Hansen Technologies WLT Operating instructions

INTRODUCTION

Hansen Level Transducer Sensors are reliable, well

engineered electronic level monitoring devices. They

provide a computer compatible 4-20 mA (milliamp) output

signal proportional to liquid level. The sensor consists

of a compact, electronic transmitter in a watertight

housing assembled on top of a rugged mechanical

base. The wire element is an insulated stainless-steel

wire and can be mounted directly in a level column. If

it needs to be installed in a vessel, then an inner pipe

is required. Typical applications include: vertical

vessels, pilot receivers and pump accumulators. These

sensors are intended to be operating control device

should never be used as safety devices. The sensor

can be installed in refrigeration systems and similar

demanding applications with high pressure fluids.

All versions emit a 4-20mA analog signal via the M12

connector and field cable.

There are two different versions of transducer sensors.

WLT: 2-wire Level Transducer Sensor

WLT- C: 3-wire Level Transducer Sensor with

integrated Motorized Valve (MCV) controller.

This bulletin will cover the WLT-C which can be

used for new installations, and direct VLT + PXVC-L

replacement for MCV control. For the quick start

guide see WLT-C-QSG

ADDITIONAL FEATURES

Specifically designed for refrigeration systems.

Flexible wire element adjustable to length.

Active length up to 157” (4000mm).

One transducer sensor fits most legacy probe lengths

.

Compact design minimizes shipping cost.

Direct replacement for VLT probe + PXVC-L controller.

Suitable for ammonia and Hansen approved Halocarbons

.

KEY FEATURES

Specifications, Applications,

Service Instructions & Parts

W LT- C

WIRE LEVEL

TRANSDUCER SENSOR

AND CONTROLLER

Bulletin P130

December 2023

for use in 4-20 mA control

loops for refrigerant level

control and monitoring

WLT-C

WIRE LEVEL

TRANSDUCER

SENSOR AND CONTROLLER

2

P130

DECEMBER 2023

MATERIAL SPECIFICATIONS

TRANSDUCER SENSOR

Signal Output: 4-20 mA, DC, isolated

Input Power: 24 VDC or VAC ± 10%, regulated

Maximum Load Resistance: 500 ohms (1.5W)

Classification: Transmitter type/class 2U ANSI/ISA-S50.1

Enclosure: Watertight NEMA 4 (IP65)

Fitting: ¾” NPT male, connection to Level Column

Wir

e Adjustable Length: 20” (510 mm) to 157” (4000 mm)

NH3 refrigerant can go down to 12” (305mm)

Safe Working Pressure (SWP): 755 psig (52 bar)

Operating Temperature:

Ambient: -22°F to +122°F (-30°C to +50°C)

Liquid: -76°F to +140°F (-60°C to +60°C)

LEVEL COLUMN

Body: 3” Schedule 40 pipe, standard

Sight Glass: Located at 50% level, standard

Safe Working Pressure (SWP): 400 psig (27 bar)

Operating Temperature: -60°F to +240°F (-50°C to +115°C

)

ADVANTAGES

The electronics can be changed without opening the

refrigeration system. These sensors have internal dampening

to avert false alarms trigged by normal turbulence and

splashing of refrigerant. The 4-20mA signal is commonly

used with computers, programmable logic controllers, and

other accessories.

REMOTE DISPLAY

A milliamp meter or Hansen RDR may be

inserted in series with the 4-20mA control loop

to facilitate localized indication of the liquid level.

INSTALLATION

Level columns are required in applications where

refrigerant evaporation occurs within the vessel

being monitored; such as flooded evaporators, low

side vessels or accumulators. Using a level column

(typically 3” diameter) separates the sensor from the

boiling which occurs in the vessel. Therefore, true

refrigerant liquid level is being measured, not surges

of bubbling liquid. Level columns can be supplied by

Hansen or fabricated in the field. See page 13 for level

column details and dimensions. When the refrigerant

temperature is lower than ambient, the level column

must be insulated.

Follow good piping practice and refrigeration system

maintenance to avoid oil accumulation inside the level

column. Equalizer lines and valves should be positioned

as shown in the Level Column Piping Installation diagram

on page 3.It is recommended that a high level float

switchcutout be installed whenever practical. This

provides a nonadjustable safety control in case of

an incorrect high level setting or failure of a high level

control device.

On halocarbon systems, over a period of time, the

refrigerant in the level column will become oil rich.

An extremely high concentration of oil may cause

the original calibration to become offset, thus causing

a false reading of refrigerant level. To prevent this,

periodically remove oil from the level column.

INSTALLATION STEPS SUMMARY

See pages 4-5 for more detailed & visual installation steps

.

1. Separate the electronic transmitter from the

mechanical base.

2. Determine sensor wire length. For replacement of

existing probes, lay wire element next to old probe on

ground. Match thread connection to end and cut to length.

3. Cut wire element to correct length and attach

counterweight.

4. Use the supplied programming cable and the Hansen

software tool to configure the sensor basic and advanced

settings. Connect the sensor based on model wiring

diagram.

5. Connect the cable to the electronic transmitter via

M12 connector.

6. Connect the signal cable to the MCV.

7. Install and tighten the mechanical base in the column

using non-electrically isolating pipe sealant. Attach the

electronic transmitter to the mechanical base.

8. Manually calibrate the sensor if the refrigerant is not

listed in the software.

9. Ready to use. Validate output vs actual level in column

or vessel.

3P130

DECEMBER 2023

LEVEL COLUMN PIPING INSTALLATION

(SCHEMATIC ONLY, NOT FOR CONSTRUCTION)

EQUALIZER PIPE

LINE HORIZONTAL

OR DOWN TO VESSEL

GLOBE VALVE WITH

STEM HORIZONTAL

POSSIBLE UNION

GLOBE VALVE WITH

STEM HORIZONTAL

EQUALIZER PIPE

LINE HORIZONTAL

OR UP TO VESSEL

INDEPENDENT

HIGH LEVEL

FLOAT SWITCH,

SUCH AS HLL

3/4'' (20MM) OIL

DRAIN (OPTIONAL)

HOUSING

CABLE

LEVEL COLUMN*

POSSIBLE UNION

VESSEL

(RECEIVER,

ACCUMULATOR,

OR OTHER)

OIL

DRAIN

TO

PUMPS

*ALLOW SPACE FOR INSULATION WHERE

AND AS NECESSARY, USUALLY THE LEVEL

COLUMN IS INSULATED TO REDUCE BUBBLING

1" (25 MM)

SEE-LEVEL™

SIGHT GLASS FOR

RE-CALIBRATION

1-1/4''

(32 MM)

3/4'' (20 MM) OR

PROBE TRANSMITTER

1-1/4''

(32 MM)

SENSOR CONNECTIONS

WLT-C: 3-WIRE SENSOR WITH 4-20MA OUTPUT

M12 Field Cable Connection to:

*PLC/Controller

*Power Supply

*USB Configuration Cable

“The WLT-C sensor can provide a signal to a PLC

via the M12 connection. An external power supply

is wired to the M12 connection to provide voltage

to the sensor.

3

December

/(9(/&2/8013,3,1*,167$//$7,21

6&+(0$7,&21/<127)25&216758&7,21

6(1625&211(&7,216

:/7-C3ZLUHVHQVRUZLWKP$RXWSXW

0)LHOG&DEOH&RQQHFWLRQWR

ƿ3/&&RQWUROOHU

ƿ3RZHU6XSSO\

ƿ86%&RQILJXUDWLRQ&DEOH

7KH :/7-C VHQVRU FDQ SURYLGH D VLJQDO WR

D 3/& YLD WKH 0 FRQQHFWLRQ $Q

H[WHUQDO SRZHU VXSSO\ LV ZLUHG WR

WKH 0 FRQQHFWLRQ WR SURYLGH YROWDJH WR WKH VHQVRU

Signal cable connected to:

* MCV (motorized control valve)

4

P130

DECEMBER 2023

INSTALLATION STEPS

Follow the steps below to install, wire, configure, and

use the sensor in a level column. The sensor length is

determined by level column height.

1. To adjust the sensor wire, the following items will be

needed. The supplied 2.5mm hex key, a wrench, wire

cutters, and liquid sealant.

2. Separate the electronic transmitter from the

mechanical base.

3. Determine L = Insertion Length

Measure the level column length. Allow for a 2” (50mm)

clearance below the tip of the wire to the bottom of the

column/ tank.

4. Shorten the wire to the appropriate length with a

wire cutter.

