Hausmann 1396 Operation manual

HAUSMANN INDUSTRIES, INC.

130 UNION STREET, NORTHVALE, NJ 07647

↥2004 Hausmann Industries, Inc.

Model 1396 (Less dowel holes and apparatus)

Model 1398 (With dowel holes and apparatus)

Ph: (201) 767-0255 Fax: (201) 767-1369

Models 1396 and 1398 Operation and Service Guide

11/3/04

Models 1396, 1398 Power Height Parallel Bars

Operation and Service Guide

CONSTRUCTION

The drive system consists of (4) "TMA" synchronized lifting columns which can be elevated and

lowered by means of control box and associated control switch with LED height readout (in

inches).

The TMA are electrical linear drives in no-clearance aluminum guide tubes. Surfaces of vertical

lift columns are anodized aluminum. A 24 V-DC motor drives through a worm drive and

threaded rod. A tapped nut, which is firmly attached to the push drive, moves up and down the

threaded rod and this provides the forward movement. Extension and contraction of the

telescopic tubes is by means of changing the direction of the rotation of the motor.

LIFTING COLUMNS

TABLE OF CONTENTS

ᔣConstruction

ᔣLifting Columns

ᔣControl Box

ᔣHand Switch

ᔣOperating Method

ᔣTechnical Data

ᔣPatient Weight Capacity

ᔣOperation

ᔣMemorizing the Memory Positions

ᔣPositioning to Memorized Position

ᔣMaintenance and Care

ᔣWiring Diagram

ᔣModel 1396 and 1398

ᔣDetail of Steel Wiring Chase

ᔣDetail of Hand Control Switch

ᔣDetail of Cord Connections

ᔣDetail of Control Box

ᔣDetail of Width Adjustment Knob

ᔣModel 1398 Only

Page 1

Page 1

Page 1

Page 2

Page 2

Page 2

Page 2

Page 3

Page 3

Page 4

Page 4

Page 5

Page 6

Page 6

Page 7

Page 7

Page 8

Page 9

Page 10

.....................................................................................................................

.................................................................................................................

......................................................................................................................

.......................................................................................................................

.............................................................................................................

..................................................................................................................

...................................................................................................

.........................................................................................................................

...................................................................................

...................................................................................

.....................................................................................................

................................................................................................................

......................................................................................................

.......................................................................................... .

........................................................................................ .

..............................................................................................

........................................................................................................

......................................................................................

............................................................................................................ .

1

↥2004 Hausmann Industries, Inc.

11/3/04

The control and supply of the lifting columns is by means of an associated micro-processor

control unit IE.

(4) Column system control unit ... LD-014 Control box is double insulated for safety.

CONTROL BOX

HAND SWITCH

Operation of the system is by means of an LD-011 Hand Control Switch (mounted on black

wooden support post near one end of platform).

PATIENT WEIGHT CAPACITY

400 lbs.

NOTE: Handrail motors are designed to electrically adjust in height , and to be stable under use

when at their fixed height level. Motors are not designed to "lift" full weight of patient from

sitting to standing position.

Not designed for continuous use.

Intermittent 10%; 30 seconds ON

270 seconds OFF

Thermal overload: Unit will shut down automatically if motor overheats due to continuous use.

Unit will restart automatically after "cool off" peiod of up to 15 minutes.

OPERATING METHOD

2

↥2004 Hausmann Industries, Inc.

11/03/04

Push Force (1 Lift Column)

Stroke

Speed

110V, 60Hz, 2.5 Amps

All electrical components are U.L. recognized components, furniture grade.

There is sufficient wheelchair clearance for most 16" and 18" wide seat wheelchairs, but

insufficient clearance for 20" or wider seat wheelchairs.

TECHNICAL DATA

1000 N

15" (29" to 44" high)

2.1"/second

3

↥2004 Hausmann Industries, Inc.

11/3/04

MEMORIZING THE MEMORY POSITIONS

As the height adjustment is variable and random from patient to patient, we normally do not

recommend use of memory control, but it is an option if needed.

With the memory capacity, you can specify a given handrail height. Up to four different heights

can be memorized. These memorized positions can be later re-specified.

Press . An S appears in the LED display.

Press one of the position keys , , or .

