Hardinge HQC User manual

Installation Instructions for the Hardinge

HQCTM

Quick-Change Collet System

Using the Hardinge Hydraulic Quick-Change Wrench

The type of machineandthe size of the collet head determineswhich colletwrench size is used.

Installthe Hardinge HQCmQuickGhange collet system as follows:

1.

lndex the spindle to the normal collet change posi-

tion. Jogging the spindle until the keyway is verti-

cal allows for an easier collet change reference.

2.

Power down the machine and remove the collet

Q

from the spindle.

-

NOTE

-

The hydraulic wrench pin travel limits how far the

neck of the collet head is compressed. Do not

compressthe neck any further than necessary.

Set the wrench pintravel as follows:

A. Loosen the lock nut on screw

"A

on the hy-

draulic wrench.

B.

Adjust the screw to limitthe closing of collet head neck

"B"

until it just fits in quick-changecollet body

"C".

The neck is compressed tighter byturningthe screw counterclockwise.

C.

Tightenthe lock nut.

Make certainthat the collet body has a collet head attached before installingit inthe spindle.

Ifthere is no collet head onthe body, mount a head as follows:

A. Plugthe hydraulic power unit intoa properlygrounded 110v receptacle.

B.

Put the collet head on the hydraulicwrench pins.

-

Warning

-

Keep clear of the slots on the collet head. Activating the Hydraulic Quick-Change

Wrench compresses the neck of the collet head.

A

pinch point exists when the neck

of the collet head is compressed.

C.

Step on the foot switch toturn ON the hydraulic power unit and compress the neck of the collet head

enoughtofit inthe body.

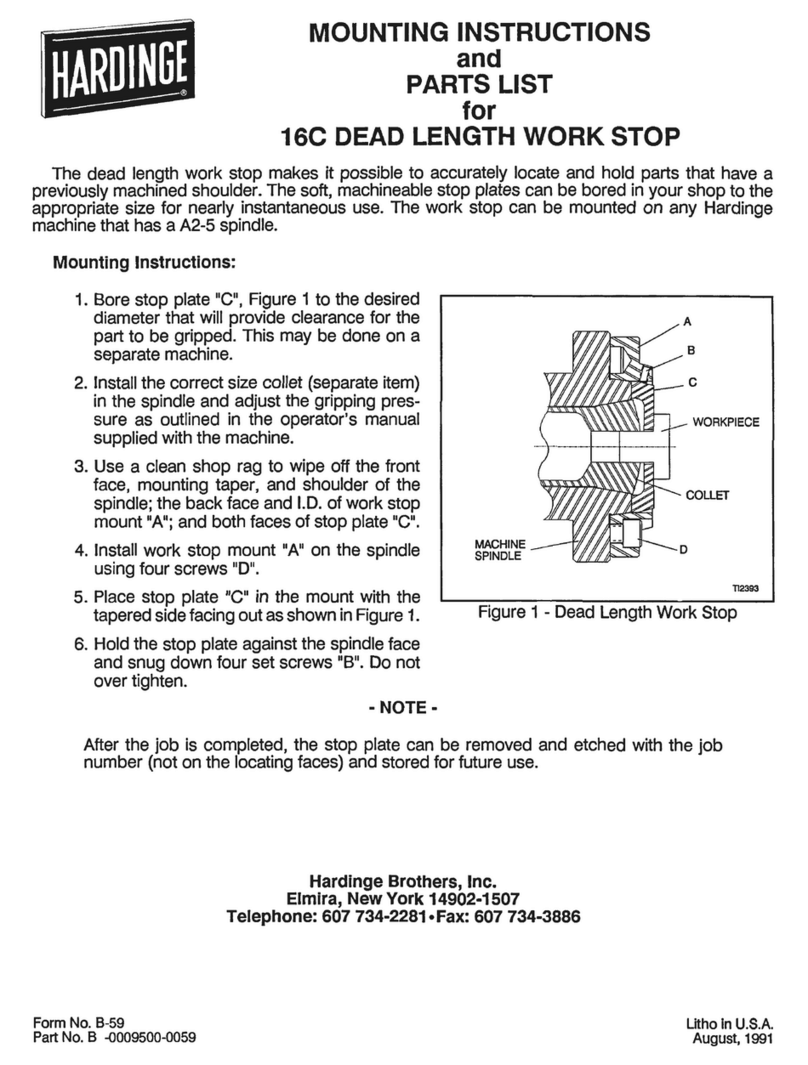

D. Align the three slots of the collet head with the lugs on the body and insert the locking lips of the

head intothe groove inthe body.

