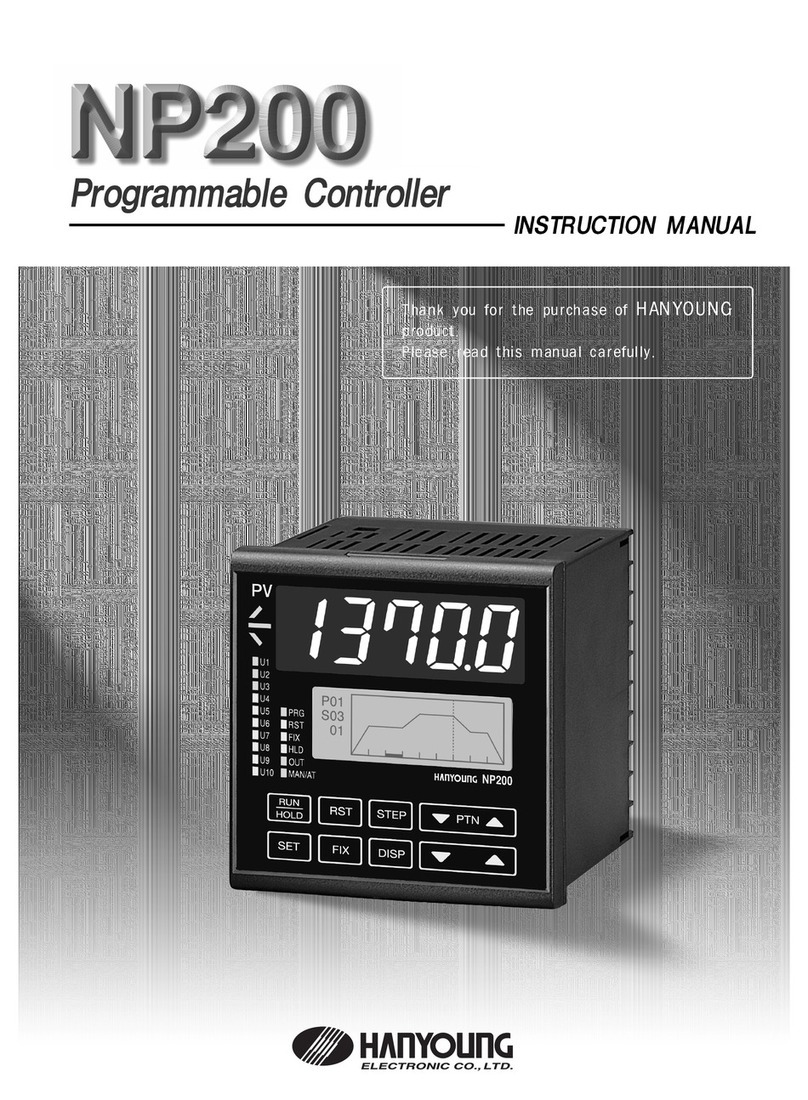

Hanyoung RT9 User manual

CONTENTS

1. SAFETY INFORMATION

2. INSTRUCTION

3. ORDERING INFORMATION

4. SPECIFICATION

5. DIMENSIONS & PANEL CUTOUT

6. TERMINAL ARRANGEMENT

7 NAME & FUNCTION

8. TABLE OF SETTING ITEMS

10. SETTING METHOD

20. GROUP SETTING

21. FUNCTION

P.4

P.6

P.6

P.7

P.11

P.11

P.12

P.13

P.15

P.16

P.23

2

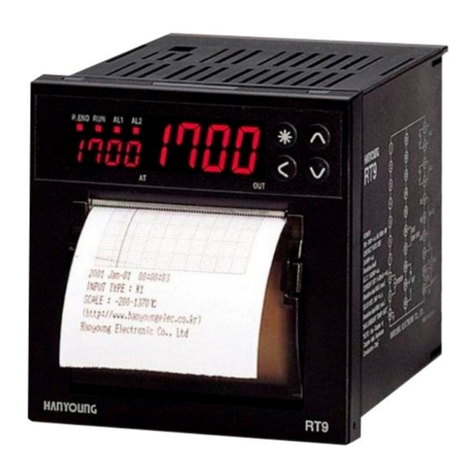

RT9

RT9

●Zoom function

●Various Alarm

● Universal Input·Output

●Interface (RS485)

●Free scale

●PID auto tuning

●Record and Temperature

control

Universal Input·Output/Small-sized Temperature controler & Recorder

(±0.3 class high accuracy)

◆

3

Features

Model : RT9

SAFETY INFORMATION

4

1

Before using, please read this (SAFETY INFORMATION) and then use this controller.

It is most important that the instructions in this manual are followed when using this instrument.

Please keep this manual for future reference.

Precautions are classified in WARNING and CAUTION.

WARNING

Caution on wiring

●

Use an external protection circuit if a fault in the control loop could possibly lead to a serious

problem.

●

This instrument do not have a switch for power and a fuse, so please set them if it is needed.

(Fuse rating 250V, 0.5A)

Power supply

●

Use a rated voltage to prevent damage or trouble.

●

To avoid electrical shock or damage, do not turn ON the power until the wiring is completed.

