Hausmann 1427 Installation instructions

Rev. 072514 aj Page 1of 7©2013 HAUSMANN INDUSTRIES, INC.

130 Union St • Northvale NJ 07647 USA • Tel: (201) 767-0255 • Fax: (201) 767-1369 • www.hausmann.com

Installation/Operation Instructions

Model 1427 –Bariatric Electric Mat Platform

A) INSTALLATION INSTRUCTIONS

1. Remove all packaging material from the platform.

2. Plug the power cord into a properly grounded 120 Volt AC

outlet and follow the procedure outlined in the

precautionary instructions.

Leveling the Platform:

1. Place the table in position before leveling.

2. Use adjustable wrench to rotate leg levelers for height adjustment.

B) OPERATING INSTRUCTIONS

Duty cycle on/off Int. 2 min./ 18 min.

1. Raise the platform by gently pressing the up arrow on the footswitch.

2. Lower the platform by gently pressing the down arrow on the footswitch.

C) MAINTENANCE

In the event it becomes necessary to replace the foot switch or power cord, make certain that the component is

connected properly and the locking tabs on the motor snaps in place.

For assistance please call Hausmann Industries at (201) 767-0255, press 5 for Customer Service. We may request

purchase details (product, date purchased, dealer) to better assist you.

Product Specifications

Model #

Length

Width

Height

Weight Capacity

1427-46

6’

4’

20” – 30”

750 lbs

1427-47

7’

4’

20” – 30”

750 lbs

1427-57

7’

5’

20” – 30”

750 lbs

1427-68

8’

6’

20” – 30”

