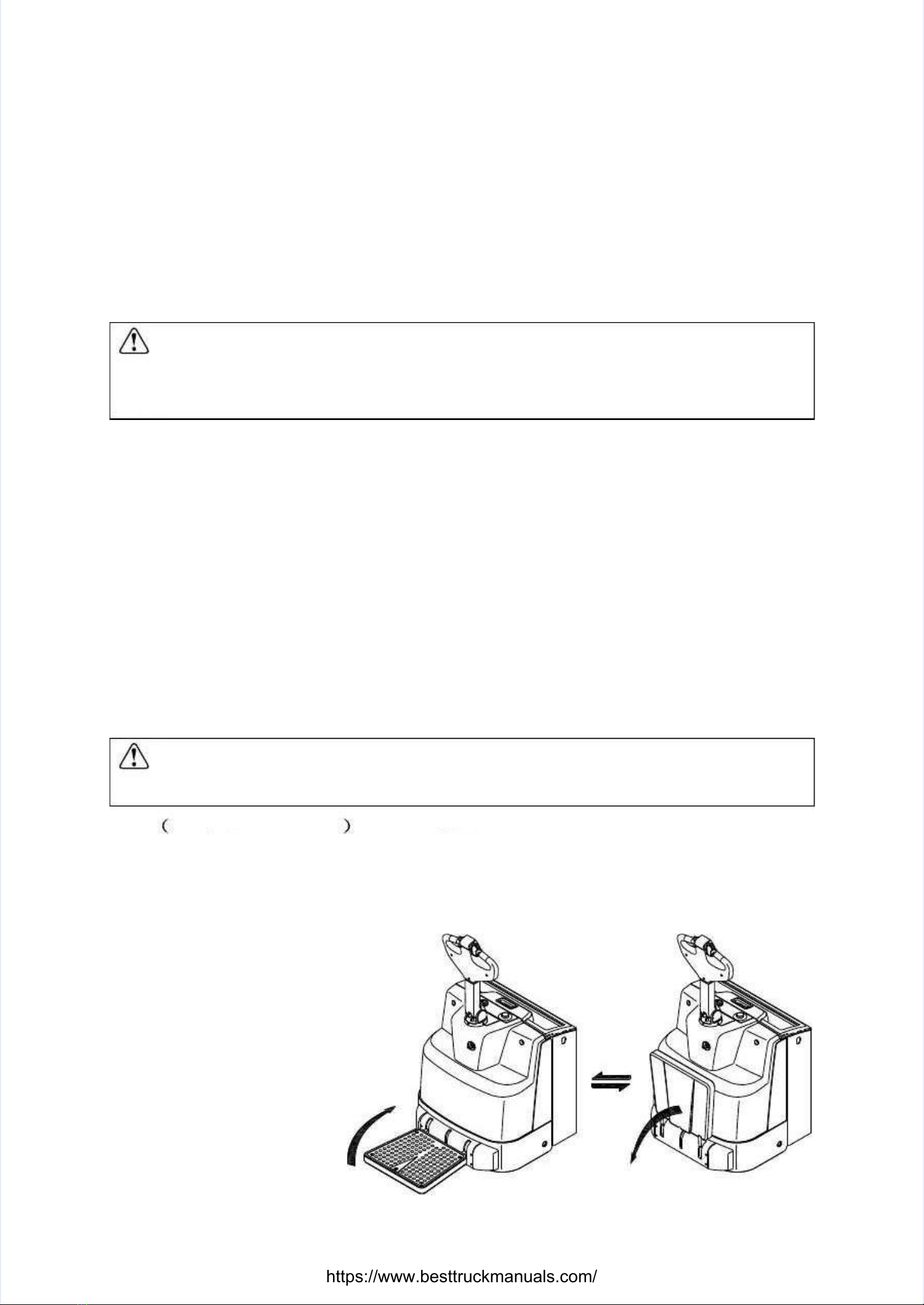

PedalPedal

((

Only for stand-on typeOnly for stand-on type

))

