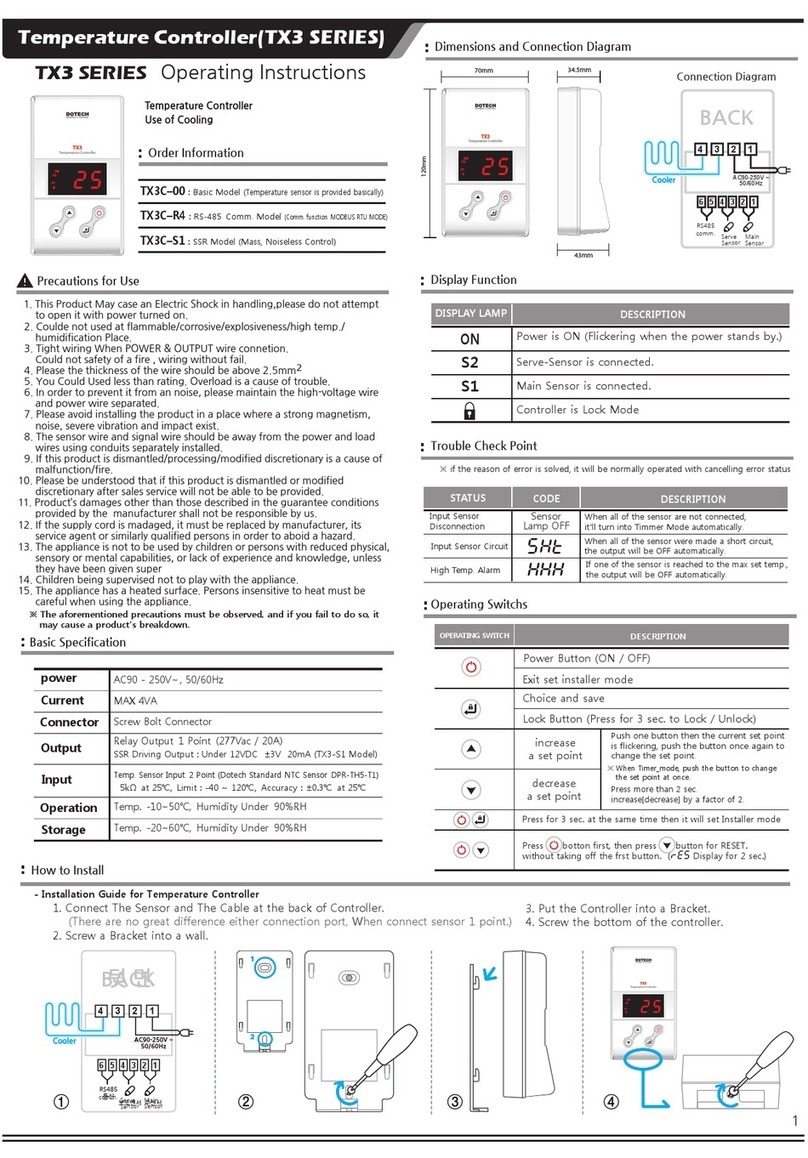

Elotech R2000-N4 Series Manual

R 2000 - N4 . .

Temperature Controller

4 - Zones „heat-only”

4 - Zones „heating-off-cooling“

Installation depth: 122 mm

DIN-Format: 96 x 96 mm

escription and operating manual

ELOTECH Ind strieelektronik GmbH

Verbind ngsstraße 27

D - 40723 HILDEN

FON +49 2103 / 255 97 0 FAX +49 2103 / 255 97 29

www.elotech.de Email: [email protected]

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page1/28

1 Contents

1 Contents..........................................................................................................2

2 General Information ........................................................................................3

3 Installation Instr ctions....................................................................................3

4 Type Code.......................................................................................................4

5 Connection Diagram.........................................................................................5

5.1 Power S pply and O tp ts..........................................................................5

5.2 Sensor Inp ts.............................................................................................7

6 Display and Keyboard........................................................................................8

6.1 Tendency Display........................................................................................9

6.2 Operating Levels.......................................................................................10

7 Parameter descriptions:...................................................................................12

7.1 Config ration Parameters, Valid for the Complete Device.............................12

7.2 Zone Config ration....................................................................................16

7.3 Control Parameters, Zone Dependent ........................................................20

7.4 Operating Level........................................................................................24

8 Error Messages................................................................................................25

9 Technical Data.................................................................................................26

10 Notes............................................................................................................27

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page2/28

2 General Information

Messages shown by the controller display

<§> Symbolizes the val e of the factory adj stment of the respective

parameters.