Prohibit use in gas atmosphere

Do not use it at a place exposed to combustible or explosive gas.

Handling of unit

●

To avoid malfunction, electrical shock or fire, this unit must not be disassembled or repaired.

●

Do not touch the terminals to avoid electrical shock or malfunction.

Caution on maintenance

●

Turn OFF the power before mounting or removing the instrument.

●

To ensure continuous and safe operation of the instrument, periodical maintenance is

recommended. Some parts are limited in life.

●

The warranty period is 1 year only if using in the correct way.

CAUTION

Caution on handling

Do not install the instrument under any of the following condltions.

●

The ambient temperature exceeds 0 ~ 50℃

●

The ambient humidity exceeds 20 ~ 90%RH.

●

A place where temperature changes suddenly or icing occurs.

●

A place exposed to corrosive gas or combustible gas.

●

Vibration or shock is likely to be transmitted to the instrument.

●

A place exposed to water, oil, chemicals, steam, sunlight.

●

A place exposed to much dust, salt or iron.

●

A place with much inductive disturbance, static electricity, magnetism noise.

●

A place where heat such as radiant heat stays.

WARNING

CAUTION

There is a possibility of death or heavy injury when handling in wrong way.

There is a possibility of injury or physical damage when handling in wrong way.

5

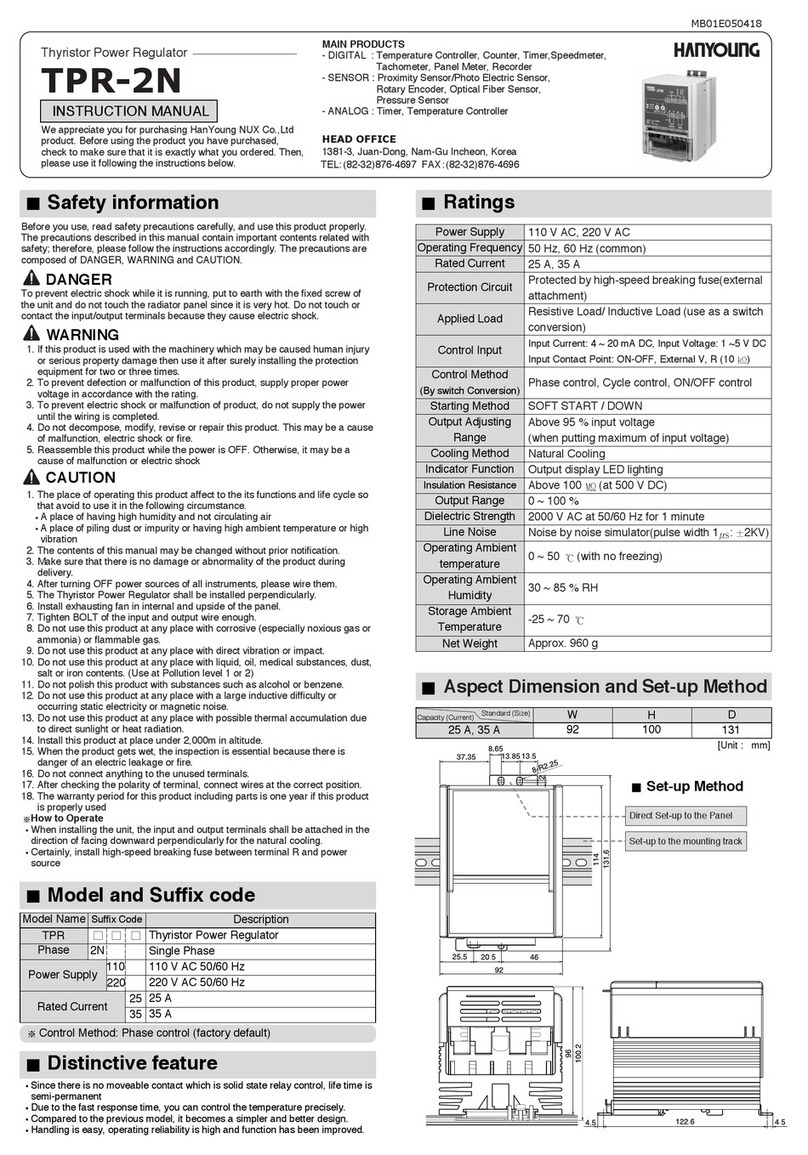

ORDERING INFORMATION

6

INSTRUCTION

2

3

RT9

0 : Recorder

1 : Recorder & Temperature Controller

0 : ℃ exclusive use

1 : Others

0 : None

1 : Alarm 1

2 : Alarm 1,2

3 : RS485

4 : RS485/Alarm 1

5 : RS485/Alarm 1,Alarm 2

※제어출력구성

0

1

2

3

RT9 - 1

Relay (ON/OFFcontrol)

SSR

SCR (4~20mADC)

Relay (P.I.Dcontro)

②Installation

●

For NX9, 7, 3 and 2, attach the brackets (2 units) on the fixed halls and tighten with a

screwdriver.

Fixing torque is about 14.7N. cm (1.5kg.cm). NX1 and NX4 has a plastic bracket.

(Care should be taken not to tighten forcedly.)

③Caution on terminal connections

●

Use a compensating cable with thermocouple.