,167$//$7,2167(36

)ROORZWKHVWHSVEHORZWRLQVWDOOZLUHFRQILJXUHDQGXVHWKH

VHQVRULQDOHYHOFROXPQ7KHVHQVRUOHQJWKLVGHWHUPLQHGE\

OHYHOFROXPQKHLJKW

3XWWKHZLUHDOOWKHZD\WKURXJKWKHFRXQWHU

ZHLJKWXQWLOLWSURWUXGHVWRDQGWLJKWHQ

DSSUR[UDQJH34LQOEVWKHWZRVHWVFUHZV

ZLWKWKHPPKH[WRIL[LWRQWKHZLUH'RQRW

RYHUWLJKWHQWKHVFUHZV'RQRWUHPRYHWKH

LQVXODWLRQRQWKHZLUH

3

December

7RDGMXVWWKHVHQVRUZLUHWKHIROORZLQJLWHPVZLOOEHQHHGHG7KH

VXSSOLHGPPKH[NH\DZUHQFKZLUHFXWWHUVDQGOLTXLGVHDODQW

6HSDUDWHWKHHOHFWURQLFWUDQVPLWWHUIURPWKHPHFKDQLFDOEDVH

'HWHUPLQH/ ,QVHUWLRQ/HQJWK

0HDVXUHWKHOHYHOFROXPQOHQJWK$OORZIRUDPP

FOHDUDQFHEHORZWKHWLSRIWKHZLUHWRWKHERWWRPRIWKHFROXPQ

WDQN

6KRUWHQWKHZLUHWRWKHDSSURSULDWHOHQJWKZLWKDZLUHFXWWHU

0D[

6HWVFUHZV

2QFH WKH OHQJWK LV GHWHUPLQHG WKH HOHFWURQLF

WUDQVPLWWHUFDQEHFRQILJXUHG

&RQQHFWWKH0WR86%SURJUDPPLQJFDEOHWRWKH

FRPSXWHUZLWKWKH+DQVHQVRIWZDUHWRROLQVWDOOHG

7KHSURJUDPLVDYDLODEOHDW

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

2SHQWKH+DQVHQWRRODQGSUHVV6WDUWVFDQQLQJWR

LQLWLDWH FRQQHFWLRQ WR WKH VHQVRU /('V ZLOO

GLVSOD\ DURXQG WKH 0 FRQQHFWRU *UHHQ UHG

DQG \HOORZ /('V ZLOO IODVK ZKHQ WKH

FRPPXQLFDWLRQLVDFWLYH

,167$//$7,2167(36

)ROORZWKHVWHSVEHORZWRLQVWDOOZLUHFRQILJXUHDQGXVHWKH

VHQVRULQDOHYHOFROXPQ7KHVHQVRUOHQJWKLVGHWHUPLQHGE\

OHYHOFROXPQKHLJKW

3XWWKHZLUHDOOWKHZD\WKURXJKWKHFRXQWHU

ZHLJKWXQWLOLWSURWUXGHVWRDQGWLJKWHQ

DSSUR[UDQJH34LQOEVWKHWZRVHWVFUHZV

ZLWKWKHPPKH[WRIL[LWRQWKHZLUH'RQRW

RYHUWLJKWHQWKHVFUHZV'RQRWUHPRYHWKH

LQVXODWLRQRQWKHZLUH

3

December

7RDGMXVWWKHVHQVRUZLUHWKHIROORZLQJLWHPVZLOOEHQHHGHG7KH

VXSSOLHGPPKH[NH\DZUHQFKZLUHFXWWHUVDQGOLTXLGVHDODQW

6HSDUDWHWKHHOHFWURQLFWUDQVPLWWHUIURPWKHPHFKDQLFDOEDVH

'HWHUPLQH/ ,QVHUWLRQ/HQJWK

0HDVXUHWKHOHYHOFROXPQOHQJWK$OORZIRUDPP

FOHDUDQFHEHORZWKHWLSRIWKHZLUHWRWKHERWWRPRIWKHFROXPQ

WDQN

6KRUWHQWKHZLUHWRWKHDSSURSULDWHOHQJWKZLWKDZLUHFXWWHU

0D[

6HWVFUHZV

2QFH WKH OHQJWK LV GHWHUPLQHG WKH HOHFWURQLF

WUDQVPLWWHUFDQEHFRQILJXUHG

&RQQHFWWKH0WR86%SURJUDPPLQJFDEOHWRWKH

FRPSXWHUZLWKWKH+DQVHQVRIWZDUHWRROLQVWDOOHG

7KHSURJUDPLVDYDLODEOHDW

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

2SHQWKH+DQVHQWRRODQGSUHVV6WDUWVFDQQLQJWR

LQLWLDWH FRQQHFWLRQ WR WKH VHQVRU /('V ZLOO

GLVSOD\ DURXQG WKH 0 FRQQHFWRU *UHHQ UHG

DQG \HOORZ /('V ZLOO IODVK ZKHQ WKH

FRPPXQLFDWLRQLVDFWLYH

,167$//$7,2167(36

)ROORZWKHVWHSVEHORZWRLQVWDOOZLUHFRQILJXUHDQGXVHWKH

VHQVRULQDOHYHOFROXPQ7KHVHQVRUOHQJWKLVGHWHUPLQHGE\

OHYHOFROXPQKHLJKW

3XWWKHZLUHDOOWKHZD\WKURXJKWKHFRXQWHU

ZHLJKWXQWLOLWSURWUXGHVWRDQGWLJKWHQ

DSSUR[UDQJH34LQOEVWKHWZRVHWVFUHZV

ZLWKWKHPPKH[WRIL[LWRQWKHZLUH'RQRW

RYHUWLJKWHQWKHVFUHZV'RQRWUHPRYHWKH

LQVXODWLRQRQWKHZLUH

3

December

7RDGMXVWWKHVHQVRUZLUHWKHIROORZLQJLWHPVZLOOEHQHHGHG7KH

VXSSOLHGPPKH[NH\DZUHQFKZLUHFXWWHUVDQGOLTXLGVHDODQW

6HSDUDWHWKHHOHFWURQLFWUDQVPLWWHUIURPWKHPHFKDQLFDOEDVH

'HWHUPLQH/ ,QVHUWLRQ/HQJWK

0HDVXUHWKHOHYHOFROXPQOHQJWK$OORZIRUDPP

FOHDUDQFHEHORZWKHWLSRIWKHZLUHWRWKHERWWRPRIWKHFROXPQ

WDQN

6KRUWHQWKHZLUHWRWKHDSSURSULDWHOHQJWKZLWKDZLUHFXWWHU

0D[

6HWVFUHZV

2QFH WKH OHQJWK LV GHWHUPLQHG WKH HOHFWURQLF

WUDQVPLWWHUFDQEHFRQILJXUHG

&RQQHFWWKH0WR86%SURJUDPPLQJFDEOHWRWKH

FRPSXWHUZLWKWKH+DQVHQVRIWZDUHWRROLQVWDOOHG

7KHSURJUDPLVDYDLODEOHDW

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

2SHQWKH+DQVHQWRRODQGSUHVV6WDUWVFDQQLQJWR

LQLWLDWH FRQQHFWLRQ WR WKH VHQVRU /('V ZLOO

GLVSOD\ DURXQG WKH 0 FRQQHFWRU *UHHQ UHG

DQG \HOORZ /('V ZLOO IODVK ZKHQ WKH

FRPPXQLFDWLRQLVDFWLYH

,167$//$7,2167(36

)ROORZWKHVWHSVEHORZWRLQVWDOOZLUHFRQILJXUHDQGXVHWKH

VHQVRULQDOHYHOFROXPQ7KHVHQVRUOHQJWKLVGHWHUPLQHGE\

OHYHOFROXPQKHLJKW

3XWWKHZLUHDOOWKHZD\WKURXJKWKHFRXQWHU

ZHLJKWXQWLOLWSURWUXGHVWRDQGWLJKWHQ

DSSUR[UDQJH34LQOEVWKHWZRVHWVFUHZV

ZLWKWKHPPKH[WRIL[LWRQWKHZLUH'RQRW

RYHUWLJKWHQWKHVFUHZV'RQRWUHPRYHWKH

LQVXODWLRQRQWKHZLUH

3

December

7RDGMXVWWKHVHQVRUZLUHWKHIROORZLQJLWHPVZLOOEHQHHGHG7KH

VXSSOLHGPPKH[NH\DZUHQFKZLUHFXWWHUVDQGOLTXLGVHDODQW

6HSDUDWHWKHHOHFWURQLFWUDQVPLWWHUIURPWKHPHFKDQLFDOEDVH

'HWHUPLQH/ ,QVHUWLRQ/HQJWK

0HDVXUHWKHOHYHOFROXPQOHQJWK$OORZIRUDPP

FOHDUDQFHEHORZWKHWLSRIWKHZLUHWRWKHERWWRPRIWKHFROXPQ

WDQN

6KRUWHQWKHZLUHWRWKHDSSURSULDWHOHQJWKZLWKDZLUHFXWWHU

0D[

6HWVFUHZV

2QFH WKH OHQJWK LV GHWHUPLQHG WKH HOHFWURQLF

WUDQVPLWWHUFDQEHFRQILJXUHG

&RQQHFWWKH0WR86%SURJUDPPLQJFDEOHWRWKH

FRPSXWHUZLWKWKH+DQVHQVRIWZDUHWRROLQVWDOOHG

7KHSURJUDPLVDYDLODEOHDW

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

2SHQWKH+DQVHQWRRODQGSUHVV6WDUWVFDQQLQJWR

LQLWLDWH FRQQHFWLRQ WR WKH VHQVRU /('V ZLOO

GLVSOD\ DURXQG WKH 0 FRQQHFWRU *UHHQ UHG

DQG \HOORZ /('V ZLOO IODVK ZKHQ WKH

FRPPXQLFDWLRQLVDFWLYH

5. Put the wire all the way through the counter-

weight until it protrudes (1/4” to 1/2”) and tighten (approx

range 3.5-4.0in-lbs) the two set screws with the 2.5mm

hex to fix it on the wire. Do not over-tighten the screws.

Do not remove the insulation on the wire.

Once the length is determined, the electronic

transmitter can be configured.

6. Connect the M12 to USB programming cable to the

computer with the Hansen software tool installed.

The program is available at (www.hantech.com/product-list/wire-level)

7. Open the Hansen tool and press Start scanning to

initiate connection to the sensor. 3 LEDs wil display

around the M12 connector. Green, red and yellow LEDs

will flash when the communication is active.

