IRNGCDCEM1-0123

2

CONTENTS

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION

CAUTION indicates a hazardous situation

which, if not avoided, could result in minor

or moderate injury.

NOTICE

NOTICE is used to address practices not

related to personal injury.

NOTE: Refer to the Symbol Identification tables on the back

cover of this manual for definitions of symbols that may

appear in this manual.

INTRODUCTION

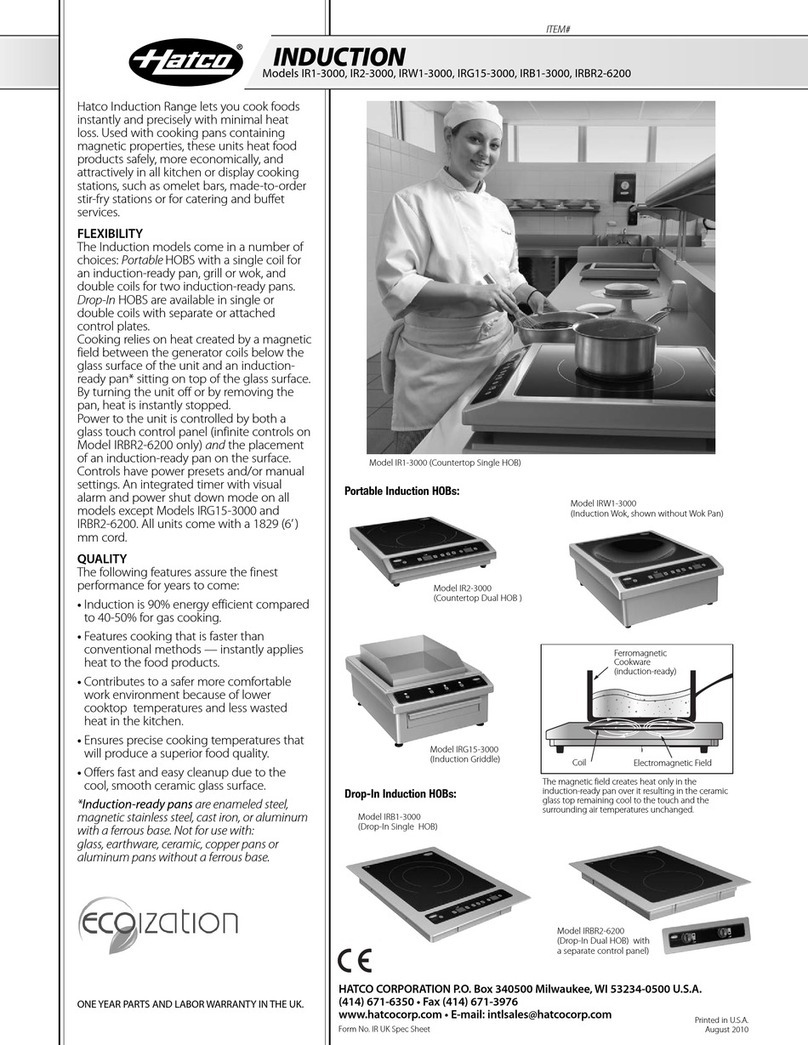

Hatco Dual Induction Ranges offer a safe, quick, efficient,

and attractive way to prepare foods in commercial kitchens as

well as display cooking locations (omelet bars, buffets, etc...).

The high efficiency, accuracy, and speed of induction cooking

make Hatco Induction Ranges the perfect choice for quality

foodservice organizations.

Induction cooking relies on the creation of a magnetic field

between the induction coils below the glass surface of the

unit and an “induction-ready” pan sitting on top of the glass

surface. This magnetic field generates induction currents in

the base of the pan, which heat the pan instantly. That heat

then is transferred to the pan contents. Since the magnetic field

exists only between the induction coils and a magnetic material

(ferrous material), the glass surface between the two does not

become heated, eliminating heat loss and increasing efficiency.

When the magnetic field is “broken” by turning off the unit or

removing the pan, heat generation stops instantly.

Hatco Dual Induction Ranges are products of extensive research

and field testing. The materials used were selected for maximum

durability, attractive appearance, and optimum performance.

Every unit is inspected and tested thoroughly prior to shipment.

This manual provides the installation, safety, and operating

instructions for Hatco Dual Induction Ranges. Hatco

recommends all installation, operating, and safety instructions

appearing in this manual be read prior to installation or

operation of a unit.