● For R.T.D input use a cable which is

a small lead wire resistance and without resistance

difference to 3wires.

●

To avoid inductive noise to input wires seperate from the power and output wires.

●

Keep input wires away from output wires and use shielded wires to earth.

●

If the wiring has noise, use the following step: connect a surge absorber to the conductor

coil side if the conductors are connected to the load output, such as the relay contact output.

●

Use an insulating transformer with a noise filter when the power suppy has much noise.

●

Noise filter should be mounted on a panel which has been earthed and the wiring between

the noise filter output and the instrument power terminals should be shorten.

●

It is effective to use a twisted cable for power supply against noise.

●

The heater power supply and the instrument power supply should be connected using the

same power suppy when a heater break alarm.

●

Time for preparation of contact output is required at power ON. When the output signal is

used for an extenal interlock circuit, connect a delay relay.

④For load circuit connection

●

Use an extra relay when the frequency of operation is rather high. In thic case,

SSR output type is Recommended.

•

Electromagnetic switch : Proportional cycle time is Min. 30sec

•

SSR : Proportional cycle time is Min. 1 sec

•

Contact output life : Mechanical : Min. 10 million times (no load)

Electrical : Min. 100 thousand times (rated load)

•

SSR drive pulse voltage, DC 4~20mA are not insulated with internal circuit.

Use non-grounded sensor to R.T.D and thermocouple.

⑤For waterproof (Waterproof type)

The instrument has IP65. Use rubber packing when installing the instrument to panel.

Please attach the rubber in correct way.

⑥Caution on key operation / trouble

●

If alarm function is not set correctly, alarm output can not be operated at a trouble.

Be sure to check the alarm operation.

●

If the input cable is disconnected, the display shows“ ”.

When replacing the sensor, please turn OFF the power supply.

⑦Other

Do not use organic solvents such as alcohol, benzine when cleaning. (Use neutral detergent)

This instrument has process-value (PV) and set-value (SV) each 4 digits with 7 segment FND. This

instrument is divided Recorder and Recorder with Controller.

Function and feature : Group P.I.D, Universal-input (19 types), Universal-output (Relay, SSR, 4~20mA),

Auto-tuning 2 types (standard type, low PV type), Communication (RS485),21 types of alarm,

Sampling cycle 250ms, ±0.3 of FS high accuracy. And there are Zoom function, Graphic or Text

printing selectable function, List function, Feed function, Free scale function. RTP is the smallest

Recorder with controller.

Recorder &

Temperature Controller Control Output

Output code

7 8

SPECIFICATION

4

1)

INPUT

Input

Sampling time

Input resolution

Input impedance

Lead wire tolerable

resistance

Input

tolerable voltage

Noise removal rate

Standard

Standard junction temp.

compensation tolerance

Burn-out

Accuracy

Input range

Thermocouple: K, J, E, T, R, S, B, L, N, U, WRe 5-26, PL-Ⅱ

R.T.D: Pt 100Ω, KPt 100Ω

Direct voltage: 1~5V, -10~20mV, 0~100mV(Programmable scale type)

250mS

Below decimal point of measurement range

T/C and mV input: 1MΩ min., DC V: 1MΩ

R.T.D: 10Ωmax. / wire

±10V (T/C, R.T.D, Voltage: mV DC)

±20V (Voltage: V DC)

NMRR(normal mode): 40dB min.

CMRR(common mode): 120dB min. (50/60Hz ±1%)

T/C, R.T.D: KS, IEC, DIN

±1.5℃(15~35℃), ±2.0℃(0~50℃)

T/C: OFF, Up/Down selectable

R.T.D: Up scale (Detection current: 50mA)

±0.3% (Full scale)

Refer to“Input signal and Measurement range”

T/C and R.T.D are changeable within range of input signal and measurement range.

Voltage: min. voltage and max. voltage are available within range of measurement.

Scaling available.

2)

OUTPUT

Relay

contact output

Contact capacity: 240VAC 1A, 30V DC 1A(resistive load)

Contact: 1a

Output points: 2 Points (AL1,AL2)

①ALARM (HBA OUTPUT)

②CONTROL OUTPUT

Relay

contact output

SSR drive

voltage output

Current output

Contact capacity: 240VAC 3A, 30VDC 3A (resistive load)

Contact: 1C

Output operation: P.I.D control, ON/OFF

Proportional cycle: 1~1,000 sec.

Output limit: 0.0~100.0% range, higher limit(OH) or lower limit(OL)

selectable (valid when AT)

ON/OFF hysteresis: 0~100%(Full scale)

Time resolution: 0.1% or 10mS

ON voltage:24VDC min.(resistive load 600Ω min., 30mA limit when short)

OFF voltage: 0.1VDC max.

Proportional cycle: 1~1,000 sec.

Output operation: P.I.D control

Output limit: 0.0~100.0% range, higher limit(OH) or lower limit(OL)

selectable (valid when AT)

Time resolution: 0.1% or 10mS

Current output range: 4~20mA DC

Resistive load: 600Ω max.

