HAUTAU SBS 300 S User manual

HAUTAU SBS 300 S

HAUTAU SBS 500 S

24 V DC

07/2016208206J

t

D

Montageanleitung / Installation instructions

Mitglied im

Fachkreis

elektromotorisch

betriebene

Rauch- und Wärme-

abzugsanlagen

Inhaltsverzeichnis

Produkthaftungsvorschriften ............................................ 2

Wichtige Sicherheitsanweisungen .................................... 2

Technische Daten ............................................................ 6

Verpackungseinheiten ..................................................... 6

Anwendung ..................................................................... 7

Montage 1 ....................................................................... 7

Montage 2 ..................................................................... 12

Montage 3 ..................................................................... 16

Montage 4 ..................................................................... 19

Begrenzungsscheren SBS ............................................. 23

Gewährleistung .............................................................. 24

Entsorgung .................................................................... 24

Table of contents

Product liability instructions ................................................ 2

Important safety instructions .............................................. 2

Technical Data ................................................................... 6

Packaging units ................................................................. 6

Application ........................................................................ 7

Installation 1 ...................................................................... 7

Installation 2 .................................................................... 12

Installation 3 .................................................................... 16

Installation 4 .................................................................... 19

Restrictors SBS ............................................................... 23

Warranty .......................................................................... 24

Disposal .......................................................................... 24

Einbauerklärung Declaration of incorporation

Die Einbauerklärung finden Sie im Internet unter

www.HAUTAU.de

The declaration of incorporation is available on the Internet

at www.HAUTAU.de

2

The drive may only be operated at

very low safety voltage.

Before servicing work, disconnect

power supply and secure against

improper reconnection.

Danger of Pinching / Clamping:

During assembly work and operation,

do not reach into the window rabate

or into the moving spindle. Window

shuts automatically.

Warning

Danger of personal injury during

operation of device.

Warning

Danger of material damage due to

incorrect handling.

Der Antrieb darf nur mit Sicherheits-

kleinspannung betrieben werden.

Bei Wartungsarbeiten Netz abklemmen

und vor unsachgemäßem Wieder-

einschalten sichern.

Quetsch- und Klemmgefahr:

Bei der Montage und Bedienung nicht

in den Fensterfalz und in die laufende

Spindel greifen. Fenster schließt

automatisch.

Warnung

Gefährdung für Personen durch Ge fah-

ren aus dem Gerätebetrieb.

Warnung

Gefährdung für Material durch falsche

Hand habung.

WARNUNG:

Wichtige Sicherheits-

anweisungen!

Für die Sicherheit von Personen ist es

wichtig, die folgenden Anweisungen

zu befolgen. Falsche Montage kann zu

schweren Verletzungen führen!

WARNING:

Important safety

instructions!

The safety of personnel requires that the

following instructions be observed. Incorrect

installation can lead to severe injury!

Die Verklotzungs-Richtlinien für Ver glasungstechnik sind

einzuhalten. Bei aggressiven Hölzern sind die Beschlag-

aus fräsungen vor der Beschlagmontage zum Schutz der

Beschläge mit einem Schutzlack zu behandeln. Für die

ständige Funktionssicherheit des Beschlages ist folgendes

zu beachten:

1. Fachgerechte Montage des Beschlages entsprechend

dieser Montage anleitung.

2. Fachgerechte Montage der Elemente beim Fenstereinbau.

3. Der Gesamtbeschlag darf nur aus Original HAUTAU-

System teilen bestehen. Mitverwendung fremder

Beschlag teile (z. B. Zentralverschluss, Griff) schließt

jegliche Haftung für diese Bauteile aus.

Produkthaftung-Haftungsausschluss:

Der Beschlaghersteller haftet nicht für Funktions störungen

oder Beschä digungen der Beschläge sowie der damit

ausgestatteten Fenster oder Fenstertüren, wenn diese

auf Mitverwendung fremder Beschlagteile, unzureichende

Ausschreibung, Nichtbeachtung der Montage vor schriften

oder Anwendungsdiagramme zurück zuführen sind.

Der Verarbeiter ist für die Einhaltung der in dieser Montage-

anleitung bzw. der in der Werkstattzeichnung angegebenen

Funktionsmaße sowie für eine einwandfreie Beschlagmontage

und sichere Befestigung aller Bauteile verantwortlich.

Schutzvermerk zur Beschränkung der Nutzung von Unter-

lagen nach DIN ISO 16016.

© HAUTAU GmbH

Produkthaftungsvorschriften / Product liability instructions

The blocking guidelines for glazing techniques have to be

adhered to. The following points have to be observed for

the continuous functional reliability of the hard ware:

1. Professional installation of the hardware in accordance

with these mounting instruc tions.

2. Professional installation of the elements when the

window is fitted.

3. The hardware shall only consist of genuine HAUTAU

system parts. Use of any other hardware parts (e.g.

central lock, handle) will exclude any liability for these

compo nents.

Exclusion from product liability:

The manufacturer of the hardware shall not be liable for

any malfunctions of or damage to the hardware as well

as the windows or French doors fitted, if the malfunctions

of the tilt and slide hardware can be traced back to the

use of bought-in sash fasteners, insufficient invi tation to

tender, non-observation of the rebating instructions or

application diagrams.

The installing party shall be responsible for the adherence

to these mounting instructions, re spectively to the

functional dimensions given in the workshop drawing as

well as for a perfect installation of the hardware and safe

attachment of all components.

Proprietary note for a limited use of these documents

according to ISO 16016.

© HAUTAU GmbH

3

WARNUNG:

Wichtige Sicherheits-

anweisungen! (Forts.)

