TABLE OF CONTENTS

Safety Notice................................................................................................................... 4

Preface................................................................................................................................. 4

Please Note Cautions ...................................................................................................... 5

Determine Tractor Compatibility.................................................................................... 5

General Information........................................................................................................ 6

Pre-Installation Instructions................................................................................................ 7

Check Tractor C.A.......................................................................................................... 7

Check for Power Take Off Capability and Location ...................................................... 7

Check 5th Wheel Capacity............................................................................................... 8

Check Parts and Assemblies........................................................................................... 8

Operating Controls.......................................................................................................... 8

Check Parts and Materials Obtained Locally.................................................................. 8

Check Tools and Supplies Required............................................................................... 9

Installation Introduction.................................................................................................... 10

Two Methods Available................................................................................................ 10

Method 1................................................................................................................... 10

Method 2................................................................................................................... 12

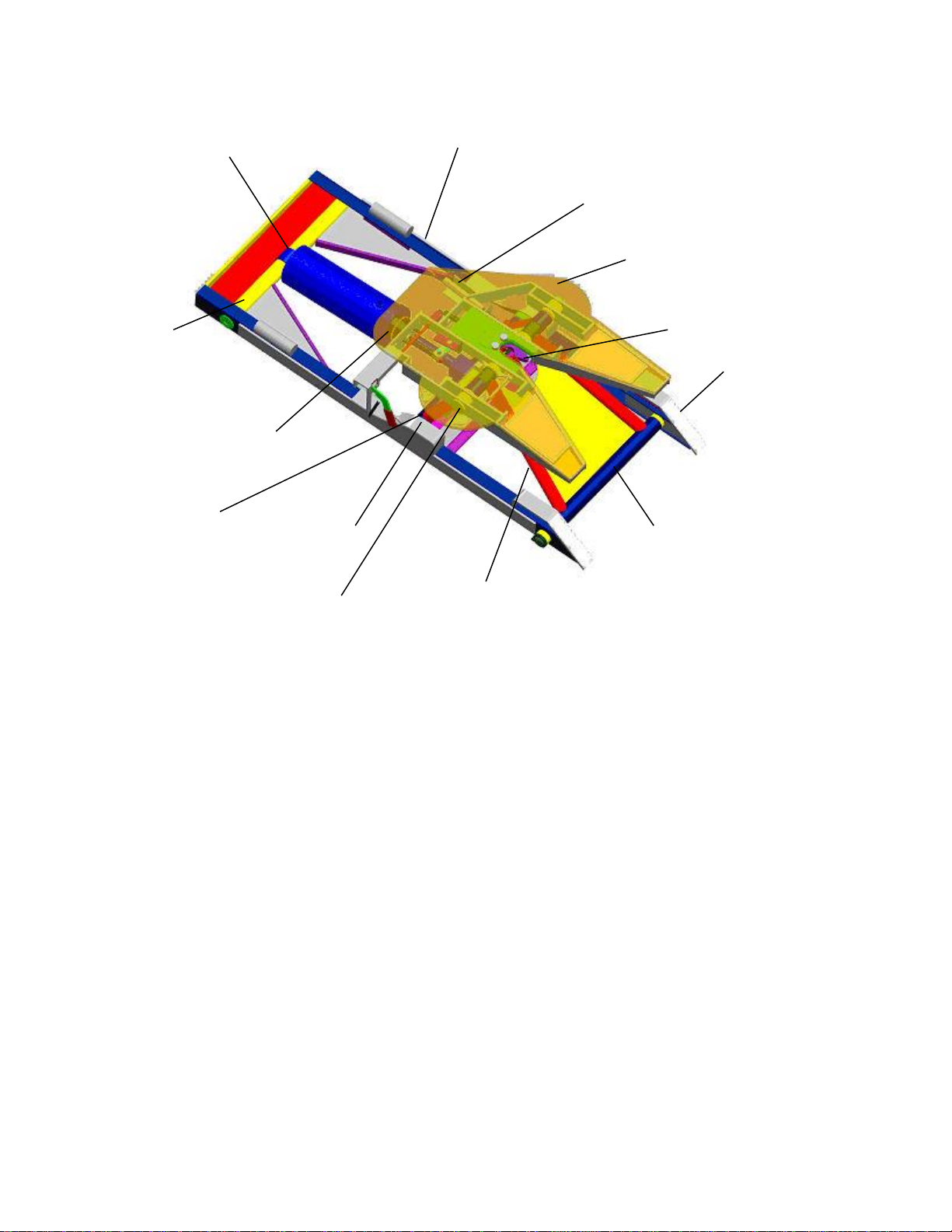

Introduction to Operating Controls................................................................................... 12

Power Take-Off ................................................................................................................ 12

Power Take Off Installation.......................................................................................... 12

Installation......................................................................................................................... 14

Air Control System....................................................................................................... 14

Installation of the 5th Wheel on Tractor............................................................................ 15

Prepare Tractor Frame .................................................................................................. 15

Prepare for Bolt-On installation.................................................................................... 15

Position 5th Wheel Assembly for FW-30 & FW-45 (see Figures 4a and 5a) .............. 15

Position 5th Wheel Assembly for FW-25HL6 (see Figure 4b) .................................... 17

All Models —Mark Interfering Cross Members ......................................................... 18

Check for Actual Contact.............................................................................................. 19

To Mark a cross Member for Alteration....................................................................... 20

Make Tractor Frame Alterations................................................................................... 20

Alter Cross members................................................................................................. 20

Installing Steel Angles.................................................................................................. 21

When To Use One Angle Per Side (Fig. 1) .............................................................. 21

When To Use Two Angles Per Side (Fig. 2)............................................................ 22

How to Install Steel Angles ...................................................................................... 22

If One Angle Per Side (Fig. 1).................................................................................. 23

If Two Angles Per Side (Fig. 2)................................................................................ 23

Drill Bolt Holes......................................................................................................... 23

Mounting 5th Wheel Assembly on Tractor .............................................................. 24

On Installations Using Two Steel Angles Per Side .................................................. 26

On Installations Using One Angle Per Side.............................................................. 26

Lower 5th Wheel Plate to Collapsed (Down) Position................................................. 26

Install Pickup Ramps .................................................................................................... 27

Prepare Tractor Frame .............................................................................................. 27