Accuracy: ±0.5% of full scale (4~20mA range), Resolution: Approx. 3,000

Output ripple: 0.3%(P-P) of max. scale (150Hz)

Sampling time: 250mS

Output operation: P.I.D control

Output limit: -5.0~105.0% range, higher limit(OH) or lower limit(OL)

selectable (valid when AT)

Input correction (Bias): -100.0~100.0% for instrument range

Scaling : According to SH, SL of measurement range

Filter : OFF, 1~120 sec.

3 settings (SV1, SV2 and SV3) and P.I.D setting each

Auto tuning : According to set value (Standard type, Low PV type)

Proportional Band : 0.1~999.9% (Max. range)

Integral Time : OFF, 1~6000 sec.

Derivative Time : OFF, 1~6000 sec.

ON/OFF control: By selecting output code (OT)“ 0 ”

P.I.D selection : Zone PID/Auto 1,2,3, selectable

Manual Reset : -5.0~105.0% of output (valid when I=OFF)

Direct / Reverse action : Changeable by parameter

Preset output limit : -5.0~105.0% of output value

ON/OFF hysteresis (HYS): 0.0~100.0% of instrument range (valid when ON/OFF control)

A.R.W(Anti Reset Wind-up): AUTO, 50.0~200.0%

Fuzzy : selection ON/OFF by parameter

Ramp function

Set point : 2 Points

Multi-alarm : High/Low process alarm, High/Low deviation alarm, Hold function of alarm,

Heater break alarm (H.B.A)

Setting range : Process alarm ⋯⋯ 0~100% of instrument range

Deviation alarm ⋯⋯ -100~100% of instrument range

Measuring point : 1

Response time : According to chart speed

Record type : Thermal line

3)

FUNCTION

Measurement input

Control

Alarm output

Record

Storage temperature

Storage humidity

Shock

Installation environment

Normal operation

condition

Influence of ambient

temperature

Continuous vibration (5~14Hz): Forward width 1.2mm max.

(4~150Hz): 4.9㎨ (0.5G) max.

Vibration : 14.7㎨ (1.5G), 15 sec. max. (each 3 direction)

Shock : 147㎨ (15G), 11msec max. (6 direction each 3 times)

Panel cutout: Page 11, 12

Ambient temperature : 0~50℃

Ambient humidity : 20~90%RH (no condensation)

Influence of magnetic : 400AT/m max.

Warm-up time: 30 min. min.

T/C, Voltage input : ±1μV/℃ or ±0.01%/℃ of max. range

R.T.D input : ±0.05Ω/℃ max.

Analog output : ±0.05%/℃ max. (continuous output)

4)

OPERATING ENVIRONMENT

5)

STORAGE CONDITION

-25~70℃

5~95%RH (no condensation)

1m max. in packing condition

9 10

6)

STRUOTURE

External Dimension

96(W)×96(H)×100(D) mm

MODEL

RT9

Weight

530 g

Material

Plastic case(ABS)

Under process

Under process

Safety standard

EMC standard

100~240VAC(90~264VAC)

50/60Hz

6.0W max., 10VA max.

Between primary terminal and secondary terminal : DC 500V, 20MΩ min.

Between primary terminal and ground : DC 500V, 20MΩ min.

Between ground and secondary terminal : DC 500V, 20MΩ min.

Between primary terminal and secondary terminal : 2,300VAC 50/60Hz for 1 min.

Between primary terminal and ground : 2,300VAC 50/60Hz for 1 min.

Between F·G and secondary terminal : 1,500VAC 50/60Hz for 1 min.

7)

POWER SUPPLY

8)

SAFETY AND EMC STANDARD

Power supply

Frequency

Power consumption

Insulation resistance

Dielectric strength

Standard

Communication address

Communication method

Synchronization

Communication sequence

Communication distance

Communication speed

Start bit

Data bit

Parity bit

Stop bit

Communication protocol

Response time

9) INTERFACE

EIA RS485

0~31, 1~99 setting available

2 wire half duplex or 4 wire half duplex

Start-stop synchronous mode

None

1.2Km max.

600, 1200, 2400, 4800, 9600 BPS

(Speed is changeable by parameter)

1 BIT

7 or 8 BIT

None, even numbers, odd numbers

1 or 2 BIT

PC LINK WITHOUT SUM(0), PC LINK WITH SUM(1)

Reception treatment time + (Response time × 10mS)

10)

INPUT SIGNAL and MEASUREMENT RANGE

Thermocouple

(T.C)

R.T.D

Direct voltage

(VDC/mVDC)

Direct voltage

(mV)

Input type (Input signal) Input code Range (℃) Range(℉) Accuracy Remarks

K

K

J

E

T

R

B

S

L

N

U

W

PlatinelⅡ

KSPt100

Pt100

1~5V

-10~20mV

0~100mV

DC 4~20mA

1~5V

-10~20mV

0~100mV

※When using current input,

use the resistor 250Ω

0.1% on input terminal.