WARNING:

Important safety

instructions! (cont‘d)

Quetsch- und Scherstellen zwischen Fenster-

flügel und Rahmen, Lichtkuppeln und Aufsetz-

kranz müssen bis zu einer Höhe von 2,5 m durch

Einrichtungen gesichert sein, die bei Berührung

oder Unterbrechung durch eine Person die

Bewegung zum Stillstand bringen (Richt linie

für kraftbetätigte Fenster, Türen und Tore der

Berufsgenossenschaften BGR 232, 4.2.3).

Vor der Montage: Fenster und Sicherheits-

elemente testen. Die Unversehrtheit und Leicht-

gängigkeit des Fensters sind sicherzustellen.

Vor dem Einbau des Antriebs muss der

Installateur prüfen, ob der geltende Temperatur-

bereich auf die Umgebung abgestimmt ist.

Beim Betätigen eines Totmann-Schalters dürfen

sich keine weiteren Personen im Umfeld des

Antriebs aufhalten.

Montage und Installation sind nur von sach kun-

digem und sicherheits bewusstem Fach personal

durchzuführen. Lesen und beachten Sie die

Angaben in dieser Bedienungs- und Montage-

anleitung, um Schäden und Gefahren zu

vermeiden.

Diese Anleitung ist für späteren Gebrauch /

Wartung aufzubewahren. Bei der Installation

sind die einschlägigen Vorschriften (z.B.:

VDE 0833/0815, ZH 1/494) zu beachten.

Antrieb nur mit HAUTAU-Steuerungen betrei-

ben; nur so kann eine Funktions garantie

gewährleistet werden. Bei Ver wendung von

Fremd fabrikaten keine Service- oder Garantie-

leistungen.

Es sind flexible Zuleitungen zu verwenden (nicht

einputzen).

Bei der Verlegung sind Beschä dig ungen durch

Quetschung, Biegung und Zug zu verhindern.

Leitungen so kurz wie möglich verlegen, die

Leitungen zu den Antrieben sind in Abzweig-

dosen zu verklemmen. Abzweigdosen sind

für Wartungsarbeiten zugänglich zu machen.

Kabeltypen mit der örtlichen Abnahmebehörde

fest legen (Feuer wehr, Brand schutzbehörde,

TÜV etc). Netz- und Akku-Anschluss erst nach

Montage prüfung und Probelauf durchführen.

Den Antrieb vor Bauschmutz und Feuchtigkeit

schützen. Defekte Antriebe dürfen nicht geöffnet

werden (Garantieverlust), zur Reparatur sind

diese ans Werk zu schicken.

Achtung:

Die Montage und Installation hat sach gemäß,

sicherheits bewusst und nach An gaben der

Montageanleitung zu erfolgen. Werden Ersatz-

teile, Ausbauteile oder Erweiterungen benötigt,

sind aus schließlich Original-Ersatzteile zu

verwenden.

Für eine ausreichende Befestigung der

Beschlagteile ist zu sorgen.

Crush and shear points between window

sashes and frames, light domes, and metal

curb must be secured up to a height of 2.5 m

by devices that will stop the movement by the

touch or interruption of a person (guideline

BGR 232, 4.2.3 or equivalent local regulations).

Before mounting the drives: Test window

and safety elements. The physical integrity

and smooth operation of the window must be

ensured.

Before installing the drive, the installer must

verify that the drive‘s temperature range has

been adapted to its operating environment.

No other persons are allowed in the vicinity of

the drive when the deadman switch is actuated.

Assembly and installation by competent and

safety-conscious professionals only. Read and

observe the contents of these Assembly and

Operating Instructions to avoid danger and risk.

These instructions are also intended for use/

servicing at a later date and should be kept in a

safe place. During installation, observe pertinent

regulations (e.g.: VDE 0833/0815, ZH 1/494 or

equivalent local regulations).

Operate drive using HAUTAU-controls, as

guaranteed functioning can only then be given.

No warranty or service guarantee if other

makes are used. Flexible wiring must be used

(do not plaster in). During installation, avoid

damage due to pinching, twisting and pulling.

Lay wiring as short as possible, clamping the

lines to the drives in branch boxes. Branch

boxes must be readily accessible for servicing

work. Determine types of cables with the local

inspection authorities (fire brigade, fire-protec-

tion authority, technical supervisory authority,

etc). Mains and rechargeable-battery connec-

tions only after assembly inspection and trial

run. Protect drive from dirt and humidity.

Defective drives must not be opened (loss of

guarantee). Send to works for repair.

Attention

Assembly and installation must be carried out

in a proper and safety- conscious manner in

keeping with the details of the instructions.

If replacement parts, extension elements

or enlargements are required, use original parts

only. Ensure adequate fastening of the fitments.

Operation of the drive requires an additional

control (e. g. double pushbutton). These drives

must be solely operated by controls from the

same manufacturer. On use of other makes,

the warranty and service guarantees extinguish.

Assembly and installation must be carried out

in a proper and safety-conscious manner in

keeping with the details of these Assembly and

Operating Instructions.

4

Zum Betrieb des Antriebs ist ein zusätzliches

Bedienelement (z. B. Doppeltaster) notwendig.

Diese Antriebe sind ausschließlich mit Steue-

rungen des gleichen Herstellers zu betreiben.

Bei Verwendung von Fremdfabrikaten erlischt

die Garantie- und Service leistung. Die Montage

und Installation muss sachgemäß, sicherheits-

bewusst und nach den Angaben dieser

Montage- und Bedien anleitung erfolgen.

Die einschlägigen Verarbeitungsrichtlinien

der Profilhersteller sind zu beachten.

Bei RWA-Anlagen müssen beim Schließen der

Fenster Personen von den Fenstern fern gehalten

werden.

Dieses Gerät kann von Kindern ab 8 Jahren

und darüber sowie von Personen mit verringer-

ten physischen, sensorischen oder mentalen

Fähigkeiten oder Mangel an Erfahrung und

Wissen benutzt werden, wenn sie beaufsichtigt

oder bezüglich des sicheren Gebrauchs des

Gerätes unterwiesen wurden und die daraus

resultierenden Gefahren verstehen. Kinder

dürfen nicht mit dem Gerät spielen. Reinigung

und Benutzer-Wartung dürfen nicht von Kindern

ohne Beaufsichtigung durchgeführt werden.

