READ ALL INSTRUCTIONS

BEFORE STARTING INSTALLATION

General Information

The HARTELL LTA-1 model pump is a completely self-contained unit

designed to remove wastewater from sinks when a traditional gravity drain

line is not available. Popular applications include; wet bar sinks, kitchenettes,

utility sinks, and laundry tray sinks.

Lightweight and compact, the LTA pump mounts directly to the drain

tailpiece of your sink, eliminating all traps and inlet piping.

The LTA design does not require any connection to the main stack vent1

which is common with other types of drain pump systems.

The LTA pump’s rugged construction, automatic operation, and ease of

installation provides the best value in a drain pump that will provide many

years of trouble free service.

Proper installation practices will ensure virtually maintenance free operation,

and extend the life of your pump.

Installation Note: All pumping and piping systems will fail at some point due

to a variety of reasons including power failures, foreign objects, neglect, or

“old age”. Proper safeguards, and precautions such as alarms, safety

switches, drain pans, etc. should be installed with any system when system

failure will result in damages to finished living spaces. It is the responsibility

of the installer to make appropriate provisions for system failure consistent

with each specific installation.

Risk of electrical shock. This pump is supplied with a

grounding type cord and plug. Do not modify cord or plug. Plug pump

into a properly grounded, grounding type, GFCI receptacle, following

all local codes.

Risk of electrical shock. Do not handle pump, cord, or plug

with wet hands, or when standing in water or on a damp surface, when pump

is plugged in. Unplug pump before servicing or performing any maintenance.

Do not work with energized electrical equipment in a wet area. Reasonable

care and safe practices should be exercised during installation and

maintenance.

MODEL LTA-1 (802210)

AUTOMATIC SINK DRAIN PUMP

INSTALLATION

OPERATION

MAINTENANCE

! WARNING

! WARNING

Troubleshooting

Condition Probable Cause

Pump does not run when water is added to

the sink.

-Check that pump is plugged in.

-Check power to outlet or circuit.

-Pump plugged into a switched outlet.

-Fuse/breaker blown or tripped.

-Foreign object lodged in pump chamber.

Pump runs but does not empty sink.

-Sink drain screen clogged.

-Sink stopper inserted in drain.

-Clogged check valve.

-Clogged discharge line.

-Shut-off (balancing) valve closed or not

adjusted properly.

-“System” lift too high or piping run too long.

Pump turns on and off (“cycles”) when no

water is in the sink.

-Check valve or back flow preventer not

installed in discharge line.

-Dirt in check valve is allowing water to flow

back into pump from drain line.

Pump turns on and off (“cycles”) rapidly

when sink is full or at maximum water flow.

-Balancing / shut-off valve not installed in drain

line.

-Balancing valve not adjusted properly.

Service and Maintenance

The LTA pump is designed to be virtually maintenance free when used in

accordance with the installation guidelines specified in these instructions.

Installation and preservation of an inlet screen will prevent excessive

accumulation of material in the pump chamber and possible obstruction of the

impeller by foreign objects such as stones, string, buttons, etc.

Before returning the unit for replacement, the pump housing should be removed

and the impeller chamber checked for obstructions.

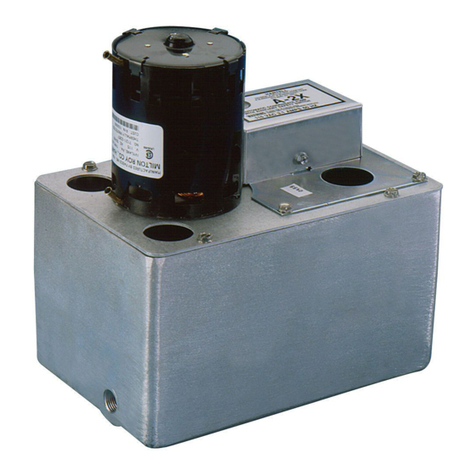

To check impeller, Unplug pump and remove from

sink. Remove four (4) ¼” hex head screws from

the “fins” of the housing as shown in figure 2.

Separate housing from motor base plate and

inspect for obstructions. After clearing any debris,

replace housing on the base plate making sure

that the rubber “o” ring is in place around the

“step” in the base plate. Re-install pump following all instructions.

Warranty

HARTELL products are warranted to be free from manufacturing defects, for a period of twelve (12)

months past the date of installation. Within the warranty period, HARTELL will replace or repair any

products determined to be defective by the Factory or an authorized Representative. Purchaser

must pay all labor and shipping charges necessary to replace product covered by this warranty.

HARTELL shall not be held liable for resultant damages, caused by products that have failed.

Installer must consider the safeguards necessary to protect the surrounding areas from possible

water damage should the pump or piping system fail. Warranty will be voided if product has been

subject to abuse, tampering, altering, negligence, improper installation, or mis-application.

Requests for service under this warranty shall be made by returning the product to the original

place of purchase along with dated sales receipt. Additional details of this warranty can be obtained

by contacting HARTELL.

HARTELL PUMPS •201 Ivyland Rd •Ivyland, PA 18974

Phone:

215-322-0730

•Fax: -322- •E-Mail: [email protected] •Web Site: www.hartell.com

HEX HEAD

HOUSING

SCREWS

FIGURE 2

(Pump will cycle with faucets partially on. This is normal and will not harm pump.)

800 5519