Harrop FDFI2650 User manual

Installation Guide

110mm Integrated Throttle Body

LS FDFI2650 & FDFI2300 Superchargers

Part numbers:

99-ACVR12568, FDFI2300

99-ACVR13169, FDFI2650

FDFI2650 & FDFI2300 110mm Integrated Throttle Body

INSTALLATION GUIDE

Important Information

Thank you for purchasing this Integrated Throttle Body which has been designed and manufactured at

Harrop Engineering with pride. The installation of this product will require the vehicle to be retuned:

It is the owner’s/driver’s responsibility to accept any consequences and liabilities of using this product and

any subsequent effect it may have. Harrop Engineering shall not be liable and shall be ‘Held Harmless’ for

any direct and/or indirect/consequential losses, costs, damages, expenses, injuries or liabilities whatsoever

incurred by the owner/driver of the vehicle or other parties arising from this supercharger upgrade, its

installation and/or its operation.

For further information on our warranty terms and conditions please visit

https://www.harrop.com.au/warranty-policy/

Warranty

This product is covered by a limited warranty on components and workmanship for a period of 12 months

from the date of purchase, subject to the following:

• Installation must be completed by a qualified motor mechanic or technician who has undertaken

appropriate training in fitting Harrop superchargers.

• The supercharger has not been modified or “overdriven” by fitting alternative drive pulleys.

• The supercharged vehicle has been tuned by an appropriately qualified and experienced technician.

• The supercharged vehicle has been driven in accordance with the conditions specified by the vehicle

manufacturer’s normal use of operation, driving care and vehicle service program.

• The supercharged vehicle has not been used for competitive racing.

No warranty shall apply where Harrop have determined improper fitment or handling, misuse in operation,

neglect, or accident damage. Engine modifications made prior to or in conjunction with the 110mm

integrated throttle fitment may invalidate the Harrop limited warranty. Any warranty claims must be made

immediately & directly in writing to Harrop Engineering so that a determination can be made promptly.

Involvement of a third party or an attempt to repair a perceived/actual fault may invalidate the warranty.

To the extent of the law, the determination on any warranty claim & associated costs will be at the sole

discretion of Harrop Engineering.

By installing the Integrated Throttle Body, you acknowledge that all conditions pertaining to this

supercharger and its operation have been read, understood and accepted.

FDFI2650 & FDFI2300 110mm Integrated Throttle Body

INSTALLATION GUIDE

Page2

For 60 years Harrop Engineering has been at the forefront of designing, developing and manufacturing

precision performance components. Today our innovative and logical approach is applied to low volume

automotive OEMs and the performance aftermarket through a dedicated team of 65 staff. Core

performance products include Superchargers, Engine Components, Brakes, Differentials and we are also

the exclusive Australian Distributor for Forgeline Motorsport Wheels.

Harrop are also the preferred supplier of Eaton Supercharger and Traction Control technology including

dual branded product designed and manufactured in-house. There are currently over 4,000 components in

our portfolio and this is growing daily as we continually develop more Harrop Performance Products.

Our high profile car manufacturing customers have included Holden, HSV, FPV, Ford, Roush, Toyota, TRD

and Lotus.

We also supply to race teams from categories including F1, NASCAR and V8 Supercars and an extensive

range of drag, circuit and off-road competitors. Just as importantly, a large portion of our customers are

performance enthusiasts and weekend warriors who are highly passionate about their ride.

Please take a moment to review the following pages and learn why Harrop is the first choice in

Superchargers.

Thank you for choosing Harrop and enjoy your Harrop Enhanced ride.

Team HARROP

Contents

Important checks, required tools and shop supplies prior to Install

3

Removal of existing supercharger head unit

3

Removal of existing front cover

3

Assembly of integrated throttle body to supercharger

4

ISSUE: 0, April 2020

FDFI2650 & FDFI2300 110mm Integrated Throttle Body

INSTALLATION GUIDE

Page3

IMPORTANT CHECKS AND EQUIPEMENT PRIOR TO INSTALLATION

Read and understand the entire installation document before attempting installation.

Special Tools and Sealants Required:

•5mm hex key

•5mm shortened hex key

•5mm ¼ drive hex socket

•Thread locker Loctite 263 or equivalent

•Flange sealant, Loctite 518 or equivalent

•Torque wrench with range of 10-20 Nm

•Soft hammer

•New tensioner pulley EP046 (Nuline), for kits without the supercharger spacer plate.

Removal of the supercharger head unit (not complete manifold)

a) Whilst the FEAD is still in operation loosen but do not remove the 4 pulley screws on the existing

supercharger head unit, 5mm hex key

b) Remove the FEAD belt off the supercharger

c) Remove the clean air intake boot

d) Disconnect the throttle body electrically

e) Disconnect the 3 vacuum lines on the supercharger front cover along with the vacuum by-pass hose.

f) Remove the 10 screws holding down the head unit. Once these are removed carefully lift the head unit off

the manifold.

