Harford Attachments Safelock User manual

MECHANICAL QUICK COUPLER

Installation & Operation Manual (English)

Important: This manual must be kept with the excavator at all

times and referred to as required

Harford Attachments Ltd

2 ©2022 Harford Attachments Ltd

SAFELOCK/GEN/MAN/R5

Table of Contents

Item Checklist ..................................................................................................3

Introduction......................................................................................................3

Guide to Safety Symbols .................................................................................4

Safety features.................................................................................................4

Safety labels ....................................................................................................5

Safety Sticker and Data Plate Location Guide.................................................6

Specified Parameters.......................................................................................6

Storage Instructions.........................................................................................6

End of Life Considerations...............................................................................7

Compatible Attachments..................................................................................7

Fitting the Safelock coupler to the Excavator...................................................8

Connecting an Attachment.............................................................................10

Releasing an Attachment...............................................................................11

Lifting a Load .................................................................................................11

Maintenance ..................................................................................................12

Warranty ........................................................................................................13

Example Declaration........................................ Error! Bookmark not defined.

Serial Number Location

Serial Number

Stamped plate on side of hitch

Sticker on rear of control box

Sticker on solenoid manifold

Serial number table (above) for completion by owner

This manual part number SAFELOCK/GEN/MAN/R5

If this Safelock quick hitch to is to be used on a jobsite, the operator shall follow the site rules

where the machine is to be used.

If at any time in the future, you require additional information on the

HARFORD SAFELOCK quick hitch or any aspects of its use, please do not hesitate to

contact:

Harford Attachments Ltd

Spar Road, Norwich. NR6 6BY. England

Tel +44 (0) 1603 403099

email: info@harfordattachments.com website: www.harfordattachments.com

©2022 Harford Attachments Ltd 3

SAFELOCK/GEN/MAN/R5

Item Checklist

The following items are supplied.

Item

Supplied

Safelock Mechanical quick coupler

✓

CE Declaration of Conformity

✓

Installation and operation manual

✓

Lifting eye test certificate

see note

Note: The lifting eye test certificate is only supplied if fitted to the quick coupler at

manufacture.

Introduction

Thank you for choosing to purchase the Harford Safelock quick coupler for excavators. The

information contained in this manual should be thoroughly read and understood by all

operators of the coupler.

The Harford Safelock quick coupler is designed to work with dedicated Safelock buckets and

attachments. The sliding wedge plate provides a locking device which has a spring pressure

acting on it, which means minimal wear over time.

It is important that installation be carried out by a competent person, preferably with quick

coupler installation experience.

It is essential that the operation and maintenance instructions are followed carefully to ensure

safe and reliable operation of the quick coupler at all times. Failure to do so could result in

serious injury and invalidate the product warranty. Several safety features are built into the

design of the coupler, which make it very safe and reliable.

This Manual contains installation and operation instructions for the mechanical Harford

Safelock quick coupler. If the quick hitch you are operate is not a Safelock, please refer to

the appropriate manual.

WARNING: The Safelock coupler is designed to pick up attachments which are dedicated

to a particular Safelock model (SL) and category (T); this information is shown on the

data plate. DO NOT use oversized attachments with this quick coupler as personal injury

could occur and any product warranty will be invalid.

IMPORTANT: This quick coupler has undergone CE certification by Harford Attachments.

Any modification will invalidate this certification and therefore new, independent

certification would be required.

4 ©2022 Harford Attachments Ltd

SAFELOCK/GEN/MAN/R5

Guide to Safety Symbols

SAFETY NOTICE:

These indicate specific precautions and recommended personal protective

equipment (PPE) for use during the given situations.

IMPORTANT:

Specific points to note and situations to be aware of.

IMPORTANT:

Prohibited situations are specified and should be avoided.

WARNING:

Situations of danger in which the operator or installer must pay particular attention

to the information provided to minimise the risk of injury to self or others

Safety features

There are several important safety features that are an integral part of the Harford Safelock

Mechanical quick coupler. Each feature is designed to reduce the eventuality of an

attachment becoming disengaged whilst connected to the coupler.

