HAWE Hydraulik PLVC 16 Series User manual

Programmable logic valve control

type PLVC 16

D 7845

Programmable logic

valve control

February 2006-00

HAWE HYDRAULIK SE

STREITFELDSTR. 25 • 81673 MÜNCHEN

5

© 2000 by HAWE Hydraulik

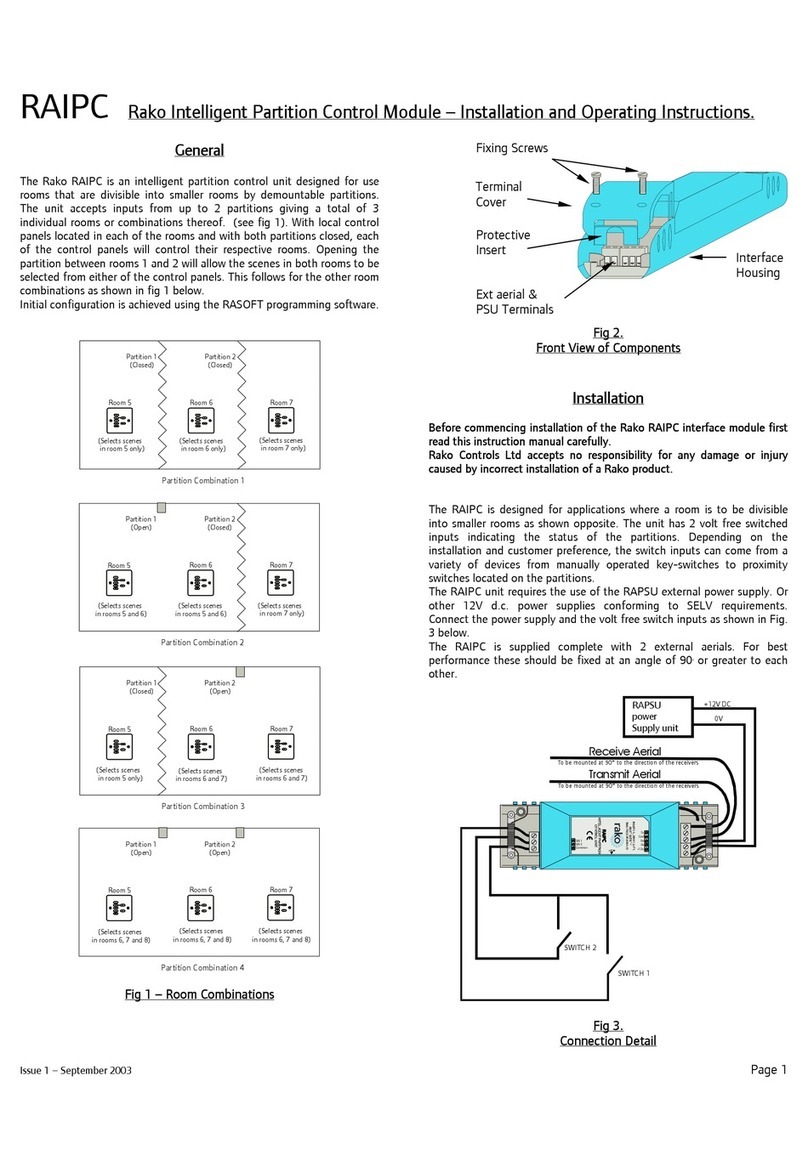

1. General information

Extension module with

-Receiver unit of the radio control (optional)

-Additional inputs/outputs

Basic module with

-Interfaces for CAN-Bus, RS232

-Inputs/Outputs

-Hardware Emergency-Stop loop

Diagnosis display

Antenna socket

for radio control

(optional)

See also other electronic valve controls/accessory:

Type PLVC 2 acc. to D 7845-2

Type PLVC 4 acc. to D 7845-4

Type PLVC-CAN acc. to D 7845-Z

The programmable logic valve control of type PLVC 16 consists of a complex PLC-enabled micro-control unit with integrated

amplifiers for mobile and stationary hydraulic applications.

