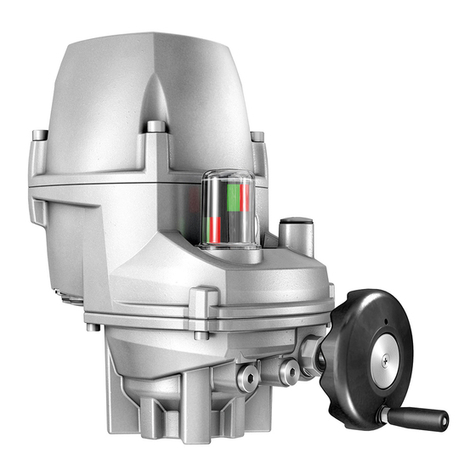

AUMA Aumatic AC 01.1 User manual

Other manuals for Aumatic AC 01.1

4

This manual suits for next models

1

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA PF-M25 Series Manual

AUMA

AUMA SA 07.2 User manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA SAVEx Series User manual

AUMA

AUMA SAN 07.2 User manual

AUMA

AUMA SGM 04.1 User manual

AUMA

AUMA ABG 10.2 User manual

AUMA

AUMA SAVEx 07.2 User manual

AUMA

AUMA VARIOMATIC SARV 10.1 User manual

AUMA

AUMA GSTI Series User manual

AUMA

AUMA SA 25.1 User manual

AUMA

AUMA SAVEx 07.2 User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA SG 05.1 User manual

AUMA

AUMA AUMATIC AC 01.2 Manual

AUMA

AUMA PROFOX PF-Q80 User manual

AUMA

AUMA AMB 01.1 User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA SA 16.2 User manual

Popular Controllers manuals by other brands

Extron electronics

Extron electronics Basic MediaLink Controllers MLC 52 IR Brochure & specs

Sentera Controls

Sentera Controls RDCV Mounting and operating instructions

Perma

Perma STAR Series operating instructions

Assa Abloy

Assa Abloy CLIQ CLM installation instructions

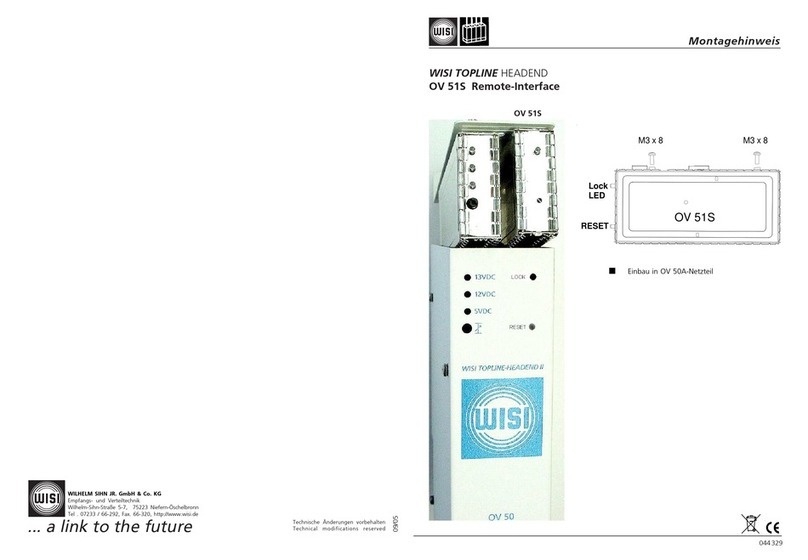

Wisi

Wisi TOPLINE HEADEND OV 51S Mounting instructions

Micro Air Corporation

Micro Air Corporation FX2-DX Operation manual

Lumel

Lumel RE62 User Manual & Quick Start

McIntosh

McIntosh MPC500 owner's manual

LED Creative

LED Creative Byte user guide

Rotek

Rotek R250 quick start guide

VAT

VAT 47146-E7 Series Installation, operating, & maintenance instructions

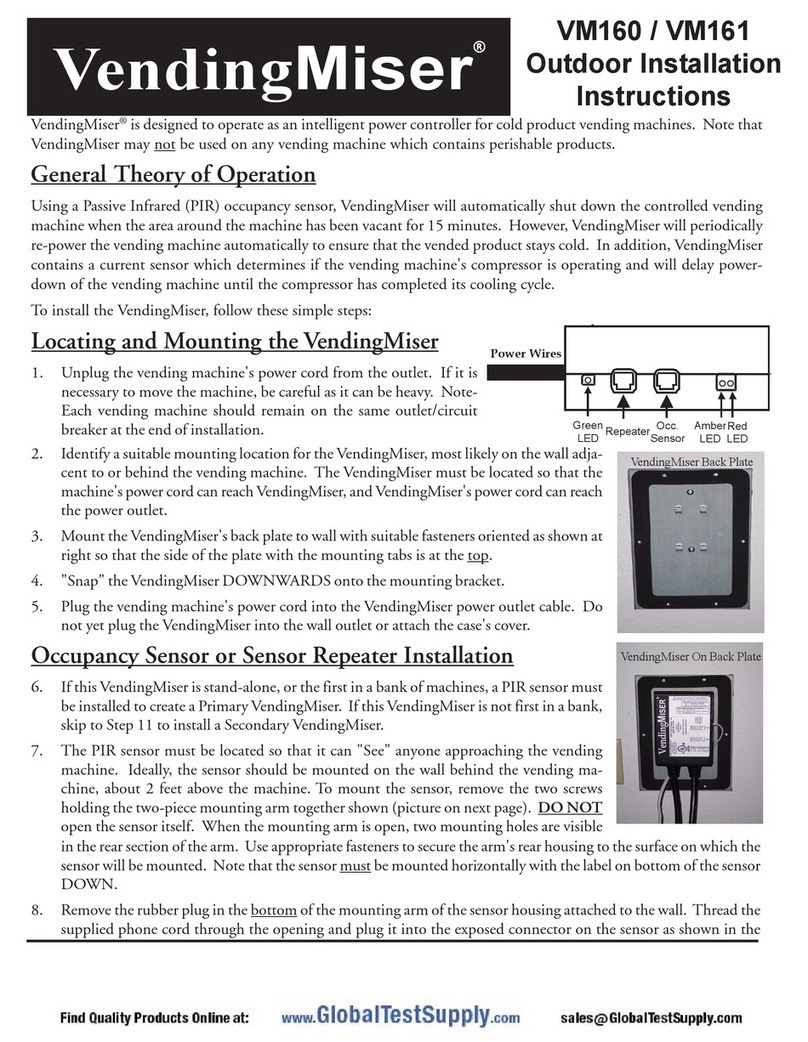

USA Technologies

USA Technologies VendingMiser VM160 Outdoor Installation Instructions