ASSEMBLY PROCEDURE FOR S-TEK BACKSHELL ADAPTORS

Harwin North America Harwin Europe Harwin Asia

T: +1 603 893 5376 F: +1 603 893 5396 T: +44 (0) 23 9231 4545 F: +44 (0) 23 9231 4590 T: +65 6 779 4909 F: +65 6 779 386

IS-32 Issue: 4 Date: 01.04.11 C/Note: 11172 Page 2 of 4

1) Feed cables through required length of braiding. It may be advisable to secure the cables together

with electrical tape or similar to prevent wires becoming entangled in braiding. Leave the tape on

until instructed to remove it later in these instructions.

2) Feed Band-It tie over cables and braiding for application later.

3) Feed cabling through ellipse/circular feature of backshell as shown below. Again, securing the cables

together with electrical tape or similar may ease this process.

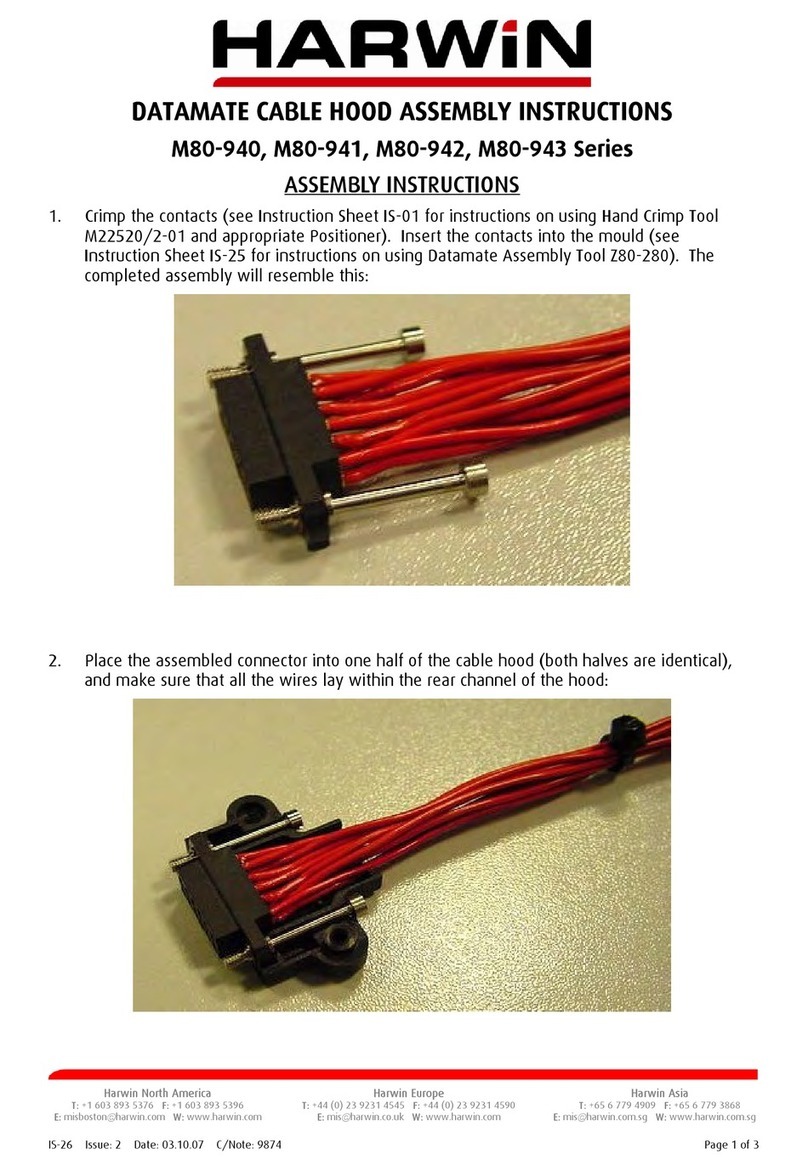

4) If tape was used, remove it now. Crimp the Datamate contacts onto the wires, and insert the

contacts into the moulding. Please consult the relevant Instruction sheets: for crimping instructions

see Instruction Sheet IS-01 for more details. For contact insertion into moulding see instruction sheet

IS-25. All instruction sheets can be found at http://www.harwin.com/downloads/instructions/.

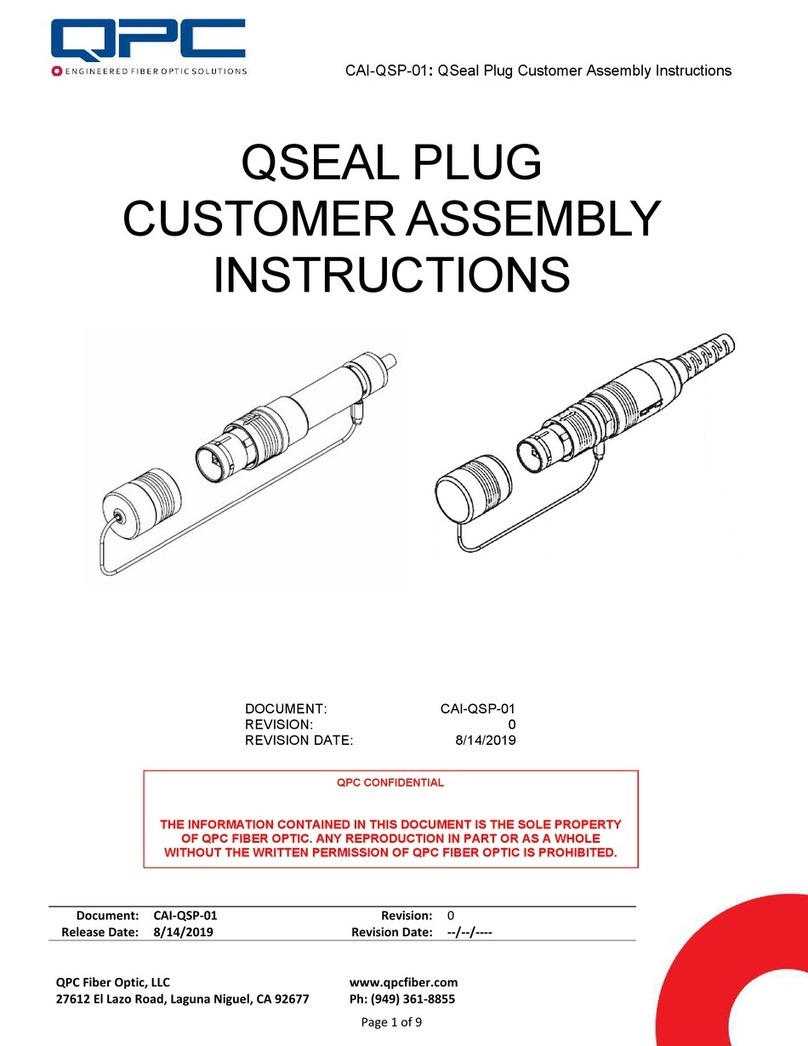

5) Terminate the braiding to the backshell using the Band-It tie. Harwin strongly recommend that all

terminations are made so that the locking lip of the Band-It Tie Dex is positioned along the longer

portion of the backshell exit to ensure a uniform band and braid compression (see example below).

This also prevents the locking lip of the tie obstructing jackscrew insertion at a later stage. For full

tooling instructions on the Band-It Tie Dex go to http://www.band-it.co.uk/tooling.htm and select

tool A590 for full details.