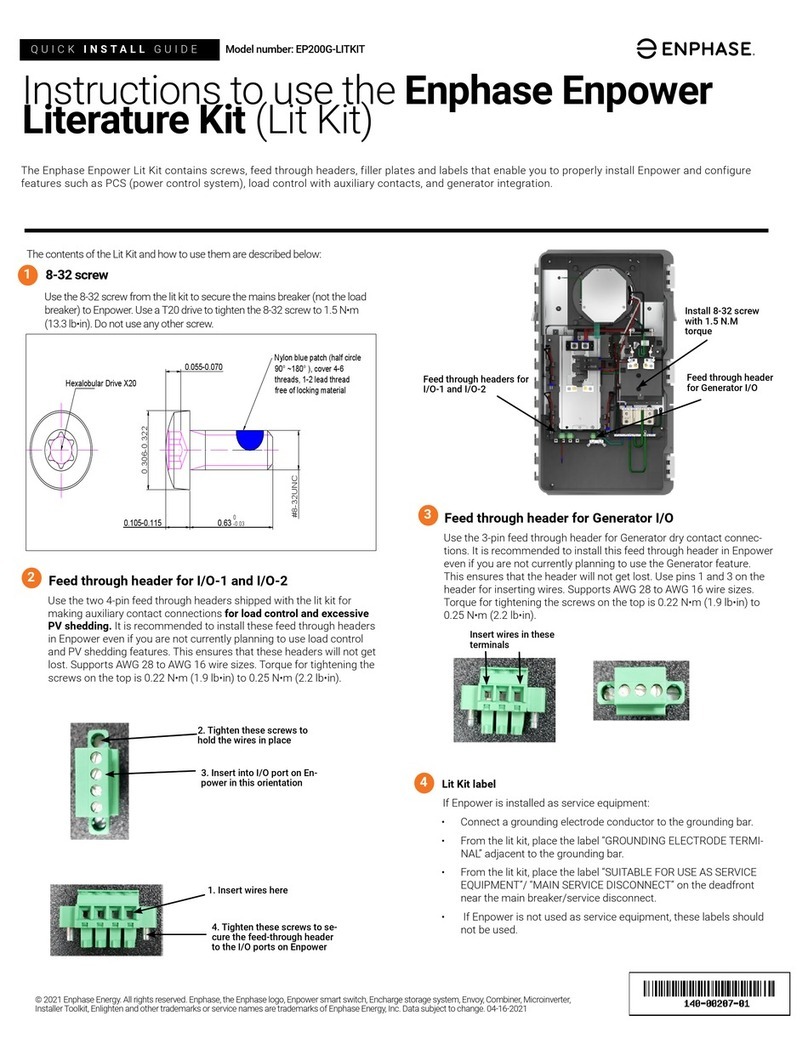

QUICK INSTALL GUIDE

Installing Enphase 200 A Production CTs

Use this instruction with the Enphase Envoy S Metered Quick Install Guide or IQ Gateway Quick Install Guide to install Enphase production

monitoring current transformers (CTs). The Enphase Envoy S Metered or IQ Gateway uses this 200 A solid-core CT for monitoring solar

production current. This ANSI C12.20 compliant CT performs revenue-grade metering with an accuracy class of 0.5%. Rated at Pollution

Degree 3, you can use the CT inside electrical equipment in residential or harsh, industrial conditions. Read and follow all warnings and

instructions in this guide and the Quick Install Guide included with your Gateway and available at: enphase.com/support.

INSTALLATION

For more information, refer to the Envoy S Me-

tered or IQ Gateway Quick Install Guide which

is included with your gateway or available at:

enphase.com/support.

Preparation

A ) If not already done, turn off

the power to the PV system.

Remove any pre-installed Production CT

A ) Remove the line 1 conductor of the solar production circuit to which

the CT is connected.

B ) Remove the existing CT.