,167$//$7,2167(36

)ROORZWKHVWHSVEHORZWRLQVWDOOZLUHFRQILJXUHDQGXVHWKH

VHQVRULQDOHYHOFROXPQ7KHVHQVRUOHQJWKLVGHWHUPLQHGE\

OHYHOFROXPQKHLJKW

3XWWKHZLUHDOOWKHZD\WKURXJKWKHFRXQWHU

ZHLJKWXQWLOLWSURWUXGHVWRDQGWLJKWHQ

DSSUR[UDQJH34LQOEVWKHWZRVHWVFUHZV

ZLWKWKHPPKH[WRIL[LWRQWKHZLUH'RQRW

RYHUWLJKWHQWKHVFUHZV'RQRWUHPRYHWKH

LQVXODWLRQRQWKHZLUH

3

December

7RDGMXVWWKHVHQVRUZLUHWKHIROORZLQJLWHPVZLOOEHQHHGHG7KH

VXSSOLHGPPKH[NH\DZUHQFKZLUHFXWWHUVDQGOLTXLGVHDODQW

6HSDUDWHWKHHOHFWURQLFWUDQVPLWWHUIURPWKHPHFKDQLFDOEDVH

'HWHUPLQH/ ,QVHUWLRQ/HQJWK

0HDVXUHWKHOHYHOFROXPQOHQJWK$OORZIRUDPP

FOHDUDQFHEHORZWKHWLSRIWKHZLUHWRWKHERWWRPRIWKHFROXPQ

WDQN

6KRUWHQWKHZLUHWRWKHDSSURSULDWHOHQJWKZLWKDZLUHFXWWHU

0D[

6HWVFUHZV

2QFH WKH OHQJWK LV GHWHUPLQHG WKH HOHFWURQLF

WUDQVPLWWHUFDQEHFRQILJXUHG

&RQQHFWWKH0WR86%SURJUDPPLQJFDEOHWRWKH

FRPSXWHUZLWKWKH+DQVHQVRIWZDUHWRROLQVWDOOHG

7KHSURJUDPLVDYDLODEOHDW

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

2SHQWKH+DQVHQWRRODQGSUHVV6WDUWVFDQQLQJWR

LQLWLDWH FRQQHFWLRQ WR WKH VHQVRU /('V ZLOO

GLVSOD\ DURXQG WKH 0 FRQQHFWRU *UHHQ UHG

DQG \HOORZ /('V ZLOO IODVK ZKHQ WKH

FRPPXQLFDWLRQLVDFWLYH

,167$//$7,2167(36

)ROORZWKHVWHSVEHORZWRLQVWDOOZLUHFRQILJXUHDQGXVHWKH

VHQVRULQDOHYHOFROXPQ7KHVHQVRUOHQJWKLVGHWHUPLQHGE\

OHYHOFROXPQKHLJKW

3XWWKHZLUHDOOWKHZD\WKURXJKWKHFRXQWHU

ZHLJKWXQWLOLWSURWUXGHVWRDQGWLJKWHQ

DSSUR[UDQJH34LQOEVWKHWZRVHWVFUHZV

ZLWKWKHPPKH[WRIL[LWRQWKHZLUH'RQRW

RYHUWLJKWHQWKHVFUHZV'RQRWUHPRYHWKH

LQVXODWLRQRQWKHZLUH

3

December

7RDGMXVWWKHVHQVRUZLUHWKHIROORZLQJLWHPVZLOOEHQHHGHG7KH

VXSSOLHGPPKH[NH\DZUHQFKZLUHFXWWHUVDQGOLTXLGVHDODQW

6HSDUDWHWKHHOHFWURQLFWUDQVPLWWHUIURPWKHPHFKDQLFDOEDVH

'HWHUPLQH/ ,QVHUWLRQ/HQJWK

0HDVXUHWKHOHYHOFROXPQOHQJWK$OORZIRUDPP

FOHDUDQFHEHORZWKHWLSRIWKHZLUHWRWKHERWWRPRIWKHFROXPQ

WDQN

6KRUWHQWKHZLUHWRWKHDSSURSULDWHOHQJWKZLWKDZLUHFXWWHU

0D[

6HWVFUHZV

2QFH WKH OHQJWK LV GHWHUPLQHG WKH HOHFWURQLF

WUDQVPLWWHUFDQEHFRQILJXUHG

&RQQHFWWKH0WR86%SURJUDPPLQJFDEOHWRWKH

FRPSXWHUZLWKWKH+DQVHQVRIWZDUHWRROLQVWDOOHG

7KHSURJUDPLVDYDLODEOHDW

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

2SHQWKH+DQVHQWRRODQGSUHVV6WDUWVFDQQLQJWR

LQLWLDWH FRQQHFWLRQ WR WKH VHQVRU /('V ZLOO

GLVSOD\ DURXQG WKH 0 FRQQHFWRU *UHHQ UHG

DQG \HOORZ /('V ZLOO IODVK ZKHQ WKH

FRPPXQLFDWLRQLVDFWLYH

,167$//$7,2167(36

)ROORZWKHVWHSVEHORZWRLQVWDOOZLUHFRQILJXUHDQGXVHWKH

VHQVRULQDOHYHOFROXPQ7KHVHQVRUOHQJWKLVGHWHUPLQHGE\

OHYHOFROXPQKHLJKW

3XWWKHZLUHDOOWKHZD\WKURXJKWKHFRXQWHU

ZHLJKWXQWLOLWSURWUXGHVWRDQGWLJKWHQ

DSSUR[UDQJH34LQOEVWKHWZRVHWVFUHZV

ZLWKWKHPPKH[WRIL[LWRQWKHZLUH'RQRW

RYHUWLJKWHQWKHVFUHZV'RQRWUHPRYHWKH

LQVXODWLRQRQWKHZLUH

3

December

7RDGMXVWWKHVHQVRUZLUHWKHIROORZLQJLWHPVZLOOEHQHHGHG7KH

VXSSOLHGPPKH[NH\DZUHQFKZLUHFXWWHUVDQGOLTXLGVHDODQW

6HSDUDWHWKHHOHFWURQLFWUDQVPLWWHUIURPWKHPHFKDQLFDOEDVH

'HWHUPLQH/ ,QVHUWLRQ/HQJWK

0HDVXUHWKHOHYHOFROXPQOHQJWK$OORZIRUDPP

FOHDUDQFHEHORZWKHWLSRIWKHZLUHWRWKHERWWRPRIWKHFROXPQ

WDQN

6KRUWHQWKHZLUHWRWKHDSSURSULDWHOHQJWKZLWKDZLUHFXWWHU

0D[

6HWVFUHZV

2QFH WKH OHQJWK LV GHWHUPLQHG WKH HOHFWURQLF

WUDQVPLWWHUFDQEHFRQILJXUHG

&RQQHFWWKH0WR86%SURJUDPPLQJFDEOHWRWKH

FRPSXWHUZLWKWKH+DQVHQVRIWZDUHWRROLQVWDOOHG

7KHSURJUDPLVDYDLODEOHDW

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

2SHQWKH+DQVHQWRRODQGSUHVV6WDUWVFDQQLQJWR

LQLWLDWH FRQQHFWLRQ WR WKH VHQVRU /('V ZLOO

GLVSOD\ DURXQG WKH 0 FRQQHFWRU *UHHQ UHG

DQG \HOORZ /('V ZLOO IODVK ZKHQ WKH

FRPPXQLFDWLRQLVDFWLYH

5P130

DECEMBER 2023

INSTALLATION STEPS - CONTINUED

8. Start the program to configure the Basic settings tab.

For the WLT-C the Control mode should automatically

be detected and the following parameters will need to

be populated. See page 9 for additional information

and settings.

• Refrigerant

• Sensor Length (“L” Dimension determined from Step #3)

• Level Column (Standpipe) Diameter Size

• Working Temperature Range

• Offset Max Level = 2.75” typical (70mm)

• P-Band = 10% typical

• I-Factor = 0 sec typical

Once complete press Save to sensor.

Note: Positioning the cursor over the selections will

provide more detailed descriptions.

3

December

6WDUWWKHSURJUDPWRFRQILJXUHWKH%DVLFVHWWLQJVWDE)RUWKH:/7-C

WKHControlPRGHVKRXOGDXWRPDWLFDOO\EHGHWHFWHGDQGWKHIROORZLQJ

SDUDPHWHUVZLOOQHHGWREHSRSXODWHG6HHSDJHIRUDGGLWLRQDO

LQIRUPDWLRQDQGVHWWLQJV

v 5HIULJHUDQW

v 6HQVRU/HQJWK/'LPHQVLRQGHWHUPLQHGIURP6WHS

v /HYHO&ROXPQ6WDQGSLSH'LDPHWHU6L]H

v :RUNLQJ7HPSHUDWXUH5DQJH

v 2IIVHW0D[/HYHO W\SLFDOPP

2QFHFRPSOHWHSUHVV6DYHWRVHQVRU

1RWH3RVLWLRQLQJWKHFXUVRURYHUWKHVHOHFWLRQVZLOOSURYLGHPRUH

GHWDLOHGGHVFULSWLRQV

'LVFRQQHFWWKHSURJUDPPLQJFDEOH&RQQHFWWKHIWP

VHQVRU ILHOG FDEOH WR WKH 0 FRQQHFWRU RQ WKH HOHFWURQLF

WUDQVPLWWHU &RQQHFW WKH ZLUHV SHU WKH GLDJUDPVEDVHG RQ

WKH DSSURSULDWH VLWH FRQILJXUDWLRQ 7KHVHQVRURXWSXWLVD

P$DQGLVOLQHDUWRWKHOHYHO

,QVWDOO DQG WLJKWHQ WKH PHFKDQLFDO EDVH LQ WKH OHYHOFROXPQ

8VH QRQHOHFWULFDOO\ LVRODWLQJ SLSH VHDODQWIRUWKH´137

FRQQHFWLRQ'RQRWXVH7HIORQWDSH

,QVWDOODQGWLJKWHQWKHHOHFWURQLFWUDQVPLWWHUWRWKH

PHFKDQLFDOEDVH

,IWKHUHIULJHUDQWLVQRWOLVWHGLQWKHVRIWZDUHWKHQPDQXDOO\

FDOLEUDWH6HHSDJH

5HDG\IRUXVH

,167$//$7,2167(36&217,18('

6

P130

DECEMBER 2023

9. Set up the advanced settings of the probe and save

to sensor.

10. Disconnect the programming cable. Connect the

16ft (5m) sensor field cable to the M12 connector

on the electronic transmitter. Connect the electronic

transmitter to the MCV valve and the MCV valve to the

power supply. Connect the wires per the diagrams

based on the appropriate site configuration. The

sensor output is a 4-20mA and is linear to the level.

11. Install and tighten the mechanical base in the level

column. Use non-electrically isolating pipe sealant

for the 3/4” NPT connection. Do not use Teflon tape.

12. Install and tighten the electronic transmitter to the

mechanical base.

13. If the refrigerant is not listed in the software, then

manually calibrate (See page 12).