1. The status of the safety handle is clearly visible by the operator.

2. Attachments can only be released when the safety handle is fully open.

3. The safety handle is retained with a spring-loaded safety lock.

4. The spring pressure acting on the locking wedge ensures there is no movement between

the coupler and dedicated attachment.

IMPORTANT: Due to the weight of the product, handling of the hitch prior to

installation should be done using appropriate lifting aids for the weight, which can be

found on the punched information plate affixed to the side of the hitch.

IMPORTANT: Ensures that the machine to which the Safelock quick hitch is installed

does not exceed its safe working load (SWL), taking into account the additional

weight of the hitch, which is stated on the punched information plate affixed to the

side of the hitch.

IMPORTANT: Be aware that the addition of the Safelock quick hitch will increase the

reach distance of the excavator arm, which may cause it to impact nearby objects and

people or to impact the operators cab, leading potentially to property damage, injury,

loss of limb or fatal injury.

IMPORTANT: It is recommended for safety reasons that the machine to which this

Safelock quick hitch is installed is operated by an experienced, competent person,

trained to ISO 7130:2013 or later.

IMPORTANT: If hammers are to be used for long periods of time the quick hitch

should be removed to prevent unnecessary wear.

©2022 Harford Attachments Ltd 5

SAFELOCK/GEN/MAN/R5

IMPORTANT: During installation, no alterations must be undertaken to any protective

structure (e.g., rollover protective structures (ROPS), tip-over protective structures

(TOPS), or falling object protective structures (FOPS) are permitted except where

authorised by the manufacturer, or according to the manufacturer’s

specifications.

IMPORTANT: It is not permitted to transport or lift persons using the Safelock quick

hitch.

