Harrington NTH User manual

EFFECTIVE: FEBRUARY1,1990

,_/

PRODUCTINFORMATION

for

:.. HARRINGTON

NAVY

TROLLEY HOIST

1,2,3,5TONCAPACllY

MODEL:NTH

~

"

CONTENTS:

1.Op~ratingandMaintenanceInstructions

2.PartsUst

3.ChainingInstructions

4.InspectionStandards

5.Disassembling&AssemblingInstructions

6. Trouble Shooting' ,<'

HARRINGTONHOISTS

HARRINGTON

HARRINGTONC~ES

""

Ii1\RRINGTONHOISTS,INC~ '"'~" ,,",

401 WEST END~AVENUE '><;-. .': '>"

MANHEtM,PA"'~7545 ' ,'".,~.,

r;, ':l' iP.HONE: (717) 6~gOOO "

.,-..J ,TOll FREE:'1-8OD-233-3010

.._.'-:..,:':;-~:-F-AX:.(717) 665-2861 '

;;: '0 "!'-o'

OperatingInstructions

Peerless NTH

ManualChainHoist

BeforeUse

Applylubricant(gearoilormachineoil)totheload

chain.Wipeoffexcess. Thisleaveslubricantatthe

bearingpointsofthelinks.

Operation

Themechanicalactionnecessarytolifttheloadis

startedbypullingonthehandchain.

Itisnormaltohearaclickingsoundwhentheload

israised,butwhenitislowered,noclicking

soundshouldbeheard.

Caution

Donotoverloadthehoist.Overloadingmayshorten

thelifeoftheunitorcauseaccidents.

Whenthehandchainsuddenlybecomestaut,STOP

OPERATION...theliftchainhasreachedeitherits

upperorlowerlimit.

Maintenance

Keephoistfreeofdirtandmoisture.Oilthehoist

periodically-especiallyifithasbeenusedinthe

rain. --

AJways-keeptheloadchainIjghtlylubricated.

Avoiddraggingthehoistontheground.

~

~

.- I I

y- t, [--i--I~+-

-:1---

i

0

:\

"