[13][13]

This pedal can be folded so that you can put down the pedal and stand on it when operating theThis pedal can be folded so that you can put down the pedal and stand on it when operating the

truck for a long distance. When transporting at a narrow space, folding the pedal, stand on ground totruck for a long distance. When transporting at a narrow space, folding the pedal, stand on ground to

operate the truck.operate the truck.

https://www.besttruckmanuals.com/

88

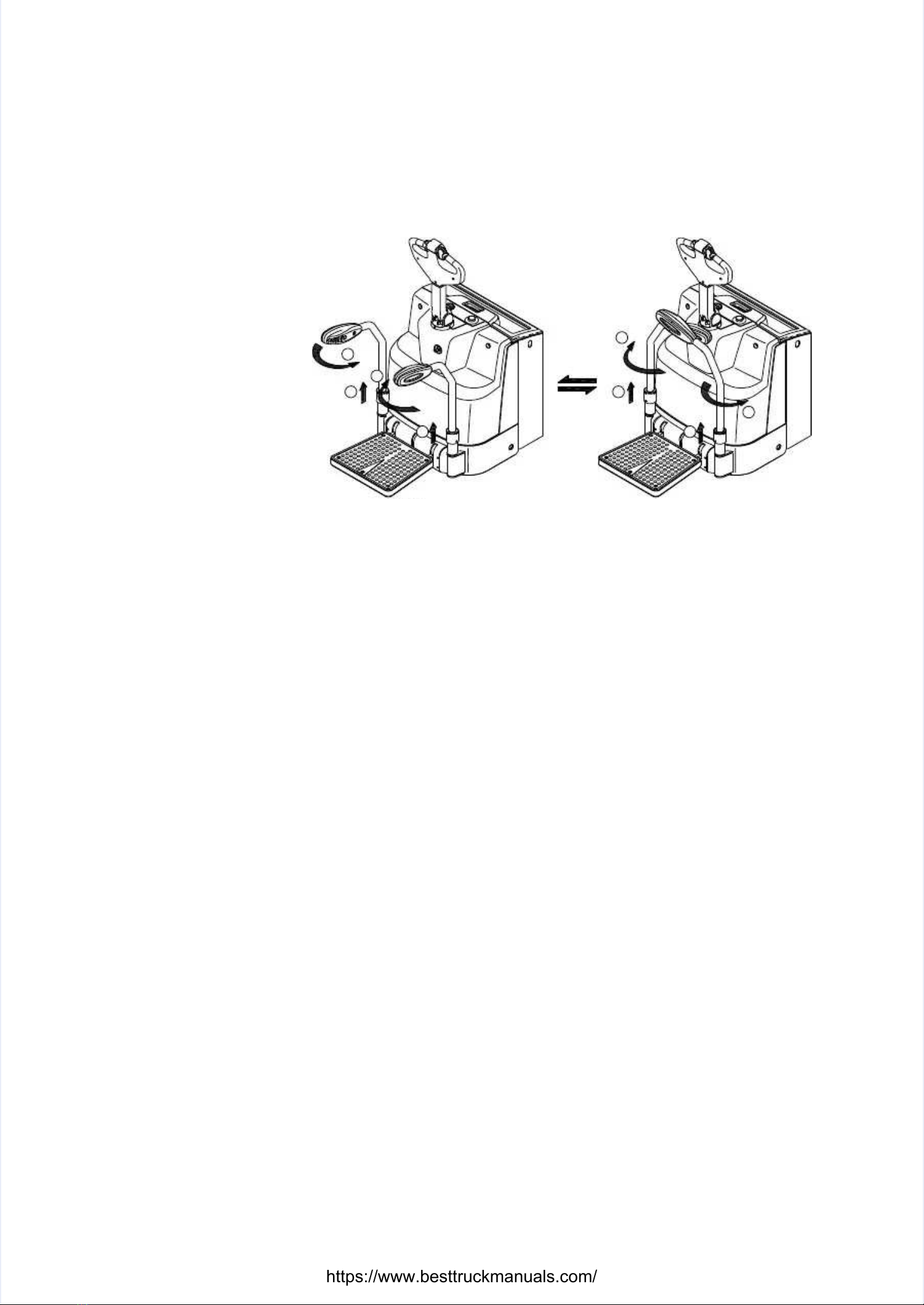

Fence [14] (optional)

