INSTALLATION

Regulators should be protected from dirt and moisture

during storage. The arrow on the body should be in

the normal direction of refrigerant flow. These valves

will not prevent reverse flow; use check valves where

necessary. Regulators are normally in horizontal pipe

lines with pilots and manual-opening stems on top. Do

not rotate the position of the valve adapter or the valve

will not operate.

The system should be free of dirt, weld slag, and rust

particles. Regulators can be equipped with separate,

close-coupled inlet strainers. No small, hidden,

internal screens are used. Gauges and gauge valves

should be installed on the inlet and outlet to help in

system diagnosis. Because of the many regulator pilot

combinations, during installation of a large job, the

regulator nameplates should be checked against piping

drawings to guarantee proper function for each location.

Where pilot solenoid control modules are used, the

nameplate coil voltage should be checked before wiring.

Pipe sizing, anchoring, valve rating, system design,

and other precautionary factors should be taken into

consideration to ensure “liquid hammer” will not occur

when the valve opens or closes.

The 5" and 6" valves are type HA4W with integral butt

weld end only. These steel-bodied regulators are directly

welded into the pipe line. During welding, the manual-

opening stem should be opened downward several turns

to protect the Teflon seat from weld heat.

Welds should be annealed as necessary in accordance

with good practice. Painting of valves and welds is

recommended for corrosion protection. Pipe covering,

where applied, should have proper moisture barrier.

Before putting valves into ser vice, all pipe connections,

valve seats, cover seals, and stem seals should be tested

for leaks at pressure levels called for in appropriate

codes.

ELECTRICAL

When the electric shut-off, wide-opening, or dual feature

is supplied, a Hansen low-wattage, molded electrical coil

is included. Standard coil voltages are 115V, 208/230V,

or 24V at 50/60Hz. Other voltages available. The coil

properly operates between 85% and 110% of the rated

voltage. Coils should only be energized while on the pilot

solenoid tube. Unless otherwise specified, the standard

coil with a ½" fitting for conduit is supplied with valves.

A watertight solenoid coil with 18" (450 mm) long

wire pigtail leads and a steel frame housing with a ½"

conduit fitting is standard.

Optional DIN Plug Coils are for grounded cord

connections and include the necessary DIN plug socket

with gasket.

Hansen long life Beacon Pilot Lights are available. They

incorporate a totally encapsulated, unique secondary

wound coil and LED light in a compact disc. These pilot

lights require no additional wiring.

Note: Beacon Pilot Lights are for AC voltage coils only.

MATERIAL SPECIFICATIONS

Body:

¾" through 4": Ductile iron, ASTM A536

5" & 6": Cast steel, ASTM A352 LCB

Adapter: Ductile iron, ASTM A536

Piston: Steel, disc type, Teflon piston seal

V-Port/Seat: ductile iron, with Teflon seat

Main Seat: ¾" through 1¼": integral ductile iron

1½" through 6": stainless steel, removable

Gaskets: Nonasbestos, graphite composite

Manual Opening Stem: Steel, plated

Pilots: Stainless steel trim

Pilot Orifice: Stainless steel

Flanges: Forged steel, ASTM A105

Safe Working Pressure: 400 psig (28 bar g), 600 PSIG

(41 bar g) available contact factory

Operating Temperature: –60°F to +240°F (–50°C to

+115°C)

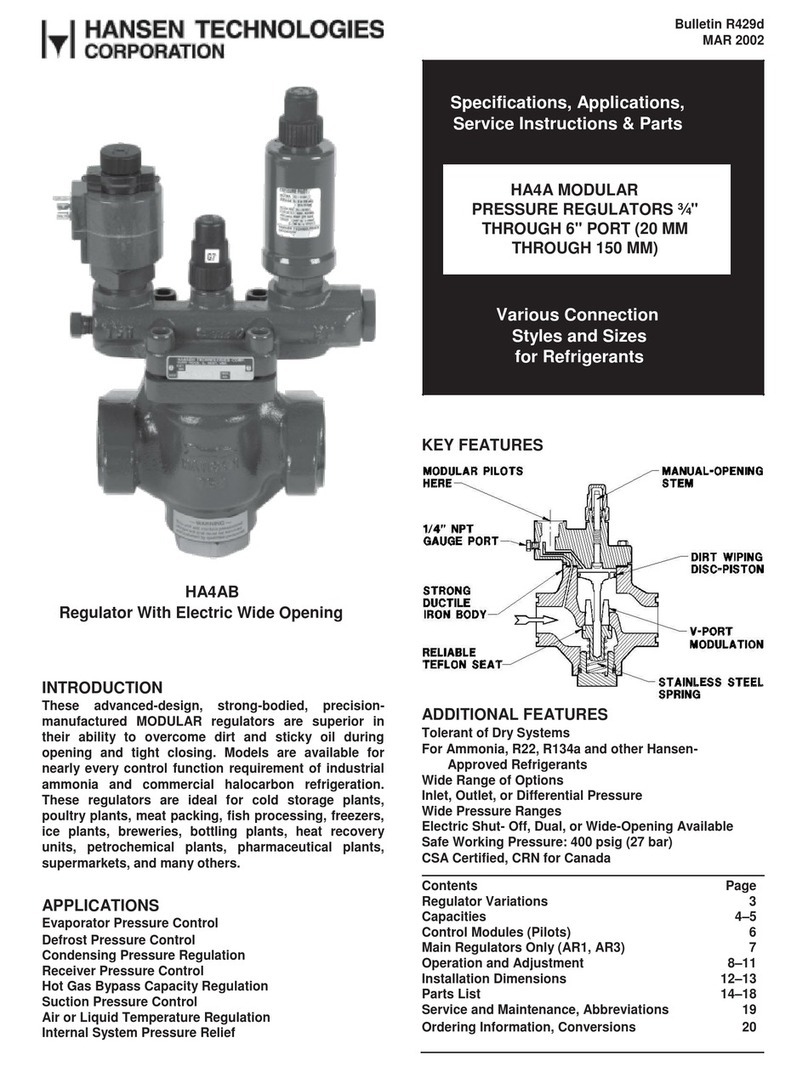

ADVANTAGES

These valves combine modern design and new age

materials with advanced manufacturing techniques

and intense quality control to offer a significantly

superior and reliable product. Their ductile iron bodies

are stronger and more rugged than common cast iron,

or so called semi-steel (class B iron), valves. They are

more dirt resistant than full skirted-piston-design valves.

All regulators use energized Teflon dirt-wiping piston

seals which operate reliably, even under dry, oil-free

conditions. The screw-on control modules (pilots) are

easy to change and can be used on all valve sizes. All

valves incorporate Teflon seating and stainless steel

spring closing. Manual-opening stems are located on

top of valves, up and away from dirt and rust particles

to avoid thread jamming. Nonasbestos gaskets are

standard. These standard regulator valves use the same

flanges and spacing as R/S model A4A, except 1¼"

(32mm). Special Hansen 1¼" 4-bolt regulators are

available from stock to exactly replace R/S 1¼" A4A only.

SIZING

Proper regulator valve sizing is important for smooth

operation and long, trouble-free life of the valve.

Therefore, capacity of the regulator at both the maximum

and minimum flow and pressure drop should be

analyzed. Pressure regulators will operate satisfactorily

to approximately 15% of the maximum capacity of valve

based on the corresponding pressure drop. In extreme

cases, downsizing or two smaller regulators in parallel

are necessary. For pressure drops exceeding 45 psi

(3.1 bar g), special construction may be required. Contact

the factory.

2

R429d

AUG 2015