Important Owner Information..............................................2

Introduction...........................................................................2

Important Safety Information ..............................................3

Model Designation ...............................................................4

Model Description ................................................................5

Specifications .......................................................................6

Plug Configurations .............................................................6

Electrical Rating Charts.......................................................6

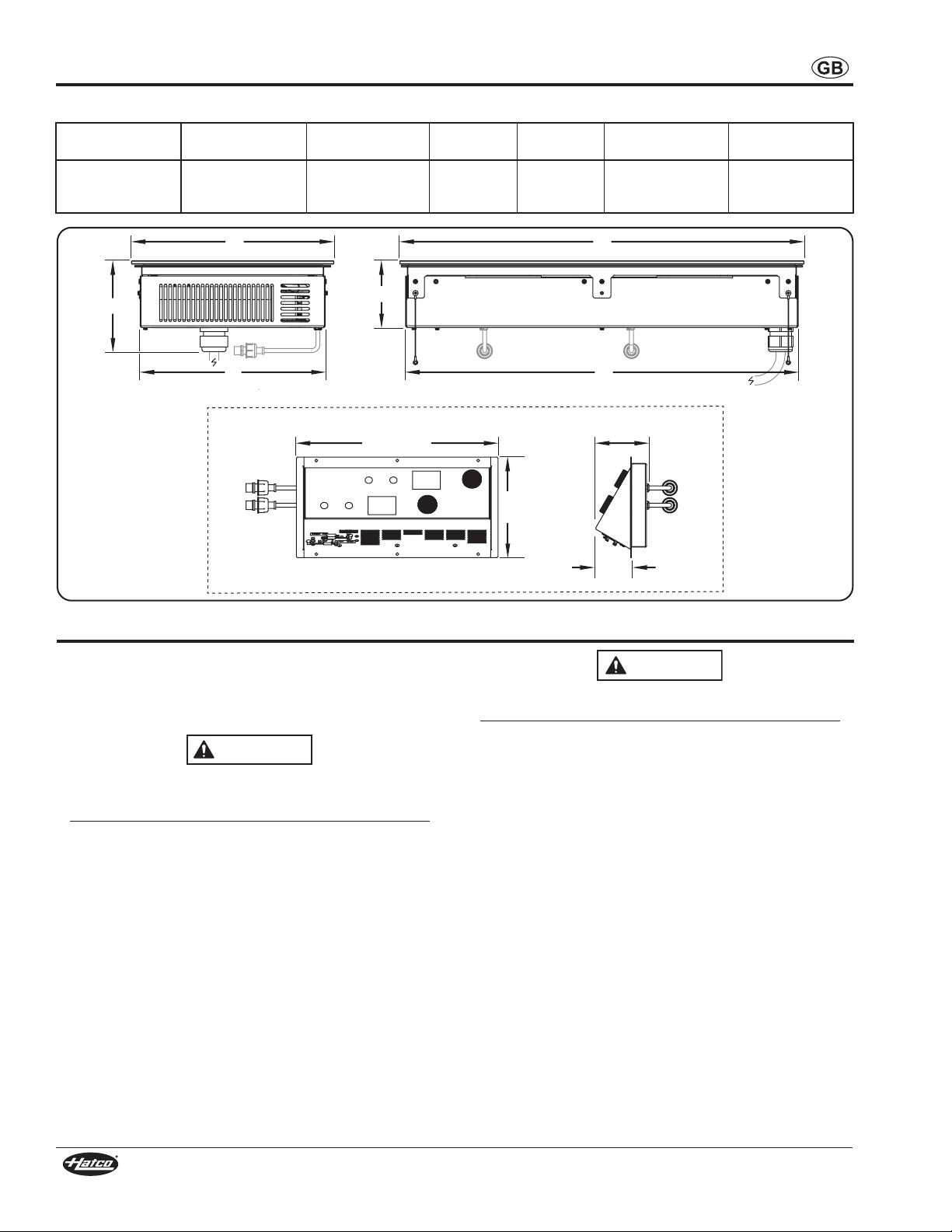

Dimensions .........................................................................7