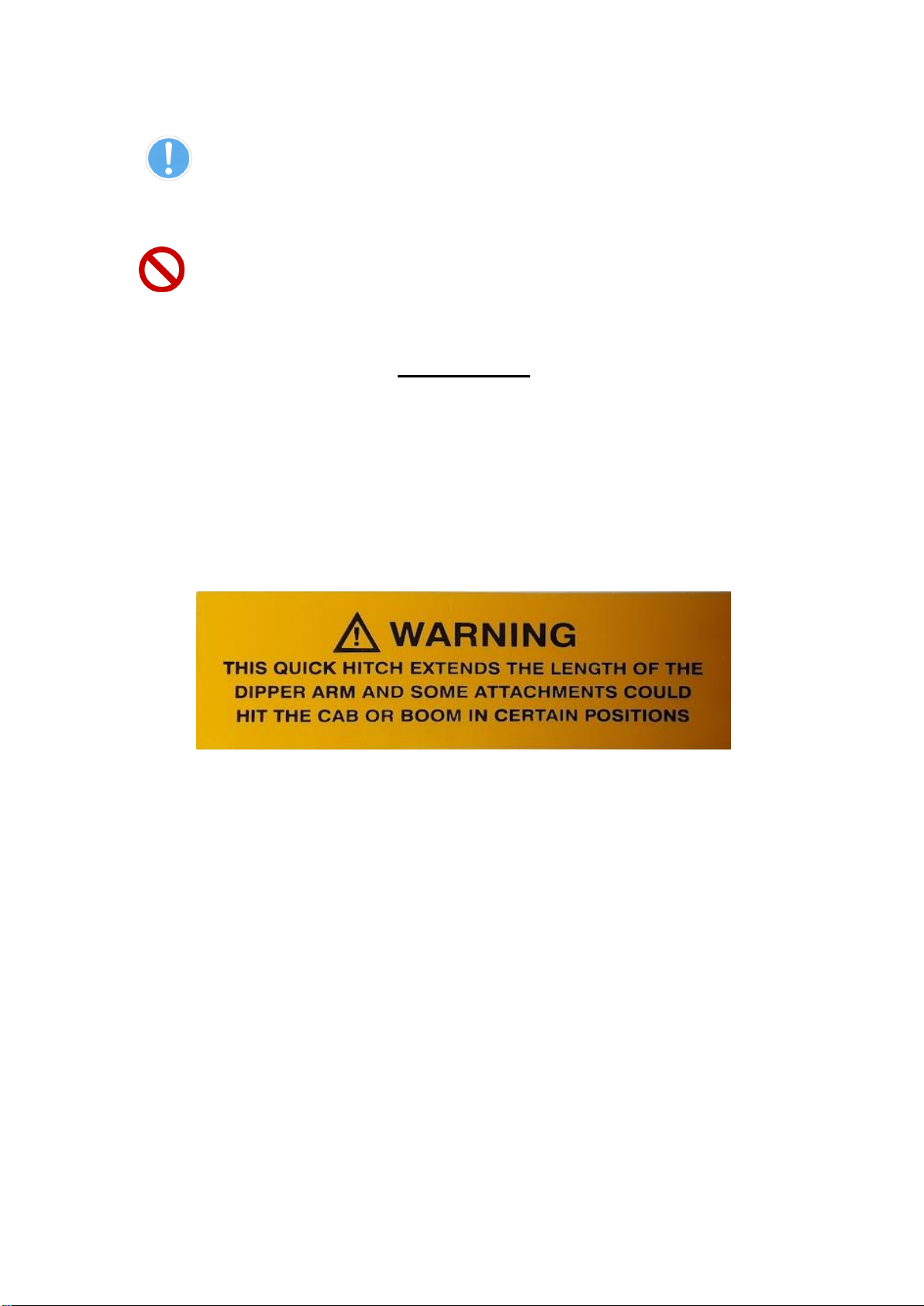

Safety labels

All safety labels are to be kept clean and legible and should be replaced if missing or

unreadable by contacting the manufacturer, Harford Attachments, on +44 (0)1603 403099.

The following safety label is supplied in the required quantities with the Safelock fitting kit.

Their locations are given in the description, and shown graphically in the following diagram.

A) One yellow warning sticker to be affixed prominently in the cab warning that the

attachment increases the overall length of the dipper arm and could therefore

impact the cab or boom if care is not taken:

6 ©2022 Harford Attachments Ltd

SAFELOCK/GEN/MAN/R5

Safety Sticker and Data Plate Location Guide

Specified Parameters

Your Harford Safelock quick hitch has been designed to the meet the original equipment

manufacturer (OEM) specifications of the excavator for which it was ordered. The excavator

model for which it was designed and the maximum load category of the hitch can be found on

the punched information plate affixed to the side of the quick hitch body.

Storage Instructions

If your Safelock Quick hitch is to be removed for an extended period of time, please observe

the following instructions:

SAFETY NOTICE:

It is strongly recommended that the Safelock quick hitch is lowered to the ground, the

machine switched off, the key removed and the parking brake engaged, blocks applied to

the wheels, the system depressurised and that safety gloves are worn during any

maintenance on the quick hitch. A warning label should be affixed prominently in the cab to

warn others of ongoing maintenance.

•Wearing appropriate PPE, hydraulic fluid should be drained from the quick hitch and

disposed of according to regulations.

•Basic maintenance tasks should be carried out on the hitch, including cleaning and

greasing (see the Daily Checks list for further information).

•The hitch should be covered and stored in a safe, dry location.

1 of A

Safelock quick

hitch

Lifting Eye (if

installed)

Location of data

plate

©2022 Harford Attachments Ltd 7

SAFELOCK/GEN/MAN/R5

End of Life Considerations

Your Safelock quick hitch is predominantly made of recyclable materials. If your quick hitch

should become damaged beyond repair and is to be disposed of, please be aware of the

environmentally unfriendly nature of the lubricants and hydraulic fluids used. Please check the

cleaning and disposal instructions of the supplier of the contaminants before disposing of the

hitch in an environmentally responsible manner.

Compatible Attachments

Attachment

Can be used (up to the

safe working load)

Can be used, with

limitations

Cannot be used

All Harford Safelock

Attachments

Buckets

Hammer or breaker

For limited periods. For

constant or long-term

use, the Pro-Lok hitch

should be removed to

prevent unnecessary

wear

Pallet forks

Under no

circumstances

Lifting Objects with

hitch

Only if a factory fitted

lifting eye was supplied

with the hitch, certified

to the SWL.