±0.5% of F.S

±1digit

±0.5% of F.S

±1digit

±0.5% of F.S ±1digit

±1.0% of F.S ±1digit

±0.5% of F.S

±1digit

±0.5% of F.S

±1digit

-300~2500

0~2300

-300~2300

-300~1800

-300~750

32~3100

32~3300

32~3100

-300~1300

-300~2400

-300~750

32~4200

32~2500

-199.9~999.9

-300~1180

1

2

3

4

5

6

7

8

9

10

11

12

13

20

21

30

32

33

30

2

2

2

2

2

2

1

2

2

3

3

-200~1370

-199.9~999.9

-199.9~999.9

-199.9~999.9

-199.9~400.0

0~1700

0~1800

0~1700

-199.9~900.0

-200~1300

-199.9~400.0

0~2300

0~1390

-199.9~500.0

-199.9~640.0

•F.S is maxium value ~

minimum value of

each RANGE.

•Digit is minimum value

of display

1 0~400℃ :

±10% of F.S±1digit

2 0℃ and below :

±1.0% of F.S±1digit

3 -150.0~150.0℃ range

: ±1.0% of F.S±1digit

※20 KPt100

※21 DPt100

※

Functions

Name Functions

No paper.

Under recording.

Alarm 1 ON.

Alarm 2 ON.

Displays set value and various parameters.

(RT9-0 : Displays input type)

Display the process value. When setting, display various modes.

Flickers when the auto tuning operates.

Lights when the control output is ON.

Model name

Manufacturer

Used to change mode.

Used to increase set-value.

Used to decrease set-value.

Used to select digit for changing.

① P.END

② RUN

③ AL1

④ AL2

⑤Set-value(SV)

⑥Process-value(PV)

⑦ AT

⑧ OUT

⑨ RT9

⑩HANYOUNG

Key

⑪모드버튼

⑫증가버튼

⑬감소버튼

⑭쉬프트버튼

NAME & FUNCTION

2) Displays

1) Front

12

7

3) Control keys

●RT9 ( 96×96 mm )

DIMENSIONS & PANEL CUTOUT

5

11

TERMINAL ARRANGEMENT

6

Relay(Terminal no. )

SSR / SCR (Termina no. )

100 - 240 VAC 50/60 Hz. (Termina no. )

Termocouple: →+, → -

R.T.D: A, → B

Alarm1 (Termina no. )

Alarm2 (Termina no. )

Sending data ( )

Receiving data ( )

Earth ( )

1) Control Output

2) POWER

3) Input sensor

4) AL1 / AL2

5) Communication

●

Terminal

●Panel cutout

(Unit : mm)

14

13

TABLE OF SETTING ITEMS

8

전원투입

1)Operation 2)Menu

3sec.

Operation display status.

Set value changeable

※Set a number

Output volume display

○Recorder exclusive use(RT9-0):

•Control group

•Alarm group (Optional)

•Communication group (Optional)

•Input group

•Time setting group will be displayed.

Parameter structure

Group Alarm Group

Communication Group Output Group Input

Group Control Group

Autotuning Group P.I.D Group

Time setting

This controller has 3 different levels of setting, thereby restricting operator access if so desired.

Signal Name Description Condition Initial

Control group display

Zone selection 1

Fuzzy function

Initial increasing temperature

Initial decreasing temperature

Time unit

Set speed of transmission

Zome

Set a control mode

OFF / ON

OFF / ON

Always

Except ON/OFF

Always

Always

Always

Always

Always

Always

OFF

OFF

OFF

OFF

HOUR

60

OFF

OFF / ON

24 ~ 900 mm/hour

16

GROUP SETTING

10

OFF / EUS (0~100 %)

OFF / EUS (0~100 %)

HOUR / MIN

Signal Display Name Discription Condition Initial

Display level setting Divide display levels into

3 stages (1~3) 3Always

●After completion of wiring, apply power ON.

(1)Management version indicated as below and then present PV and SV will be indicated.

(Record exclusiue use : Input type and PV will be indicated)

(2)For setting a level, press button for 3 sec. to enter setting mode.(Initial value : 3 )

(3)In the condition, press button to enter group control.

SETTING METHOD

15

9

For 3 sec

Group Control

Group Auto tuning

Group PID

Group Alarm

Group

Communication

Group Output

Group Inputl

Group

Time setting

Group

Control

Group

Alarm

Group

Commu

nication

Group

Inputl

Group

Time setting

●Recorder

(Model:RT9-0) ●Recorder

& Controller

(Model:RT9-1)

●Parameter shift

Power ON

How to operate RECORDER

①RUN buttons simultaneously

(RUN lamp will be ON)

② Stop buttons simultaneously

(RUN lamp will be OFF)

③Graphic or Word selection

In condition of printing, press

button for 3 sec.(Graphic →Word

→Graphic→...)

④List printing

In condition of printing, press

button for 3 sec.

1)

Control group setting

※

Display level setting

·Recorder:Displays input

type and PV

·Recorder & controller:

Displays SV and PV

①Auto-tuning

The Auto tuning function automatically measures, computes and set the optimum P.I.D value.

【Note】After setting all group, select“AUTO ”in Auto tuning group.

②Auto-tuning type

This controller has two type of auto tuning as STD (standard type) and Low (Low PV type : SV-10%) .