14. Ready for use.

Recomended settings:

Ramp startup = 5

Valve speed open = 5

Valve speed Closed = 5

Min valve opening = 0

Max valve opening = 100

7<3,&$/:,5,1*1(:,167$//$7,216

:/7-CWR3/&ZLWK,QWHJUDWHG3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

3

December

:/7-CWR&RQWUROOHU3/&ZLWK([WHUQDO3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

7<3,&$/:,5,1*1(:,167$//$7,216

:/7-CWR3/&ZLWK,QWHJUDWHG3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

3

December

:/7-CWR&RQWUROOHU3/&ZLWK([WHUQDO3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

7P130

DECEMBER 2023

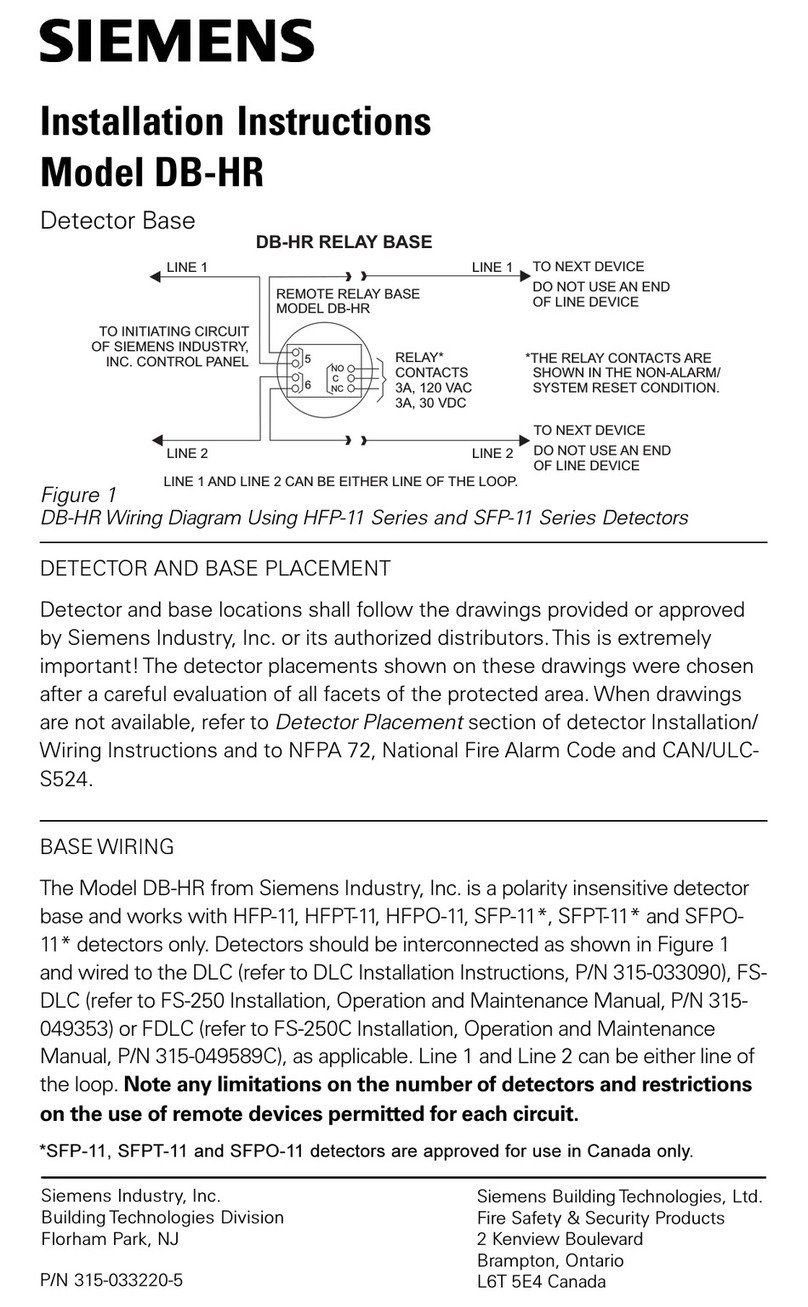

TYPICAL WIRING: NEW INSTALLATIONS AND DIRECT REPLACEMENT OF VLT +PXVC-L

WLT-C TO PLC WITH INTEGRATED POWER SOURCE AND MCV: 3-WIRE 4-20MA OUTPUT

WLT-C TO CONTROLLER/PLC WITH EXTERNAL POWER SOURCE AND MCV: 3-WIRE 4-20MA OUTPUT

7<3,&$/:,5,1*1(:,167$//$7,216

:/7-CWR3/&ZLWK,QWHJUDWHG3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

3

December

:/7-CWR&RQWUROOHU3/&ZLWK([WHUQDO3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

7<3,&$/:,5,1*1(:,167$//$7,216

:/7-CWR3/&ZLWK,QWHJUDWHG3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

3

December

:/7-CWR&RQWUROOHU3/&ZLWK([WHUQDO3RZHU6RXUFH and MCV3ZLUHP$RXWSXW

8

P130

DECEMBER 2023

SETUP USING A SPLITTER BOX

When using a splitter box it is possible to run

the refrigeration system and connect a PC to the sensor

at the same time. The splitter box is not suited

for normal operation, but only for installation and

modification. The splitter box is connected to the

M12 plug on the WLT-C sensor and then both the pc

and the normal M12 plug can be connected. See wiring

diagram below.

9P130

DECEMBER 2023

HANSEN SOFTWARE TOOL DETAILS

Software Available on Hansen Website:

www.hantech.com/product-list/wire-level

CONNECTING TO THE SENSOR

The sensor is connected to a laptop using the

programming cable which contains a USB connection

at one end and the M12 connection at the opposite end.

The USB/M12 programming cable is 5ft (1.5m) long. If

a longer cable is desired, a 33ft (10m) extender cable

(WLT-M12 EXTENSION) is available that connects directly

in series with the M12 connector. The laptop will contain

the Hansen Configuration tool. The Start scanning

button looks for a connected sensor and determines

the model. Once detected, the WLT tool application

will flash 3 LEDs around the M12 connector. Green, red

and yellow LEDs will flash when the communication

is active.

SETTING UP THE SENSOR

The Hansen software tool has three configuration

tabs: Basic settings, Advanced settings, and

Diagnostics/Calibration. The Basic settings screen

consists of the necessary selections for all sensors. The

Advanced settings screen allows for the adjustment

of alarms. The Diagnostic screen displays the

sensor readings and allows for manual calibration.

Some fields will be shown in gray when they are not

relevant/active with the chosen setting. Detailed

explanations of the individual fields will show up when

the mouse is moved over the field. A setting can be

changed by typing in a new value or by selecting in the

drop down. After changing the value, it is stored to

the sensor by clicking ”Save to sensor”. It remains in

the sensor even when the power supply is disconnected.