E.

Releasethe switch and pullthe hydraulicwrench from the collet head.

Align the keyway inthe head with the key inthe spindle and insert the body and head as an assembly into

the spindlethe same as a standard collet.

Thread the drawtube tothe collet body.

Put a pieceof stock at least

4

inches [I02 mm] long inthe collet.

Closethe collet to check the chuckingforce. Adjust the chucking force as needed.

-

NOTE

-

Once the collet body is in place, only change the collet head for the size and shape of

the stock required for each job.

Change the Hardinge HQC" Quick-Change collet heads as follows:

1. lndex the spindle with the Quick-Changecollet head to the normal collet change position. Jog the spindle

untilthe spindle keyway is vertical. Power downthe machine.

2.

Wipe away any chips or oil and clean the pinholeson the face of the collet head.

3.

Plugthe hydraulic power unit into a properly grounded 110v receptacle.

4.

Insertthe hydraulic wrench pins intothe pin holes. (continuedon next page)

FormNo. B-57

Part No.

B

-0009500-0057 Litho in U.S.A.

August,lW

5. Step on the foot switch to turn ON the hydraulic power unit until the neck of the collet head is compressed

enoughto be removed from the body.

6. Removethe collet head from the bodyand spindle.

-

NOTE

-

DO NOT

JOG

the spindle while the collet head is removed from the collet body. Spindle

movementwill changethe alignment betweenthe spindle key and the lugs on the collet body.

7. Releasethe foot switch and pullthe collet headfrom the hydraulic wrench pins.

8.

Installa clean collet head on the wrench pins.

-

Warning

-

Keep clear of the slots on the collet head. Activating the Hydraulic Quick-Change

Wrench compresses the neck of the collet head. A pinch point exists when the neck

of the collet head is compressed.

9.

Step on the foot switch to turn ON the hydraulic power unit and compress the neck of the collet head so

that it can be inserted inthe body.

10. Align the head keyway with the key in the spindle while aligning the body lugs with the slots in the head;

then, insertthe lockinglips of the head intothe groove inthe body.

11. Releasethe foot switch and withdrawthe hydraulic wrench from the collet head.

12.

Gripthe collet head and pullon it to make certain that it is mounted securely inthe body.

13. Put

a

pieceof stock inthe collet. Closethe collet and adjust the chuckingforce.

-

NOTE

-

Collet heads may be difficult to re-insert in the collet body

if

oil and other contaminates are not

cleanedfrom the head segmentsand inserts.

14. Cleanthe collet heads as follows beforethey are stored or re-insertedinthe collet body:

A.

Wipe oil and any contaminatesfrom the head segments and inserts.

B.

Agitate the head in

a

containerof cleaning solvent.

C. Use compressed air to blow off the excess solvent.

D.

Wipe the head dry with a clean shop towel.

E.

Re-insert the collet head in the body or store

it

in the originaltube or box. If the collet head is to be

stored, make certainthat an anti-humidity chip is inthe containerto prevent rust.

Replacethe Hardinge

HQC"

Quick-Change collet head inserts as follows:

1. Removethe collet head from the collet body per the instructionsabove.

2.

Wipe the head as clean as possiblebefore replacingthe inserts.

-

NOTE

-

Removeand replaceonly one insert at atime.

3. Pry the retaining plugs and insert materialfrom the slots and clean the collet segment surfaces.

4. Place the tapered side of the insert toward the outside of the head and push

it

down into the space

betweenthe segments. Pressthe roundtabs intothe holes untilthey bottom.

5. Trim the inserts per drawing H-1100, which is includedwith each collet head. If the drawing information is

not available, trim the tapered tip near the neck and the long part of the insert which extends into the

opening inthe center of the head as follows:

A.

Mark each part a minimum of 1/16inch [I.6 mm] withinthe edges of the segments.

B.

Carefully removethe insert.

C. Cut the tabs at the mark.

6.

Replacethe insert and pressthe roundtabs fully intothe bottom of the holes.

7. Repeat steps #3 through #6 to changethe other two inserts.

8.

Make certainthat all three insertsare bottomedfully inthe holes.

9. Cover each of the insert holeswith a round nylon retainingplug (Hardingepart number 7759).

10. Usea soft-facedhammer and tap each plugflush with the surface of the collet head.

Hardinge Brothers, Inc.

Elmira,

New

York

14902-1507

U.S.A.

O

1991, HardingeBrothers, lnc.

Table of contents

Other Hardinge Tools manuals