Operator cages

Under no

circumstances

Thumb

Ripper Tooth

Rake

IMPORTANT:

Attachments should be within the recommended limits of the carrying machine when

the quick coupler is attached

8 ©2022 Harford Attachments Ltd

SAFELOCK/GEN/MAN/R5

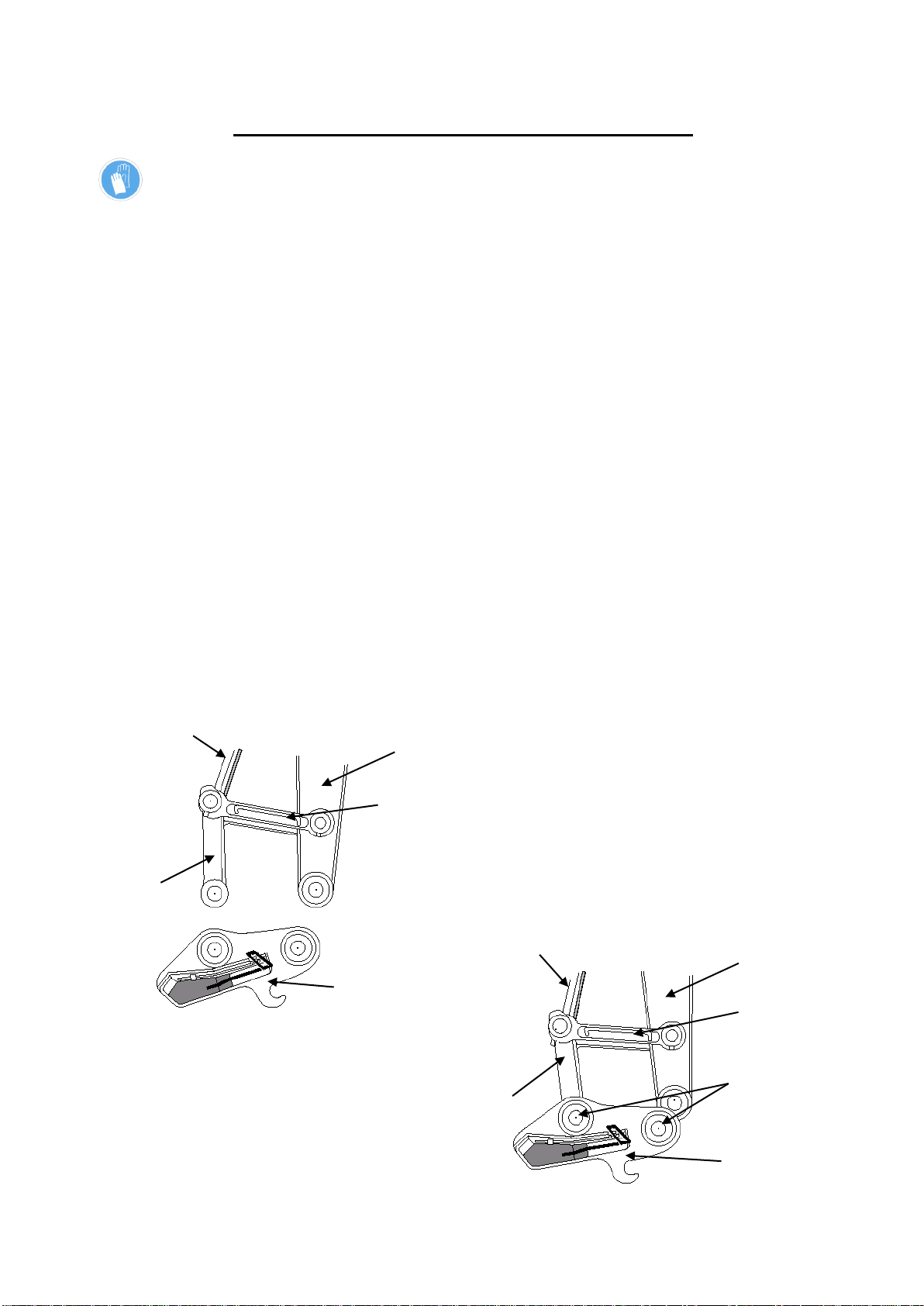

Crowd Cylinder

Idler Link

Crowd Link

Safelock Coupler

Dipper Arm

Fitting the Safelock coupler to the Excavator

SAFETY NOTICE: It is recommended that safety gloves are worn during the installation of

the coupler. It should not be necessary to use excessive force, at any stage of the

installation procedure.