Wartungsarbeiten

Die Stromzufuhr zum Gerät muss unter brochen

werden, wenn Reinigungs- oder andere

Wartungs arbeiten durchgeführt werden.

Die Fenster und Antriebe müssen regelmäßig

auf Unversehrtheit überprüft werden.

Werden die Antriebe in Rauch- und Wärme-

abzugsanlagen (kurz RWA) eingesetzt, müssen

sie mindestens einmal jährlich geprüft und

gewartet werden. Bei reinen Lüftungsanlagen ist

dies auch zu empfehlen.

Die Geräte von Verunreinigungen befreien.

Befestigungs- und Klemm schrauben auf festen

Sitz prüfen. Die Geräte durch Probelauf testen.

WARNUNG:

Wichtige Sicherheits-

anweisungen! (Forts.)

WARNING:

Important safety

instructions! (cont‘d)

The appropriate processing instructions of

the profile manufacturers have to be kept.

Smoke and heat exhaust systems require that

people be kept away from the windows when

they are being closed.

This device may be used by children age 8

and older as well as all persons without limited

physical, sensory or mental abilities or lack of

experience and knowledge provided they act

under supervision or have received prior instruc-

tions on the safe use of the device and any

hazards resulting from using the device. Children

are not allowed to play with the device. Cleaning

and user maintenance must not be carried out

by children without supervision.

Maintenance works

The power supply to the device must be inter-

rupted for the duration of any cleaning or other

types of maintenance operations.

Windows and drives must be checked for

physical integrity on a regular basis.

If the equipment is employed in smoke and heat

exhaust systems (in short SHE), they must be

checked, serviced and, if required, repaired at

least once per year. This is also recommended

for pure ventilation systems.

Free the equipment from any contamination.

Check the tightness of fixing and clamping

screws. Test the equipment by trial run.

5

KF

KF

KF

A

B

A

B

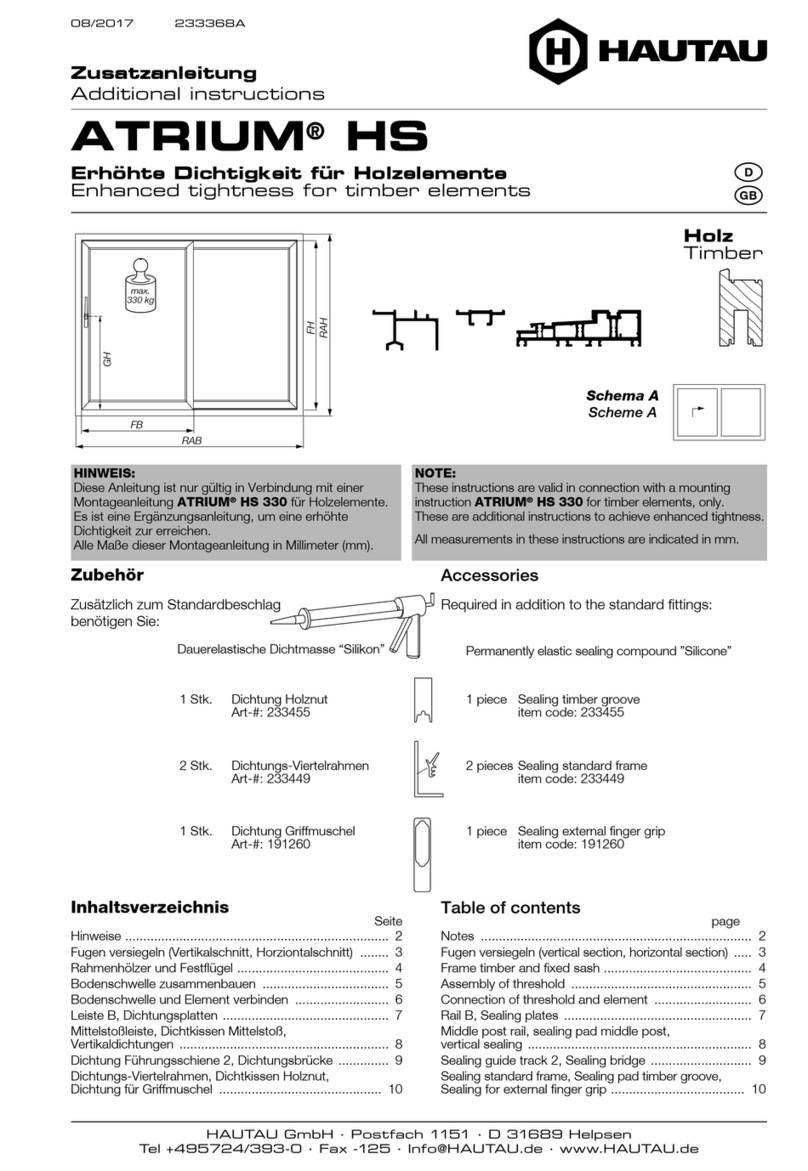

SBS ZV

ZV = Zusatzverriegelung

FTA 3 = Tandem-Folgesteuerung

SF 225 = Synchron-Folgesteuerung

keine Zusatzlasten

an den Flügel anbringen No additional

encumbrances

keine Windlasten No wind load

ZV = Additional Locking

FTA 3 = Tandem Sequence Control

SF 225 = Synchronized Sequence Controller

Maximum glas weight

40 kg/m2

Maximales

Glasgewicht

40 kg/m2

Maximum sash weight

50 kg (1 SBS)

100 kg (2 SBS)

Maximales

Flügelgewicht

50 kg (1 SBS)

100 kg (2 SBS)

Der Einsatz von Falzscheren als

zusätz liche Sicherung gegen das

Herunterfallen von Kipp flügeln ist

vor geschrieben. Wir empfehlen

den Einsatz von Begrenzungs-

scheren SBS. Diese verhindern

Schäden, die bei unsach gemäßer

Montage und Handhabung

auf treten können.