③Auto-tuning start·stop

ⓐAuto tuning start : 1~ 3 selection

(After auto tuning , P.I.D value will be stored at a selected number)

ⓑSelection

When setting a value on L.RP and 2.RP, it is stored in group 1,2,3 automatically

ⓒAuto tuning stop : Select OFF

1817

STD

OFF

Signal Name Description Condition Initial

Auto tuning group

Auto tuning type

Auto tuning start

Indicates Auto-turing

/

OFF /1~3 /

RT9-1

ABS

ABS

P.I.D group

ANTI RESET WIND-UP

P.I.D group selection

n.Proportional band (P)

n.Integral time (I)

n.Derivative time (D)

n.Manual reset

n.Zone position

RT9-1

Except ON/OFF

Always

P.I.D group

P.I.D group

P.I.D group

Integral time: OFF

ZONE : ON시

Auto

0

5.0 %

240 sec

60 sec

50.0 %

EU(100.0 %)

2)

Auto tuning group setting (Model: RT9-1)

3)

P.I.D설정그룹 (모델: RT9-1)

4)

Alarm group setting(Optional)

Set P.I.D mode

Auto / 50.0~200.0 %

0 / 1~3

0.1~999.9 %

OFF / 1~6000초

OFF / 1~6000초

-5.0~105.0 %

EU(0) < 1.RP < 2.RP < EU(100.0 %)

Signal Name Description Condition Initial

Time

Zone 3 Set point of Zone 2 (2,RP)

Set point of Zone 1 (1,RP)

Maximum Range (Eu:100%)

Minimum (Eu: 0%)

Zone 2

Zone 1

When checking P.I.D. values or setting SV in manual

mode, this can be done in P.I.D. Group.

Press key to get Anti Reset Wind value by auto or

manual and then press once more to be indicated

P.I.D mode which is selectable 3 types of P.I.D group

(0~3). Example,“0”is no P.I.D mode and after seleting

“1”using or and pressing , it is available to

change P.I.D value in zone“1”. (“2”and“3”are same as

“1”)

When integral time is OFF, manual reset mode is indicated

and then you could set reset value to remove off set.

(range: -5%~105.0% of proportional band). You could set

3 zones by selecting zone mode ON.

※ In diagram,“n”is available to set 1~3 and proportional band of cooling side, integral time of

cooling side, hysteresis are indicated in Heating / Cooling type.

There are 2 alarm outputs available per conrtoller. In Alarm Group, setting are made for mode, dead

band and value of each alarm. Refer to the next page for the 20 different types of alarm functions.

In Heating·Cooling type of,

is not indicated when selecting 10,11,12 (Refer to page 21.)

Signal Name Description Condition Initial value

1

2

EUS(0.5%)

EU(100.0%)

EU(0.0%)

Always

Always

Always

Set alarm mode

OFF / 1~22

Refer to“Alarm type and code”

EUS ( 0.0~100.0% )

PV alarm, Deviation alarm

EU ( -100.0~100.0% )

Alarm group

Type of Alarm 1

Type of Alarm 2

Dead band of Alarm 1

Dead band of Alarm 2

Set value of Alarm 1

Set value of Alarm 2

※Reference : Display lamp will be OFF when output ON in inverted type.

Signal Name Description Condition Initial value

Communication group

RS485/RS422

Protocol

Communication rate

(B.P.S)

Parity check

Stop bit

Data length

Address

Response time

Set communication mode

PC.LINK(Set value:0) / PC.LINK SUM (Set value:1)

600(SV:0) / 1200(SV:1) / 2400(SV:2)

4800(SV:3) / 9600(SV:4)

NONE(SV:0)/EVEN(SV:1)/ODD(SV:2)

1bit (SV:1) / 2bit (SV:2)

7bit (SV:7) / 8bit (SV:8)

(Except PC LINK :8)

1~99 , maximum 31 devices

0~10. response time = (handling time + response

time) X 10ms

Optional

0

4

1

1

8

1

0

2019

5)

Communication group setting(Optional)

6)

Output group setting (Model : RT9-1)

(△ : Set point , : Minus Alarm set point , ▲ : Alarm set point )

Code

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

High absolute value

Low absolute value

High deviation value

Low deviation value

High deviation value (inverted)

Low deviation value (inverted)

High·Low deviation value

High·Low band

High absolute (inverted)

Low absolute (inverted)

High absolute with hold function

Low absolute with hold function

High deviation with hold function

Low deviation with hold function

High deviation with hold function

(inverted)

Low deviation with hold function

(inverted)

High·Low deviation with hold

function

High·Low band with hold

function

High absolute value with hold

function (inverted)

Low absolute value with hold

function (inverted)

Function

ALARM TYPE AND CODE

Alarm type

※

Hysteresis

(Notice) : Display lamp will be ON when output OFF in inverted type.

*

*

*

*

*

*

*

*

*

*

*

*

*

Marked alarms are not available in RT9-0

NX series are equipped with 4 wire /2 wire half-duplex the RS485 / RS422 communication

interfaces.Using the interfaces, communications are available with maximum 31 devices.

