Harford Attachments Pro-lok User manual

DOUBLE-LOCKING

MECHANICAL QUICK HITCH

Installation & Operation Manual (English)

Important: This manual should be kept with the excavator at all times

for easy reference.

2 ©2022 Harford Attachments Ltd

PROLOK/GEN/MAN/R4

Table of Contents

Contents

Item Checklist ..................................................................................................................................3

Introduction......................................................................................................................................4

Safety Features.................................................................................................................................4

Guide to Safety Symbols..................................................................................................................5

General Safety Information..............................................................................................................5

Safety labels .....................................................................................................................................6

Safety Sticker and Data Plate Location Guide.................................................................................7

Specified Parameters........................................................................................................................7

Storage Instructions..........................................................................................................................7

End of Life Considerations ..............................................................................................................8

Compatible Attachments..................................................................................................................8

Fitting the Harford Pro-Lok to your Excavator................................................................................9

Connecting an Attachment to your Pro-Lok..................................................................................10

Releasing an Attachment................................................................................................................12

Lifting a Load.................................................................................................................................12

Important Maintenance Information ..............................................................................................14

Routine Maintenance Information .................................................................................................15

Warranty.........................................................................................................................................16

Example Declaration...................................................................... Error! Bookmark not defined.

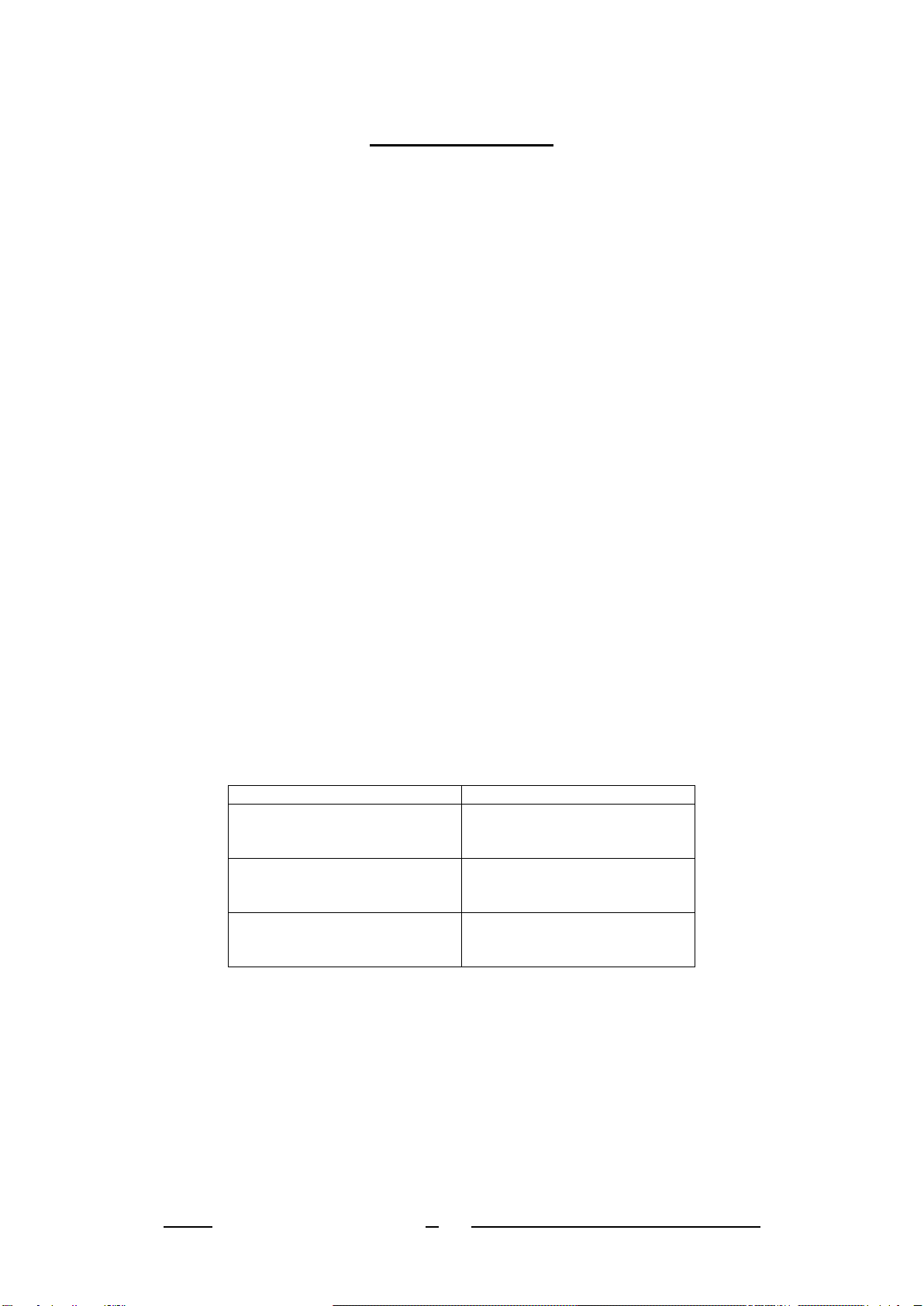

Serial Number Location

Serial Number

Stamped plate on side of hitch

Sticker on rear of control box

Sticker on solenoid manifold

Serial number table (above) for completion by owner

This manual part number PROLOK/GEN/MAN/R4

If this Pro-Lok quick hitch to is to be used on a jobsite, the operator shall follow the site rules where the

machine is to be used.