1D

+"/

1D

+"/

3

December

+$16(162)7:$5(722/'(7$,/6

6RIWZDUH$YDLODEOHRQ+DQVHQ:HEVLWH

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

&211(&7,1*727+(6(1625

7KH VHQVRU LV FRQQHFWHG WR D ODSWRS XVLQJ WKH

SURJUDPPLQJFDEOH ZKLFK FRQWDLQV D 86% FRQQHFWLRQ DW

RQH HQG DQG WKH 0 FRQQHFWLRQ DW WKH RSSRVLWH

HQG 7KH 86%0SURJUDPPLQJ FDEOH LV IW P

ORQJ ,I D ORQJHU FDEOH LV GHVLUHG D IW P

H[WHQGHU FDEOH :/70(;7(16,21 LV DYDLODEOH

WKDW FRQQHFWV GLUHFWO\ LQ VHULHV ZLWK WKH 0

FRQQHFWRU 7KH ODSWRS ZLOO FRQWDLQ WKH +DQVHQ

&RQILJXUDWLRQ WRRO 7KH 6WDUW VFDQQLQJ EXWWRQ

ORRNV IRU D FRQQHFWHG VHQVRU DQG GHWHUPLQHV WKH

PRGHO 2QFH GHWHFWHG WKH :/7 WRRO DSSOLFDWLRQ

ZLOO RSHQ /('V ZLOO GLVSOD\ DURXQG WKH 0

FRQQHFWRU*UHHQUHGDQG \HOORZ /('V ZLOO IODVK ZKHQ

WKH FRPPXQLFDWLRQ LVDFWLYH

6(77,1*837+(6(1625

7KH +DQVHQ :/7 WRRO KDV WKUHH FRQILJXUDWLRQ WDEV %DVLF

VHWWLQJV $GYDQFHG VHWWLQJV DQG 'LDJQRVWLFV&DOLEUDWLRQ

7KH %DVLF VHWWLQJV VFUHHQ FRQVLVWV RI WKH QHFHVVDU\

VHOHFWLRQV IRU DOO VHQVRUV 7KH $GYDQFHG VHWWLQJV VFUHHQ

DOORZV IRU WKH DGMXVWPHQW RI DODUPV 7KH 'LDJQRVWLF VFUHHQ

GLVSOD\V WKH VHQVRU UHDGLQJV DQG DOORZV IRU PDQXDO

FDOLEUDWLRQ

6RPH ILHOGV ZLOO EH VKRZQ LQ JUD\ ZKHQ WKH\ DUH QRW

UHOHYDQWDFWLYH ZLWK WKH FKRVHQ VHWWLQJ 'HWDLOHG

H[SODQDWLRQV RI WKH LQGLYLGXDO ILHOGV ZLOO VKRZ XS ZKHQ WKH

PRXVH LV PRYHG RYHU WKH ILHOG

$ VHWWLQJ FDQ EH FKDQJHG E\ W\SLQJ LQ D QHZ YDOXH RU E\

VHOHFWLQJ LQ WKH GURS GRZQ $IWHU FKDQJLQJ WKH YDOXH LW LV

VWRUHGWR WKH VHQVRU E\ FOLFNLQJ 6DYH WR VHQVRU ,W UHPDLQV

LQWKHVHQVRUHYHQZKHQWKHSRZHUVXSSO\LVGLVFRQQHFWHG

6(77,1*837+(6(1625/(9(/&21752/

7KHVHQVRUFDQRSHUDWHLQWZRGLIIHUHQWPRGHV7KHEDVLF

DQGDGYDQFHGVHWWLQJVDXWRPDWLFDOO\DGMXVWEDVHGRQWKH

LGHQWLILHGPRGH

v/HYHO$OHYHOLQSXWWRD3/&FRPSXWHURURWKHUGHYLFH

WKDWXVHVWKHDQDORJVLJQDO:/7

v&RQWURO$GLUHFWFRQWUROOHURIDPRWRUL]HGYDOYHEDVHGRQ

WKHOHYHO:/7&

$'-867,1*6(77,1*6

6HWWLQJVFDQEHPRGLILHGWKURXJKWKHGURSGRZQDQGLQSXW

ER[HVRUE\ORDGLQJDQHZVHWWLQJVILOH7RFUHDWHDQHZ

VHQVRUILOHGRQRWFRQQHFWWRWKHVHQVRURSHQWKH+DQVHQ

7RRODQGWKHVWHSVDUHDVIROORZV

6LPXODWLQJWRROVĺ:/7WRROĺXSGDWHGHVLUHGILHOGV

7RVDYHWKHILOH

$GYDQFHG6HWWLQJVĺ6DYH6HWWLQJVILOHĺ6DYHWRIROGHU7R

ORDGWKHILOH

&RQQHFWSURJUDPPLQJFDEOHWRVHQVRUĺRSHQ+DQVHQ7RRO

ĺ 6WDUWVFDQIRUVHQVRUĺ$GYDQFHG6HWWLQJVĺ/RDG

6HWWLQJVILOHĺ6DYHWRVHQVRUĺ%DVLF6HWWLQJVĺ6DYHWR

VHQVRU

1D

+"/

1D

+"/

3

December

+$16(162)7:$5(722/'(7$,/6

6RIWZDUH$YDLODEOHRQ+DQVHQ:HEVLWH

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

&211(&7,1*727+(6(1625

7KH VHQVRU LV FRQQHFWHG WR D ODSWRS XVLQJ WKH

SURJUDPPLQJFDEOH ZKLFK FRQWDLQV D 86% FRQQHFWLRQ DW

RQH HQG DQG WKH 0 FRQQHFWLRQ DW WKH RSSRVLWH

HQG 7KH 86%0SURJUDPPLQJ FDEOH LV IW P

ORQJ ,I D ORQJHU FDEOH LV GHVLUHG D IW P

H[WHQGHU FDEOH :/70(;7(16,21 LV DYDLODEOH

WKDW FRQQHFWV GLUHFWO\ LQ VHULHV ZLWK WKH 0

FRQQHFWRU 7KH ODSWRS ZLOO FRQWDLQ WKH +DQVHQ

&RQILJXUDWLRQ WRRO 7KH 6WDUW VFDQQLQJ EXWWRQ

ORRNV IRU D FRQQHFWHG VHQVRU DQG GHWHUPLQHV WKH

PRGHO 2QFH GHWHFWHG WKH :/7 WRRO DSSOLFDWLRQ

ZLOO RSHQ /('V ZLOO GLVSOD\ DURXQG WKH 0

FRQQHFWRU*UHHQUHGDQG \HOORZ /('V ZLOO IODVK ZKHQ

WKH FRPPXQLFDWLRQ LVDFWLYH

6(77,1*837+(6(1625

7KH +DQVHQ :/7 WRRO KDV WKUHH FRQILJXUDWLRQ WDEV %DVLF

VHWWLQJV $GYDQFHG VHWWLQJV DQG 'LDJQRVWLFV&DOLEUDWLRQ

7KH %DVLF VHWWLQJV VFUHHQ FRQVLVWV RI WKH QHFHVVDU\

VHOHFWLRQV IRU DOO VHQVRUV 7KH $GYDQFHG VHWWLQJV VFUHHQ

DOORZV IRU WKH DGMXVWPHQW RI DODUPV 7KH 'LDJQRVWLF VFUHHQ

GLVSOD\V WKH VHQVRU UHDGLQJV DQG DOORZV IRU PDQXDO

FDOLEUDWLRQ

6RPH ILHOGV ZLOO EH VKRZQ LQ JUD\ ZKHQ WKH\ DUH QRW

UHOHYDQWDFWLYH ZLWK WKH FKRVHQ VHWWLQJ 'HWDLOHG

H[SODQDWLRQV RI WKH LQGLYLGXDO ILHOGV ZLOO VKRZ XS ZKHQ WKH

PRXVH LV PRYHG RYHU WKH ILHOG

$ VHWWLQJ FDQ EH FKDQJHG E\ W\SLQJ LQ D QHZ YDOXH RU E\

VHOHFWLQJ LQ WKH GURS GRZQ $IWHU FKDQJLQJ WKH YDOXH LW LV

VWRUHGWR WKHVHQVRU E\ FOLFNLQJ 6DYH WR VHQVRU ,W UHPDLQV

LQWKHVHQVRUHYHQZKHQWKHSRZHUVXSSO\LVGLVFRQQHFWHG

6(77,1*837+(6(1625/(9(/&21752/

7KHVHQVRUFDQRSHUDWHLQWZRGLIIHUHQWPRGHV7KHEDVLF

DQGDGYDQFHGVHWWLQJVDXWRPDWLFDOO\DGMXVWEDVHGRQWKH

LGHQWLILHGPRGH

v/HYHO$OHYHOLQSXWWRD3/&FRPSXWHURURWKHUGHYLFH

WKDWXVHVWKHDQDORJVLJQDO:/7

v&RQWURO$GLUHFWFRQWUROOHURIDPRWRUL]HGYDOYHEDVHGRQ

WKHOHYHO:/7&

$'-867,1*6(77,1*6

6HWWLQJVFDQEHPRGLILHGWKURXJKWKHGURSGRZQDQGLQSXW

ER[HVRUE\ORDGLQJDQHZVHWWLQJVILOH7RFUHDWHDQHZ

VHQVRUILOHGRQRWFRQQHFWWRWKHVHQVRURSHQWKH+DQVHQ

7RRODQGWKHVWHSVDUHDVIROORZV

6LPXODWLQJWRROVĺ:/7WRROĺXSGDWHGHVLUHGILHOGV

7RVDYHWKHILOH

$GYDQFHG6HWWLQJVĺ6DYH6HWWLQJVILOHĺ6DYHWRIROGHU7R

ORDGWKHILOH

&RQQHFWSURJUDPPLQJFDEOHWRVHQVRUĺRSHQ+DQVHQ7RRO

ĺ 6WDUWVFDQIRUVHQVRUĺ$GYDQFHG6HWWLQJVĺ/RDG

6HWWLQJVILOHĺ6DYHWRVHQVRUĺ%DVLF6HWWLQJVĺ6DYHWR

VHQVRU

SETTING UP THE SENSOR: LEVEL / CONTROL

The sensor can operate in two different modes. The

basic and advanced settings automatically adjust based

on the identified mode.

• Level: A level input to a PLC, computer or other device

that uses the analog signal (WLT)

• Control: A direct controller of a motorized valve based

on the level. (WLT-C)

ADJUSTING SETTINGS

Settings can be modified through the drop-down and

input boxes or by loading a new settings file. To create

a new sensor file, do not connect to the sensor, open

the Hansen Tool, and the steps are as follows:

Simulating tools WLT tool update desired fields

To save the file:

Advanced Settings Save Settings file Save to folder

To load the file:

Connect programming cable to sensor open Hansen

Tool Start scan for sensor Advanced Settings

Load Setting file Save to sensor Basic Settings

Save to sensor

1D

+"/

1D

+"/

3

December

+$16(162)7:$5(722/'(7$,/6

6RIWZDUH$YDLODEOHRQ+DQVHQ:HEVLWH

ZZZKDQWHFKFRPSURGXFWOLVWZLUHOHYHO

&211(&7,1*727+(6(1625

7KH VHQVRU LV FRQQHFWHG WR D ODSWRS XVLQJ WKH

SURJUDPPLQJFDEOH ZKLFK FRQWDLQV D 86% FRQQHFWLRQ DW

RQH HQG DQG WKH 0 FRQQHFWLRQ DW WKH RSSRVLWH

HQG 7KH 86%0SURJUDPPLQJ FDEOH LV IW P

ORQJ ,I D ORQJHU FDEOH LV GHVLUHG D IW P

H[WHQGHU FDEOH :/70(;7(16,21 LV DYDLODEOH

WKDW FRQQHFWV GLUHFWO\ LQ VHULHV ZLWK WKH 0

FRQQHFWRU 7KH ODSWRS ZLOO FRQWDLQ WKH +DQVHQ

&RQILJXUDWLRQ WRRO 7KH 6WDUW VFDQQLQJ EXWWRQ

ORRNV IRU D FRQQHFWHG VHQVRU DQG GHWHUPLQHV WKH

PRGHO 2QFH GHWHFWHG WKH :/7 WRRO DSSOLFDWLRQ

ZLOO RSHQ /('V ZLOO GLVSOD\ DURXQG WKH 0

FRQQHFWRU*UHHQUHGDQG \HOORZ /('V ZLOO IODVK ZKHQ

WKH FRPPXQLFDWLRQ LVDFWLYH

6(77,1*837+(6(1625

7KH +DQVHQ :/7 WRRO KDV WKUHH FRQILJXUDWLRQ WDEV %DVLF

VHWWLQJV $GYDQFHG VHWWLQJV DQG 'LDJQRVWLFV&DOLEUDWLRQ

7KH %DVLF VHWWLQJV VFUHHQ FRQVLVWV RI WKH QHFHVVDU\

VHOHFWLRQV IRU DOO VHQVRUV 7KH $GYDQFHG VHWWLQJV VFUHHQ

DOORZV IRU WKH DGMXVWPHQW RI DODUPV 7KH 'LDJQRVWLF VFUHHQ

GLVSOD\V WKH VHQVRU UHDGLQJV DQG DOORZV IRU PDQXDO

FDOLEUDWLRQ

6RPH ILHOGV ZLOO EH VKRZQ LQ JUD\ ZKHQ WKH\ DUH QRW

UHOHYDQWDFWLYH ZLWK WKH FKRVHQ VHWWLQJ 'HWDLOHG

H[SODQDWLRQV RI WKH LQGLYLGXDO ILHOGV ZLOO VKRZ XS ZKHQ WKH

PRXVH LV PRYHG RYHU WKH ILHOG

$ VHWWLQJ FDQ EH FKDQJHG E\ W\SLQJ LQ D QHZ YDOXH RU E\

VHOHFWLQJ LQ WKH GURS GRZQ $IWHU FKDQJLQJ WKH YDOXH LW LV

VWRUHGWR WKHVHQVRU E\ FOLFNLQJ 6DYH WR VHQVRU ,W UHPDLQV

LQWKHVHQVRUHYHQZKHQWKHSRZHUVXSSO\LVGLVFRQQHFWHG

6(77,1*837+(6(1625/(9(/&21752/

7KHVHQVRUFDQRSHUDWHLQWZRGLIIHUHQWPRGHV7KHEDVLF

DQGDGYDQFHGVHWWLQJVDXWRPDWLFDOO\DGMXVWEDVHGRQWKH

LGHQWLILHGPRGH

v/HYHO$OHYHOLQSXWWRD3/&FRPSXWHURURWKHUGHYLFH

WKDWXVHVWKHDQDORJVLJQDO:/7

v&RQWURO$GLUHFWFRQWUROOHURIDPRWRUL]HGYDOYHEDVHGRQ

WKHOHYHO:/7&

$'-867,1*6(77,1*6

6HWWLQJVFDQEHPRGLILHGWKURXJKWKHGURSGRZQDQGLQSXW

ER[HVRUE\ORDGLQJDQHZVHWWLQJVILOH7RFUHDWHDQHZ

VHQVRUILOHGRQRWFRQQHFWWRWKHVHQVRURSHQWKH+DQVHQ

7RRODQGWKHVWHSVDUHDVIROORZV

6LPXODWLQJWRROVĺ:/7WRROĺXSGDWHGHVLUHGILHOGV

7RVDYHWKHILOH

$GYDQFHG6HWWLQJVĺ6DYH6HWWLQJVILOHĺ6DYHWRIROGHU7R

ORDGWKHILOH

&RQQHFWSURJUDPPLQJFDEOHWRVHQVRUĺRSHQ+DQVHQ7RRO

ĺ 6WDUWVFDQIRUVHQVRUĺ$GYDQFHG6HWWLQJVĺ/RDG

6HWWLQJVILOHĺ6DYHWRVHQVRUĺ%DVLF6HWWLQJVĺ6DYHWR

VHQVRU

10

P130

DECEMBER 2023

BASIC SETTINGS: CONTROL (WLT-C)

The Basic Settings screen contains the necessary

selections for all sensors. When connected to the

sensor, some settings are grayed out and cannot

be changed. If changes are desired, see Adjusting

Settings on page 9.