1. Remove any existing attachment from the machine dipper arm and crowd link arm.

The two original pins that are removed from these pivot points must be used to attach

the coupler to the excavator (These pins are usually hardened and greaseable).

2. Position the Safelock coupler within easy operating reach of the excavator.

3. With the crowd link positioned above the rear mounting hole, lower the dipper arm to

within 50-75 mm of the top of the Safelock, as shown in Figure 1.

4. Extend the crowd cylinder. Carefully align the crowd link arm between the two rear

mounting holes. Replace any ‘O’ rings that were removed previously and slide one of

the original pins through the coupler and crowd link arm. Securely fix the pin in place

by using the original retention method.

5. Operate crowd and boom cylinders simultaneously, to slowly raise the hitch and align

the front mounting holes as shown in

.Carefully align the dipper arm between the two front mounting holes.

Replace any ‘O’ rings that were removed previously and slide the other original pin

through the coupler and dipper arm. Securely fix the pin in place by using the original

retention method.

6. Use the excavator hydraulics to carefully rotate the coupler to the extremes of the

crowd cylinder (e.g., no stroke and full stroke). Check the clearance of the Safelock

with any part of the dipper arm and linkage.

Figure 1

Figure 2

Crowd Cylinder

Idler Link

Crowd Link

Safelock Coupler

Original Pins

Dipper Arm

©2022 Harford Attachments Ltd 9

SAFELOCK/GEN/MAN/R5

WARNING: During operation there should be no movement between the quick hitch

and attachment. If any movement is detected, stop operation immediately, lower

attachment to the ground and inspect the hitch.

WARNING: The quick hitch extends the length of the dipper arm and some attachments

could hit the cab or boom in certain positions.

WARNING: The quick hitch is designed to accept attachments which are manufactured

to OEM specifications and capacities. Oversized attachments could be hazardous

when used with this quick hitch and could invalidate any warranties.

WARNING:

Ensure the Safe Working Load of the excavator is not exceeded by the combined

weight of the hitch, attachment and load. Refer to the excavator manufacturer’s

information.

IMPORTANT:

If hammers are to be used for long periods of time the quick hitch should be removed to

prevent unnecessary wear.

IMPORTANT:

The use of pallet forks with this quick hitch is not permitted

IMPORTANT

The operator of the machine should be adequately trained in the quick hitch’s safe

operation before use.

