Haswill AL8010F User manual

www.thermo-hygro.com

User’sManualofAL8010F

Heating or Cooling Controller (TC1-1412-1006)

1. Features

Within adjustable Aim Temperature Value, Temp. Difference Value, Compressor Delay

Time and calibration value; Higher and Lower temperature limit exceed which range will

trigger alarms.

It will change the room temperature by turn on / off the load automatically.

Auto memory exist data if electric off, need not to configure it again once power back.

With 0.1°C precision and ±1.0°C accuracy;

The voltage of input electric for the load need not to same as the voltage of this controller

and it is also working if they are same.

The output relay for load max bear 30A current under 220V, allow 6600W load.

2. Application

Suit to place where need constant temperature, like beer fermentation chamber / pool, brewing

hardware, boiler, fridge, freezer, Incubators, Aquariums, Hatchers, terrariums etc.

3. Package

Controller

1PCS

Fasteners

2PCS

Sensor

1PCS

Manual

1PCS

Waterproof Cover

1PCS

4. Specification

Input Power

220VAC ± 10% 50/60HZ; (12V/24/110V Option)

Maximum current

10A (Default) under 220V AC

Sensor

NTC, 25°C /10 KΩ, sensor cable 200cm

Protection Class

IP65 to front panel

Storage

-10°C ~ 60°C, RH<90%, without condensation

Meas. & Control:

-50°C ~ +120°C

Precision:

0.1°C

Accuracy:

± 1°C

Rated Power:

≤ 3W

5. Environmental Information

Package:

The packages material is 100% recyclable; Just dispose it through

specialized recyclers.

Product:

The electro components can be recycled or reused if it is disassembled

for specialized companies.

Disposal:

Please do not burn or throw the controllers in domestic garbage, observe

the respectively law in your region concerning the environmental

responsible manner of dispose its devices.

6. Interface & Operation

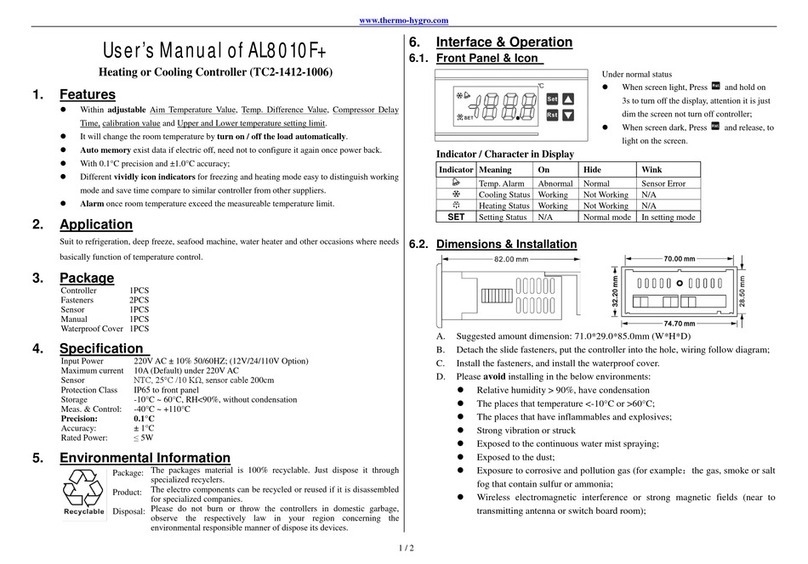

6.1. Front Panel & Icon

Under normal status

When screen light, Press and hold on

3s to turn off the display, attention it is turn

off controller not just dim the screen;

When screen dark, Press and release, to

light on the screen.

Indicator / Character in Display

Indicator

Meaning On Hide Wink

Working status of load

Load Working

Stop

Delay

Setting status

On Set

Non-setting

N/A

6.2. Dimensions & Installation

A. Suggested amount dimension: 71.0*29.0*85.0mm (W*H*D)

B. Detach the slide fasteners, put the controller into the hole, wiring follow diagram;

C. Install the fasteners, and the waterproof cover.

D. Please avoid installing in the below environments:

Relative humidity > 90%, have condensation

The places that temperature <-10°C or >60°C;

The places that have inflammables and explosives;

Strong vibration or struck

Exposed to the continuous water mist spraying;

Exposed to the dust;

Exposure to corrosive and pollution gas (for example: The gas, smoke or salt

fog that contain sulfur or ammonia;

Wireless electromagnetic interference or strong magnetic fields (near to

transmitting antenna or switch board room);

1 / 2

www.thermo-hygro.com

6.3. Wiring Diagram

A. 10K NTC sensor, Need not to distinguish + or - when wiring it.

B. The input voltage must within the voltage value marked in diagram ±10% value.

C. Load Power ≤Voltage of load ∗Max current of Relay

Factor

The factor for Inductive Load like compressor, heating pump, usually be 5~8;

The factor for Resistive Load like Electric heating rod, Electric blanket

usually is 1.5~2;

The factor for Incandescent lamp usually is 15.