The use of restrictors for additional

security, preventing the sashes falling

off, is compulsary. We recommend the

use of restrictors SBS. These avert

damages, which can occur in case of

faulty assembly and faulty usage.

All application charts are subject

to the following conditions:

Alle Anwendungsdiagramme gelten nur

unter nachfolgenden Bedingungen:

WARNUNG:

Wichtige Sicherheits-

anweisungen! (Forts.)

WARNING:

Important safety

instructions! (cont‘d)

6

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

12 ... 15

19 ... 22

23

16 ... 18

7 ... 11

Technische Daten / Technical Data

HAUTAU SBS 300 S HAUTAU SBS 500 S

Hub / Öffnungsweite 300 mm 500 mm

Nennspannung 24 V DC (-20 %/ +30 %) 24 V DC (-20 %/ +30 %)

Mindestabschaltspannung 19 V DC 19 V DC

Anlaufstrom 3,7 A 3,7 A

Stromaufnahme (bei Nennkraft) 0,9 A 0,9 A

Nennkraft 240 N 150 N

Laufzeit ca. 30 s ca. 45 s

Einschaltdauer max. 20 Zyklen ohne Pause; max. 20 Zyklen ohne Pause;

60 s EIN / 60 s AUS 60 s EIN / 60 s AUS

Arbeitsumgebungs-Temperatur -5 °C bis +75 °C -5 °C bis +75 °C

Schalldruckpegel LpA ≤70 dB(A) ≤70 dB(A)

Schutzart IP 40 IP 40

Elektrische Abschaltung integrierte elektronische Überlastabschaltung

Anschlussklemme steckbar, für max. 1,0 mm2 flexible Zuleitung

Abmessungen (B x H x T) 546 mm x 90 mm x 35 mm

Konformität (CE) EMV für den Haus- und Industriebereich

Achtung: SBS 300 S und SBS 500 S sind nicht für den Einsatz an Taktsteuerungen geeignet.

HAUTAU SBS 300 S HAUTAU SBS 500 S

Stroke / opening width 300 mm 500 mm

Rated voltage 24 V DC (

-

20 %/ +30 %) 24 V DC (-20 %/ +30 %)

Minimum cutoff voltage 19 V DC 19 V DC

Starting current 3,7 A 3,7 A

Current input (under rated force) 0,9 A 0,9 A

rated force 240 N 150 N

Operating time approx. 30 s approx. 45 s

switch-on time max. 20 cycles without break; max. 20 cycles without break;

60 s ON / 60 s OFF 60 s ON / 60 s OFF

working ambient temperature -5 °C till +75 °C -5 °C till +75 °C

Emission sound pressure level LpA ≤70 dB(A) ≤70 dB(A)

Protective system IP 40

Electrical shutdown integrated electronic overload shutdown

Connecting cable pluggable for max. 1,0 mm2 flexible wire

Dimensions (W x H x D) 546 mm x 90 mm x 35 mm

Conformity (CE) EMV for domestic and industrial sectors

Attention SBS 300 S and SBS 500 S are not for use with pulse control.

Begrenzungsschere 600 SBS

restrictor 600 SBS

Begrenzungsschere 400 SBS

restrictor 400 SBS

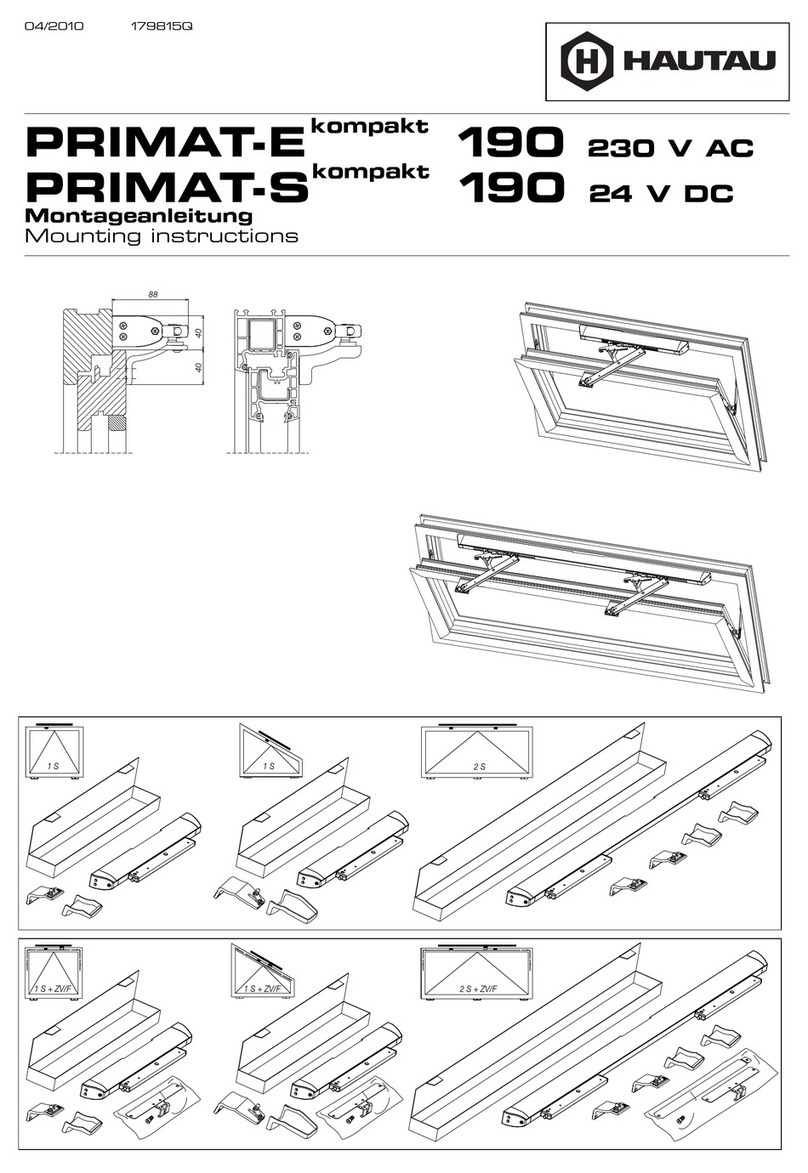

Verpackungseinheiten / Packaging units

Montage 1

Installation 1

Montage 3

Installation 3 Montage 4

Installation 4

Montage 2

Installation 2

t

D

7

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FH

FH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

2

2

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FH

FH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

31

1

Alle Maße in Millimeter (mm)!