10 ©2022 Harford Attachments Ltd

SAFELOCK/GEN/MAN/R5

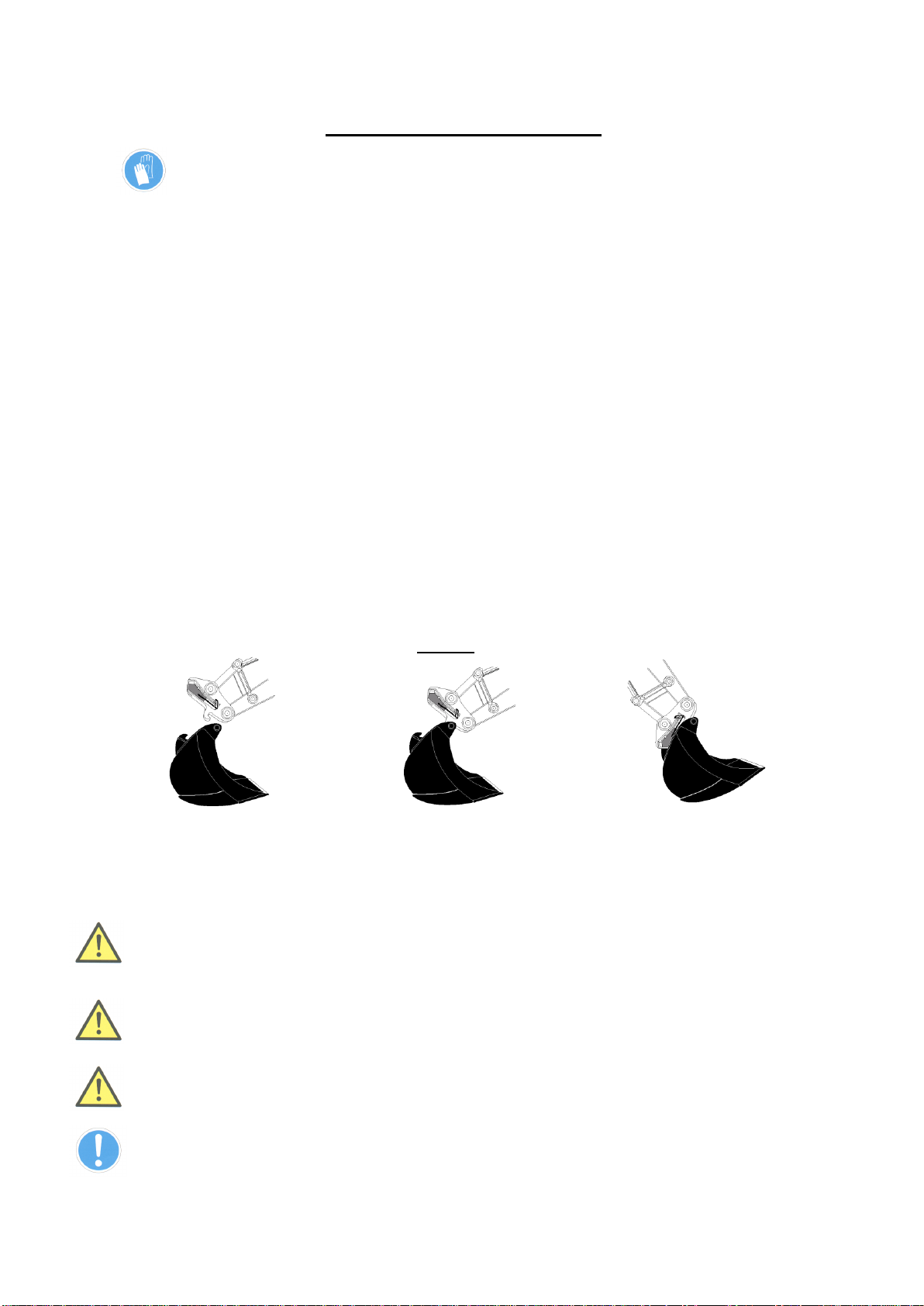

Connecting an Attachment

SAFETY NOTICE: It is recommended that safety gloves are worn during the attachment

changeover operation.

1. Disengage the safety lock and release the safety handle.

2. Fully open the safety handle.

3. Lower the quick hitch front ‘C’ shaped jaw down towards the front attachment pin as

shown in Figure 3, step 1.

4. Engage ‘C’ shaped jaws with the front attachment pin as shown in Figure 3, step 2.

5. Extend the crowd cylinder down towards the rear locking plate and lift the attachment

at the same time as shown in Figure 3, step 3.

6. Keep extending the crowd cylinder so that the front attachment pin is firmly seated in

the ‘C’ shaped jaw and the Safelock coupler is seated onto the rear locking plate.

7. Close the safety handle against the safety lock. Ensure the attachment is clear of the

ground (failure to do so could put undue stress on the front hooks and cause

distortion).

8. Engage the safety lock and lock the safety handle.

9. Visually check that the attachment is connected and locked correctly.

Figure 3

WARNING: During operation there should be no movement between the coupler and

attachment. If any movement is detected, stop operation immediately, lower attachment to the

ground and inspect the coupler.

WARNING: The Safelock coupler is designed to pick up attachments which are dedicated to a

particular Safelock model (SL) and category (T), which is shown on data plate. DO NOT

use oversized attachments with the coupler as personal injury could occur and the product

warranty will be invalidated.

WARNING: Ensure that the Safe Working Load of the excavator is not exceeded. Refer to the

manufacturer’s operation manual for this information.

IMPORTANT: If hammers are to be used on the excavator for long periods of time, remove

the Safelock to prevent unnecessary wear and tear.