After the position key has been pressed, the number of the position key appears in the LED

display next to S. After the memorization procedure, a double-click is heard, and after

approximately 2 seconds the current height appears again in the LED display.

1

S

32 4

OPERATION (See hand control switch at top of page 7.)

Unit is pre-wired and pre-tested at factory ready for use. Set the platform in place and plug

power cord into 110V wall outlet.

IMPORTANT

Follow these instructions exactly upon initial use, as follows:

Press "Up" Button and elevate both handrails approximately 2" (not more) - the LED

display will read-out the height in inches.

Press "Down" Button and lower both handrails until they are at lowest height

(bottomed out). The unit will stop automatically at lowest level.

Press "Down" Button again for 5 seconds to make sure all (4) columns have

bottomed out to their lowest height.

Press "Up" Button and elevate hand rails to maximum highest height of 44".

Press "Up" Button again for a second or two to make sure all (4) lift motors are at

maximum height.

Press "Down" Button to lower to normal height level.

YOU ARE NOW READY TO OPERATE FOR NORMAL USE.

MAINTENANCE AND CARE

Maintenance

The motor cables and power cord should be periodically checked for any signs of wear or tear.

Care

A damp (non-dripping) cloth is best for manual cleaning.

Responsibility

Responsibility for the operation of the apparatus falls in all cases on the proprietor or operator, if

the apparatus has been improperly installed , maintained or adjusted, or if use is made of it

which does not correspond with its intended use.

4

↥2004 Hausmann Industries, Inc.

11/3/04

POSITIONING TO MEMORIZED POSITIONS

Variant A

Press and hold one of the position keys , ,

or .

The handrails move to the selected position as long as the key is

kept pressed. If the key is released, the handrails stop.

If the key is kept pressed, the handrails keep moving until they

reach the memorized position.

Variant B (optional)

Double-click one of the position keys , ,

or .

The handrails automatically move to the memorized position.

1 32

4

1 32

4

If a key is pressed during automat-

ic positioning the handrails stop

moving.

i

1396/1398 WIRING DIAGRAM

5

↥2004 Hausmann Industries, Inc.

11/3/04

HS

2134

56789

Lift Motor

Column 4

# TMA

Lift Motor

Column 3

# TMA

Lift Motor

Column 2

# TMA

Lift Motor

Column 1

# TMA

Control Box

# LD-014

Blank

Electrical Power Cord

hardwired to Control Box

110V, 60 Hz

Port

Actuator Connecting Cable

(at both ends of cable)

Memory

Buttons

LED

Display Up Down

Hand Switch Panel

# LD-011

Unit is shipped fully wired and ready for operation.

1

S

234

Connectors

Port Port Port Port

Note:

TMA Lift Motors

are 24V-DC.

CAUTION: You must remove 110V power plug before attempting any factory authorized repair.

ALL CORD CONNECTIONS FROM LIFT COLUMNS TO CONTROL BOX ARE PRE-CONNECTED AT

FACTORY. DO NOT REMOVE CONNECTIONS WITHOUT FACTORY AUTHORIZATION.