Setpoint level in% (control mode only) Desired level:

Shows the percentage level that one wants to maintain

in the vessel or the level indicator.

P-band in% (control mode only) Proportional band:

Control area that describes how much the valve should

open, dependent upon the deviation from the desired

level. If proportional band is set to 10%, for example,

a liquid level that is under 5% will make the valve open

50%; the valve will open to 100% if the level is under

10%. Small proportional band results in a system which

reacts quickly, while a large proportional band results

in a system that reacts more slowly.

I-Factor in sec (control mode only) I value in controller:

A small number will make the controller faster, and a

large number will make the system slower. If you type 0

the controller will work as a P controller.

Filter time constant in sec.: Filter function: Filter

time averages the output over a period (in seconds) and

reduces fluctuations that can lead to unstable control.

Recommended to leave at default value of ”20” seconds.

Alarm setting in %: The vessel level % set point off

which the alarm LED will trigger.

Offset max/min level: Allows for the reduction of the

measured maximum and/or minimum level. Based on

the sensor design the typical max value is 2.75” (70mm).

Example (Max): 10ft (3058mm) high level column and full

indication desired at 9.5ft (2987mm), then 71mm would

go on the box.

Select mechanical type: All current Hansen probes

are version ”Wire Sensor V3”.

Refrigerant: Indicates the refrigerant type. If medium is

not in the list, select ”Not Specified” and a manual

calibration will have to be performed.

Sensor Length: The measurement length of the wire

assembly. The value that was determined in step 3 on

page 4.

Standpipe (Level Column) size in inch: The diameter

of the level column.

Working Temperature in degrees: The refrigerant

operating temperature range. Hover over the drop-down

to view Fahrenheit conversion.

11 P130

DECEMBER 2023

ADVANCED SETTINGS (WLT-C)

If changes are desired, see Adjusting Settings on page 6.

High or Low Alarm: High alarm triggers when the

level gets above the Alarm setting % and Low

alarm triggers when level gets below the setting.

The Alarm setting % is found in the Basic Settings.

Alarm Hysteresis: The percentage difference from

the Alarm setting % for when the alarm will turn off and

reset. The default of 10% is adequate for

most installations. Example: High Alarm setting %

= 80%, Alarm Hysteresis % = 10; The high level alarm

will trigger when the level reaches 80% and will

stay in alarm until the level goes down below 70%.

Alarm relay function: Output status when an alarm

occurs. Normally open will close upon an alarm and

normally close will open when the alarm is triggered.

Output direction: Determines the milliamp value

in accordance to the vessel level. Select LP or HP

mode. LP: Empty vessel = 0% (4mA), Full vessel 100%

(20mA) HP: Empty vessel = 0% (20mA), Full vessel

100% (4mA).

Set mA or digital 2 output: Allows for the selection

of an analog output or just a digital alarm output

based on the trigger. Most cases will be analog mode.

Digital 2 alarm in %: Additional alarm trigger set point

Digital Hysteresis in %: The percentage difference

from the Digital 2 alarm % for when the alarm will

turn off and reset.

Alarm LED indication: The LED on the electric

transducer that illuminates when an alarm condition

is met.

Ramp startup in sec (control mode only)

The Ramp startup function makes it possible to start

slowly or fast. Default is 5% and it means the valve

opens 5% the first second, 10% after two seconds and

so on until it gets close to the setpoint.

Valve speed open% in sec (control mode only) Normal

valve opening speed for the system. Large numbers

make the system fast and small numbers make it slower.

5 is relatively fast.

Valve speed close% in sec (control mode only) Normal

valve closing speed for the system. Large numbers make

the system fast and small numbers make it slower. 5 is

relatively fast.

Minimum valve opening in% (control mode only) For

a system with a constant flow, it can make sense to add

a minimum valve opening.

Maximum valve opening in% (control mode only) If

the valve is too large and to limit the valve opening for

other reasons, you can limit the opening here .

Adjust parameters for

the valve control

12

P130

DECEMBER 2023

DIAGNOSTICS & SENSOR CALIBRATION

VIA HANSEN TOOL

If the sensor is operating in one of the pre-defined

refrigerants it is delivered factory calibrated and does

not normally need further calibration. If the refrigerant

is not in the list, perform the calibration below.

Make sure the electronic transmitter is mounted on the

mechanical wire in the column.

Zero calibration in pF: Displays the current 0%

SPAN calibration in pF: Displays the full range value

from 0% to 100%.

Actual Measurement in pF: Displays the current

measurement.

Zero calibration: Sets the 0% value during manual

calibration. The vessel should be empty when this button

is pressed.

Calibrate known level: Can be used to input a known

value between 20% and 100% based on visual

confirmation and set the actual value to the sensor when

the button is pressed.

',$*1267,&66(1625&$/,%5$7,219,$

+$16(1722/

,I WKH VHQVRU LV RSHUDWLQJ LQ RQH RI WKH

SUHGHILQHG UHIULJHUDQWV LW LV GHOLYHUHG

IDFWRU\ FDOLEUDWHG DQG GRHV QRW QRUPDOO\

QHHG IXUWKHU FDOLEUDWLRQ ,I WKH UHIULJHUDQW LV QRW LQ

WKH OLVW SHUIRUP WKHFDOLEUDWLRQ EHORZ 0DNH VXUH WKH

HOHFWURQLF WUDQVPLWWHU LV PRXQWHG RQ WKH PHFKDQLFDO

ZLUHLQWKHFROXPQ

=HUR FDOLEUDWLRQ LQ S) 'LVSOD\V WKH FXUUHQW

UHIHUHQFHYDOXH

63$1 FDOLEUDWLRQ LQ S) 'LVSOD\V WKH IXOO UDQJH YDOXH

IURPWR

$FWXDO 0HDVXUHPHQW LQ S) 'LVSOD\V WKH FXUUHQW

PHDVXUHPHQW

=HUR FDOLEUDWLRQ 6HWV WKH YDOXH GXULQJ PDQXDO

FDOLEUDWLRQ7KHYHVVHOVKRXOGEHHPSW\ZKHQWKLVEXWWRQ

LVSUHVVHG

&DOLEUDWHNQRZQOHYHO &DQ EHXVHGWR LQSXW DNQRZQ

YDOXH EHWZHHQ DQG EDVHG RQ YLVXDO

FRQILUPDWLRQDQGVHWWKHDFWXDOYDOXHWRWKHVHQVRUZKHQ

WKHEXWWRQLVSUHVVHG

3

December

0$18$/&$/,%5$7,211262)7:$5(

,I WKH VHQVRU LV RSHUDWLQJ LQ RQH RI WKH SUH

GHILQHG UHIULJHUDQWV LW LV GHOLYHUHG IDFWRU\

FDOLEUDWHG DQG GRHV QRUPDOO\ QRW QHHG IXUWKHU

FDOLEUDWLRQ ,I PDQXDO FDOLEUDWLRQ LV GHVLUHG

WKURXJK WKH HOHFWURQLF WUDQVPLWWHU WKH IXQFWLRQ

QHHGV WR EH DFWLYDWHG 7KH =HUR VSDQ FDO

)XQFWLRQ ILHOG IRXQG XQGHU EDVLF VHWWLQJV KDV WR

EH217KHGHIDXOWLV2))

&DOLEUDWLRQ IRU RU FDQ EH FDUULHG

RXWLQGHSHQGHQW RI HDFK RWKHU SHU WKH IROORZLQJ VWHSV

7KH DFWLRQV ZLOO FDOO RXW WKH XVH RI WKH 5 EXWWRQ

IRXQG RQWKHHOHFWURQLFWUDQVPLWWHU

,QVWUXFWLRQIRUFDOLEUDWLRQ

v&RQQHFWWKHVWDQGDUGFDEOHWRSRZHUWKHVHQVRU

v(PSW\WKHYHVVHO

v3UHVVWKH5EXWWRQIRUVHFRQGVWRDFWLYDWH

FDOLEUDWLRQPRGH7KH<HOORZ/('ZLOOEH21

GXULQJWKHVHFRQGDFWLYDWLRQSHULRGDQGWXUQV

2))ZKHQFDOLEUDWLRQPRGHLVDFWLYDWHG

v3UHVV5RQFHWRFDOLEUDWH7KH<HOORZ/('ZLOO

IODVKRQFH$IWHUZDUGVWKHJUHHQ/('IODVKHVWR

FRQILUPFDOLEUDWLRQ

,QVWUXFWLRQIRUFDOLEUDWLRQ

v&RQQHFWWKHVWDQGDUGFDEOHWRSRZHUWKHVHQVRU

v)LOOWKHYHVVHOWR

v3UHVVWKH5EXWWRQIRUVHFRQGVWRDFWLYDWH

FDOLEUDWLRQPRGH7KH<HOORZ/('ZLOOEH21

GXULQJWKHVHFRQGDFWLYDWLRQSHULRGDQGWXUQVRII

2))ZKHQFDOLEUDWLRQPRGHLVDFWLYDWHG

v3UHVVWKH5EXWWRQWZLFH7KH<HOORZ/('ZLOO

IODVKWZLFH$IWHUZDUGVWKHJUHHQ/('IODVKHVWR

FRQILUPFDOLEUDWLRQ

13 P130

DECEMBER 2023

LEVEL COLUMN DIMENSIONS

LEVEL COLUMN DIMENSIONS

CATALOG

NUMBER

6(1625

ACTIVE

LENGTH

A

EQUALIZER

LEGS

E

FLOAT

SWITCH LEG

F

SIGHT GLASS

LOCATION

G

COLUMN

OVERALL

HEIGHT

L

-$

NN

NN

NN

NN

NN

-$

NN

NN

NN

NN

NN

-$

NN

NN

NN

NN

NN

-$

NN

NN

NN

NN

NN

-$

NN

NN

NN

NN

NN

-$

NN

NN

NN

NN

NN

-$

NN

NN

NN

NN

NN

'PS'JFME

$POTUSVDUJPO

NN

NN

NN

NN

NN

'PS'JFME

$POTUSVDUJPO

NN

NN

NN

NN

NN

3

December

““

“

“

“

“

““

“

“

“

“ “

“ “

“

“

“

“

14

P130

DECEMBER 2023

PROBE DIMENSIONS

4

P109b

JUN 1999

LEVEL COLUMN DIMENSIONS

*Add 3" (75 mm) for stainless steel extended neck version

SENSOR DIMENSIONS

CATALOG

NUMBER

PROBE

ACTIVE

LENGTH

A

EQUALIZER

LEGS

E

FLOAT

SWITCH LEG

F

SIGHT GLASS

LOCATION

G

PROBE

REMOVAL

HEIGHT*

H

COLUMN

OVERALL

HEIGHT

L

LC.02

20"