The wide range of possible applications includes, among others:

'Cranes, crane systems

'Construction machines

'Complex hoisting equipment

'Logging equipment

'Hydraulic clamping systems for machine tools

'Presses

The various control tasks are realized through:

'A modular system with extension and supplementary modules

-Basic module

-Extension module (additional inputs/outputs, receiver for radio control) (optional)

- Text display for diagnosis, and parameterization (via CAN-Bus)

-Large display for diagnosis, and parameterization (via CAN-Bus)

-CAN-Bus controlled power relay

'Flexible programmability according to IEC 61131-3 standard (PLC-programming via instruction list (IL), function block diagram

(FBD) or structured text (ST))

'Various interfaces (RS232, CAN-Bus)

'Free parameterization of all outputs, as well as complete diagnosis capability and short-circuit protection

'Remote diagnosis via modem or mobile phone

'Combination of multiple PLVC’s via CAN-Bus within one integrated unit for the control of complex systems

All relevant standards regarding personal safety, EMC, vibration- and shock-proofness are complied with.

The main performance parameters include furthermore:

(the values in brackets specify the performance range of the basic module)

'Input

-Max. 24 (8) digital inputs (for limit switches, pressure switches, push buttons, etc.)

-Max. 24 (8) analog inputs (for joysticks, potentiometers, sensors such as analog pressure sensors)

-Emergency-Stop signal (opto-decoupled)

-4 (1) frequency inputs (for indexing switches, rev. counter, incremental encoder, etc.)

-Optionally integrated radio control module (receiver) incl. Emergency-Stop lock

-Power supply 10 ... 30 VDC, max. 16 A

'Output

-Max. 32 (16) outputs for prop. or ON/OFF valves

-2 analog outputs 0 ... 10 VDC

-Emergency-Stop signal

-2 programmable auxiliary voltage outputs (5, 8, 10, 12 VDC, max. 500 mA, e.g. for potentiometer supply)

-3 Relay outputs

-7- segment display on basic module for error detection

'Functional software features

-PLC programming via IL, FBD or ST

-Parameterization during runtime

-CAN-Bus integrated in the operating system

D 7845 page 2

2. Available versions

2.1 Basic module

Order examples: PLVC 16 - G

PLVC 16 - X - ABC

Basic module Extension module,

see sect. 2.2

General data

Casing, protection class IP 20 acc. to DIN EN 60529 / IEC 60529

Temperature range -40°C to +80°C

Power supply 10 VDC to 30 VDC

Max. total current 16 A

Required external fusing 15 A (slow blow)

Protection Reverse polarity protection

Load dump protection (DIN 40839)

Shock proof (vibration: IEC 68-2-6, shock: IEC 68-2-27)

EMC (EN 50081-1, EN 50081-2, EN 58082-1, EN 58082-2)

Monitoring Short-circuit, undervoltage and overvoltage

Cable break

Cable connections via plug system Phoenix, type MKDS (the connector rails are coded)

Micro controller 80C167, 16 bit

Basic parameter memory EEPROM 256 words

Memory Flash: 256 kByte

RAM: 256 kByte

Accessories Plug set (see sect. 2.3.1)

Software

Diagnosis display (see D 7845 Z)

CAN-Bus power relays (see D 7845 Z)

CAN-Bus display (see D 7845 Z)

Mounting 4 x M4

Casing material Stainless-steel, brushed

Mass (weight) approx. 1.7 kg (basic module)

approx. 0.5 kg (extension module)