750 lbs

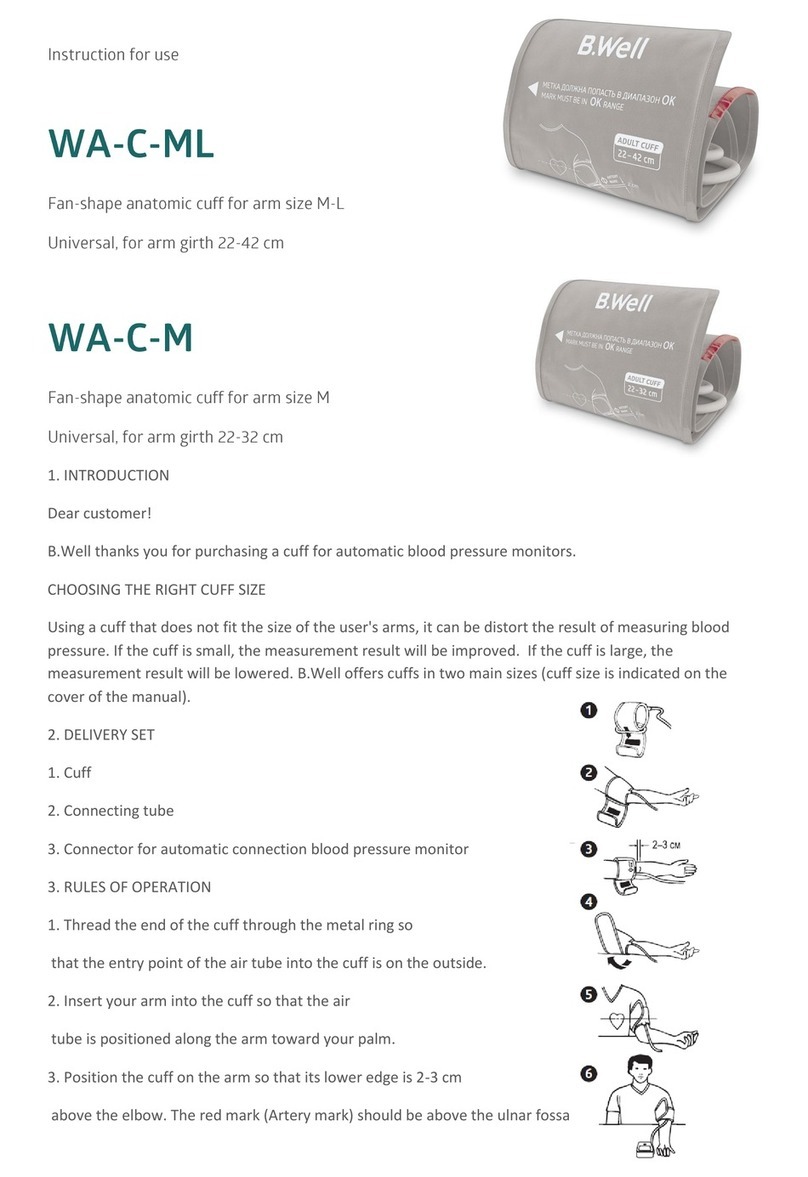

Part Lists

Part

Qty

Description

A

1

Upholstered Top

B

4

Black Steel Aprons (2 long, 2 short)

C

4

Corner Steel Legs

D

4

Hydraulic Lift Cylinder/Legs

E

1

115 V Motor/Hydraulic Pump Assm.

F

4

Adjustable Leg Levelers

G

1

Foot Control, 12V DC with 6’ cord

H

1

Control Box

Figure 3: Fully Assembled

Figure 3: Fully Assembled (1340)

12” to 24”

C

C

Figure 1: Hi-Lo Treatment Table

Product Specifications

Length

43”

Depth

24”

Height

36”

Weight Capacity

40 lbs

Figure 1: Examination Table

Platform Ships Fully Assembled

Figure 1: Mat Platform

Product Specifications

Length

43”

Depth

24”

Height

36”

Weight Capacity

40 lbs

Figure 1: Examination Table

A

C

B

D

F

G

Rev. 072514 aj Page 2of 7©2013 HAUSMANN INDUSTRIES, INC.

Movotec® Refill Instructions

Q-Drive Motorized Lift Systems

Movotec® Refill Kit Contents

Movotec® Refill Instructions

Movotec® NT15 Hydraulic Fluid MSDS

(0.5) Liters (16.9 oz.) of Movotec® NT15 Hydraulic Fluid

Filler Bottle

Filler Bottle Cap

Filler Bottle Needle

(10) Meters (32.8 ft.) of Movotec® Flexible Hydraulic Tubing

(12) Ferrules

(12) Compression Nuts

1.0 Safety Instructions

This document contains safety and user service instructions for refilling a Movotec

®

Q-Drive Motorized Lift System. Suspa

®

Incorporated is not responsible for any alteration or deviation from these instructions resulting in property damage, personal

injury or death.

FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS DOCUMENT COULD

RESULT IN FIRE, PROPERTY DAMAGE, ELECTRC SHOCK, PERSONAL

INJURY OR DEATH.

The instructions in this document are intended to be used in conjunction with the Movotec

®

Refill Kit. The Movotec

®

NT15

hydraulic fluid contained in this kit is specially formulated for the improved performance of our lift systems. DO NOT, FOR

ANY REASON, USE ANY FLUID OTHER THAN MOVOTEC

®

NT15 HYDRAULIC FLUID WHEN REFILLING A MOVOTEC

®

LIFT

SYSTEM.

READ ALL INSTRUCTIONS BEFORE ATTEMPTING TO REFILL A MOVOTEC

®

LIFT SYSTEM.

2.0 System Preparation

2.1 Motorized System Preparation.

Lower the system by holding “down” arrow button on the switch. Continue holding “down” arrow button until all lift

cylinders have reached their fully retracted position. Remove finger from the switch. Then, press and hold “down” arrow

button again. After approximately 5 seconds the system will begin to retract until the “zero” position is reached. The system

is now fully retracted.

COMPRESS CYLINDERS COMPLETELY

Rev. 072514 aj Page 3of 7©2013 HAUSMANN INDUSTRIES, INC.