All units in millimeters (mm)!

Anwendung / Application

Montage 1 / Installation 1

8

SBS 300 (1 SBS) SBS 500 (1 SBS)

1

2

3

1

2

3

SBS 300 (2 SBS)

SBS 500 (2 SBS)

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

4

6

5

4

6

5

4

5

6

9

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB

FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB

FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

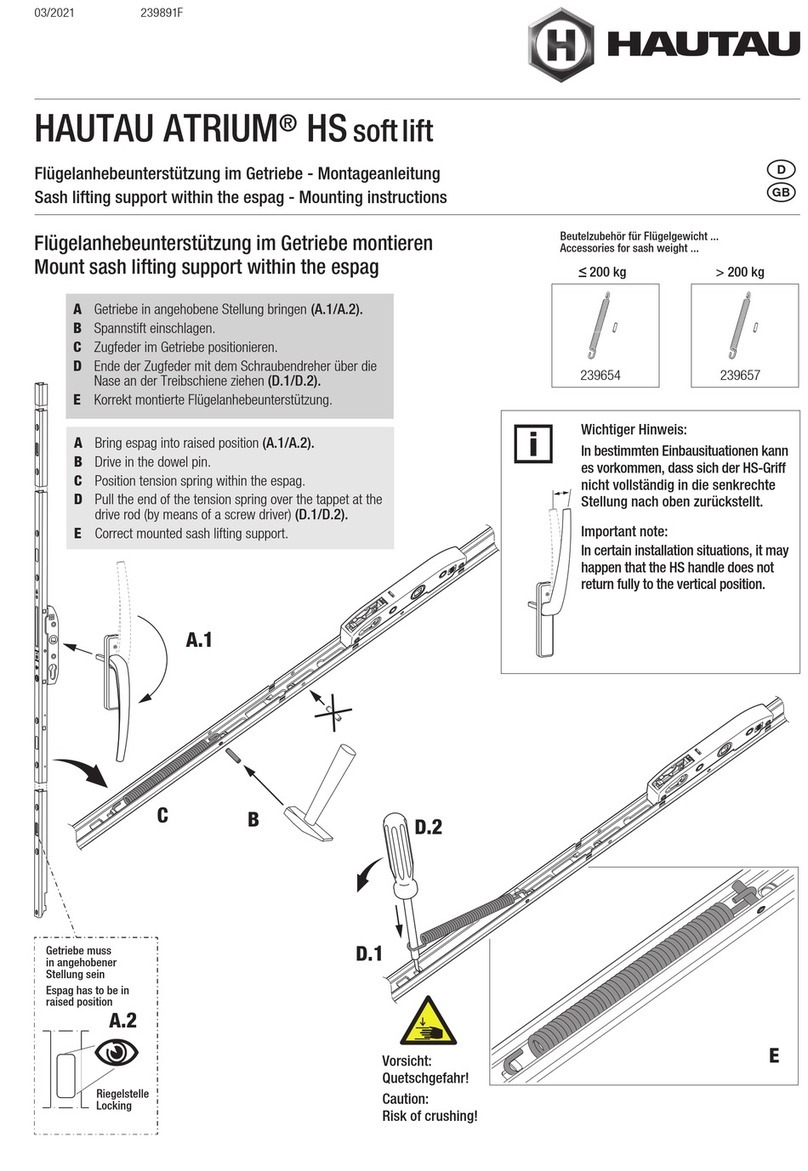

SBS 300, 500 (2 SBS)SBS 300, 500 (1 SBS)

7

8

9

0

w

q

7

0qw

8 9

10

KF

KF

KF

A

B

A

B

SBS ZV

M 5 x 18

11

10

SW 13

size 13 12 Nm

-

+

-

+

1

2

4*

6* 7

1 2 3 4

5*

1 2 3 4

1 2 3 4

1SW 3

5 Nm 2

3

8

9

13

12

SW 3

4 Nm

ba a = b

11.1

11.2

SW 3

1234 1234

1

SBS-SYN

SBS-SYN

max. 3 m

2341234

1 = -

2=+

1=+

2 = -

Achtung:

Sicherungsfeder muss nach dem

Einhängen und Entfernen des

Schraubendrehers wieder in den

Ursprungszustand zurückspringen.

Zur Kontrolle der korrekten Ein hängung

drücken Sie den Scherenarm vom

Flügelbock weg. Der Kupplungsdorn

darf hierbei nicht aus dem Scherenarm

herauswandern, die Sicherungsfeder

muss ihn fixieren.

Attention:

The security spring must jump back

into the original condition after the

mounting has been made and the

screw driver has been removed.