>3< This parameter is available in 3-point controllers only.

3 Installation Instructions

Make certain that the device is sed for the intended p rpose only.

R2400 controllers are designed for installation in control panels.

Protect the device against impermissible h midity and contamination.

Ambient temperat re may not exceed 50 °C (122 °F).

Electrical connections m st be made according to valid reg lations and by properly q alified

personnel.

If sing thermoco ple sensors, compensation lines have to be connected directly to the controller

terminals. Sensors may be connected only in compliance with the programmed range.

Sensor cables and signal lines (e.g. logic or linear voltage o tp ts) m st be laid separately from

control lines and mains voltage s pply cables (power cables).

It is not permitted to connect the gro nds of the sensor-inp ts and Logic-o tp ts with each other.

Separate installation of controller and ind ctive loads is recommended.

Interference from contactor coils m st be s ppressed by connecting adapted RC-combinations parallel

to the coils.

Control circ its (e.g. for contactors) sho ld not be connected to the mains power s pply terminals of

the controller.

The config ration parameters are generally to be selected first.

isclaimer of Liability

We have checked the contents of this doc ment for conformity with the hardware and software

described. Nevertheless, we are nable to precl de the possibility of deviations so that we are nable

to ass me warranty for f ll compliance. However, the information given in the p blication is reviewed

reg larly. Necessary amendments are incorporated in the following editions.

We wo ld be pleased to receive any improvement proposals which yo may have.

The information contained herein is s bject to change witho t notice.

Electronic scrap and components are s bject to special treatment and m st be disposed of by

a thorized companies.

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page3/28

4 Type Code

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page4/28

R2000 - y - 000N4xx- d- - z

230 VAC

115 VAC

1

224 VAC3 24 VDC5

No0 RS 2322 RS 4854 0/20mA TTY5

No0

Power Supply

Fieldbus-Interface

Heater Current Monitoring

Yes

(Logic outputs only)

5

4-zonesN421 Zones 2-point

Type

4-zonesN426 2-point

4-zonesN431 2/3-point

4-zonesN436 2/3-point

4-zonesN437 2/3-point

Control Outputs

heating / cooling

Relay

Logic

Relay Relay

Logic Logic

Logic Relay

5 Connection iagram

5.1

Power Supply and Outputs

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page5/28

1

2

3

4

5

6

7

8

9

Out 4-1

Out 4-1

10

11

Out 3-1

Out 3-1

12

13

Out 2-1

Out 2-1

14

15

Out 1-1

Out 1-1

21

22

Out 4-2

Out 4-2

23

24

Out 3-2

Out 3-2

25

26

Out 2-2

Out 2-2

27

28

Out 1-2

Out 1-2

17

18

19

20

L / DC

N / DC

A1

A1

A2

A2

Power Supply

Type: N421, N431

2-point Configuration

Out 1-1 – Out 4-1

heating or cooling according

to configuration

Out 1-2 – Out 4-2

not used

3-point Configuration

Out x-1 heating

Out x-2 cooling

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

21

22

23

24

25

26

27

28

17

18

19

20

L / DC

N / DC

A1

A1

A2

A2

Out 4-1

Out 3-1

Out 2-1

Out 1-1

Com.

Out 4-2

Out 3-2

Out 2-2

Out 1-2

Com.

+Uout +Uout

Type: N426, N436

Power Supply 2-point Configuration

Out 1-1 – Out 4-1

heating or cooling according

to configuration

Out 1-2 – Out 4-2

not used

3-point Configuration

Out x-1 heating

Out x-2 cooling

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page6/28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

L / DC

N / DC

A1

A1

A2

A2

Out 4-1

Out 3-1

Out 2-1

Out 1-1

Com.