Once the system has reached the “zero” position, unplug power

cord from the power outlet. Then disconnect motor cable from

controller (keep cables plugged in to back of motor drive).

2.2 Cylinder Preparation

To properly refill a cylinder, the load must be removed from all cylinders and/or the workstation. For Movotec

®

“Bolt-On” lift

systems, this can be achieved by lifting the entire workstation off of the floor with a lift truck or pallet jack. Blocks can be

used to stabilize the workstation during the refill procedure.

For Movotec

®

ATU and Corner Leg systems, lift cylinder(s) that are to be refilled must be removed from their corresponding

support leg. Movotec

®

ATU lift systems will require external retaining ring pliers to remove the 13mm retaining ring from the

top of the lift cylinder. For Movotec

®

Corner Leg lift systems, a T25 torx driver will be required to remove (4) torx screws at

the top of the corner leg support housing. Additionally, external retaining ring pliers will be required to remove a 13mm

retaining ring and upper cap from the top of the lift cylinder.

ATU Cylinder Removal Corner Leg Cylinder Removal

Rev. 072514 aj Page 4of 7©2013 HAUSMANN INDUSTRIES, INC.

2.3 Pump Preparation

Detach pump from work surface. Orient and secure pump in an upright position to prevent

fluid loss during the refill procedure. Be careful not to stretch, kink, or damage the hydraulic

tubing and connections.

Crank Driven Pump (Shown in Upright Position)

3.0 Tubing Disconnection

To disconnect tubing from pump, unscrew and remove the compression nut, ferrule, and tubing assembly which corresponds

with the lift cylinder to be refilled.

To disconnect tubing from cylinder, unscrew and remove compression nut,

ferrule, and tubing assembly from cylinder port. NOTE: CB cylinders will require

the removal of plastic cap to expose the compression nut.

CB Cylinder Shown

4.0 Refill Procedure

To refill the pump, fill open port with Movotec

®

NT15 Hydraulic Fluid to level

indicated below using the filler bottle with needle. NOTE: The pump element will

not fill properly if the filler bottle needle is not inserted past the smallest opening

in the port as shown.

To refill a top-ported cylinder, slowly pull cylinder rod to an extended length of

approximately 4 inches (102mm) from end of cylinder body. Fill open cylinder

port with Movotec

®

NT15 Hydraulic Fluid to level indicated below using the filler

bottle with needle. NOTE: The cylinder will not fill properly if the filler bottle

needle is not inserted past the smallest opening in the port as shown.

Rev. 072514 aj Page 5of 7©2013 HAUSMANN INDUSTRIES, INC.

5.0 Tubing Attachment

Original tubing assembly can be reused if undamaged. When cutting a new section of

Movotec

®

Flexible Hydraulic Tubing to required length, make sure any cuts made are

square and clean. Tubing length must not exceed 196 inches (5m). Slide compression

nut and ferrule onto tubing. NOTE: If a CB cylinder is used, slide plastic cap over tubing

end first as shown below.

To attach tubing to cylinder, insert tubing end into cylinder port. While maintaining a

slight downward pressure on tubing, slide compression nut and ferrule down into port.

Re-tighten compression nut to 84-88 lbf-in (9.5-10 N-m) torque. NOTE: For a CB

cylinder, slide plastic cap down tubing and insert into CB cylinder housing.

CB Cylinder Shown

For this step, a container will be required to collect fluid. Hold the open end of flexible

tubing over the container. With cylinder in upright position, completely compress

cylinder rod. This action will expel fluid from the cylinder and fill the flexible tubing with

fluid.