Output group

Output signal

Output operation

Cycle time

Hysteresis of universal type

Hysterecis of Heating/Cooling type

Output volume when input

disconnection Output (Out)

Maximum value of output

Minimum value of output

Always

Output code

1~3

Relay / SSR

ON/OFF Control

Heating/Cooling

Always

Except ON/OFF

Except ON/OFF

3

REV

30 sec

0

0.5%

0.0%

100.0%

0.0 %

Signal Name Description Conditi Initial value

Output type and mode selection

Refor to type of control output

REV: Reverse DIR: Direct action

1~1000 sec

EUS(0.0~100.0%)

0.0~10.0%

-5.0~105.0%

OL-L + 1Digit~ 105.0%

-0.5%~ OL-H-1Digit

Model:RT9-1

When setting,“Input type selection number” must be selected in the input type selection

mode and also“Output type selection number”must be selected in the output type selection

mode before moving to other mode.

If not, data of other group will be changed to prior value.

CAUTION

Output is selectable from Relay, SSR and Current(4~20mA DC)

For Recorder & Controller, output code 0~3 are available for your use.

Selection

NO.1

1370

-200

1

100.0

0.0

OFF

EUS(0.0%)

UP

Signal Name Description Condition Initial value

Input group

Input signal selection

High limit

Low limit

Decimal point(on voltage input)

Maximum on scale

(on voltage input)

Minimum on scale

(on voltage input)

PV filter

PV bias

Burn-out

Input type and mode selection

Refer to input signal and rang

Refer to input signal and range

( Notice : FR-H > FR-L )

Thermocouple or R.T.D : decimal point

of instrument / DC Voltage : 0~3

-1999~9999

Notice : SL-H › SL-L

Deimal point : according to DP-P

OFF/1~120sec

EUS (-100.0~100.0%)

OFF / UP / DOWN

Always

Always

Always

On voltage

input (mV,V)

On voltage

input (mV,V)

Always

Always

Always

Always

② Maximum and Minimum range

Press key to set Maximum and Minimum range using or

or key. Press key once more to finish.

22

Time setting

Set Year

Set Month

Set Day

Set Mour

Set Minute

Set Second

Set Y, M, D, T.

2000 ~ 2099

1 ~ 12

Always

Always

Always

Always

Always

Always

Always

Present

value

Present

value

Present

value

Present

value

Present

value

Present

value

0 ~ 59

1 ~ 31

0 ~ 23

0 ~ 59

21

7)

Input group setting

8)

Time group setting

When setting,“Input type selection number” must be selected in the input type selection

mode and also“Output type selection number”must be selected in the output type selection

mode before moving to other mode.

If not, data of other group will be changed to prior value.

CAUTION

① Input type selection

After power ON and when PV is indicating, press key for 3 sec to be displayed at

PV and 3 at SV. (If it is not indicated 3, set again in the level setting mode)

Control group is indicated when press key once more. At the time, input group is indicated

when press key and then“Input type and range selection is shown at SV when press .

At this time the input and range is selected by or key. Press key to confirm

③ Decimal point

Parameter is not indicated in T.C and R.T.D input, but when selecting voltage input“Decimal

point”mode is indicated. (set 1 : 0.0, set 2 : 0.00, set 3 : 0.000)

④

Maximum and Minimum on scale

It is the same function as Maximum and Minimum Range setting when R.T.D or thermocouple

input. This mode is indicated when voltage input ( 30, 31, 32, 33 )

⑤ PV filter

When PV value becomes unstable due to effects of noise, the filter helps suppress the unstable

status. (Range: OFF or 1~120sec. initial value: OFF)

⑥ PV bias

Use this function to adjust PV value in cases where it is necessary for PV value to agree with

another recorder or indicator, or when the sensor cannot be mounted in correct location.

(Range : -100.0~100.0% of SPAN, lnitial value : 0.0%)

Setting a value using or or key and press key to finish.

Signal Name Description Condition I nitial value

Graphic Text

List printing : You can check and keep an im portant data

which is set in each parameter.

24

3) RAMP FUNCTION

It is a rate of set value to arrive to set value

according to setting temperature and time.

ex) Present temp 20℃, set value 100℃,20℃per min.

1) Initial uprising set value(up,rt) : 100℃

2) Unit time : Minute min)

100

℃

시간/분(t)

1 2 3 4

80

60

40

현재온도 20 ℃

23

FUNCTION

11

4) ZOOM FUNCTION

When you choose Zoom function ON in Group control,

you can see a temperature with zooming as soon as you

select ON. The tenperature will be in center of paper.

ex) Scale : 0.0 ~ 100.0 ℃

Zoom ON : ZOOM IN 》PV. 25.5℃ at the center

1) AUTO TUNING

a) STANDARD TYPE AUTO-TUNING

Temperature

Set point

value(SV)

Process

value(PV)

Control

output ON ON ON

Time(t)

Time(t)

PID control

ON/OFF operation

AT started AT finished

AT finished

Under AT

OFF OFF

b) LOW PV TYPE AUTO-TUNING

The Auto tuning function automatically measures,

computes and sets the optimum Proportional band(P),

Integral time(I), and Deri-vative time(D). When Auto-tuning,

the controller performs ON/OFF

control and determine proper P.I and D. (Limit cycle type)

RT9-1 series controller have two types of Auto-tuning as

below.

Standard type auto-tuning :

This type is based on set point value (SV)

Low PV type auto-tuning :

This type is based on the value 10% lower than

the set point value (SV)

2) Auto-tuning in Zone PID

Zone PID automatically sets PID group in accordance

with a measured value. In Zone PID, auto-tuning sets

the proper PID value by recognizing a mid-value of

reference point as set point value.