510 mm

21.25"

540 mm

18.50"

470 mm

14.00"

356 mm

40.00”

1015 mm

26.50"

673 mm

LC.03

30"

760 mm

31.25"

794 mm

31.13"

791 mm

19.00"

483 mm

50.00"

1270 mm

36.50"

927 mm

LC.04

40"

1015 mm

41.25"

1048 mm

36.13"

918 mm

24.00"

610 mm

60.00"

1525 mm

46.50"

1181 mm

LC.06

60"

1525 mm

61.25"

1556 mm

46.13"

1172 mm

34.00"

864 mm

80.00"

2030 mm

67. 2 5"

1708 mm

LC.08

80"

2030 mm

81.25"

2064 mm

56.13"

1426 mm

44.00"

1118 mm

100.00"

2540 mm

87. 2 5"

2216 mm

LC.10

100"

2540 mm

101.25"

2572 mm

66.13"

1680 mm

54.00"

1372 mm

120.00"

3050 mm

107. 25"

2724 mm

LC.12

120"

3050 mm

121.25"

3080 mm

76.13"

1934 mm

64.00"

1626 mm

140.00"

3556 mm

127. 25"

3232 mm

(For Field

Construction)

144"

3660 mm

145.25"

3689 mm

88.13"

2239 mm

76.00"

1930 mm

164.00"

4166 mm

151.25"

3842 mm

(For Field

Construction)

168"

4270 mm

169.25"

4299 mm

100.13"

2543 mm

88.00"

2235 mm

188.00"

4775 mm

175. 25"

4451 mm

NOV 2019

77-1053

77-1053

13

7.62''

(194 MM)

5.69''

(145 MM)

5.31'' (135 MM)

(APPROX

INSTALLED

HEIGHT)

2.85''

(72 MM)

2.02''

(22 MM)

1.00''

(26 MM)

Ø.78''

(22 MM)

5.78''

(147 MM)

3/4''-14 NPT

P129

June 2023

15 P130

DECEMBER 2023

/(',1',&$7,21

/('6LJQDO 212)))UHTXHQF\ )XQFWLRQDOLW\

*UHHQ 21 6XSSO\9ROWDJHFRQQHFWHG

)ODVK 5XQLQVWDUWVLJQDOLQRSHUDWLRQ

2)) 1RVXSSO\YROWDJH

<HOORZ 21 $FWLYDWLRQRIYDOYHFRQWURODQGGXULQJFDOLEUDWLRQ

2)) 9DOYHFRQWUROQRWDFWLYH

5HG 21 $ODUPKLJKRUORZOHYHOGHSHQGLQJXSRQWKHVHWXS

)ODVKVORZ 1RFRQWDFWWRVHQVRURUVHQVRUVKRUWHG

)ODVKIDVW 86%FDEOHFRQQHFWHGDQGFRPPXQLFDWLRQDFWLYH

2)) 1RDODUP

<HOORZ5HG )ODVK ,QVXIILFLHQWSRZHUVXSSO\

$OO )ODVK 86%FDEOHFRQQHFWHGDQGFRPPXQLFDWLRQDFWLYH

2)) 1RDODUP

1R/('LVRQQRWRSHUDWLQJ 1RVXSSO\WRWKHVHQVRU

RUGHIHFWLYHFDEOHSOXJ

&KHFNDQGILQGIDXOWVLQWKHSRZHU

VXSSO\RUUHSODFHWKHVXSSO\FDEOH

<HOORZDQGUHG/('IODVKLQJ 3RZHUVXSSO\LVQRWVXIILFLHQW ,,QVWDOOSURSHUSRZHUVXSSO\

1RFRQWDFWDFWLYDWLRQ 7KHUHPD\EHGHEULVEHWZHHQ

WKHHOHFWURQLFKRXVLQJDQGWKH

PHFKDQLFDOKRXVLQJ

6HSDUDWHWKHWZRSDUWVDQGFOHDQ

WKHVSULQJWLS5HPHPEHUWRDSSO\

VLOLFRQHJUHDVHWRWKHVSULQJWLSVR

DVWRDYRLGSUREOHPVZLWKPRLVWXUH

'HOD\LQVHQVRUDFWLYDWLRQ 0D\EHFDXVHGE\JDV

DQGEXEEOHVLQWKHV\VWHP

&KHFNLIWKHVHQVRULVSODFHG

RSWLPDOO\VRWKDWJDVLVDYRLGHG

7KHVHQVRULVQRWUHDGLQJ

GRHVQWPDWFKWKHVLJKWJODVVHV

2LOKDVDFFXPXODWHGLQWKHOHYHO

FROXPQZKLFKFDQQRWHVFDSH

'UDLQWKHOHYHOFROXPQRIRLODQGLI

QHFHVVDU\FOHDQWKHRLOIURPWKHZLUH

7KHUHLVQRDOLJQPHQWEHWZHHQ

WKHRXWSXWVLJQDODQGWKHOHYHO

LQWKHOHYHOLQGLFDWRU

7KHVHQVRUZDVQRWSURSHUO\VHWXS

RULQFRUUHFWO\FDOLEUDWHG

5HYLHZVHQVRUVHWXSYLDVRIWZDUHWRRO

,IQHFHVVDU\SHUIRUPFDOLEUDWLRQ

)DXOWGHWHFWLRQDQGRUFKDQJLQJWKHHOHFWURQLFIXQFWLRQFDQEHFDUULHGRXWZLWKRXWUHOHDVLQJSUHVVXUHIURPWKHV\VWHP

RUGLVDVVHPEOLQJWKHPHFKDQLFDOSDUWRIWKHVHQVRU

/(',QGLFDWLRQORFDWHGDWERWWRPRIWUDQVPLWWHUKRXVLQJ

t*UHHQ/('LQGLFDWHV9'&VXSSO\LWÀDVKHVGXULQJ

RSHUDWLRQ,IUXQLQLVQRWXVHGWKLVIXQFWLRQPXVWEH

GHDFWLYDWHGLQWKHWRRO

t<HOORZ/('LQGLFDWHVFRQWURO7KHIODVKLQJVHTXHQFH

LQGLFDWHVLIWKHYDOYHLVFORVLQJRURSHQLQJ

t5HG/('LQGLFDWHVKLJKRUORZOHYHODODUPGHSHQGLQJ

XSRQWKHVHWXS

7528%/(6+227,1*

352%/(0 &$86($&7,21

3

December

LED INDICATION

/(',1',&$7,21

/('6LJQDO 212)))UHTXHQF\ )XQFWLRQDOLW\

*UHHQ 21 6XSSO\9ROWDJHFRQQHFWHG

)ODVK 5XQLQVWDUWVLJQDOLQRSHUDWLRQ

2)) 1RVXSSO\YROWDJH

<HOORZ 21 $FWLYDWLRQRIYDOYHFRQWURODQGGXULQJFDOLEUDWLRQ

2)) 9DOYHFRQWUROQRWDFWLYH

5HG 21 $ODUPKLJKRUORZOHYHOGHSHQGLQJXSRQWKHVHWXS

)ODVKVORZ 1RFRQWDFWWRVHQVRURUVHQVRUVKRUWHG

)ODVKIDVW 86%FDEOHFRQQHFWHGDQGFRPPXQLFDWLRQDFWLYH

2)) 1RDODUP

<HOORZ5HG )ODVK ,QVXIILFLHQWSRZHUVXSSO\

$OO )ODVK 86%FDEOHFRQQHFWHGDQGFRPPXQLFDWLRQDFWLYH

2)) 1RDODUP

1R/('LVRQQRWRSHUDWLQJ 1RVXSSO\WRWKHVHQVRU

RUGHIHFWLYHFDEOHSOXJ

&KHFNDQGILQGIDXOWVLQWKHSRZHU

VXSSO\RUUHSODFHWKHVXSSO\FDEOH

<HOORZDQGUHG/('IODVKLQJ 3RZHUVXSSO\LVQRWVXIILFLHQW ,,QVWDOOSURSHUSRZHUVXSSO\

1RFRQWDFWDFWLYDWLRQ 7KHUHPD\EHGHEULVEHWZHHQ

WKHHOHFWURQLFKRXVLQJDQGWKH

PHFKDQLFDOKRXVLQJ

6HSDUDWHWKHWZRSDUWVDQGFOHDQ

WKHVSULQJWLS5HPHPEHUWRDSSO\

VLOLFRQHJUHDVHWRWKHVSULQJWLSVR

DVWRDYRLGSUREOHPVZLWKPRLVWXUH

'HOD\LQVHQVRUDFWLYDWLRQ 0D\EHFDXVHGE\JDV

DQGEXEEOHVLQWKHV\VWHP

&KHFNLIWKHVHQVRULVSODFHG

RSWLPDOO\VRWKDWJDVLVDYRLGHG

7KHVHQVRULVQRWUHDGLQJ

GRHVQWPDWFKWKHVLJKWJODVVHV

2LOKDVDFFXPXODWHGLQWKHOHYHO

FROXPQZKLFKFDQQRWHVFDSH

'UDLQWKHOHYHOFROXPQRIRLODQGLI

QHFHVVDU\FOHDQWKHRLOIURPWKHZLUH

7KHUHLVQRDOLJQPHQWEHWZHHQ

WKHRXWSXWVLJQDODQGWKHOHYHO

LQWKHOHYHOLQGLFDWRU

7KHVHQVRUZDVQRWSURSHUO\VHWXS

RULQFRUUHFWO\FDOLEUDWHG

5HYLHZVHQVRUVHWXSYLDVRIWZDUHWRRO

,IQHFHVVDU\SHUIRUPFDOLEUDWLRQ

)DXOWGHWHFWLRQDQGRUFKDQJLQJWKHHOHFWURQLFIXQFWLRQFDQEHFDUULHGRXWZLWKRXWUHOHDVLQJSUHVVXUHIURPWKHV\VWHP

RUGLVDVVHPEOLQJWKHPHFKDQLFDOSDUWRIWKHVHQVRU

/(',QGLFDWLRQORFDWHGDWERWWRPRIWUDQVPLWWHUKRXVLQJ

t*UHHQ/('LQGLFDWHV9'&VXSSO\LWÀDVKHVGXULQJ

RSHUDWLRQ,IUXQLQLVQRWXVHGWKLVIXQFWLRQPXVWEH

GHDFWLYDWHGLQWKHWRRO

t<HOORZ/('LQGLFDWHVFRQWURO7KHIODVKLQJVHTXHQFH

LQGLFDWHVLIWKHYDOYHLVFORVLQJRURSHQLQJ

t5HG/('LQGLFDWHVKLJKRUORZOHYHODODUPGHSHQGLQJ

XSRQWKHVHWXS

7528%/(6+227,1*

352%/(0 &$86($&7,21

3

December

TROUBLESHOOTING

• Green LED indicates 24 V DC supply; it flashes during

operation. If “run-in” is not used, this function must be

deactivated in the tool.

