Hartzell HC-12X20 User manual

This manual suits for next models

2

Table of contents

Other Hartzell Aircraft manuals

Hartzell

Hartzell HC-E4 3 Series User manual

Hartzell

Hartzell HC-Y-1 Series User manual

Hartzell

Hartzell HC-82XF-1 User manual

Hartzell

Hartzell HC-E3YR-7 User manual

Hartzell

Hartzell HC-B3-2 Series User manual

Hartzell

Hartzell HC-D2MV20-3 Series User manual

Hartzell

Hartzell HC-A6A-3 Series User manual

Hartzell

Hartzell HC-D2MV20-3 Series User manual

Hartzell

Hartzell HC-D2X20-3 User manual

Popular Aircraft manuals by other brands

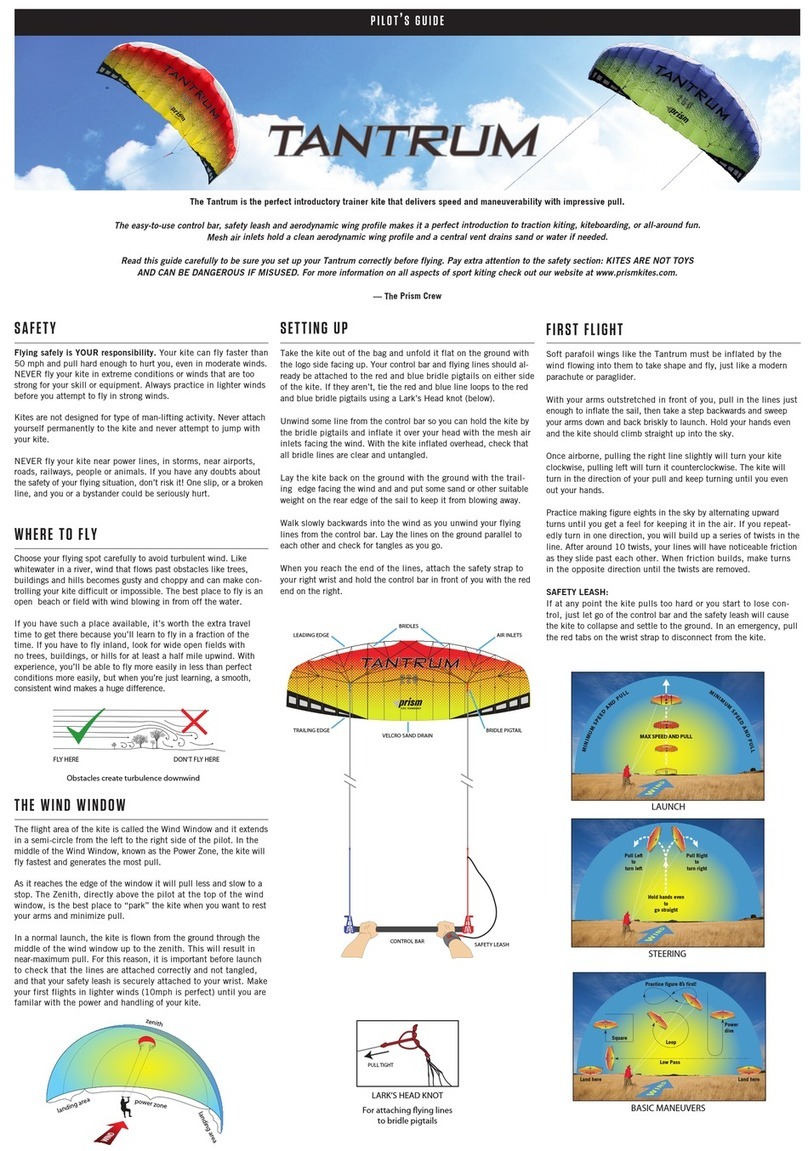

PRISM+

PRISM+ Tantrum 250 pilot's guide

Gulfstream

Gulfstream V operating manual

Rand-Kar

Rand-Kar X-AIR HANUMAN 602T AP user manual

FlySynthesis

FlySynthesis Storch S 500 LSA Pilot operating handbook and training manual

Gulfstream

Gulfstream G150 Flight manual

AUTO GYRO

AUTO GYRO MTOsport Flight and operation manual

ZAGI

ZAGI Zagi-Fixx Assembly manual

Tecnam

Tecnam ROTAX 912UL 80Hp Flight manual

Urban Air

Urban Air UFM - 13 LAMBADA Operating and maintenance manual

ITV PARAPENTES

ITV PARAPENTES Jedi 2 manual

LittleCloud

LittleCloud Baby Goose manual

Robinson Helicopter Company

Robinson Helicopter Company RTR 660 Maintenance manual