Install the Production CT

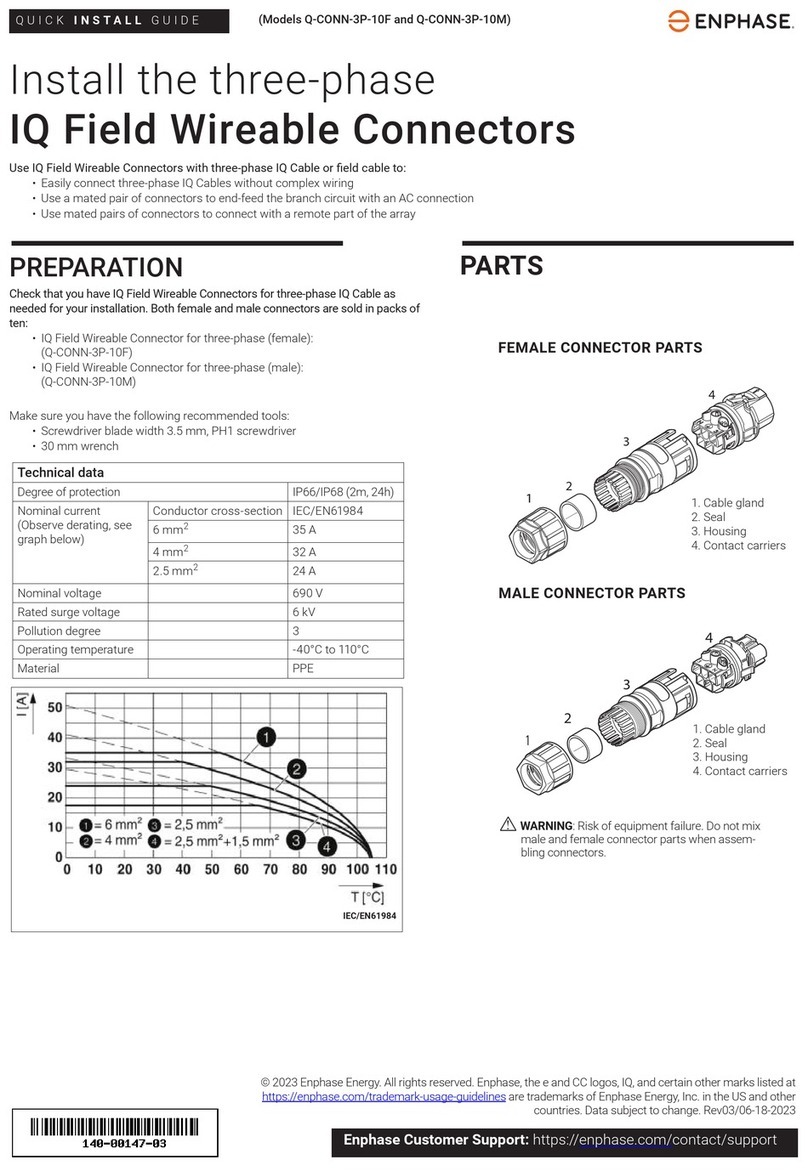

A ) Locate the arrow on the CT label.

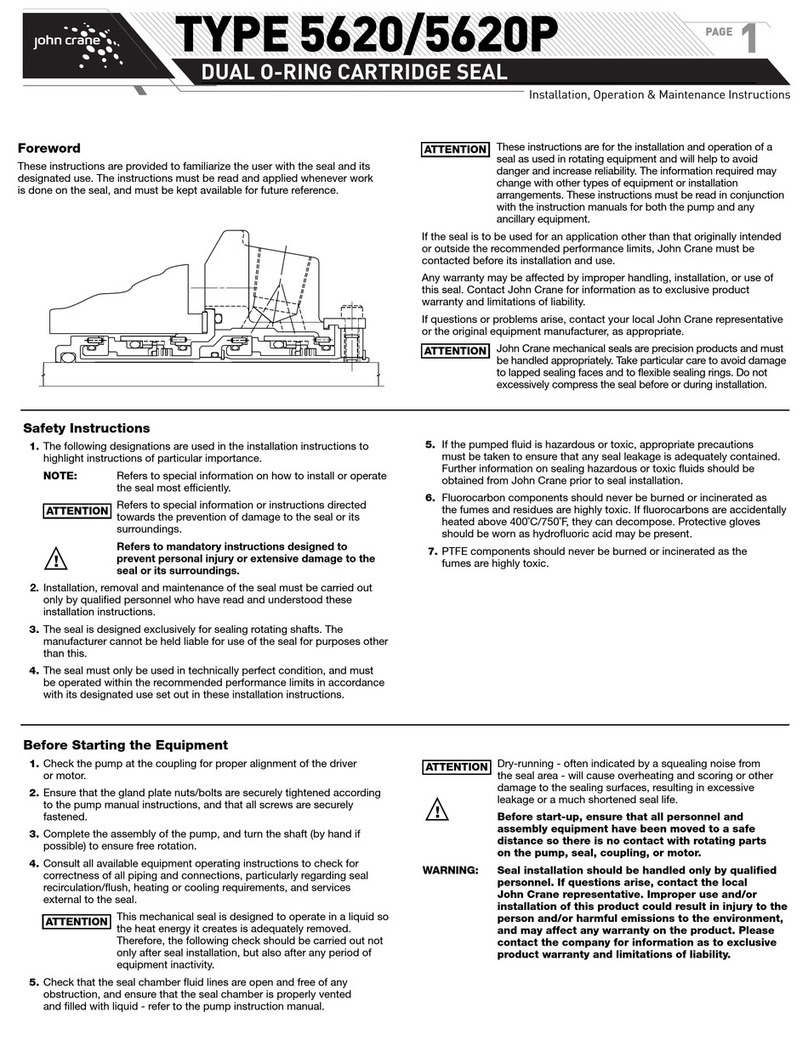

B ) Refer to the diagram on the reverse of this document for wiring.