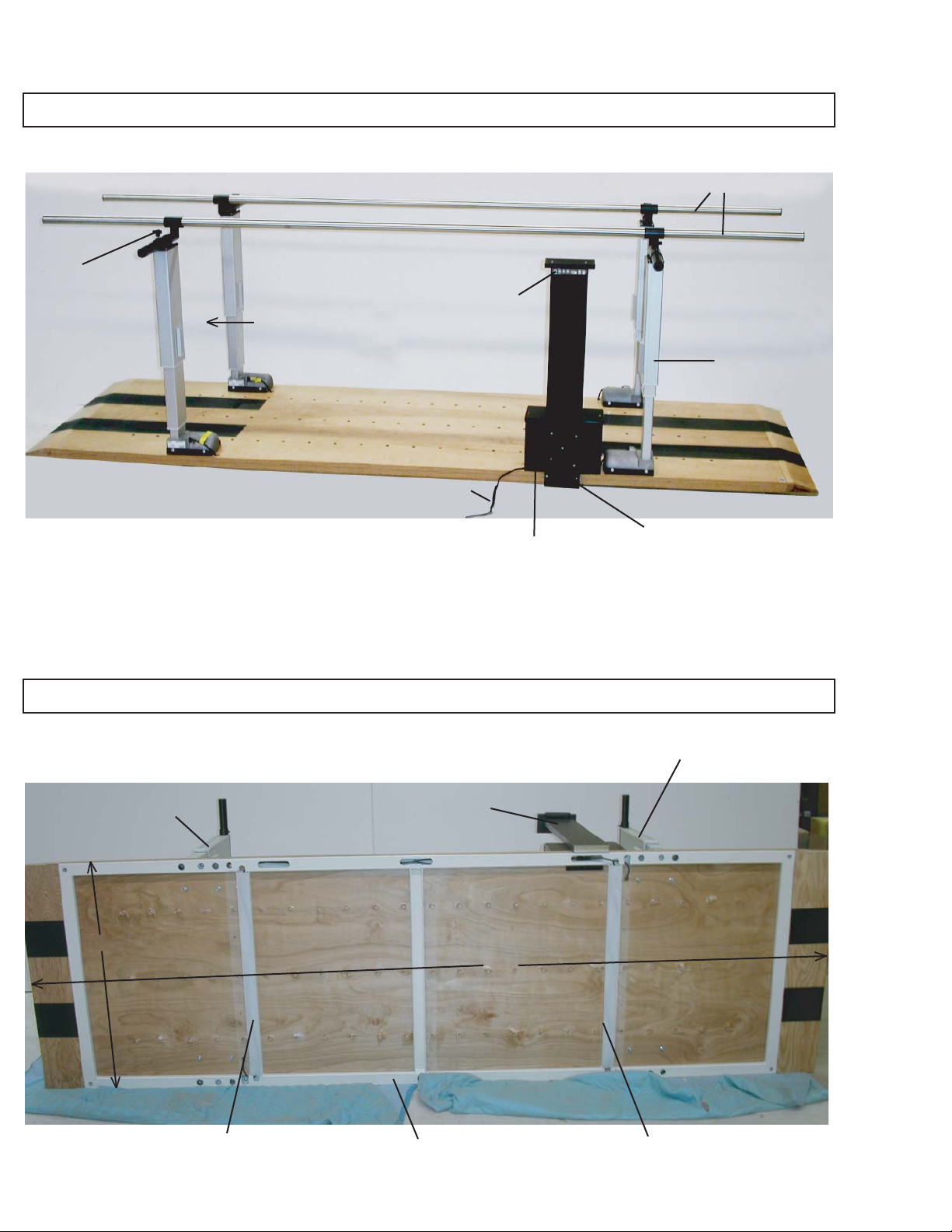

MODEL 1396 AND 1398 (1396 has no dowel holes in platform)