D 7845 page 3

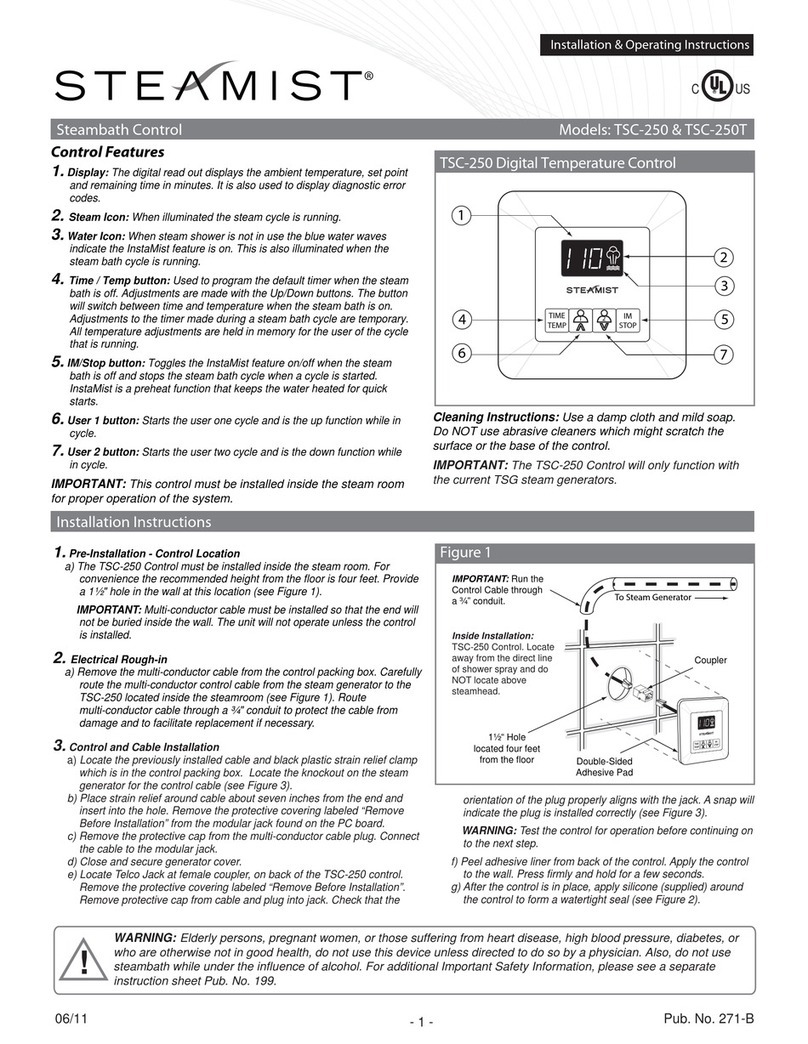

Block diagram for basic module

X1

X5

X4

X7

X6

X3

X8

X2

X5

X3

X4

X2

Ubat

Protected

against:

Reverse

polarity, load

dump, under/

over voltage

Emergency-Stop, in

Emergency-Stop, out Emergency-Stop

Emergency-Stop

Monitoring:

Ubat,

temperature,

power on,

system o.k.,

hardware o.k.,

under/over

voltage

Safety relays

UL, CSA, TÜV

Relays 1

Relays 2

Relays 3

3x Relays

out 1 ADC

Monitoring:

Short-circuit,

broken wire,

range

Adjustable power supply 1

5V, 8V, (10 V, 12 V)

max. 500 mA

Adjustable power supply 2

5 V, 8 V, 10 V

max. 500 mA monitoring

Selectable power supply 1 out

Selectable power supply 2 out

Frequency input 1

On-board diagnosis:

1-digit display

Keys: up, down #

8 analog Inputs

0...10 VDC

Range monitoring

8 digital Inputs

0...10 VDC

Voltage monitoring

Words

nominal

actual

Extension module

digital I/O Radio

Control Receiver

Unom

Unom

Uactual

2x Adjustable power supply

Emergency-Stop loop

General data

Supply voltage 10 to 30 VDC

Max. total current 16 A

Required external fusing 15 A (slow blow)

All additional data see sect. 2.1

Mounting with 4 screws onto the basic module

D 7845 page 4

2.2 Extension module

PLVC 16 - X - ABC

PLVC 16 - X - ABCRNBB

Complete set with basic module acc. to sect. 2.1 and

extension module with additional inputs and outputs

Extension with radio control (X14)