7. Configurations

7.1. Code and Function Menu

Code

Function Min Max Default

Step

HC Heating or Cooling C H C

D Return Difference (°C) 1 15 5 1

LS Lowest set Limit (°C) -50 ATV

-50 1

HS Highest Limit (°C) ATV 120 120 1

CA

Temperature Calibration (°C)

-5

+5

0

1

PT

Delay Time (Min)

0

10

1

1

7.2. What is ATV and how to set it?

ATV means Aim Temperature Value which is the ideal temperature you wish to reach,

once exceed this value (if difference value = 0) the status of load will be changed,

Details of setting as follow

Step1

Assure power on, Press and release key once times you will find display

blink a data which is changeable.

Step2

Now press the or keys to get you aim value;

press and hold on the or is fast forward function;

the steps length is 0.1°C;

The editable range between lower (LS) and higher (HS) limit.

The buzzer will scream once Room Temperature < LS

, or Room

Temperature > HS, Press any key to stop screaming if you want to.

Step3

Waiting for 10s the device will save data automatically or press to save it.

7.3. When will the load working?

Firstly of all, the instant time passed the delay time (PT), and then matches one of the following

A. In heating mode (

HC

=

C

), the relay will turn on heater when

Measured Temperature Value ≤ATV - Temp. Differential (D)

B. In cooling mode (

HC

=

H

), the relay will turn on cooler

Measured Temperature Value ≥ATV +Temp. Differential (D)

7.4. How to correct measured temperature if found it not right?

Exist gap/distance between the measured temperature and the real temperature is normal

especially the first time launch this controller; the gaps could be corrected by setting the value in

CA, and please follows the formula: CA= Real Temperature-Measured Temperature.

7.5. How to set other parameters?

Step1

Press and hold on until appears the code HC (nearly 3s).

Step2

Now press the or keys to select the code you want to update;

Step3

Press and release to see exist value; then press the or to get your aim value;

Step4

Press key to memorize the configured value and return to the menu.

Repeat operation from Step 2 / 3 / 4 to adjust other parameters;

Step5

P

ress to save data and quit from setting mode back to normal monitor status. r let it

alone, the modified value will be saved automatically if without operation in 10s

7.6. How to get Factory Reset?

In normal status, press and keys in same time, do not release them until screen shows

YS which means success, nearly 3s.

8. Error & Alarm

When alarm occur, if the readout flash ---and buzzer sounds,

A. Press any key to stop buzz scream;

B. Check the room temperature and then change the compressor / heater working

status manually if necessary,

C. fix or replace the sensor; after that screen will back to normal state

D. And other code please, reference below content to fix problem.

Code Reason Troubleshooting

HHH Measured temperature >

HS

Check the room temperature and then change the

compressor / heater working status manually if

necessary.

LLL Measured temperature <

LS

XUZHOU HASWILL ELECTRONICS CO., LTD.

www.thermo-hygro.com ; tech@thermo-hygro.com

Copyright 2016 Haswill-Haswell All Rights Reserved

2 / 2

Other Haswill Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

elsner elektronik

elsner elektronik KNX T-AP Installation and adjustment

Polar Electro

Polar Electro 2020 instructions

Siemens

Siemens AQR2531 Series Mounting instructions

Altecnic

Altecnic DeltaSol BS user manual

Gatekeeper Systems

Gatekeeper Systems ITSS Desktop Mount Installation Guide

Würth

Würth IVT PRINETO manual

Viessmann

Viessmann VITOTROL 100 Installation and service instructions

Elotech

Elotech R2000-N4 Series Description and operating manual

Pan-Globe

Pan-Globe MG900 Series instruction manual

alre

alre RTERU-010.715# Series Operating and installation instructions

LG

LG ARNH08GK3A2 owner's manual

Vega

Vega TD-11 user manual