Removal of the supercharger front cover

a) Undo the eight M6 socket head cap screws using a good 5mm hex key as these are pre coated thread locking

screws, the shortened hex key will be required for 2 of these screws.

b) Using a soft hammer tap the front cover off making sure that it comes off squarely as there are 2 diameter 5

dowels in the supercharger housing that cannot be damaged.

c) Now that the cover is off clean the mating surfaces free from the flange sealant ensuring none of this gets

inside the supercharger. (Late model superchargers have an ‘O’ ring on the bottom manifold face and care

must be taken not to damage this in the disassembly and assembly process)

FDFI2650 & FDFI2300 110mm Integrated Throttle Body

INSTALLATION GUIDE

Page4

Assembly of the supercharger front cover

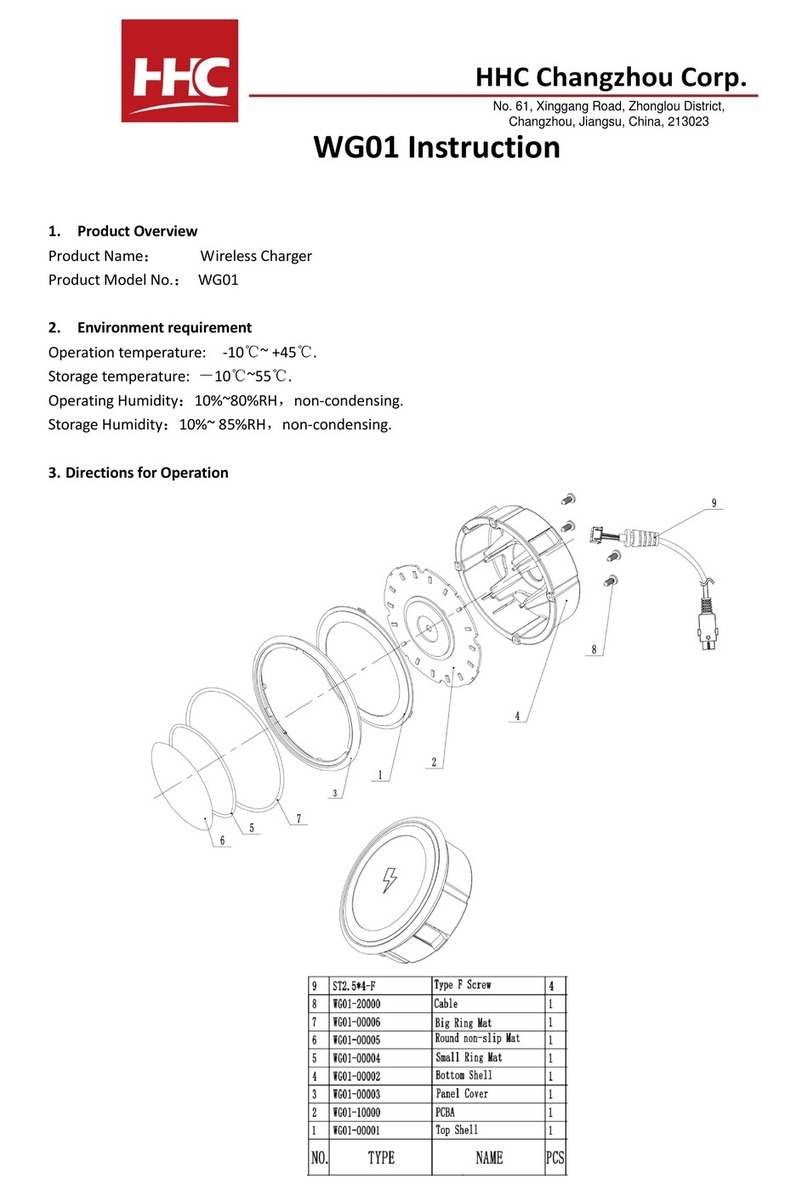

a) Ensure that the coupling is fitted correctly, refer to image ‘A’ below, coupling should be orientated so that

the bosses on the 3 holes that will accept the drive pins are facing outwards.

b) Apply the flange sealant as per image ‘B’ below.

c) Align the drive pins to the coupling holes and slide the new cover on aligning the dowel pins on the side of

the supercharger housing.

d) Refit all of the old bolts with the exception of 2 ensuring there is enough thread locker still left on the

threads, if not apply thread locker Loctite 263. Using the Loctite thread locker 263 apply this to the 2

supplied bolts and fit the longer one in the top hole behind the throttle blade and the shorter one to the

bottom hole behind the blade (refer image ‘C’ that has the shaft and blade removed for clarity).

e) Torque the 8 screws up to 11Nm making sure the integrated throttle body pulls up parallel, wipe off excess

flange sealant.

f) Fit the supercharger pulley to the drive hub and torque these to 14-16Nm, ensure that the cap screws have

sufficient thread locker still on them otherwise apply Loctite 243 medium strength thread locker.

g) If the intercooler reservoir is mounted on the RH head of the engine, relocate this onto the body or if in a VF

commodore use bracket 14644 for the relocation onto the fuse box sheet metal support. This relocation will

require 16mm (5/8”) heater hose about a meter in length.

h) Refit the supercharger head unit in reverse order on to the manifold, torque these screws to 12-14Nm in a

pattern starting in the centre working outward.

i) Connect the relevant hoses and throttle body harness.

j) Fit the tensioner pulley EP046 on the rear FEAD tensioner, if no spacer plate fitted. The old pulley can be

changed over to the idler on the left-hand side so as to negate a belt length change – refer image ‘D’ below.

k) Refit the belt and the clean air intake tube, note the diameter for the clean air inlet hose is 118mm.

l) ETC drive is same configuration as LS3, however recalibration for larger size Throttle Body is required.

A

B

C

D

This manual suits for next models

3

Table of contents

Other Harrop Batteries Charger manuals