Fence [14] (optional)

In order to further enhance the security of standing drive forklift, prevent the operator body out ofIn order to further enhance the security of standing drive forklift, prevent the operator body out of

balance was thrown, the user can optional fence.When open or put fence, need to first filed abalance was thrown, the user can optional fence.When open or put fence, need to first filed a

guardrail slightly upward, then rotate to guardrail slightly upward, then rotate to open or folded up open or folded up barriers.barriers.

11

22

33

44

44

22

33

11

https://www.besttruckmanuals.com/

99

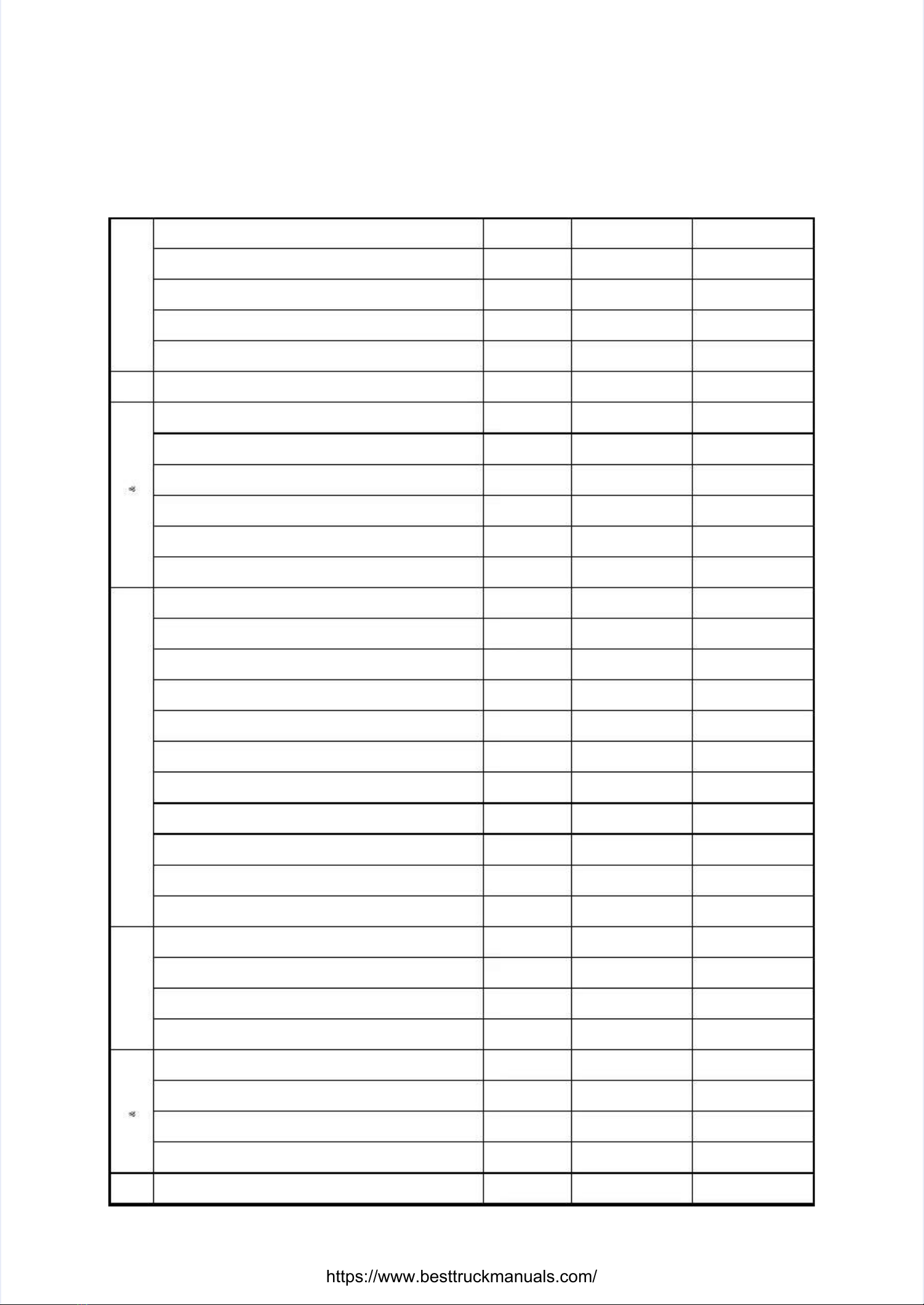

1.5 1.5 Standard Standard technical technical datadata

The following technical data are all standard data. Our company reserves the right of alterationThe following technical data are all standard data. Our company reserves the right of alteration

and extension.and extension.

CC

hh

aa

rr

aacc

tt

ee

rr

ii

ss

tt

ii

cc

ss

Model Model CBD20-AEC1 CBD20-AEC1 CBD20-AEC1SCBD20-AEC1S

Operator Operator type type Pedestrian Pedestrian Stand-onStand-on

Load Load capacity capacity Q Q (kg) (kg) 2000 2000 20002000

Load Load center center c(mm) c(mm) 600 600 600600

Wheelbase Wheelbase y(mm) y(mm) 1415 1415 14151415

WeightWeight Service Service weight weight with with battery battery kg kg 490 490 540540

WW

hh

ee

ee

ll

ss

TT

yy

rr

ee

ss

Tyre Tyre type type PU PU PUPU