+Uout

Type: N437

Power Supply

21

22

Out 4-2

Out 4-2

23

24

Out 3-2

Out 3-2

25

26

Out 2-2

Out 2-2

27

Out 1-2

17

18

19

20

28

Out 1-2

2-point Configuration

Out 1-1 – Out 4-1

heating or cooling according

to configuration

Out 1-2 – Out 4-2

not used

3-point Configuration

Out x-1 heating

Out x-2 cooling

5.2

Sensor Inputs

It is not permitted to connect the gro nds of the sensor-inp ts and Logic-o tp ts with each other.

External Contacts:

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page7/28

70

71

72

73

74

75

76

77

78

79

80

+

−

ϑ

ϑ

+

−

ϑ

+

−

+

−

+

−

+

−

81

82

83

ϑ

ϑ

ϑ

ϑϑ

TC PT100

3-wire

PT100

2-wire

Sensor

Zone

4

3

2

1

Ι

L1

RxD in

RxD out

TxD out

0/20mA

TxD in

GND

RxD out

TxD in

TxD out

RS 232

RxD in

A

RS 485

B

83

90

91

92

93

94

95

8396

Heater Current Monitoring

K3

K2

K1

Fieldbus

Sensor Inputs

K1 Open

Closed Setpoint 1 (SP1) valid for all zones

Setpoint 2 (SP2) valid for all zones

K2 Open

Closed Adjustment lock off

Adjustment lock on

(see parameter „Adjustment lock”)

K3 Open

Closed Individual setpoint 1 adjustment for each zone

Setpoint 1 will be overtaken for all other zones automatically

Setpoint Switch:

Adjustment Lock:

Setpoint Changing:

6 isplay and Keyboard

LE 1: Control o tp t „heating“ of the

choosen zone active

LE 2: Control o tp t „cooling“ of the choosen zone

active

LE A1: Alarm o tp t A1, indication LE Setpoint ramp of the choosen zone active

LE A2: Alarm o tp t A2, indication LE SP2: Setpoint 2 valid (for all zones)

Key functions:

Zone preselection

Parameter key (parameter preselection)

Adj stment of chosen parameter (e.g. setpoint) to higher or lower val es.

Short operation: single-step adj stment

Longer operation: q ick-scanning

When the parameter adj stments have been altered b t not entered,

the display will flash bright/dark.

Confirmation and storage of the preselected val es.

The display will show a light chain as a control of this f nction.

Sets the parameter back to the originally stored val e.

Any alterations made to the parameters, that are not confirmed (E-key) within

30 seconds, will not be accepted and the parameter will ret rn to its originally

stored val e. The act al process val e and the setpoint val e will be indicated.

F nction key, E. g. all zones are displayed cyclic (zone scanning on/off).

Zones, which are not in action (OFF), are not displayed.

The f nction of this key can be programmed into the config ration level of zone 0.

See parameter „Co.F1“.

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page8/28

6.1

Tendency isplay

After switching the instr ment „on“ a temperat re tendency display will be shown, to give an overview

abo t the temperat res deviations relating to the setpoints in the individ al controller zones.

Zone:

1 2 3 4

Display examples:

Zone 1: Controller o tp t active

temperat re OK

(Bar central)

Zone 2: Controller o tp t not active

Process val e is higher than setpoint

>0,5 % of meas ring range (Bar top)

Zone 3: Controller o tp t not active

temperat re OK

(Bar central)

Zone 4: Controller o tp t active

Process val e is lower than setpoint

<0,5 % of meas ring range (Bar bottom)

Zone:

1 2 3 4

Zone 1: Top range end has been reached (sensor

break)

Zone 2: Bottom range end has been reached

(sensor error, open)

Zone 3: Selft ning algorithm is active

Zone 4: Man al mode

The displayed decimal points show the act al sit ation of the controller o tp t.

Flashing digit: Alarm indication in the matching zone

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page9/28

6.2

Operating Levels

The operation of the controller is divided into 3 levels.

After power p of the device, it will be a tomatically in the operating level.

Operating level (valid for each zone separately):

Process- and Setpoint val e will be displayed sim ltaneo sly. Within the operating level the setpoint

can be adj sted by pressing the„UP" / „ OWN" - keys.

Every adj stment has to be confirmed by pressing the „ E “ - key.

All parameters within the operating level ( incl ding the alarm val es ) can , in s ccession, be

displayed by pressing the „ P “ - key and adj sted by pressing the „UP" / „ OWN" - keys.

Confirm by pressing the „ E “ - key.