NOTE:Do not pass conductors from AC battery branch circuits through

the Production CT. This will distort production readings.

C ) Install the CT on Line 1 of the solar production circuit with the arrow

pointing towards the load (away from the solar array).

• For Envoy S Metered, Line 1 matches the “A” voltage terminal

• For IQ Gateway, Line 1 matches the “L1” voltage terminal

D ) For an Envoy S Metered, connect the white wire to the “IA•” terminal.

For an IQ Gateway, connect the white wire to the left “P1” terminal.

E ) For an Envoy S Metered, connect the blue wire to the “IB•” terminal.

For an IQ Gateway, connect the blue wire to the right “P1” terminal.

F ) Tighten the terminal block screws to 5 in-lbs.

G ) Close and secure the terminal block door of the Gateway.

H ) Turn on the PV system.

SAFETY

SAFETY AND ADVISORY SYMBOLS

+DANGER: This indicates a hazardous situation, which if not avoid-

ed, will result in death or serious injury.

✓NOTE: This indicates information particularly important for opti-

mal system operation. Follow instructions carefully.

SAFETY INSTRUCTIONS

+DANGER: To reduce the risk of electric shock, always open or

disconnect the circuit from the power-distribution system (or

service) of the building before installing or servicing the current

transformers.

+DANGER: Risk of electrocution! Do not install CTs when current

is owing in the sensed circuit. Always install CT wires in the

terminal blocks before energizing the sensed circuit.

+DANGER: If equipment is used in a manner not specied by

Enphase Energy, the protection provided by the equipment may

be impaired.

+DANGER: Risk of electric shock. Be aware that installation of

this equipment includes the risk of electric shock. If you wire the

IQ Gateway or Envoy S at the subpanel, always de-energize the

subpanel before beginning.

+DANGER: Risk of electric shock. Risk of re. Only qualied per-

sonnel should troubleshoot, install, or replace the CTs.

✓NOTE: Because of variances in switchboard design and main pow-

er feed, there may not always be enough space to install CTs.

✓NOTE: Do not install the CTs in a switchboard where they exceed

75% of the wiring space of any cross-sectional area within the

equipment.

✓NOTE: Perform all electrical installations in accordance with all

national and local electrical codes.

✓NOTE: Restrict installation of current transformers in an area

where they would block ventilation openings, or in the area of

breaker arc venting.

✓NOTE: Not suitable for Class 2 wiring methods and not intended

for connection to Class 2 equipment.

✓NOTE: Secure current transformer and route conductors so that

they do not directly contact live terminals or bus.

✓NOTE: When wiring the Envoy S Metered or the IQ Gateway for

production and consumption metering, be sure to install the cur-

rent transformers (CTs) exactly as described for your application.

✓NOTE: When installing CTs, it is important to match CT and sense

voltage phases. Be sure to consistently identify the two AC lines

at three points: the main load center feed, the Gateway, and the

solar production circuit breaker. Wire colors (typically black and

red) may not always consistently identify L1 and L2. If in doubt,

use a multimeter to check.

✓NOTE: Only run active conductors through the CT. The CT can

monitor multiple active conductors. You may run more than one

wire through the CT if all wires are on the same phase and they t

the opening in the CT.

SPECIFICATIONS

SPECIFICATION CT-200-SOLID

CT type Solid core

CT accuracy (error rate) <0.5%

Max primary supported current 200 A

Turns ratio 2,000

Pollution degree 3

Dimensions 1.93" diameter

Aperture 0.76" diameter

Primary voltage (range) 250 VAC

Frequency 60 Hz (45–66 Hz)

Operating temperature −40°C to 65°C

Humidity 95%

Pollution degree 3

Compliance RoHS, UL 2808, ANSI C12.20

Enphase customer support: enphase.com/en-us/support/contact © 2023 Enphase Energy. All rights reserved. Enphase, the e and CC logos, IQ, and cer-

tain other marks listed at https://enphase.com/trademark-usage-guidelines are trade-

marks of Enphase Energy, Inc. in the US and other countries. Data subject to change.

(Model: CT-200-SOLID)

NOTE: The IQ Combiner ships pre-installed with this CT. However, this SKU can be used for replacement in case of damage in eld.