If at any time in the future, you require additional information on the

HARFORD PRO-LOK quick hitch or any aspects of its use, please do not hesitate to contact:

Harford Attachments Ltd

Spar Road, Norwich. NR6 6BY. England

Tel +44 (0) 1603 403099

©2022 Harford Attachments Ltd 3

PROLOK/GEN/MAN/R4

Item Checklist

The following items are supplied with the Harford Pro-Lok.

Item

Supplied

Mechanical quick hitch

✓

CE Declaration of Conformity

✓

Ratchet

✓

Installation and operation manual

✓

Safety pin not required stickers

✓

Warning label

✓

Lifting eye test certificate

see note

Note: The lifting eye test certificate is only supplied if a lifting eye is fitted to the Pro-Lok during

manufacture.

4 ©2022 Harford

Attachments Ltd PROLOK/G

EN/MAN/R4

Introduction

Thank you for purchasing the Harford Pro-Lok quick hitch for excavators. The

information contained in this manual should be read carefully and understood by all

operators of the quick hitch, to ensure optimum performance of the product.

The Harford Pro-Lok is designed to pick up standard attachments for excavators,

made to OEM specification. The adjustable sliding wedge plate provides a locking

device, which is free from movement. This minimises any wear over the lifetime of the

hitch.

There are several unique safety features are built-in to the Pro-Lok. The combination

of which results in a safe, tough and durable product. Regular maintenance of the hitch

will give you many hours of reliable, trouble-free operation.

It is important that the installation is carried out by a competent person, preferably

someone with experience of quick hitch operation.

The operation and maintenance instructions should be followed carefully to ensure safe

and correct use of the quick hitch. Failure to do so could cause injury and/or invalidate

the product warranty.

IMPORTANT:

All Harford Pro-Lok hitches are CE certified, having undergone a thorough

evaluation process by Harford Attachments. Any subsequent modification to the

hitch will invalidate this certification and the product warranty.

Safety Features

There are several unique safety features incorporated into the Harford Pro-Lok quick

hitch. The features combine to prevent attachments becoming unintentionally

disengaged from the quick hitch.

1. The wedge plate is tightened the same way as a bolt, i.e., in a clockwise direction.

2. A patented anti-unwind feature is built into the threaded actuator. This can easily

be adjusted to ensure firm rotation during maintenance.

3. The geometry of the wedge plate and quick hitch locking surface creates a locking

mechanism in its own right. The clamping force of the wedge surface is up to 4.5

times the force applied by the threaded actuator. This feature creates a secure and

safe locking device.

4. A sprung loaded front lock ensures that the front pin is secure when connecting an

attachment and during operation. This is visible to the operator from the cab.

5. A rear lock indicator allows the operator to check that the rear locking wedge is in

its correct operating position. This is also visible from the cab.

©2022 Harford Attachments Ltd 5

PROLOK/GEN/MAN/R4

Guide to Safety Symbols

SAFETY NOTICE:

These indicate specific precautions and recommended personal protective

equipment (PPE) for use during the given situations.

IMPORTANT:

Specific points to note and situations to be aware of.

IMPORTANT:

Prohibited situations are specified and should be avoided.

WARNING:

Situations of danger in which the operator or installer must pay particular

attention to the information provided to minimise the risk of injury to self or

others

General Safety Information

IMPORTANT:

Due to the weight of the product, handling of the hitch prior to installation should be

done using appropriate lifting aids for the weight, which can be found on the punched

information plate affixed to the side of the hitch.

IMPORTANT:

Ensures that the machine to which the Pro-Lok quick hitch is installed does not

exceed its safe working load (SWL), taking into account the additional weight of the

hitch, which is stated on the punched information plate affixed to the side of the hitch.

IMPORTANT:

Be aware that the addition of the Pro-Lok quick hitch will increase the reach distance

of the excavator arm, which may cause it to impact nearby objects and people or to

impact the operators cab, leading potentially to property damage, injury, loss of limb

or fatal injury.

IMPORTANT:

It is recommended for safety reasons that the machine to which this Pro-Lok quick

hitch is installed is operated by an experienced, competent person, trained to ISO

7130:2013 or later.

IMPORTANT:

If hammers are to be used for long periods of time the quick hitch should be removed

to prevent unnecessary wear.

IMPORTANT:

During installation, no alterations must be undertaken to any protective structure

(e.g., rollover protective structures (ROPS), tip-over protective structures (TOPS), or

falling object protective structures (FOPS) are permitted except where authorised by

the manufacturer, or according to the manufacturer’s specifications.

Other manuals for Pro-lok

1

Table of contents

Other Harford Attachments Construction Equipment manuals