Designation extension module

Power specifications of connections

Connector

rail

Function Description Parameters

X1

X2

X3

X4

X5

X6

X7

X8

-Power supply Rated voltage UN10 VDC ... 30 VDC

max. total current (power) 16 A

-Proportional and/or ON/OFF outputs Imin 100 ... 1200 mA

0 - 9 1) Imax 100 ... 2200 mA

(with high-side measuring) Dither frequency 25 ... 200 Hz

Dither amplitude (for PWM) 0 ... 50 %

Cold resistance 2 ... 35 Ohm

-Frequency input Limit frequency flim = 5 kHz

-Prop. and/or ON/OFF outputs 10 - 15 see X2

-Digital inputs 0 - 5 Voltage range 10 ... 30 VDC / 5 kOhm

Debouncing for increasing/

decreasing signal edge can be

activated separately

-Auxiliary voltage 1 and 2 Auxiliary voltage 5, 8, 10, 12 VDC / max. 500 mA

-Emergency-Stop input Opto-decoupled

-Emergency-Stop output Voltage range 10 ... 30 VDC / 6 A

-Relay outputs 1, 2, 3 Voltage 10 ... 30 VDC / 1 A

-Interface CAN-Bus 100, 125, 250 kBaud

-Interface RS232 Interface parameter 19.2 kBaud

-Digital inputs 6, 7 see X3

-Analog inputs 0 - 7 10 bit ADC &1024 steps 4 ... 20 mA

(for joystick, potentiometer 0 ... 10 VDC (default)

Parameterization, see sect. 5.1)

Range monitoring

Parameterization variants:

1)'The outputs 0, 2, 4, 6 etc. can be configured for double solenoids with separate Imin, Imax values, application scenario e.g. to

actuate prop. directional spool valves type PSL / PSV acc. to D 7700 ++, directional spool valves type SWS acc. to D 7951 or

type HSRL acc. to D 7491.

'Simple parameter settings can be used for more efficient circuit functions for ON/OFF solenoids, (parameters, switchover time,

holding current). This may be necessary for reducing the solenoid temperature at 100% ON-time and/or to increase the

switching speed via over-voltage.

'Further parameter settings enable the realization of a fine adjustment range and/or operating with creeping speed at max.

input signal (e.g. with joystick moved to end stop).

Order examples:

D 7845 page 5

X12

X13

RX14

Extension Connector

rail

Function Description Parameters

X10

X11

X

Digital inputs 8 - 23 Voltage range 10 ... 30 VDC / 5 kOhm

Debouncing for increasing/

decreasing signal edge,

can be activated separately

Digital outputs 0 - 7 Imin 100 ... 1200 mA

Safety locked Imax 100 ... 2200 mA

PWM-enabled in 5% steps 1)Cold resistance 2 ... 35 Ohm

Digital outputs 8 - 15

PWM-enabled in 5% steps 1)

Frequency inputs 2, 3, 4 Limit frequency flim = 5 kHz

Analog inputs 8 - 23 see description X 8 (sect. 2.1)

Power supply see description X 1 (sect. 2.1)