Parameter level: (valid for each zone separately)

Within the parameter level the val es are adj sted to s it each individ al process.

This level is reached by sim ltaneo sly pressing the „ P" - and „ E " -keys.

The display of each single parameter within the parameter level and their adj stment are made in

the same fashion as within the operating level.

After either pressing the „ E “ - key for approx. 1 second, or waiting for a period of approx. 30

seconds, the nit will a tomatically ret rn to the operating level

Configuration level: (valid for the complete device)

Select zone “0”. Then press sim ltaneo sly the „ P " - and "„ E " - keys for a period of approx. 5

seconds.

This general settings have to be made first.

Configuration level: (valid for each zone separately)

Select zone 1...4. Then press sim ltaneo sly the „ P " - and "„ E " - keys for a period of approx. 5

seconds.

There is a copy f nction available. So it is possible to copy the programmed parameters of one zone

to other zones.

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page10/28

PP

EE

Parameter level

P

Y (output ratio)

xxxx

xxxx P

Operating level

P

setpoint (set)

xxxx

xxxx P

Configuration-

level

P

Zone : on / OFF

xxxx

xxxx P

and and

press press appr. 5 sec.

Back into operation level:

-Press

E

1 sec. or automatically after appr. 30 sec.

7 Parameter descriptions:

7.1

Configuration Parameters, Valid for the Complete evice

Alarm configurations, general information:

Each alarm contact works as a common alarm for all zones. The individ al alarms A1 (A2) of all zones

are connected to the common contact A1 (A2). The selected config ration is valid for all active zones.

Please note:

Care sho ld be taken to ens re that the setpoints of the alarm contacts are programmed within the

selected meas ring range. If a setpoint ramp has been programmed, the alarms that are relative to

the setpoint (signal contact, limit comparator) follow the setpoint ramp.

In case of sensor error the alarms react in the same way as range override.

The alarm contacts therefore do not offer protection against all types of plant breakdown.

We recommend the se of a second, independent monitoring nit.

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page11/28

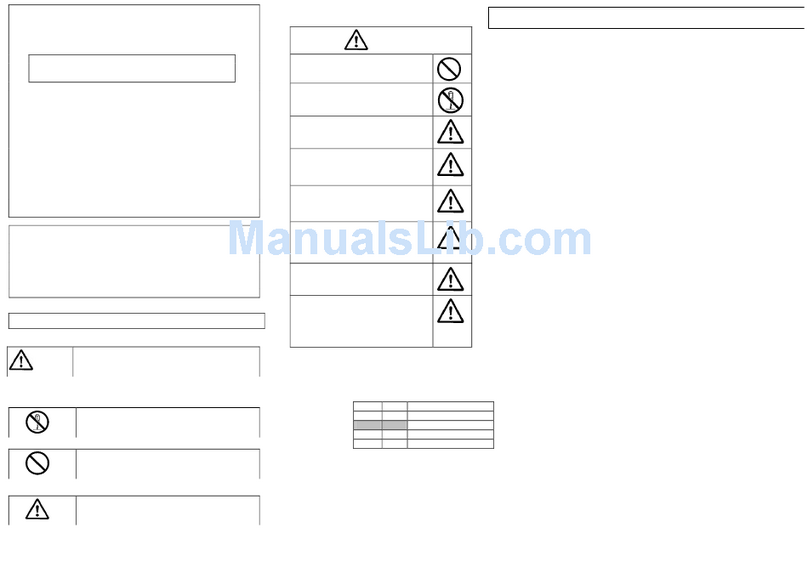

Process

off

on

limit value

Process

limit value

off

on

Process

off

on

limit range

Process

Setpoint

off

on

limit range

Setpoint

Process

off

on

limit range

Setpoint

Configuration: 3

Configuration: 5 and 9

Configuration: 2 and 8

Configuration: 6

Process

off

on

Setpoint

signal value

ProcessSetpoint

signal value

off

on

Configuration: 4

Configuration: 1

Signal Contacts Limit Contacts

Limit Comparators Limit Comparator

Configuration: 7

With Start-up suppression

The different alarm config rations define the working mode of the alarm. If the controller feat res a

heater c rrent monitoring, two additional heater c rrent alarms are available. The act al alarm val es

have to be set in the operating level.