COMPRESS CYLINDER COMPLETELY

Before reconnecting tubing to pump, make sure that the cylinder is

completely compressed. Slide compression nut and ferrule onto free

end of tubing. Insert free tubing end into pump port. While maintaining

a slight downward pressure on tubing, slide compression nut and

ferrule down into port. Re-tighten compression nut to 84-88 lbf-in (9.5-

10 N-m) torque.

6.0 Operation

Once all cylinders have been refilled and tubing connections are made as needed, re-attach the pump to workstation.

Crank driven systems should now be fully operational and ready for normal use.

For motorized systems, re-attach motorized pump to the workstation. Re-connect the motor cable to the controller. Finally,

connect power cord to a power receptacle. The controller should make an audible “double-clicking” sound. The motorized

system should now be fully operational and ready for normal use.

Rev. 072514 aj Page 6of 7©2013 HAUSMANN INDUSTRIES, INC.

Lift System Controller Reset Procedure

The following procedure should be used to reset a Movotec® Q-Drive motor controller and pump to their respective

“home” positions. The procedure should be performed only if the following conditions exist:

1.) A new or replacement controller is introduced to an existing motor driven system.

The Movotec® Q-Drive motor and motor controller leaves our manufacturing facility programmed as a matched set. If a

different motor controller is used other than the one that was sent with the original unit, it must be matched and

reset with the original motorized pump using the system reset procedure below; the controller will likely force this

procedure when introduced to a new system.

2.) The motor cable is disconnected from the gear motor.

If this happens, reconnect the motor cable to the gear motor. Perform the system reset procedure below to ensure that

the motorized pump will function within its preprogrammed limits.

3.) The system is behaving unusually.

Although it is not very common, a power outage or brown-out condition can cause a motor controller to lose its

programmed position. If this happens, the motor may move in one revolution increments in one or both directions. To

remedy this problem, perform the system reset procedure below.