• Yellow LED indicates control. The flashing sequence

indicates if the valve is closing or opening.

• Red LED indicates high- or low-level alarm, depending

upon the setup.

LED Indication located at bottom of transmitter housing

16

P130

DECEMBER 2023

VARI-LEVEL® ADJUSTABLE LEVEL CONTROL The

system consists of a control unit and a sensor which

is inserted in a level column. Control unit models are

available with up to five individual level set point relays.

Level set points and differentials can be easily set up, and

then simply changed by moving knobs when necessary.

A built-in level simulator enables the operator to easily

check proper operation of control valves, pumps, and

alarms at the various set points.

HLL FLOAT SWITCH

The Hansen Refrigerant liquid level float switches

(HLL Series) are used to electrically indicate or control

a liquid level by opening or closing a SPDT switch.

Their simple, reliable design provides a long life

performance for almost any application.

WARRANTY

Hansen electronics are guaranteed against defective

materials or workmanship for 90 days F.O.B. our factory.

All other components are guaranteed for one year F.O.B.

our factory. No consequential damages or field labor is

included.

To Order: Specify catalog number, refrigerant, and if

a level column is desired. Where possible describe and

sketch the application.

CAUTION

Hansen controller wire probes have been designed

specifically for refrigeration systems. These instructions

and related safety precautions must be completely read

and understood before selecting, using, or servicing

these probes. Only knowledgeable, trained refrigeration

technicians should install, operate, or service these

probes. Stated temperature and pressure limits should

not be exceeded and all electronics should be protected

from moisture. Do not remove probes from level columns

or vessels unless the system has been evacuated to zero

pressure. See also Safety Precautions in the current List

Price Bulletin and the Safety Precaution Sheet supplied

with the product. Escaping refrigerant can cause injury,

especially to the eyes and lungs.

WARNING: As with all electronic and mechanical

components, there is a limited life expectancy. An

expected life of seven to ten years is typical. However, this

should be understood as only a suggested replacement

time period. Actual performance and physical condition

of the electronics due to ambient conditions, quality

of electrical current or voltage, etc., may necessitate

a different replacement schedule. Regardless, probes

should be inspected at least once a year to ensure safe

and continuous service.

+DQVHQ7HFKQRORJLHV&RUSRUDWLRQ

&RPPHUFH6W

%XUU5LGJH,OOLQRLV86$

7HO)D[7ROO+$16(1

(PDLOVDOHV#KDQWHFKFRP:HEZZZKDQWHFKFRP

86$Ã$VLDÃ(XURSHÃ,QGLDÃ/DWLQ$PHULFDÃ0LGGOH(DVW

ª+DQVHQ7HFKQRORJLHV&RUSRUDWLRQ

&$87,21

+DQVHQ OHYHO ZLUH SUREHV KDYH EHHQ GHVLJQHG

VSHFLILFDOO\ IRU UHIULJHUDWLRQ V\VWHPV 7KHVH LQVWUXFWLRQV

DQGUHODWHG VDIHW\SUHFDXWLRQV PXVWEH FRPSOHWHO\UHDG

DQG XQGHUVWRRG EHIRUH VHOHFWLQJ XVLQJ RU VHUYLFLQJ

WKHVH SUREHV 2QO\ NQRZOHGJHDEOH WUDLQHG UHIULJHUDWLRQ

WHFKQLFLDQV VKRXOG LQVWDOO RSHUDWH RU VHUYLFH WKHVH

SUREHV 6WDWHG WHPSHUDWXUH DQG SUHVVXUH OLPLWV VKRXOG

QRWEHH[FHHGHGDQGDOOHOHFWURQLFVVKRXOGEHSURWHFWHG

IURPPRLVWXUH'RQRWUHPRYHSUREHVIURPOHYHOFROXPQV

RU YHVVHOV XQOHVV WKH V\VWHP KDV EHHQ HYDFXDWHG WR

]HUR SUHVVXUH 6HH DOVR 6DIHW\ 3UHFDXWLRQV LQ WKH

FXUUHQW /LVW 3ULFH %XOOHWLQ DQG WKH 6DIHW\ 3UHFDXWLRQ

6KHHW VXSSOLHG ZLWK WKH SURGXFW (VFDSLQJ UHIULJHUDQW

FDQFDXVHLQMXU\HVSHFLDOO\WRWKHH\HVDQGOXQJV

:$51,1* $V ZLWK DOO HOHFWURQLF DQG PHFKDQLFDO

FRPSRQHQWV WKHUH LV D OLPLWHG OLIH H[SHFWDQF\ $Q

H[SHFWHG OLIH RI VHYHQ WR WHQ \HDUV LV W\SLFDO +RZHYHU

WKLV VKRXOG EH XQGHUVWRRG DV RQO\ D VXJJHVWHG

UHSODFHPHQW WLPH SHULRG $FWXDO SHUIRUPDQFH DQG

SK\VLFDO FRQGLWLRQ RI WKH HOHFWURQLFV GXH WR DPELHQW

FRQGLWLRQV TXDOLW\ RI HOHFWULFDO FXUUHQW RU YROWDJH HWF

PD\ QHFHVVLWDWH D GLIIHUHQW UHSODFHPHQW VFKHGXOH

5HJDUGOHVVSUREHVVKRXOGEHLQVSHFWHGDWOHDVWRQFHD

\HDUWRHQVXUHVDIHDQGFRQWLQXRXVVHUYLFH

237,21$/(48,30(1763$5(3$576

0RGHO1XPEHU

:/7C-(/

:/73/80%

:/70(;7(16,21

0RGHO1XPEHU

:/7-C

9$5,/(9(/ $'-867$%/( /(9(/ &21752/

7KH V\VWHP FRQVLVWV RI D FRQWURO XQLW DQG D VHQVRU

ZKLFK LV LQVHUWHG LQ D OHYHO FROXPQ &RQWURO XQLW

PRGHOV DUHDYDLODEOH ZLWK XSWR ILYHLQGLYLGXDO OHYHOVHW

SRLQW UHOD\V /HYHO VHW SRLQWV DQG GLIIHUHQWLDOV FDQ EH

HDVLO\ VHW XSDQG WKHQ VLPSO\ FKDQJHG E\ PRYLQJ

NQREV ZKHQ QHFHVVDU\ $ EXLOWLQ OHYHO VLPXODWRU

HQDEOHV WKH RSHUDWRU WR HDVLO\ FKHFN SURSHU

RSHUDWLRQ RI FRQWURO YDOYHV SXPSV DQG DODUPV DW WKH

YDULRXVVHWSRLQWV

+//)/2$76:,7&+

7KH +DQVHQ 5HIULJHUDQW OLTXLG OHYHO IORDW VZLWFKHV

+//6HULHVDUHXVHGWRHOHFWULFDOO\LQGLFDWHRUFRQWUROD

OLTXLG OHYHO E\ RSHQLQJ RU FORVLQJ D 63'7 VZLWFK 7KHLU

VLPSOHUHOLDEOHGHVLJQ SURYLGHV DORQJOLIH SHUIRUPDQFH

IRUDOPRVWDQ\DSSOLFDWLRQ

:$55$17<

+DQVHQ HOHFWURQLFV DUH JXDUDQWHHG DJDLQVW GHIHFWLYH

PDWHULDOVRUZRUNPDQVKLSIRUGD\V)2%RXUIDFWRU\

$OO RWKHU FRPSRQHQWV DUH JXDUDQWHHG IRU RQH

\HDU)2% RXU IDFWRU\ 1R FRQVHTXHQWLDO GDPDJHV RU

ILHOGODERULVLQFOXGHG

7R2UGHU6SHFLI\FDWDORJQXPEHUUHIULJHUDQWDQGLID

OHYHOFROXPQLVGHVLUHG:KHUHSRVVLEOHGHVFULEHDQG

VNHWFKWKHDSSOLFDWLRQ

02'(/25'(5,1)250$7,21

'HVFULSWLRQ

:/75HSODFHPHQW3:LUH7UDQVPLWWHU.LW

:/7&RXQWHUZHLJKW.LW

0([WHQVLRQ&DEOHIWP

:/7:,5(0HFKDQLFDO%DVHZLWK:LUH(OHPHQW.LW

3ZLUH/HYHO6HQVRU and Controller

'HVFULSWLRQ

3

December

:/786%86%03URJUDPPLQJ&DEOH

:/70*0)LHOG&DEOHIWP

127(LQGLFDWHVLQFOXGHGLQ:/7

-C

5'5 5HPRWH'LJLWDO'LVSOD\

368 3RZHU6XSSO\9$&9'&:

:/7C-SPLITBOX Splitbox for Dignostics

Hansen Technologies Corporation

681 Commerce Street

Burr Ridge, Illinois 60527 USA

Tel: 630.325.1565 Fax: 630.325.1572 Toll: 866.4HANSEN

USA ∙ Asia ∙ Europe ∙ India ∙ LatinAmerica ∙ MiddleEast

© 2023 Hansen Technologies Corporation

This manual suits for next models

1

Table of contents