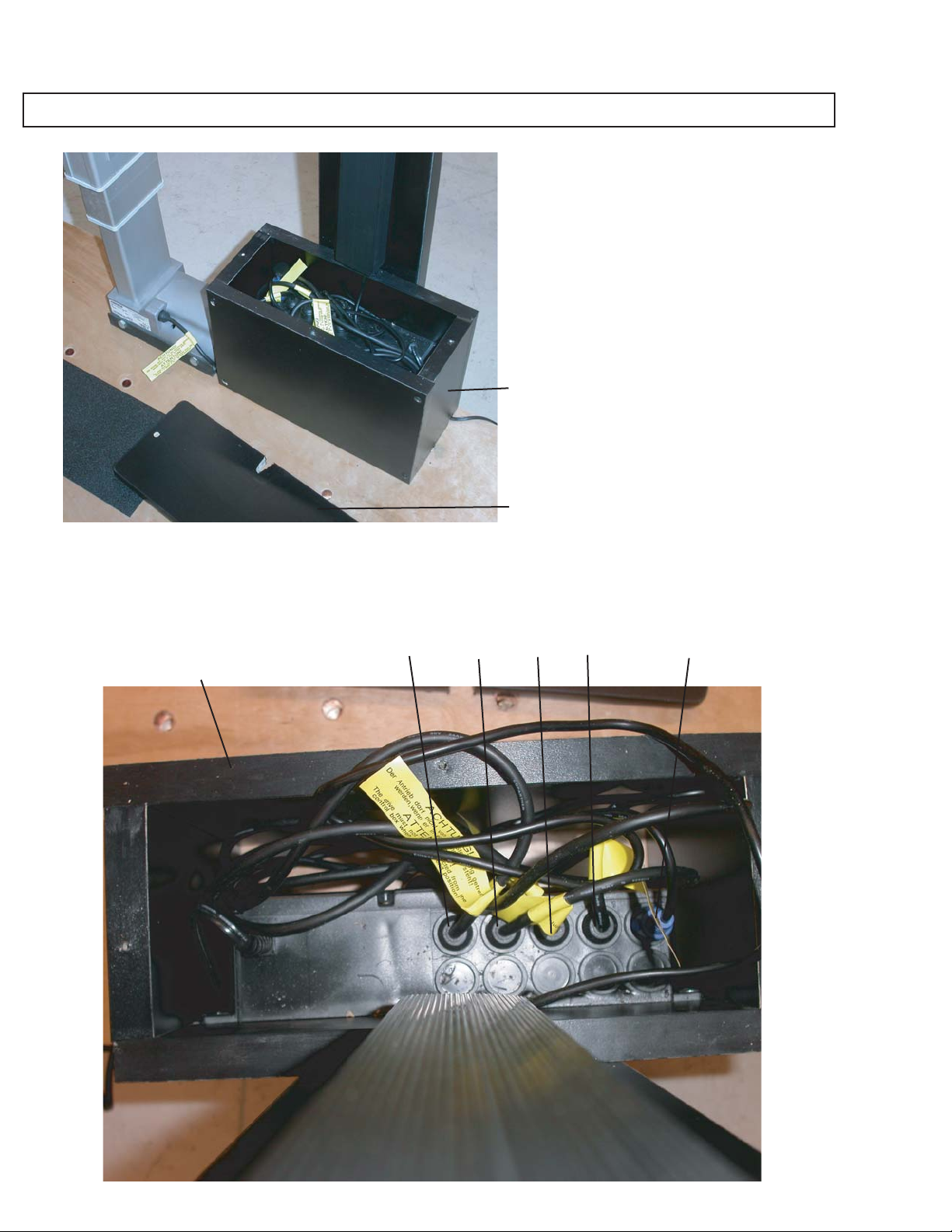

DETAIL OF STEEL WIRING FRAME (UNDER WOOD PLATFORM)

6

↥2004 Hausmann Industries, Inc.

11/3/04

Manual

Width

Controls

110V Power Cord

10' Stainless

Steel Handrails

(4) "TMA"

Powerlift

Columns

Control Panel

with LED display

of height of bars

(in inches)

Black upright

with hand switch

"height" control

Control Box

enclosure

Lift

Column

Black upright

with switch control

Steel wiring chase

underneath wood platform

Lift

Column

27" Clearance

between uprights

Removable plastic cover

plate to access wires

Removable plastic cover

plate to access wires

130"

38"

1

S

234

DETAIL OF HAND CONTROL SWITCH WITH LED DISPLAY OF HEIGHT READ-OUT

ALL CORD CONNECTIONS FROM LIFT COLUMNS TO CONTROL BOX ARE PRE-CONNECTED AT

FACTORY. DO NOT REMOVE CONNECTIONS WITHOUT FACTORY AUTHORIZATION.

7

↥2004 Hausmann Industries, Inc.

11/3/04

Memory Controls Height

read-out

in inches

"Up"

Button

"Down"

Button

10'

Stainless

Steel

Handrails

Width

Control

Knob

TMA Lift Column

Cord Connection

to Control Box

(See wiring diagram

on page 5)

Wood Platform

(Shown with #1398

dowel holes - #1396

has no dowel holes)

TMA Lift Column

Cord Connection

to Control Box

(See wiring diagram

on page 5)

See page 2 for initial operating instructions upon delivery.