Antenna socket for radio control Coaxial connection

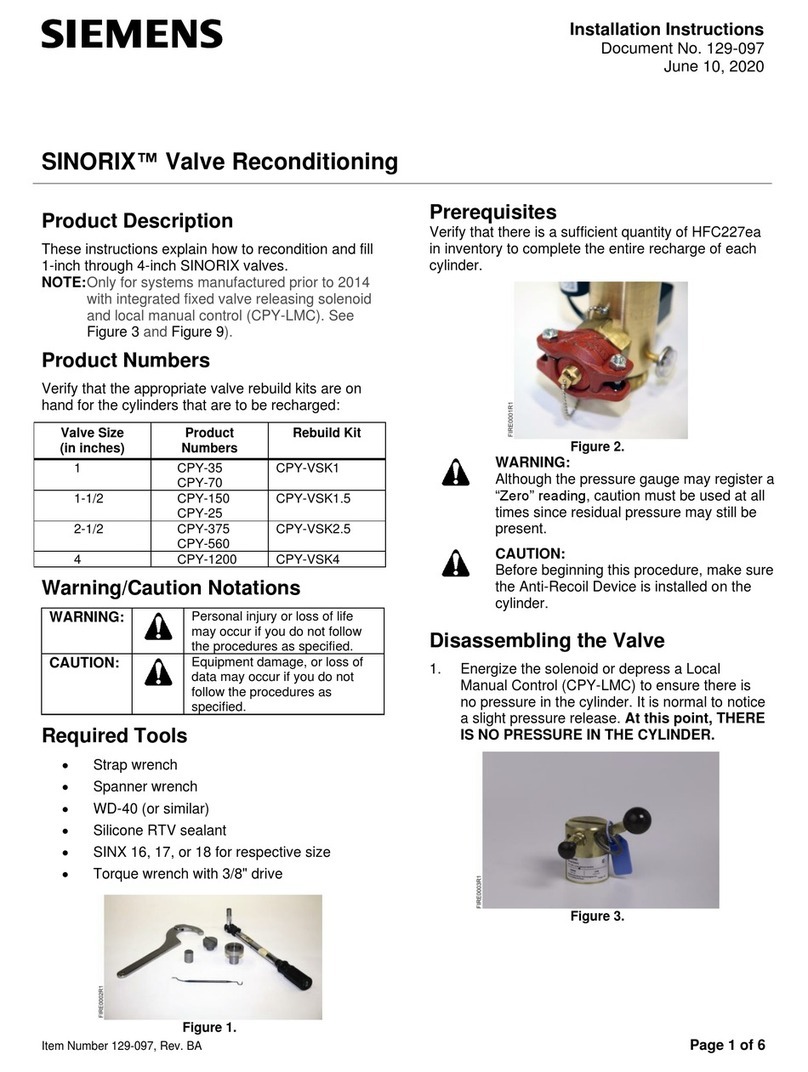

Block diagram extension module

X10

X13

X12

X11

X14

Power specifications of connections

1)without high-side measurement

Monitoring:

Short-circuit,

broken wire,

range

Frequency input 2

Frequency input 3

Frequency input 4

Emergency-Stop

Emergency-Stop

Relays 1

16 analog Inputs

0...10 VDC

Range monitoring

16 digital Inputs

10 VDC...30 VDC

Voltage monitoring

From Basic Module

Extension module

digital I/O

Radio Control Receiver

2x Voltage Output

Voltage Output 1

0...10 VDC

Voltage Output 2

0...10 VDC

Voltage Output 1 out

Voltage Output 2 out

Radio ON/OFF

Antenna

Radio - Control

Receiver

D 7845 page 6

3. Software, programming, diagnosis

3.1 Software

The scope of delivery includes the following software package as standard:

-Operating system ("C"-programmed real-time operating system) with integrated CAN-functionality as well as PLC-capability

-Functionality of prop. amplifier for outputs 0-15 (connector rail X2, X3)

-Initializing functions for all inputs and outputs

-Diagnosis software

Available as additional options:

-Diagnosis for CAN-Bus (incl. continuous chart logger)

-Function module, adapted for specified applications (on request)

Examples: -Max. load control

-Synchronicity / Positioning

-Position control (e.g. via option W with prop. directional spool valves type PSL(V) acc. to D 7700 ++)

-Quantity control (e.g. via current regulation valve, types SE and SEH acc. to D 7557/1)

-Pressure control (e.g. via prop. pressure limiting valves type PMV acc. to D 7485/1 and electrical pressure

transducer type DT 1 acc. to D 5440 T and / or type DT 2 acc. to D 5440 T/1)

2.3 Accessories

2.3.1 Plug set

The cable sets are provided for simple completion and start-up of the system

Order coding: Plug set (Basic module) Part No. 6217 2010-00

Plug set (Extension module) Part No. 6217 2100-00

3.2 Programming

3.3 Diagnosis

A distinction has to be made between two different steps of programming:

-Parameterization

Adjusting inputs and outputs to the connected devices

-Process control (PLC-programming)

Evaluation of incoming signals with corresponding actuation of the different outputs (including the initializing of inputs and outputs).