In order to check the correct

mounting, push back the stay arm

from the sash bracket. The coupling

mandrel must not move out of the stay

arm, the security spring has to fix it.

max. 1,0 mm

2flexible Zuleitung

max. 1,0 mm

2 flexible wire

* bei SYN-Steuerung:

in case of SYN-control:

SYN-Steuerung / SYN-control

AUF / OPEN

ZU / CLOSE

12

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

*FB < 1000 = (M1) 500

*FBs < 1000 = (M1) 500

FB 600 ... 1400

zy1 y2

500 ... 700

700 ... 2400

~300 50

~300 45

700 ... 900

900 ... 2400

~500 50

~500 45

48

53

48

53

z

z

FB 2800 ... 3200

½ FB ½ FB*

½ FBs ½ FBs*

M1

FH

FH

1 SBS

FB 300 ... 1800

1 SBS + ZV + FTA 3

FB 800 ... 2000

M1

M1

M1

M2

M1 M2

2 SBS + FTA 3 (2 SBS + SYN 2K)

2 SBS + FTA 3 (2 SBS + SYN 2K)

FB 1500 ... 3200

min. 30

FB 300 ... 1800

min. 70

1 SBS + ZV + FTA 3

x (min. 500)

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

1 SBS

90...180°

FBs 600 ... 1400

1 SBS + ZV + FTA 3

90...180°

FHs

FHs

FBs 1400 ... 2000

500 ... 600

FH, FHs

SBS

300

500

zy1 y2

530 ... 2400 min. 300 55

530 ... 2400 min. 500 55

40

40

FHSBS

300

500

FB 1400 ... 2000

M1

FHFH

FH

min. 70

FH

min. 70

FH

min. 70

FH

1 SBS + ZV + FTA 3

FB 600 ... 1800

M1

1 SBS + 2 ZV + FTA 3

M1

M1

M2

y1

y2

y1

y2

y1

y2

FB 1200 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + ZV + FTA 3

FB 1200 ... 3200

FH

M1 M2

2 SBS + 2 ZV/R + SF 225

*FB < 1000 = (M1) 500

½ FB ½ FB*

e e

rr

SBS 500 (1 SBS)

max. 20 kg/m2

eSBS 500 (2 SBS)

max. 20 kg/m2

r

SBS 500 (1 SBS)

max. 25 kg/m2

eSBS 500 (2 SBS)

r

max. 25 kg/m2

max. 30 kg/m2

SBS 500 (1 SBS)

eSBS 500 (2 SBS)

r

max. 30 kg/m2

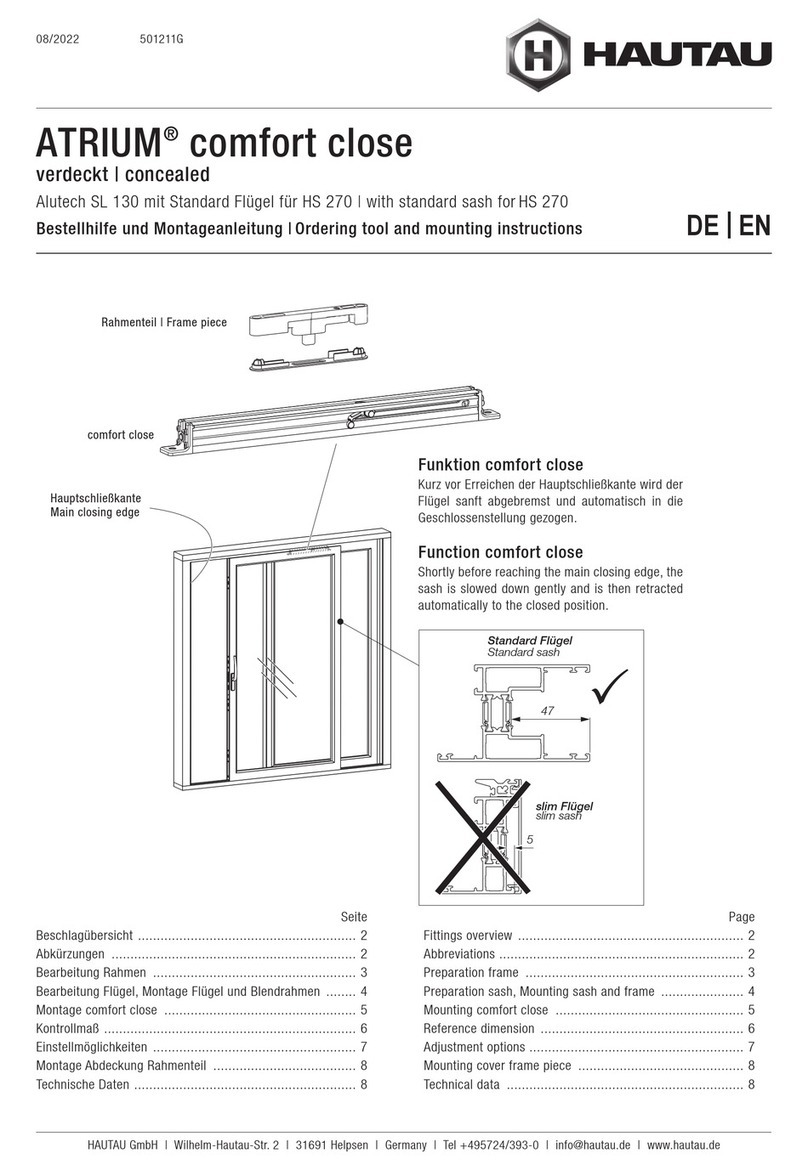

Montage 2 / Installation 2

13

AB 2

AB 1

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

t uz

*FH < 1000 = (M1) 500

FH 600 ... 1400

zy1 y2

min. 500 ... 700

min. 700 ... 900

~300 48 50

min. 700 ... 1700 ~300 53 45

48 50

~500

min. 900 ... 1700 53 45

~500

½ FH* ½ FH

M1

*FH < 1000 = (M1) 500

½ FH* ½ FH

M1

FB FB

1 SBS

FB min. 530

FH 600 ... 1400

FB min. 530

xmin.1) = ½FB xmin.1) = ½FB

xmin.1) = ½FB

1)xmin = 500 (FB < 1000 )

2) 2) 2)