Temperature

Set point

value(SV)

Process

value(PV)

Control

output ON ON ON

Time(t)

SV-10%

Time(t)

PID control

ON/OFF operation

AT started Under AT

OFF OFF

max. value of

measuriag

range (SV)

Reference

point 2

Reference

point 1

min. value of measuring range

PID 1

PID 2

PID 3

Time(t)

5) FUZZY CONTROL

Fuzzy control eliminates overshoot using Fuzzy Logic.

Employing Fuzzy control and Auto-tuning, the

controller effectively control as below.

When the controller starts control at the position

which has a big gap between SV and PV.

When reducing warming up time

When the load is fluctuating extreamly

When changing a set point value frequently

Target set

value

Set point value Subsidary target value

measured

value

Fuzzy Logic start Time(t)

Control output is set in high and low limit as operating range.

Output limit is -5~105% of output.

6) OUTPUT LIMIT

20mA

Output signal

12mA

4mA

OL-H

Output limit (%)

OL-L setting range

105%50%-5%

When A/D error or input disconnection occur in auto

mode, PID output is cut and than Pre-set output is

operated. (PO Output)

7) Emergency output

Hold function

Hold function : None

(Picture 1)

8) HOLD FUNCTION

Without hold function, Low limit alarm will be ON

when increasing temperature. (Picture 1)

SV

(low limit alarm)

Power ON

Alarm output ON OFF ON OFF

PV

(Picture 2)

SV

(low limit alarm)

Power ON

Alarm output OFF OFF ON OFF

PV

9) RECORDER

①Run/Stop : You can record or stop when you need.

②Feed : Paper be transmitted forcedly.

③Graphic or Text selectable

Other manuals for RT9

1

Table of contents

Other Hanyoung Controllers manuals

Popular Controllers manuals by other brands

IFM

IFM Ecomat 300 AC1318 Supplementary device manual

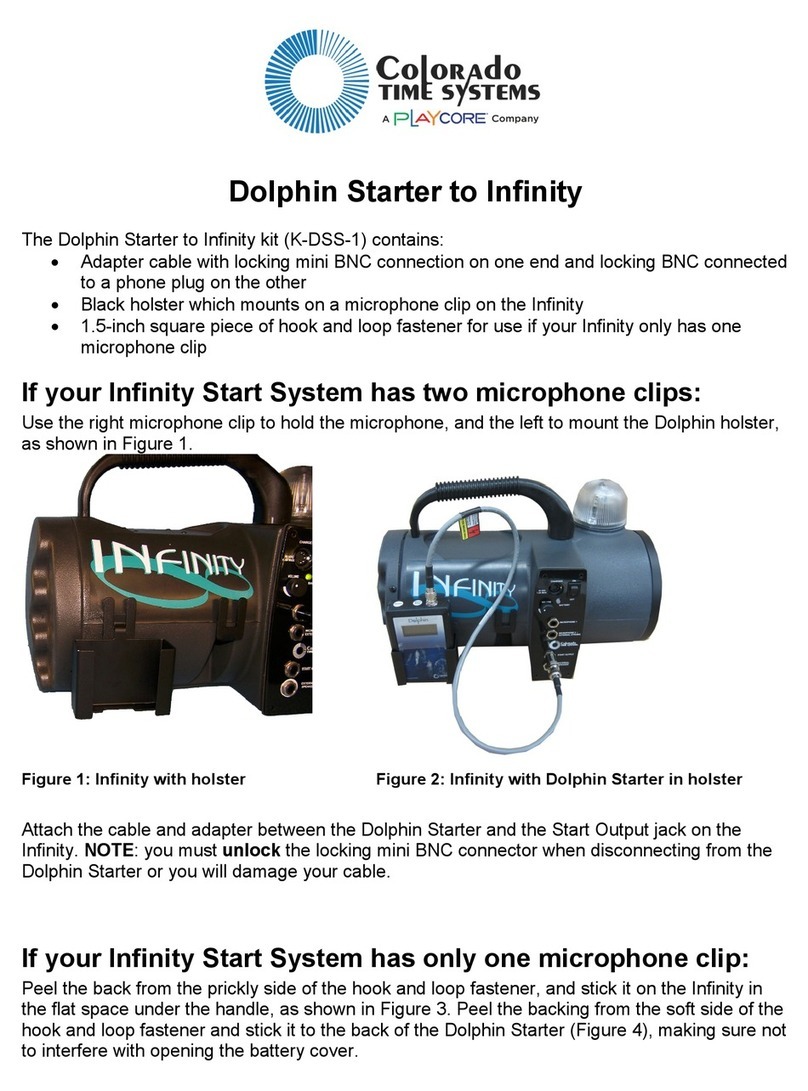

Playcore

Playcore Colorado Time Systems Dolphin quick start guide

NORALSY

NORALSY ECP190 manual

Remote Control Systems

Remote Control Systems ALPHA-3 instructions

ZPA Pecky, a.s.

ZPA Pecky, a.s. MODACT MOKPED 100 Ex Installation and operating instructions

Vacon

Vacon 10 quick guide