Step 1 –Lower hitch towards

front attachment pin

Step 2 –Engage ‘C’ shaped

jaw with front attachment pin.

Step 3 –Crowd and lift attachment

until there is contact with rear

locking surface

©2022 Harford Attachments Ltd 11

SAFELOCK/GEN/MAN/R5

Releasing an Attachment

1. Place the attachment on level ground or in a position so that once released the

attachment cannot roll away from the coupler. Ensure people and property are well

clear of the immediate area.

2. Disengage the safety lock and release the safety handle.

3. Fully open the safety handle.

4. Using the crowd cylinder of the excavator, rotate the Safelock away from the rear

locking plate of the attachment and then lift away from the front attachment pin.

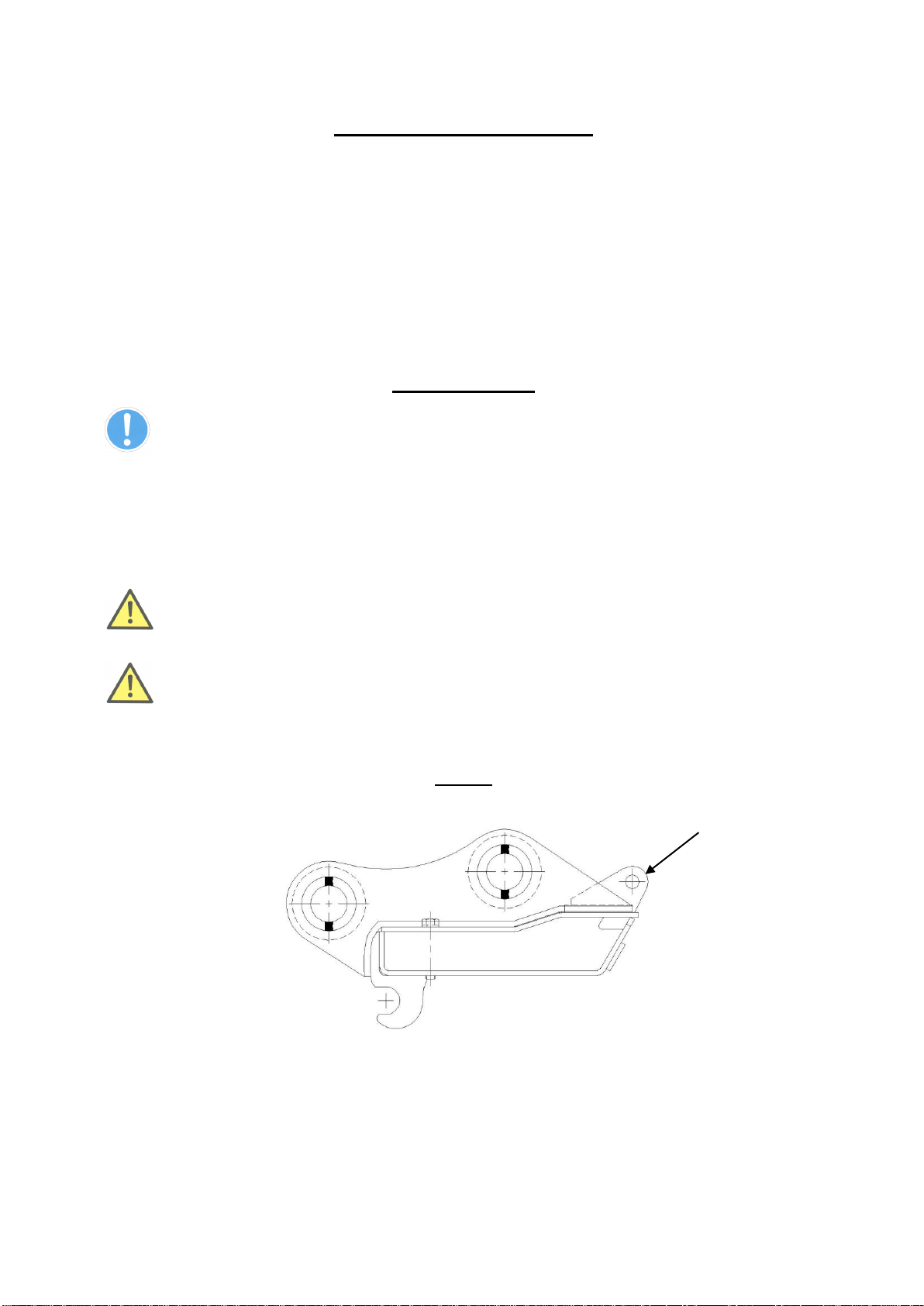

Lifting a Load

IMPORTANT: This section only applies to Safelock couplers which are manufactured with

a lifting eye as shown in Figure 4.