Tyre Tyre size/Quantsize/Quantity,operator ity,operator side side mmmm Φ250×80/1Φ250×80/1 Φ250×80/1Φ250×80/1

Tyre Tyre size/Quantsize/Quantity,load ity,load side side mmmm Φ85×70/4

Φ85×70/4Φ85×70/4Φ85×70/4

Auxiliary wheel Auxiliary wheel size/Quantity size/Quantity mmmm Φ100×40/2Φ100×40/2 Φ100×40/2Φ100×40/2

Tread,

Tread, operator operator side side b10(mm) b10(mm) 530 530 530530

Tread, load sideTread, load sideb11(mm) b11(mm) 370 370 370370

DD

ii

mm

ee

nn

ss

ii

oo

nn

ss

Lift Lift height height h3(mm)h3(mm) 125 125

125 125

Fork Fork height, height, lowered lowered h13(mm) h13(mm) 85 85 8585

Overall Overall length(fold length(fold the the pedal) pedal) L1(mm) L1(mm) 1770 1770 18201820

Overall Overall length(unfold length(unfold the the pedal) pedal) L1(mm) L1(mm) // 22522252

Overall Overall width width b1(mm) b1(mm) 750 750 750750

Fork Fork size size s/e/L(mm)s/e/L(mm) 64×170×1150 64×170×1150

64×170×1150 64×170×1150

Outside Outside fork fork width width b5(mm)b5(mm) 540/680 540/680

540/680 540/680

Ground Ground clearance, clearance, center center of of wheelbase, wheelbase, min min m2(mm) m2(mm) 25 25 2525

Min, Min, right right angle angle stacking stacking aisle aisle width1000×1width1000×1200 200 across across forks forks Ast(mm)Ast(mm) 1980

1980 20402040

Min, Min, ringht ringht angle angle stacking stacking aisle aisle width width 800×1200 800×1200 across across forks forks Ast(mm)Ast(mm) 2030