Programming is made with the help of an PLC-software in accordance with IEC 6131-3 using instruction list (IL), function block

diagram (FBD) or structured text (ST).

This way it is possible to quickly get solutions for many applications. More complex applications may require programming in "C".

The RS232-interface is used for loading the software into the valve control's flash memory.

It is possible to set the parameterization during runtime.

The following output equipment can be used for diagnosis:

-PC - connected to interface CAN-Bus (X6) or RS232 (X7), for parameterization, programming, error detection as well as remote

diagnosis via modem. See also description of the "Terminal program" (acc. to B 7845 T)

-7-segment display at the basic module,

for on-site diagnosis (error detection)

-CAN-Bus display (see D 7845 Z),

connected via CAN-Bus, for error detection and adjustment parameterization

3.4 Function blocks

General:

The manufacturer-specific function blocks serve to indicate to the PLC-programmer the interfaces to the actual system. They are

structured into the following two groups.

Group 1: Initializing functions (INI functions)

These functions are used for parameterization and/or configuration of the inputs and outputs - normally only once at

start-up.

It is also possible to apply this parameterization through the operating system. All these parameters and configurations

are included in the system's EEPROM. Thus they are preset and can be overwritten by the PLC-system.

The terminal program (scope of delivery), allows to check , change and save (EPROM and/or file) all settings. Due to

these configurations and parameterizations all data is available at runtime in an already converted and standardized

form, which even can include a ramp or debouncing information. This makes it possible to write the date directly onto the

outputs without conversion and supplemented with ramp information and/or other time-related information.

Group 2: Functions that are normally invoked cyclically during runtime (runtime module)

These functions are used to read input data, logically link them and to write them onto the outputs.

The documentation of the existing function blocks is included in the software package of the PLVC.