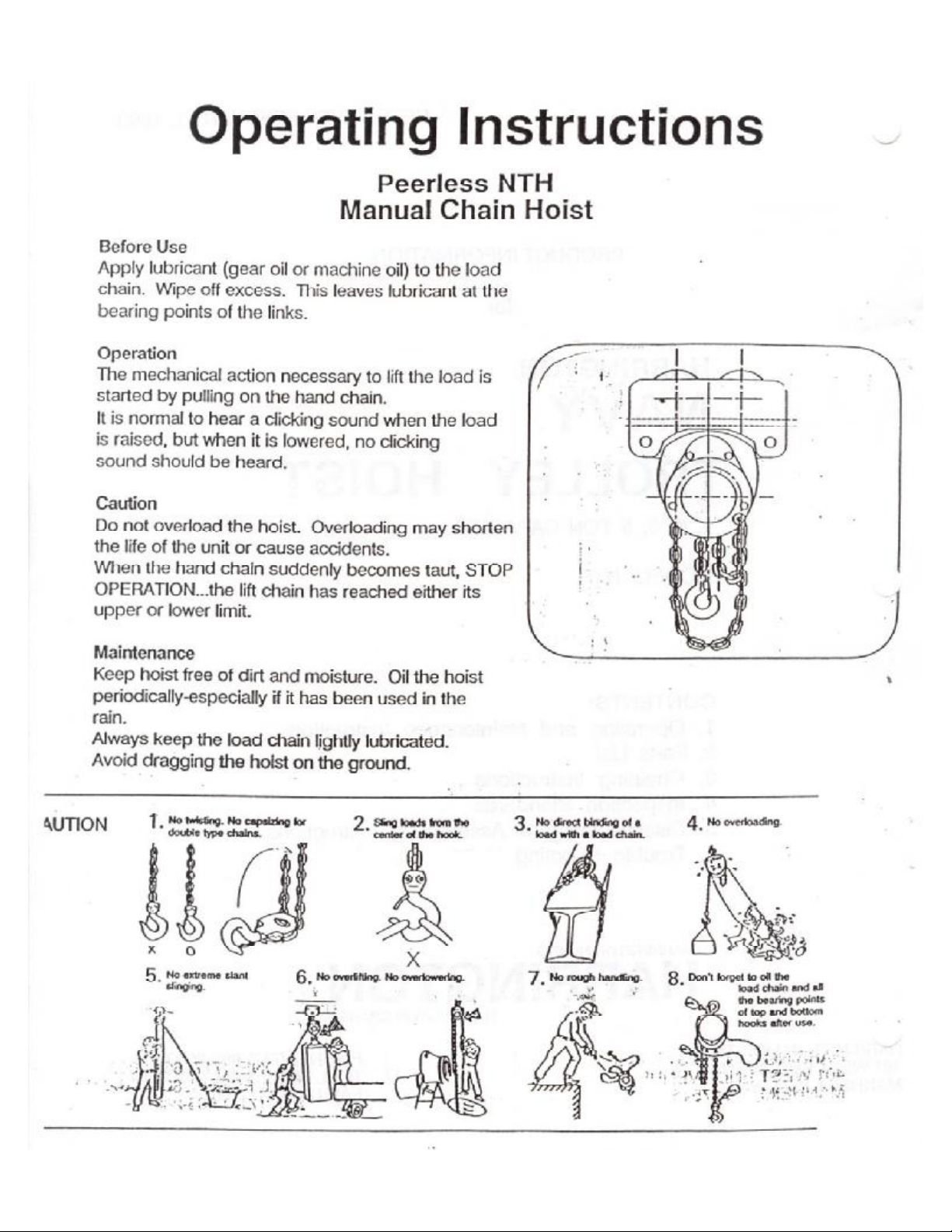

a.UTlON 4.Nooverloading.

1'. NotM6ting. Nocapsizing tor

doubIlI type chains. 2-Slingloadsfromthe

.center of.the hook.

(~

x0X

6. Nooverlifting.No0Yert0WerIng.

~

5Noextreme &!ant

.slinging.

~

3No .directbtridingofa

.load with . load chain.

8Don'tforgetto011the

.loadchainandaD

~R. thebearingpoints

~"\:-, oftopandbottom

hooksafteruse.

/

,~Operating Instructions

Peerless Manual andGeared Trolley

BeforeUse

Thepeerlessmanualtrolleycanbeadjustedinincrementsof1/8"bysimplyin~ertingor

removingadjustingspacerstofitavarietyofbeamflanges.Noadditionalspacersarerequired.

Toadjusttrolley(Fig.1): '

1.Removethestoppinsandslideoffsideplate8andspacersfromthesuspensionshafts.

2.Reinserttheappropriatenumberofinnerspacers for thedesiredflangewidth(Table1).

3.Insertsideplate"8"andexternalspacersandlockintoplacewiththestoppins.

~Installation

Foreasyinstallationthetrolleymaybeputontothe1-8eamflangefromtheopenendofthe

beam.StoppersshouldbeinstalledonbothendsoftheI-beamto.preventthetrolleyfrom

runningoffthebeam.

Ifthetrolleycannotbeinstalledfromtheopenendofthebeamthen:

1)Disconnectsideplate8fromtrolley.Leavehoistattachedtothesuspender (See1above).

CAUTION:Sincehoistandcomponentsareveryheavy,getassistancetoliftandholdhoist

andtrolleypartsinplace.

2)Check for propernumberofspacers. Useequalnumberofspacersoneachsideof

suspendersothatthehoistiscenteredbetweentrolleywheels.Ufthoistontobeam.

(SeeAg.1)

~3) Reinstallsideplate8andremainingspacers. Installstoppins.

4)Checktoseethathoistandtrolleyissecureonbeam.Allpinsareinplaceandkeepersplit

pinsareinstalled. -

5)Movetrolley.Itshouldmovefreely.Ititistootightorloose,adjustasrequiredbygoing

backtoStep1above.

Operation

Moveanunloadedtrolleybypullingontheloadchainofthehoist.

Movealoadedtrolleybypushingthesuspended load.

PrecautionsToBeTakenInOperation

1)Avoidslantpullingofchain.

Itisdangeroustopullthechainslant,withthetrolleyconnectedtothehoist,asthe

trolleyistiltedtoomuchandgivestoomuchstraintothebeam.

-2)Donotlet~etrolleybumpagainststopperatbear1.1orothE7trolleyonthesamebeam.

c. TakesuffiC1entcarenottoletthetrolleybumpagainstastopperattheendofthebeam

orothertrolleyonthesamebeam,asthiswillcausedamagetothetrolleysandthe

beamstopper.: ''L. -

3)Donotletthe'nandchaincatchaload.

Italoadiscaughtbythehandchainasitislowered,theloadedhandchainmaycause

damagetotheside-plate. '

4)Nev~rrT19yetrolleybypullingonthehoisthandchain.

.,i'J

.i~

_

"fl

_/il lihi

.'i' :" ,

.:>~~\iwr~' ..." .~'-

!'IJIalnteQ~_Q~:::' i :;IIJ .".

lubrIcationonthetrolleywheelsisrequired.Theyhaveshielded,pre-:lubricatedballbe~nngs.

~s_i~nally applyoilthroughthesmallholeinthepinionsupportonthegearedtrolley(FIg.3).