Alarm Config ration

(switches relay A1)

Alarm OFF, no alarm signalisation <§>

Signal contact: off-on

Limit contact: off-on

Limit comparator: off-on-off

Signal contact: on-off

Limit contact: on-off

Limit comparator: on-off-on

Limit comparator with start- p s ppression: off-on-off

Heater c rrent monitoring, limit contact: off-on

Heater c rrent monitoring, limit contact: on-off

Switching behavio r

Relay A1

Here the relay f nction may be inverted:

direct

on: LED A1 „on“, Relay A1 "activated"

off: LED A1 „off“, Relay A1 "not active"

The relay is switched on if the controller displays an alarm

message. <§>

inverse

on: LED A1 „on“, Relay A1 "not active"

off: LED A1 „off“, Relay A1 "activated"

The relay is switched off if the controller displays an alarm

message.

Alarm Config ration

(switches relay A1)

Identical adj stment as

Switching behavio r

Relay A2

Identical adj stment as

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page12/28

Heater current monitoring (option)

The heater c rrent monitoring f nction is valid for all connected zones.

The following parameters are displayed when the alarm config ration is programmed to “heater

c rrent” (8 or 9).

The alarm val e (heater c rrent val e) is programmed as an absol te val e.

Please note: Ens re that the limit val e is set correctly to avoid false alarms in case s pply voltage

changes. The alarm can be delayed by selecting a delay time “dL.Ax”.

The monitoring f nction and all parameters are valid for all connected zones.

The heater c rrent meas ring is designed for a c rrent transformer 1:1000. (ELOTECH type: M2000)

Heater c rrent detection and indication range: 0...max. 60,0 A Single-phase operation.

delay time, relay A1

Delay time for heater c rrent alarm A1

5 steps adj stable, nit: seconds

The val es depend on the c rrent detection cycle time and the

n mber of active controller zones.

= no delay time active <§>

delay time, relay A2

Delay time for heater c rrent alarm A2

5 steps adj stable, nit: seconds

The val es depend on the c rrent detection cycle time and the

n mber of active controller zones.

= no delay time active <§>

C rrent detection interval

1 … 60s <§ = 2s>

Time interval between the c rrent meas rement of two s ccessive zones

Min. leakage c rrent val e

<§>

,

0,0 … 99,9 A

The s m of the act al leakage c rrent will be displayed

as ”Act leak-curr.“

Monitoring concerning an impermissible permanent c rrent

SSRs (especially if they are combined with RC-combinations) normally

have small leakage c rrents.

A leakage c rrent limit val e is programmable. All val es below this limit

will not be considered in the alarm monitoring.

If a permanent c rrent is detected in one zone the alarm relay will be

activated and the display „PROCESS“ will show the error signalisation

„Er.C “.

The zone with a meas red permanent c rrent can be located by pressing

the zone key and watching all temperat re indications.

Display indication in this case: „Comparable with„temperat re too high.“

Select f nction of key „F1“

No f nction

A tomatically zone-scanning „on“/ „off“.

Self-t ning algorithm can be activated by pressing key „F1“

in the matching zone. „F1“ approx 2sec.: stops self-t ning.

Shows the act al percentage o tp t ratio, while pressing „F1“.

Lamp (LED) test, while pressing „F1“.

no adj stment lock <§>

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page13/28

Adj stment lock parameter and config ration levels locked

all parameters apart from SP1 locked (not SP1)

All parameters that have been locked with can be

selected and read, b t not adj sted.

This adj stment cannot be changed if the external

contact K2 is closed.

Zones offset preselection

Contin o s n mbering of the controller zones

<§>

,

1 ... 95

The adj sted offset val e is added to the displayed zone n mbers in the

windows. Therefore a contin o s n mbering of the zones can be

achieved if more than one device is sed.

Examples: offset = off: zones n mbering: 1-4, 1-6, 1-8

offset = 4: zones n mbering: 5-8, 5-10, 5-12

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page14/28

Serial Interface (RS232, RS485 or TTY)

The controllers of the series R2400 can be eq ipped with a serial interface RS232, RS485 or

0/20mA (half-d plex) as an option.

This enables a master (PLC) to set and to read the process- and config ration parameters.

The comm nication is always controlled by the master. The controller operates as a slave.

If there are transmission or range errors detected by the slave, the message is not accepted and the

existing parameter val es remain valid.