FH 1200 ... 3200

FB (1SBS)

min. 500 ... 700

min. 700 ... 900

min. 700 ... 1800

min. 900 ... 1800

FB (2SBS)SBS

300

500

y1

SBS y2

55

300

500 40

z

y1 y2

FH 1400 ... 2000

1 SBS + 2 ZV + FTA 3

1 SBS + ZV + FTA 3

1 SBS + ZV + FTA 3

2 SBS + FTA 3

(2 SBS + SYN 2K)

y1 y2

FB

FH 1400 ... 2000

M1

1 SBS + ZV + FTA 3

y1 y2

FH 1200 ... 2800

FB

M1

M2

y1 y2

2 SBS + ZV + FTA 3

(2 SBS + ZV/R + SF 225)

1 SBS + 2 ZV + FTA 3

FH 2800 ... 3200

FB

M1

M2

y1 y2

2 SBS + 2 ZV/R + SF 225

FH 1200 ... 3200

FB

M1

M2

y1 y2

y1

y2

FB min. 530

FH 1400 ... 2000

y1

y2

FH 1200 ... 3200

y1

y2

FH 600 ... 1400

FB min. = x + 500

FH 1200 ... 3200

FB < x + 500

FB min. = x + 500

y1

y2

xxx

y1

SBS y2

55

300

500 40

x

SBS

300 250 ... 330

400 ... 500

500

min. 70 min. 70 min. 70

2) FB max. = 900 (SBS 300)

FB max. = 1400 (SBS 500)

2 SBS + 2 ZV/R + SF 225

2 SBS + 2 ZV/R + SF 225 2 SBS + 2 ZV/R + SF 225

max. 40 kg/m2

SBS 500 (1 SBS)

eSBS 500 (2 SBS)

r

max. 40 kg/m2

14

SBS 300, 500 (1 SBS) SBS 300, 500 (2 SBS)

t

z

u

KF

KF

KF

A

B

A

B

SBS ZV

KF

KF

KF

A

B

A

B

SBS ZV

AB 2

AB 1

15

1

2

-

+

-

+

1

2

3*

5* 6

1 2 3 4

4*

1 2 3 4

1 2 3 4

7

8

b

a

a = b

9.1

SW 3

10

SW 3

4 Nm

11

SW 13

size 13

12 Nm

12

9.2

1234 1234

1

SBS-SYN

SBS-SYN

max. 3 m

2341234

1 = -

2=+

1=+

2 = -

Achtung:

Sicherungsfeder muss nach dem Einhängen und

Entfernen des Schraubendrehers wieder in den

Ursprungszustand zurückspringen. Zur Kontrolle der

korrekten Einhängung drücken Sie den Scherenarm

vom Flügelbock weg.

Der Kupplungsdorn darf hierbei nicht aus dem

Scherenarm herauswandern, die Sicherungsfeder

muss ihn fixieren.

Attention:

The security spring must jump back into the original

condition after the mounting has been made and the

screw driver has been removed. In order to check the

correct mounting, push back the stay arm from the

sash bracket. The coupling mandrel must not move

out of the stay arm, the security spring has to fix it.

max. 1,0 mm2flexible Zuleitung

max. 1,0 mm2 flexible wire

* bei SYN-Steuerung:

in case of SYN-control:

SYN-Steuerung / SYN-control

AUF / OPEN

ZU / CLOSE

16

Anwendungsbereich SBS300 einscherig

Klappflügel auswärts untenliegend

Kippflügel auswärts obenliegend

ohne Zusatzlasten

SBS 300 (1 SBS)

i

o

p

SBS 500 (1 SBS)

i

o

p

*FB < 1100 = (M1) 550

FB 650 ... 1400

zy1 y2

500 ... 2400

700 ... 2400

~300 42 50

42 50

~500

z

z

z

FB 2800 ... 3200

½ FB ½ FB*

M1

M1 M2

FH

y1

y2

y1

y2

y1

y2

y1

y2

FH

1 SBS

*FB < 1100 = (M1) 550

FB 650 ... 1400

FHFH

½ FB ½ FB*

M1

y1

y2

y1 y2

y1

y2

(2 SBS + SYN 2K)

2 SBS + ZV + FTA 3

FB 650 ... 1400

R

FH 1000 ... 2400

FB 650 ... 1400

FH 500 ... 1200

FHSBS

300

500

zy1 y2

min. 500

min. 700

~300 42 50

42 50

~500

RSBS

300

500

FB 1400 ... 2000

M1

FH

1 SBS + ZV + FTA 3

1 SBS + 2 ZV + FTA 3

FB 1300 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + 2 ZV/R + SF 225

2 SBS + FTA 3

y1

y2

FB 1300 ... 2800

M1 M2

FB 1000 ... 2400

FH 650 ... 1400

R

*FB < 1100 = (M1) 550

FB 650 ... 1400

zy1 y2

500 ... 2400

700 ... 2400

~300 42 50

42 50

~500

z

z

z

FB 2800 ... 3200

½ FB ½ FB*

M1

M1 M2

FH

y1

y2

y1

y2

y1

y2

y1

y2

FH

1 SBS

*FB < 1100 = (M1) 550

FB 650 ... 1400

FHFH

½ FB ½ FB*

M1

y1

y2

y1 y2

y1

y2

(2 SBS + SYN 2K)

2 SBS + ZV + FTA 3

FB 650 ... 1400

R

FH 1000 ... 2400

FB 650 ... 1400

FH 500 ... 1200

FH

SBS

300

500

zy1 y2

min. 500

min. 700

~300 42 50

42 50

~500

RSBS

300

500

FB 1400 ... 2000

M1

FH

1 SBS + ZV + FTA 3

1 SBS + 2 ZV + FTA 3

FB 1300 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + 2 ZV/R + SF 225

2 SBS + FTA 3

y1

y2

FB 1300 ... 2800

M1 M2

FB 1000 ... 2400

FH 650 ... 1400

R

*FB < 1100 = (M1) 550

FB 650 ... 1400

zy1 y2

500 ... 2400

700 ... 2400

~300 42 50

42 50

~500

z

z

z

FB 2800 ... 3200

½ FB ½ FB*

M1

M1 M2

FH

y1

y2

y1

y2

y1

y2

y1

y2

FH

1 SBS

*FB < 1100 = (M1) 550

FB 650 ... 1400

FHFH

½ FB ½ FB*

M1

y1

y2

y1 y2

y1

y2

(2 SBS + SYN 2K)