,'-.-,nt/,r'J '. \~

.->

--.".r-, --,"-1'" --{',-

Fig 1

a/@)

ñ

×ÒÒÛÎßÜÖËÍÌ×ÒÙÍÐßÝÛÎÍ ñù

ÞÑÔÌÚÑÎÍËÍÐÛÒÍ×ÑÒÍØßÚÌÑËÌÛÎ

ÊñÍÔÑÌÌÛÜÒËÌßÒÜÍÐÔ×ÌóÐ×Ò ,--;

-----

-.J

~

@

_Ol@)

SPLIT PIN

~(.

7

ÍØßÚÌÍÌÑÐÐÛÎÐ×Ò

ßÜÖËÍÌ×ÒÙÍÐßÝÛÎÍù

Table 1

NumberofAdjustingSpacers -"~.. ..J

,,'

--'--~~- ----- !-

lote;) Ì¿µ»ù²ø÷¬»¬¸»²«³¾¢®±²-°¿½»®-±º·²²»®-·¼»¿-

æ±´´·±©-:-.~' ,.' - -

~ample 1+:2

,ILNumber ±² Side Plate ß

Number ±²Í·¼»Ð´¿¬» B

011

Hole

A

BA-B= 1/S"

/

:.i y

Trotley

WMef -

Hand'

-""'-In,;., :°,"".. . "

-:> ..,,":~,.)i(.:,<..:,.I'

C::App.3/S"

.-.,,~ -~-

Fig.3 0.' .

"" ,.'

,-c'-,--',. Í«-°»²¼»®

".': ':° Fig.2

."\" ..:. '.-~'.

"

.,-,...-

-331/4 3'5/8 37/8 41/8 45/8 551/8 51/4 51/2 55/8 ?3(4 661/4 63/8 61/2 7

,WJdth 33/8 .,4

:aD-" ;

1Inner 3+3 4+4 5+5 6+6 7+7 9+9 ---, - - -- - - - -

Outer 12 10 8 6 4 0>

- - - - - - - - - - -

11/2Irtner ---1+1 1+2 4+4 5+6 6+6 6+7 7+8 8+8 8+9 9+9 - - - '--

2Outer ---16 15 10 7 6 5-: 3 2 1 0 - - ,- -

3Inrier ,_., --, 1+1 1+24+4 5+6 6+6 6+7 7+8 8+8 8+99+9 ---

Outer - - -16 15 10 ,7 ,,:6 -.5- '"3," '--:2 -1 0-- - -

5Inner - - - - - - 0+1 1+1 1+2 2-t:3 3+3 4+3 5+46+56+6 7+6 :9+8

Outer -----.- 16 ,15 14 12 11 10 8 654'.0

PARTSLIST

"ol-'n:1'"' I

\qq~i~p'-one assemblytorSTononly.

~t'~(M.o_~l~oJY --0 --- --" ,-- _0-----"--

,..

;',;.' ,:: ,\:

-- .. --, , --- !_-,~,--;

," =p-;' ':,

.""""""'" ok ,-

,-

No. Capacity

Fig. per

No. PartName Hoist 1 2 3 5

.

1SuspenderAssembly 1 50604 ëðêîî 50679 50725

3TopPin 1 CF163010 CF163015

4BottomHookCompleteSet 1M3021A010

16 SafetyLeverAssembly 1 CF071010

7 ChainPin 1 M3041010

8 SlottedNut 1M204901 0

9SplitPin 19009411 .

0BodyA 1CF101010 CF101015

1BodyB 1CF102010 CF102015

2 NamePlate 1 CF800010 CF800020 CF800030 CF800050

3 Frame 1CF1 05010 CF105015

1CF111010 CF111015 CF111050

14 Pinion 1**CF4111010 **CF4111015 fk*CF411105

5BallBearingA(Ag.14 1 9000103

6BallBearingB(Fig.14 1 9000201 9000202 9000300

BallBearingC(FiQ.14 1 9000105 9000106

'riA BallBearingD(Ag.14) 1 9000105 9000106

18 LoadSheave' 1CF116010 CF116015 CF116A050*

19 LoadGear 1CF114010 CF114015 CF116A050*

20 ChainGuide 1CF178010 CF178015

21 Stripper 1 CF162010 CF162015

22 SocketBolttor Body 29091284 9091285

?2A SocketBatttor Body 2 9091282 9091283

:>3 UNut for Body' 49098506

:>4 PawlPin 1CF156005

:>5 UNut for Fig.24 1 9098506

:>6 PawlSpring 1CF158005

7Pawl,:," 1.' CF155005

8SnapRingfor Ag.24 1 9047108

1 CF153010

29, fnctionDisc 1 **M3153020

0.FrictipnPlateB 1CF151010 ,-

,;/"" 1CF152010 - ' "-",, '

31 'RatchetDisc 1 ,CF4152010 ",'" "

,--"..' , '-,

311 8.4f.shirtfffofHatchet Disc 1M3.154020 ' i}:.]:':;i.cY_I,

.' --

-

Other Harrington Industrial Equipment manuals