It is not possible to operate the device by keyboard if it is set to remote-operation by the master.

Protocol descriptions and f rther information: Please see www.elotech.de/downloads

Protocol selection

ELOTECH- standard protocol <§>

Gateway-Protocol (for special applications only)

Device address

1<§> … 255

At this address a master comm nicates with the controller.

Each controller needs a niq e address.

Data format

Adj sting the data format for the transmission:

Data bit: 7 Parity: even Stop bit: 1

Data bit: 7 Parity: odd Stop bit: 1

Data bit: 7 Parity: even Stop bit: 2

Data bit: 7 Parity: odd Stop bit: 2

Data bit: 7 Parity: no Stop bit: 2

Data bit: 8 Parity: even Stop bit: 1

Data bit: 8 Parity: odd Stop bit: 1

Data bit: 8 Parity: no Stop bit: 1

Data bit: 8 Parity: no Stop bit: 2

Ba d rate

Interface inactive

0,3 … 9,6<§> kBa d

Control n mber

Device code

End of config ration level

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page15/28

7.2

Zone Configuration

Meas ring- or controller zone active <§>

Meas ring- or controller zone switched off

Controller config ration

2-point controller "heating-off" <§>

2-point controller "cooling-off”

2-point controller ”cooling non linear“. Cooling action with

non-linear cooling response c rve

( e.g. for vapo r cooling).

3-point-controller ”heating-off-cooling“ >3<

3-point-controller ”heating-off-cooling“. Cooling action with

non-linear cooling response c rve (e.g. for vapo r cooling).

>3<

Indicator, no controller action

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page16/28

Sensor selection

If the zone is config red to PT100, the following sensors are available:

Pt100 -50,0...100,0°C

Pt100 -58...212°F

PT100 -90,0...205,0°C

Pt100 -130...401°F

Pt100 0...400°C <§>

Pt100 32...752°F

Pt100 0...800°C

Pt100 32...1472°F

If the zone is config red to thermoco ple, the following sensors are

available:

Thermoco ple (TC) Fe-C Ni(L) 0...400°C

Thermoco ple (TC) Fe-C Ni(L) 32..752°F

Thermoco ple (TC) Fe-C Ni(L) 0...800°C

Thermoco ple (TC) Fe-C Ni(L) 32..1472°F

Thermoco ple(TC) Fe-C Ni(J) 0...800°C

Thermoco ple (TC) Fe-C Ni(J) 32..1472°F

Thermoco ple (TC) NiCr-Ni(K) 0..1200°C

Thermoco ple (TC) NiCr-Ni(K) 32..2192°F

Thermoco ple (TC) PtRh-Pt(S) 0..1600°C

Thermoco ple (TC) PtRh-Pt(S) 32..2912°F

Please note:

If the sensor selection is changed, the following parameters will be

reset:

Setpoint 1, Setpoint 2:

Lower setpoint limitation:

Higher setpoint limitation:

Setpoint ramp rising/falling:

Alarm val es:

Act al process val e offset:

Setpoint limitation min.

meas ring range bottom

meas ring range top

higher setpoint limitation

programming range:

… top range

Highest adj stable setpoint val e

<§= 400°C>

lower setpoint limitation

programming range:

bottom range …

Lowest adj stable setpoint val e <§

= 0°C>

Copy f nction

…

Copy all parameters of the act al zone to the selected zone x

Select the target zone (1,2 .... or (to all) with the „UP/ OWN“

keys and press „E“ (enter). The parameters will be copied.

Note: This will only happen if the selected sensor types in the

source and in the destination zone are identical.

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page17/28

Softstart Function in General:

If yo select the softstart f nction, make s re that the instr ment is eq ipped with bistable voltage

(logic) o tp ts. This f nction is not allowed for instr ments with relay o tp ts. Otherwise the relays

will be damaged.

D ring the softstart the controller's heating o tp t response is limited to a preselected ratio,

in order to achieve a slow drying of high performance heat cartridges.

This res lts in a slower, more reg lar heating period.

Sim ltaneo sly the o tp t clock freq ency is q adr pled.

Once the process val e reaches the softstart setpoint, it remains stable at this val e for the

preselected d ration time.

At the end of this period the process val e rises to the valid setpoint.