2 SBS + ZV + FTA 3

FB 650 ... 1400

R

FH 1000 ... 2400

FB 650 ... 1400

FH 500 ... 1200

FHSBS

300

500

zy1 y2

min. 500

min. 700

~300 42 50

42 50

~500

RSBS

300

500

FB 1400 ... 2000

M1

FH

1 SBS + ZV + FTA 3

1 SBS + 2 ZV + FTA 3

FB 1300 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + 2 ZV/R + SF 225

2 SBS + FTA 3

y1

y2

FB 1300 ... 2800

M1 M2

FB 1000 ... 2400

FH 650 ... 1400

R

*FB < 1100 = (M1) 550

FB 650 ... 1400

zy1 y2

500 ... 2400

700 ... 2400

~300 42 50

42 50

~500

z

z

z

FB 2800 ... 3200

½ FB ½ FB*

M1

M1 M2

FH

y1

y2

y1

y2

y1

y2

y1

y2

FH

1 SBS

*FB < 1100 = (M1) 550

FB 650 ... 1400

FHFH

½ FB ½ FB*

M1

y1

y2

y1 y2

y1

y2

(2 SBS + SYN 2K)

2 SBS + ZV + FTA 3

FB 650 ... 1400

R

FH 1000 ... 2400

FB 650 ... 1400

FH 500 ... 1200

FHSBS

300

500

zy1 y2

min. 500

min. 700

~300 42 50

42 50

~500

RSBS

300

500

FB 1400 ... 2000

M1

FH

1 SBS + ZV + FTA 3

1 SBS + 2 ZV + FTA 3

FB 1300 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + 2 ZV/R + SF 225

2 SBS + FTA 3

y1

y2

FB 1300 ... 2800

M1 M2

FB 1000 ... 2400

FH 650 ... 1400

R

*FB < 1100 = (M1) 550

FB 650 ... 1400

zy1 y2

500 ... 2400

700 ... 2400

~300 42 50

42 50

~500

z

z

z

FB 2800 ... 3200

½ FB ½ FB*

M1

M1 M2

FH

y1

y2

y1

y2

y1

y2

y1

y2

FH

1 SBS

*FB < 1100 = (M1) 550

FB 650 ... 1400

FH

FH

½ FB ½ FB*

M1

y1

y2

y1 y2

y1

y2

(2 SBS + SYN 2K)

2 SBS + ZV + FTA 3

FB 650 ... 1400

R

FH 1000 ... 2400

FB 650 ... 1400

FH 500 ... 1200

FHSBS

300

500

zy1 y2

min. 500

min. 700

~300 42 50

42 50

~500

RSBS

300

500

FB 1400 ... 2000

M1

FH

1 SBS + ZV + FTA 3

1 SBS + 2 ZV + FTA 3

FB 1300 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + 2 ZV/R + SF 225

2 SBS + FTA 3

y1

y2

FB 1300 ... 2800

M1 M2

FB 1000 ... 2400

FH 650 ... 1400

R

ip o

*FB < 1100 = (M1) 550

FB 650 ... 1400

zy1 y2

500 ... 2400

700 ... 2400

~300 42 50

42 50

~500

z

z

z

FB 2800 ... 3200

½ FB ½ FB*

M1

M1 M2

FH

y1

y2

y1

y2

y1

y2

y1

y2

FH

1 SBS

*FB < 1100 = (M1) 550

FB 650 ... 1400

FHFH

½ FB ½ FB*

M1

y1

y2

y1 y2

y1

y2

(2 SBS + SYN 2K)

2 SBS + ZV + FTA 3

FB 650 ... 1400

R

FH 1000 ... 2400

FB 650 ... 1400

FH 500 ... 1200

FHSBS

300

500

zy1 y2

min. 500

min. 700

~300 42 50

42 50

~500

RSBS

300

500

FB 1400 ... 2000

M1

FH

1 SBS + ZV + FTA 3

1 SBS + 2 ZV + FTA 3

FB 1300 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + 2 ZV/R + SF 225

2 SBS + FTA 3

y1

y2

FB 1300 ... 2800

M1 M2

FB 1000 ... 2400

FH 650 ... 1400

R

*FB < 1100 = (M1) 550

FB 650 ... 1400

zy1 y2

500 ... 2400

700 ... 2400

~300 42 50

42 50

~500

z

z

z

FB 2800 ... 3200

½ FB ½ FB*

M1

M1 M2

FH

y1

y2

y1

y2

y1

y2

y1

y2

FH

1 SBS

*FB < 1100 = (M1) 550

FB 650 ... 1400

FHFH

½ FB ½ FB*

M1

y1

y2

y1 y2

y1

y2

(2 SBS + SYN 2K)

2 SBS + ZV + FTA 3

FB 650 ... 1400

R

FH 1000 ... 2400

FB 650 ... 1400

FH 500 ... 1200

FHSBS

300

500

zy1 y2

min. 500

min. 700

~300 42 50

42 50

~500

RSBS

300

500

FB 1400 ... 2000

M1

FH

1 SBS + ZV + FTA 3

1 SBS + 2 ZV + FTA 3

FB 1300 ... 2800

M1 M2

FH

(2 SBS + ZV/R + SF 225)

2 SBS + 2 ZV/R + SF 225

2 SBS + FTA 3

y1

y2