2030 20902090

Outer Outer turning turning radius, radius, min min Wa(mm)Wa(mm) 1610

1610 16701670

PP

ee

rr

ff

oo

rr

mm

aa

nn

cc

ee

Travel Travel speed, speed, laden/unladen laden/unladen km/h 5.0/5km/h 5.0/5.0 .0 5.0/5.05.0/5.0

Lift Lift speed, speed, laden/unladen laden/unladen mm/s mm/s 30/45 30/45 30/4530/45

Lowering Lowering speed, speed, laden/unladen laden/unladen mm/s mm/s 50/50/35

35 50/50/3535

Max Max GradeabilityGradeability, , laden/unladen laden/unladen % % 6/15 6/15 6/156/15

MM

oo

tt

oo

rr

BB

aa

tt

tt

ee

rr

yy Drive Drive motor motor power power kW kW 1.1 1.1 1.11.1

Lift Lift motor motor power power kW kW 0.8 0.8 0.80.8

Battery Battery voltage, voltage, rated rated capacity capacity V/Ah V/Ah 24/165 24/165 24/16524/165

Optional Optional battey battey voltage, voltage, rated rated capacity capacity V/AhV/Ah 24/21024/210~~240 24/210240 24/210~~240240

Controller modeController mode Curtis

Curtis AC AC Curtis Curtis ACAC

https://www.besttruckmanuals.com/

1010

a/2a/2 a/2a/2

AstAst

L6L6

ee

WW

aa

bb

55bb

11

11

44

22

00

11

44

77

432432

LL

CC QQ

XX

yy

L1L1

m2m2

hh

33

hh

11

33

https://www.besttruckmanuals.com/

1111

1.6 1.6 Product Product plates plates and and warning warning labels labels locationlocation

Plates and labels, such as nameplate, load curve plate, warning labels must be legible, if

Plates and labels, such as nameplate, load curve plate, warning labels must be legible, if

identification is unclear, and must be replaced.identification is unclear, and must be replaced.

The figure below shows The figure below shows the approximate location of the the approximate location of the various identity resides. Before operatingvarious identity resides. Before operating

the truck, the truck, please understaplease understand the meaning of nd the meaning of the various identities.the various identities.

VV

kWkW

mmmm

kgkg

kgkg

kgkg

kgkg

ELECTRIC PALLET TRUCKELECTRIC PALLET TRUCK

MODEL-TYPEMODEL-TYPE

SERIALNO.SERIALNO.

LOADCENTERLOADCENTER

BATTERY VOLTAGEBATTERY VOLTAGE

RATED DRIVE POWERRATED DRIVE POWER

YEAROF YEAROF MANUFACTMANUFACTUREURE

RATED CAPACITYRATED CAPACITY

WEIGHT WEIGH T WITHO UTBATTERWITHOUT BATTERYY

MAX.ALLOWABLE MAX.ALLOWABLE BATTERYBATTERY WEIGHTWEIGHT

MIN.ALLOWABLE MIN.ALLOWABLE BATTERYBATTERY WEIGHTWEIGHT

Add: Lin'an Economic Development Zone,Zhejiang,China License No.:TS2510002-2016Add: Lin'an Economic Development Zone,Zhejiang,China License No.:TS2510002-2016

HANGCHA GROUP CO.,LTD.HANGCHA GROUP CO.,LTD.

WARNINGWARNING

https://www.besttruckmanuals.com/

1212

Item Description

Item Description

2525

Nameplate:

Nameplate: The rated capacity on theThe rated capacity on the nameplatenameplate is the max. load capacity by the is the max. load capacity by the

label listed equipment. Any change to the forklift or other equipment may change ratedlabel listed equipment. Any change to the forklift or other equipment may change rated

capacity.capacity.

2626 ManufactureManufacturer’s r’s logologo

2727 Hoist label: Strap points for crane lifting.

Hoist label: Strap points for crane lifting.

2828 Hazard label: Risk of Hazard label: Risk of trapping when cylinder extended.trapping when cylinder extended.

2929 Emergency stop label

Emergency stop label: press this button when in emergency, thus the truck power is: press this button when in emergency, thus the truck power is

off.off.