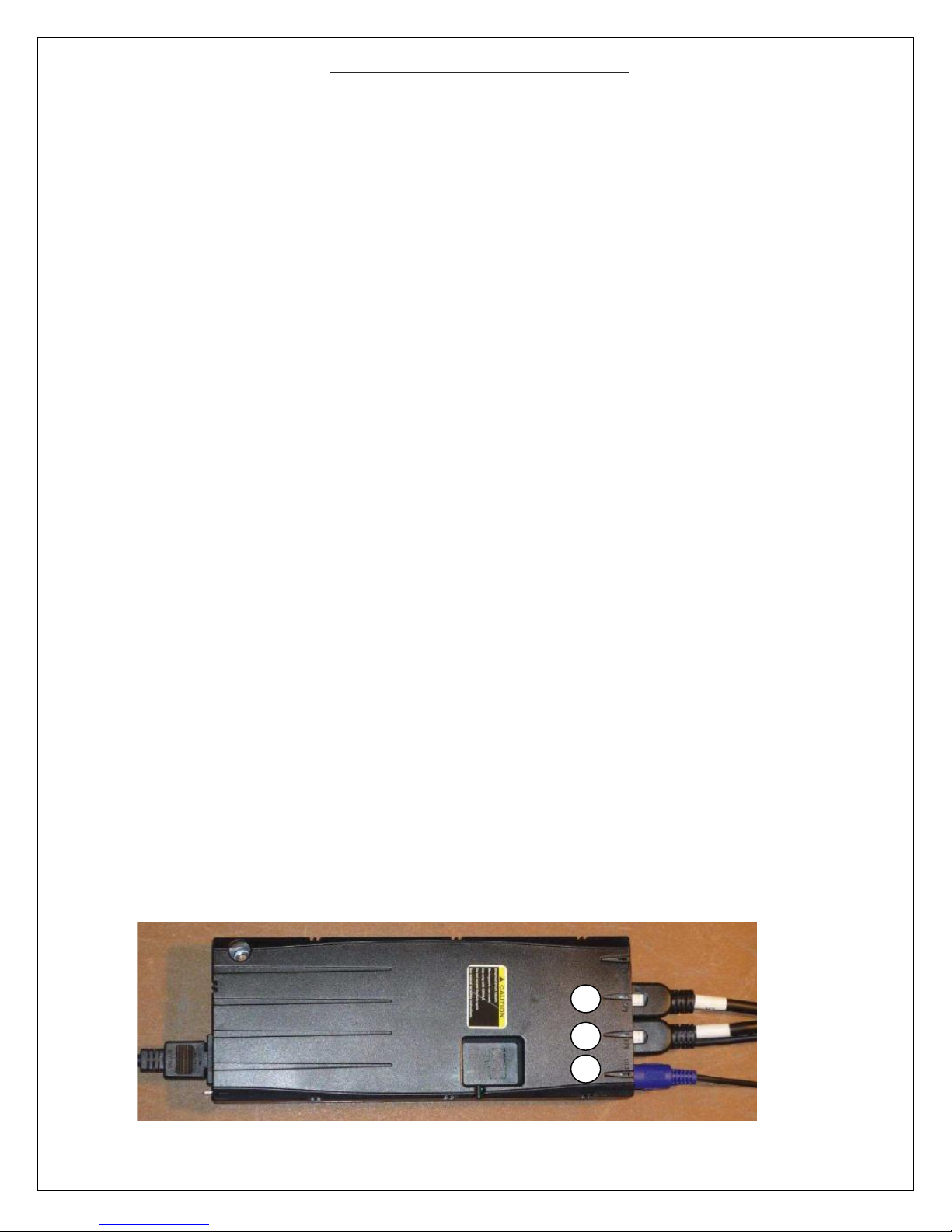

Remove the motor cables from the “M” slots on the controller (M1, M2, etc.), keeping the switch (the “HS” slot) and

power cord plugged into the control box. After removing the M1 and M2 cables, a reset will be triggered

automatically.

Re-install the M1 and M2 plugs in to their respect ports on the control box.

Press and hold the down button on the switch to bring the system down to its bottom position. Once the system hits

the bottom, release the down button and press and hold it again and the system will automatically move further

down a slight distance and come back up indicating that the system is been reset. Release the down button once the

system is reset.

NOTE: During the reset the system also makes slight single and dual click sound. The double click followed by the

single click indicates that the system is been reset.

After the legs have stopped, remove finger from the down button.

At this point, your lift system should be reset to its home position. To verify, operate the system by moving it upwards with

the up button, and again downwards; ensure the system returns to the home position.

M1

M2

HS

Rev. 072514 aj Page 7of 7©2013 HAUSMANN INDUSTRIES, INC.

D) TROUBLESHOOTING

Many system problems can be attributed to electrical cables that are not connected correctly, system load conditions,

or incorrect mounting hardware usage. In most cases, problems can be solved by reviewing the following system

problems, possible causes, and implementing the recommended solutions.

Problem: System does not operate.

Possible Causes

Recommended Solutions

Power Cord is not connected

Connect power cord to motor controller and/or power

source completely.

Motor Cable is not connected

Connect motor cable to gear motor and/or motor

controller completely.

Switch Cable is not connected

Connect switch cable to motor controller completely.

Defective Motor Controller

Contact Hausmann Industries Inc. for replacement.

Defective Switch

Contact Hausmann Industries Inc. for replacement.

System Load Rating Exceeded

Verify system load does not exceed rating and remove

weight as needed.

Problem: Motor runs but does not extend or retract system.

Possible Causes

Recommended Solutions

Broken Pusher Block

Contact Hausmann Industries Inc. for replacement

pump.

Broken Coupler Sleeve

Contact Hausmann Industries Inc. for replacement.

Problem: Motor runs intermittently and requires repeated switch activation.

Possible Causes

Recommended Solutions

System Load Rating Exceeded

Verify system load does not exceed rating and remove

weight as needed.

Motor Controller in Reset Mode

Perform “System Reset Procedure”

Table of contents

Other Hausmann Medical Equipment manuals