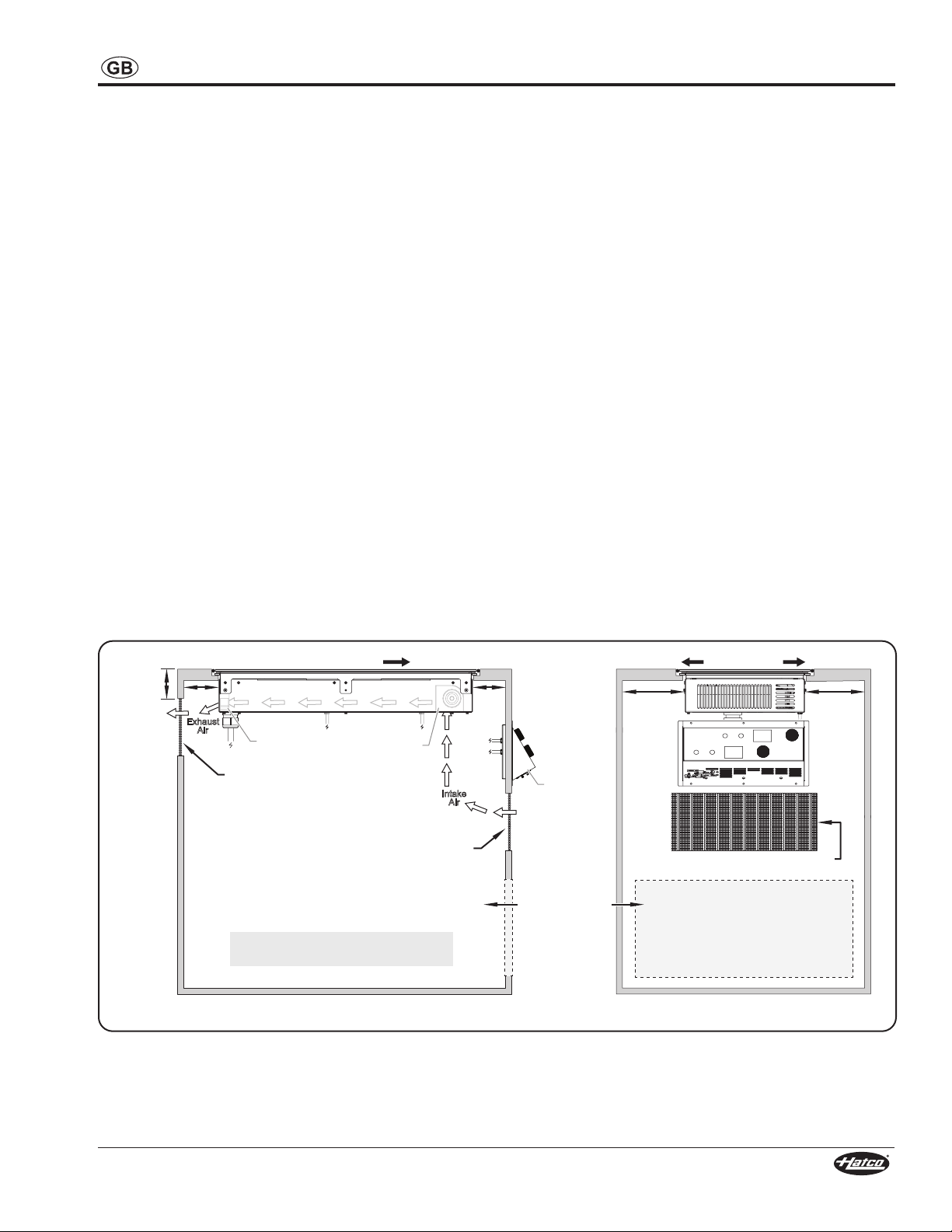

Installation.............................................................................8

General................................................................................8