1. Ensure that the load to be lifted does not exceed the safe working load of the lifting eye.

2. The lifting eye is designed to be used with a lifting shackle with the same safe working

load rating.

3. Release any attachment from the Safelock coupler prior to using it to lift a load.

WARNING: Ensure that the safe lifting capacity of the excavator is not exceeded. Refer to

the excavator manufacturer’s operational manual for this information.

WARNING: If your Safelock hitch was not supplied with a factory fitted and certified lifting

eye you must not attempt to lift loads that are not wholly contained within a bucket-type

attachment, it is unsafe, may lead to damage and will invalidate the warranty.

Figure 4

Lifting Eye

12 ©2022 Harford Attachments Ltd

SAFELOCK/GEN/MAN/R5

Maintenance

SAFETY NOTICE:

It is strongly recommended that the Safelock quick hitch is lowered to the ground, the

machine switched off and the ignition key removed, the parking brake engaged and

blocks applied to the wheels, and safety gloves are worn during any maintenance on

the quick hitch. A warning label should be affixed prominently in the cab to warn

others of ongoing maintenance.

Daily:

1. Remove dirt and debris from all moving parts. It is necessary to remove any attachment

to gain access to the underside of the coupler.

2. Check all retaining bolts and nuts for tightness on the coupler.

3. Grease the wedge slide housing.

4. Check Safelock coupler for correct operation by connecting an attachment. Ensure there

is spring resistance acting on the wedge when locating the safety handle.

Weekly

1. Check the Safelock coupler visually for evidence of fatigue, weld failure or stress.

2. Lubricate pivot points and other moving parts.

IMPORTANT: Due to the self-tightening and infinite wear feature accommodated with

the hydraulic cylinder, if any attachment is fitted to the hitch for long periods of time it

should be released daily. If the daily maintenance tasks are adhered to, this will happen

automatically.

WARNING: If the quick hitch is damaged in any way and/or there is any doubt as to the

continued safety, cease operation immediately and contact Harford Attachments Ltd,

Technical Department on Europe: +44 (0)1603 403099, USA: 727 477 3044

WARNING: If the warning buzzer does not sound on machine start-up, please refer to

the troubleshooting guide.

IMPORTANT: Any unauthorised modification of the quick hitch and/or associated

control systems may compromise the safety of the operator and those nearby, and will

invalidate the product warranty.

IMPORTANT: Opening the control box is strongly discouraged as doing so could

make the product unsafe and will pass full liability to the end user and invalidate the

warranty.

©2022 Harford Attachments Ltd 13

SAFELOCK/GEN/MAN/R5

Warranty

Earthmoving Attachment

Harford Attachments Ltd (the seller) warrants their quick hitches as follows:

1. The seller shall repair or replace at the seller’s option any of the goods which are, or which

become, defective within 12 months from delivery due to faulty workmanship, materials or

faulty design, provided that the buyer shall have notified the seller in writing of such defect

and have given the seller a reasonable opportunity to inspect the defective goods.

2. If, in the opinion of the seller, the goods have not been operated or maintained in

accordance with the instructions in this manual, or have been subject to unauthorised

repair or modification, the warranty will be invalidated.

3. The seller’s liability in respect of defects in the goods shall be limited to those stated in this

clause and subject to Clause 2(1) of the Unfair Contract Terms Act 1997, the seller shall

not be liable whether in contract or in tort, including but not limited to negligence, or by

reason of breach of statutory duty or otherwise, for any damage or loss whatsoever

suffered by the buyer arising out of or attributable to such defects.

Table of contents

Other Harford Attachments Construction Equipment manuals