Mounting

Plate

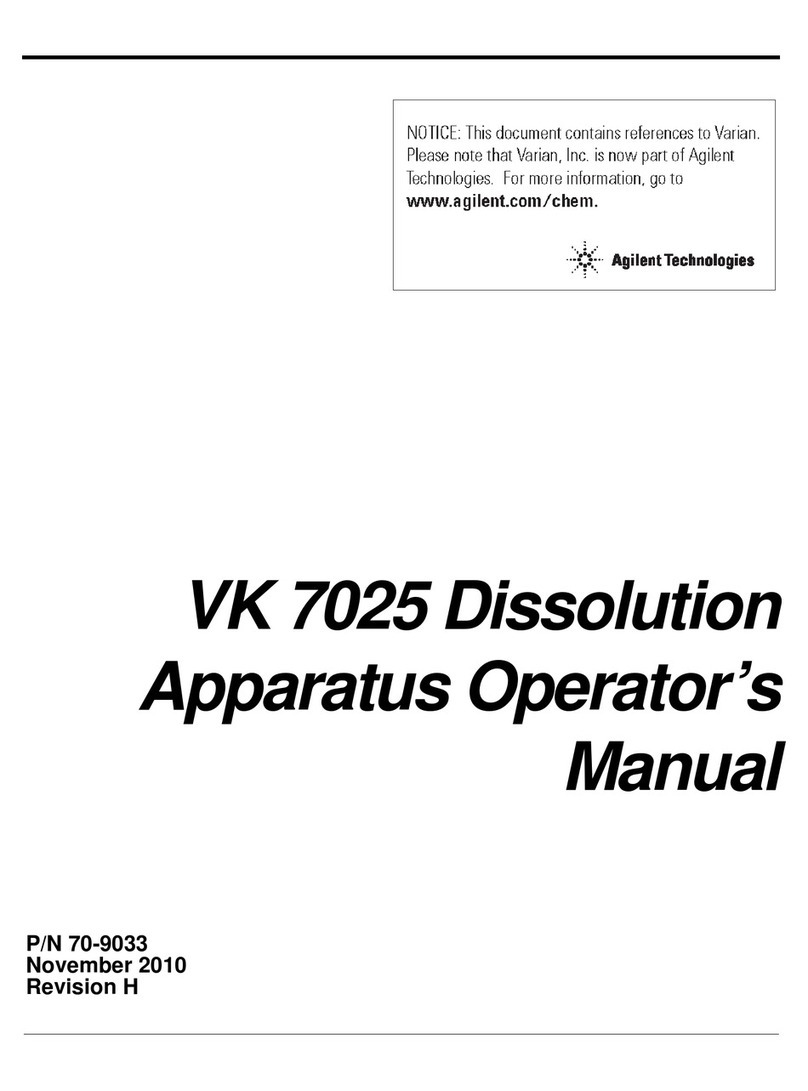

DETAIL OF CONTROL BOX WITH LID "OFF"

8

↥2004 Hausmann Industries, Inc.

11/3/04

Control Box

Lid Removed

LD-014

Control Box

(shown with lid "off")

Port 4 Port 1Port 2Port 3 Control Switch Port

CAUTION:

Do not open or access control box

without prior factory authorization.

Disconnect 110V power cord before

authorized access.

DETAIL OF WIDTH ADJUSTMENT KNOB OF STAINLESS STEEL HANDRAIL

9

↥2004 Hausmann Industries, Inc.

11/3/04

Width Control Knob

Mounting plate for

width control knob

To adjust width, turn both width control knobs counter-clockwise until "loose", then move handrail "in" or

"out" as needed, and retighten friction control knobs to lock-in width position of handrails. Width adjusts

from 15" to 28" wide. Each side should be adjusted at the same time. See image below: Adjust side A-B,

then adjust side B-C.

1/4" x 1/20

Set Screw

1/4" x 1/20

Set Screw

AB

CD

1398 ONLY

10

↥2004 Hausmann Industries, Inc.

11/3/04

Detail showing (23) rows of holes in wood platform for variable placement of "blue" ladder steps

Detail showing insertion of ladder step into dowel holes in wood platform.

Detail of (1) balance beam 6' 5" long x 6" wide x 3" high.

Detail of dowel pin of balance beam.

Control Box

Wood Enclosure

4 1/2"

typical

Control box with lid in place

(Do not remove lid without

factory authorization.)

(11) Ladder Steps

included in #1398

Position dowel pins on each end of

balance beam in center row of dowel

holes before use.

This manual suits for next models

1

Table of contents

Other Hausmann Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Agilent Technologies

Agilent Technologies Varian VK 7025 Operator's manual

FujiFilm

FujiFilm Sonosite PX System Service manual

Atos Medical

Atos Medical PROVOX Vega Instructions for use

Welch Allyn

Welch Allyn Acuity Directions for use

DEHAG

DEHAG Nystagmus Spectacle User instruction

HeartCare

HeartCare LOX100A user manual