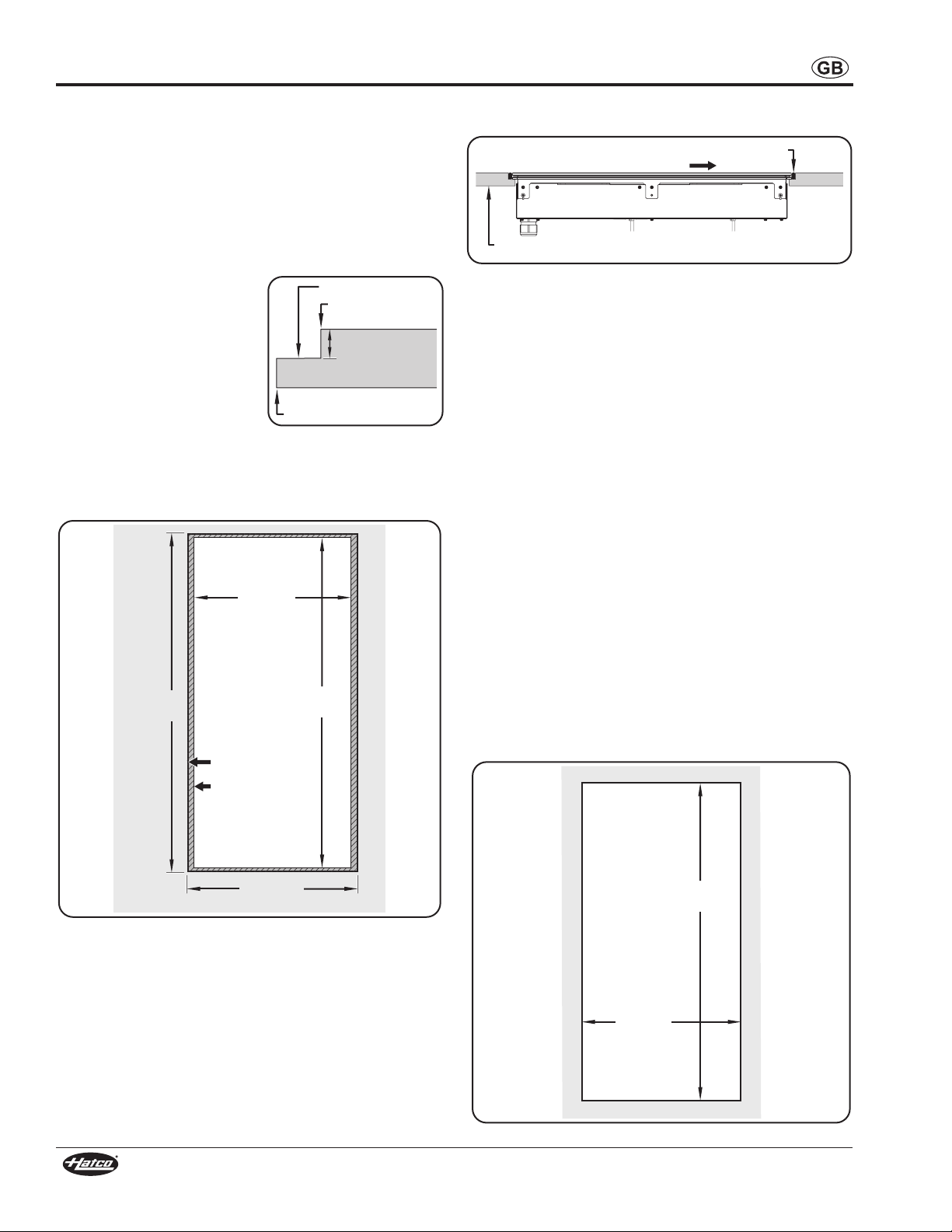

Installing Built-In Models .....................................................9

Installing the Control Panel ............................................... 11

Operation.............................................................................12

General..............................................................................12

Changing Cooking Control Method ...................................13

Using the Timer .................................................................14

Cooking with Menu Items..................................................14

Programming Menu Items .................................................15

Changing Operation Mode ................................................15

Changing Between Fahrenheit and Celsius......................16

Resetting the Software ......................................................16

Updating Firmware ............................................................16

Maintenance........................................................................17

General..............................................................................17

Daily Cleaning ...................................................................17

Troubleshooting Guide ......................................................18

Service Information............................................................18

International Limited Warranty .........................................19

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and purchase

date of your strip heater in the spaces below (specification

label located on the underside of the unit). Please have this

information available when calling Hatco for service assistance.

Model No. ________________________________________

Serial No._________________________________________

Voltage___________________________________________

Date of Purchase___________________________________

Register your unit!

Completing online warranty registration will prevent delay in

obtaining warranty coverage. Access the Hatco website at

www.hatcocorp.com, select the Support pull-down menu,

and click on “Warranty”.

Business

Hours: 7:00 to 5:00 Monday–Friday,

Central Time (CT)

(Summer Hours—June to September:

7:00 to 5:00 Monday–Thursday

7:00 to 4:00 Friday)

Telephone: +1-414-671-6350

Additional information can be found by visiting our web site at

www.hatcocorp.com.

Correct Disposal of this Product

This marking indicates that this product and its electronic

components should not be disposed of with other

commercial waste. To prevent possible harm to the

environment or human health from uncontrolled waste

disposal, recycle responsibly to promote the sustainable

reuse of material resources. To dispose of product and its

electronic components, contact supplier where product

was purchased for environmentally safe recycling.