3030 Key switchKey switch::“OFF”position is off“OFF”position is off

,,“ON”position is on.“ON”position is on.

3131 Hydraulic oil label: Add hydraulic oil.

Hydraulic oil label: Add hydraulic oil.

32 32 Series Series tonnage tonnage label: label: A A series series 2.0 2.0 TT

https://www.besttruckmanuals.com/

1313

2 2 Safety Safety RulesRules

1)1) Only trained and authorized operatorOnly trained and authorized operator

shall be permitted to operate the forklift.shall be permitted to operate the forklift.

2)2) Operator must wear helmet, workingOperator must wear helmet, working

shoes and uniformshoes and uniform

3)3) It is not allowed to reconfigure the truckIt is not allowed to reconfigure the truck

without manufacturer’s permissionwithout manufacturer’s permission..

4)4) Do not work in flammable andDo not work in flammable and

combustible combustible environmeenvironment.nt.

5)5) Check the oil, fluid leakage, deformation,Check the oil, fluid leakage, deformation,

flexibility in certain time. If neglected,flexibility in certain time. If neglected,

service life of forklift will be shorter and inservice life of forklift will be shorter and in

serious condition there will be serious condition there will be accident.accident.

–– Make sure change the “safety parts”Make sure change the “safety parts”

during the schedule maintenance.during the schedule maintenance.

–– Wipe off the oil, grease or water on theWipe off the oil, grease or water on the

soleplate, foot pedal and control stick.soleplate, foot pedal and control stick.

–– No smoking or any spark, smoke near theNo smoking or any spark, smoke near the

battery when checking.battery when checking.

–– Be careful of scald when checking motorBe careful of scald when checking motor

and controller.and controller.

6)6) The controller equips with energyThe controller equips with energy

accumulator, do not touch between B+accumulator, do not touch between B+

and B- to avoid electric injury. If you needand B- to avoid electric injury. If you need

check or clean the controller, connectcheck or clean the controller, connect

load(like load(like contactor contactor coil coil or or horn) horn) betweenbetween

controller B+ and B- to discharge thecontroller B+ and B- to discharge the

controller capacity.controller capacity.

7)7) Whenever you find the forklift abnormal,Whenever you find the forklift abnormal,

stop the truck, put on the DANGEROUSstop the truck, put on the DANGEROUS

or FAULT sign to the truck, remove theor FAULT sign to the truck, remove the

key, and report to the managing person.key, and report to the managing person.

Only after eliminating the fault can youOnly after eliminating the fault can you

use the truck.use the truck.

–– If there occurs to fault, battery electrolyte,If there occurs to fault, battery electrolyte,

hydraulic oil or brake fluid leakage whenhydraulic oil or brake fluid leakage when

lifting loads, going up and down lifting loads, going up and down the slope,the slope,

please organize staff to repair.please organize staff to repair.

8)8) Internal battery may generate explosiveInternal battery may generate explosive

gas, it’s prohibited any flame close thegas, it’s prohibited any flame close the

battery. Never allow the tools close twobattery. Never allow the tools close two

poles of the battery to avoid spark orpoles of the battery to avoid spark or

short circuit.short circuit.

9)9) The work ground of forklift shall be solidThe work ground of forklift shall be solid

and smooth concrete surface or similarand smooth concrete surface or similar

ones. Pre-check the ground condition ofones. Pre-check the ground condition of

working site. Tidy the working site, cleanworking site. Tidy the working site, clean

obstacle, sweep macadam, muddy sandobstacle, sweep macadam, muddy sand

and wipe off greasy dirt.and wipe off greasy dirt.

10)10) Do not overload. Before operation, firstDo not overload. Before operation, first

know the curve chart on the load curveknow the curve chart on the load curve

plate well, which indicates the relationplate well, which indicates the relation

https://www.besttruckmanuals.com/

This manual suits for next models

1

Table of contents

Other HANGCHA Truck manuals