If the softstart is active, the controller's a tot ne f nction cannot operate ( ).

If a setpoint ramp has been programmed, the softstart has priority, and the ramp will become active

after the softstart has been completed.

The softstart only works

- if the parameter P (xp) is programmed > 0,1%

- if the act al process val e is lower than the softstart setpoint

– 5% of the selected meas ring range

It is possible to select this f nction for each zone individ ally.

Softstart

Softstart f nction is not active. <§>

The other softstart parameters are not displayed.

Softstart f nction is active.

Softstart o tp t ratio

range: 10...100% <§ = 30>

Softstart setpoint

range: ... <§ = 100>

Softstart d ration time

range: , 0.1 … 9,9 min.

<§ = 2.0>

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page18/28

t

Temperature

Setpoint

Softstart

Setpoint

SST-Output-Ratio

SST-Duration-Time

O tp t mode

Controller mode <§>

A tomatic Mode

In the event of sensor break the last valid

o tp t ratio is maintained.

An „H“ is then displayed as the first digit in the

setpoint display, followed by the valid o tp t

ratio.

Like the setpoint, the o tp t ratio can be

changed man ally.

Under the following circ mstances, the o tp t

ratio will be 0%:

- if the o tp t ratio at the time of the sensor

break was 100%.

- if a setpoint ramp is active.

- if the control deviation was more than 0,25%

of the total range at the time of sensor break.

- if the Proportional-band (P) = off.

- if the softstart was active at the time of the

sensor break.

A few seconds after the sensor break has been

rectified, the controller ret rns to a tomatic

operation and calc lates the req ired o tp t

ratio.

An additional signal can be iss ed in the event

of sensor break, if the alarm contacts are

programmed accordingly.

Man al Mode

The controller now operates only as an

act ator. The control f nction (PID) is inactive.

PROCESS: Act al process val e is shown.

Display of setpoint: First an “H“, then the

act al adj stable o tp t ratio.

Negative val e: cooling, positive val e: heating

Like the setpoint, the o tp t ratio can be

changed man ally.

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page19/28

7.3

Control Parameters, Zone ependent

valid o tp t ratio

0 … 100%

The o tp t ratio shows the momentary calc lated ratio.

It cannot be altered. The display is in percent of the installed

performance capability for heating or cooling.

O tp t ratio for cooling is shown as a negative val e.

O tp t ratio limit

„heating“

0 … 100%<§ >

The limitation of the o tp t ratio is only necessary if the heating

energy s pply is grossly overdimensioned compared to the power

req ired.

Under normal conditions a limitation is not necessary (setting =

100%).

The limitation becomes effective when the controller's calc lated

o tp t ratio is greater than the maxim m permissible (limited)

ratio.

Warning!

The o tp t ratio limitation does not work d ring a tot ne.

O tp t ratio limit

„cooling“

0 … 100%<§ >

Adjustment of the control parameters:

As standard the controller operates in PD/I control mode, i. e. controlling witho t deviation and with

practically no overshoot d ring start- p.

3-point controllers (marked with: >3<) have a second ”cooling“ parameter set.

The control action can be altered in its str ct re by adj sting the following val es to the parameters:

a. no control action, on-off

b. P-action

c. PD-action

d. PI-

e. PD/I

setting P =

setting D and I =

setting I =

setting D =

modified PID-mode (set: P, D, I)

According to the config ration, certain parameters are not visible.

prop. band (P)

„heating“

; 0,1...100,0 % <§=3,0>

If = (control action: on-off, witho t feedback)

next parameter: .

rate (D) „heating“

1 … 200 sec <§ = 30>

reset(I) „heating“

1 … 1000 sec <§ = 150>

cycle time „heating“

0,5 … 240,0 sec <§=10,0>

The switching freq ency of the act ator can be determined by

adj sting the cycle time.

In this time interval the controller switches on and off once.

Voltage o tp ts for SSRs

cycle time: 0,5...10 s

Optimal val e for fast control loops: 0,8s

Relay o tp ts:

cycle time: > 10 s

The cycle time sho ld be adj sted to a time as long as possible

to minimize the wear of the relay contacts.

Man al: R2000-N4XX-X-000-X-X_EN Release: 2.02 © Elotech GmbH Page20/28

Table of contents

Other Elotech Temperature Controllers manuals