D 7845 page 7

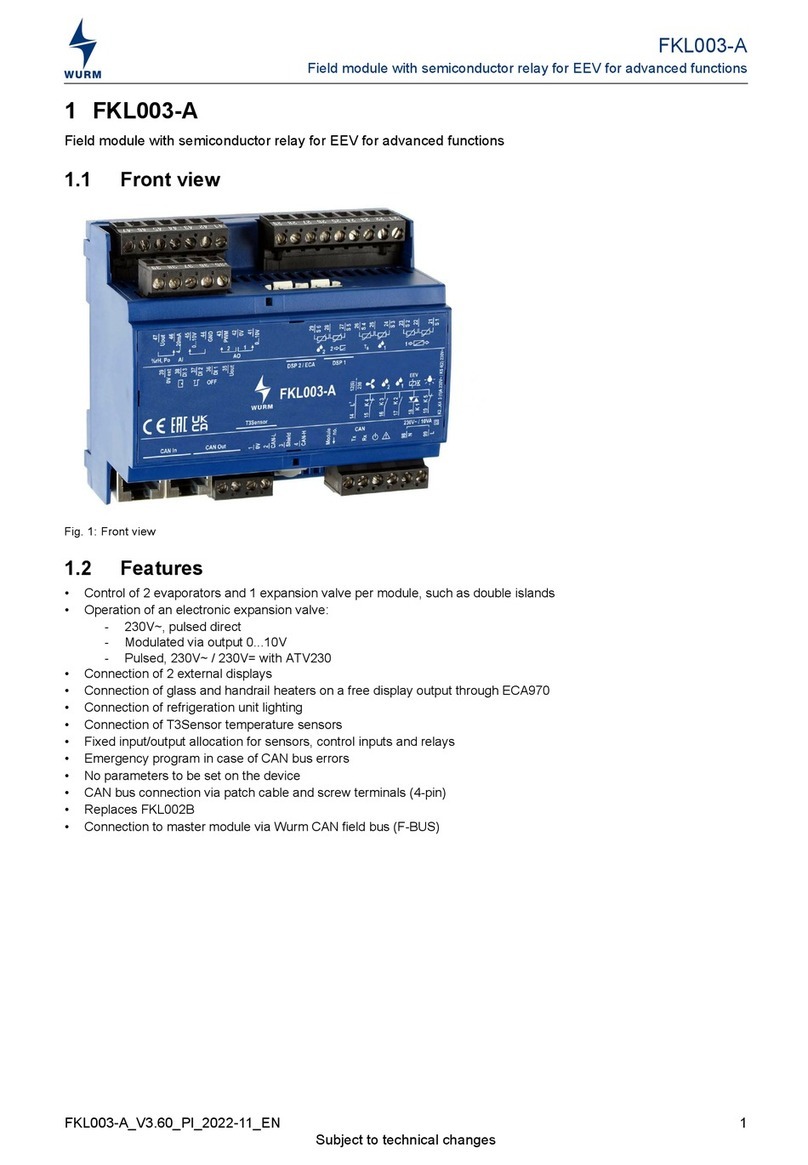

4. Dimensions

4.1 Basic and extension module, type PLVC 16

Extension module Basic module 7-segment display

There are three keys below the display

Press left key: error number, unit of ten

Press right key: error number, unit of one

Example: cable break at analog port 17:

No key: capital "A"

Left key: "1" (1x10)

Right key: "7" (7x1)

Center key: Additional errors are displayed if

no additional errors: "0"

It will return to highest priority error, when no is key pressed for 5 sec.

Individual errors:

Merely one flashing point: No error

One dash in center: No radio signal

Two dashes: PLC-error

Three dashes: Emergency-Stop

Upper-case "A": Cable break, analog output

Upper-case "C": CAN-Bus error

Lower-case "c": CAN-Bus warning

Lower-case "d": Undefined level (1.0 ... 3.5 V) at digital input port

Upper-case "F": Radio control error

Upper-case "H": Proportional valve range

Upper-case "P": Proportional valve open

Upper-case "U": Over-voltage

Lower-case "u": Under-voltage

Flash-symbol, downw.: Short-circuit at prop. valve

Flash-symbol, upw.: Short-circuit at digital output or wrong connection

5. Appendix

5.1 Error message of 7-segment display

5.2 Note

The scope of delivery for the programmable logic valve control type PLV includes an operating system and - on special agreement -

a customized software. It is the duty of the customer to test the requested functionality of the PLVC as he is responsible for the

faultless operation and final application of the PLVC.

Attention: Whenever a PLVC is replaced it is additionally necessary to order the current version of the software including the

operation parameter by the manufacturer of the machine.

The customer is responsible to take care that the requested functionality and safety of the application program is fulfilled. When

local laws make an approval by a notified body (testing or approval organization) necessary the customer has to apply for it.

D 7845 page 8

5.3 Installation notes

Electrical connection/ To guarantee the electrical interference protection of the controller, the housing must be connected

Grounding: to GND.

Ground connection has to be carried out on the shortest way between housing and machine and

independent of the minus connection to the module.

Safety instructions: This description is part of the unit. It contains texts and drawings concerning the correct handling of

the controller and must be read before installation or use. Observe the information of the

description. Non-observance of the notes, operation which is not in accordance with use as

prescribed below, wrong installation or handling can result in serious harm concerning the safety of

persons and plant.

The instructions are for authorised persons according to the EMC and low voltage guidelines. The

controllers must be installed and commissioned by a skilled electrician (programmer or service

technician).

The wiring has to comply with the respective standards and has to be galvanically separated from

other circuits. The devices connected at the terminals have to be approved by HAWE Hydraulik

GmbH & Co. KG and the signals fed have to comply with the specifications in this pamphlet. The

device may be used in a temperature range (-40°C to +80°C). Due to the additional self-heating the

housing walls can have high perceptible temperatures when touched in hot environments.

Tampering with the unit can lead to considerable risks for the safety of persons and plant. It is not

permitted and leads to the exclusion of any liability and warranty claims.

Note: Prior to any welding at the machine (vehicle) all PLVC-devices must be diconnected from their

power supply i.e. both terminals (+ and -) respectively a potential separation (electrical isolation) must

be ensured.

This manual suits for next models

1

Table of contents

Other HAWE Hydraulik Control Unit manuals