4 –62 Assembly instructions EN ◼GMQ 32 RM 16-25 ◼19.04.2023 ◼V3.0

4.3 Transport ....................................................................................................25

4.4 Packaging...................................................................................................25

4.5 Storage.......................................................................................................26

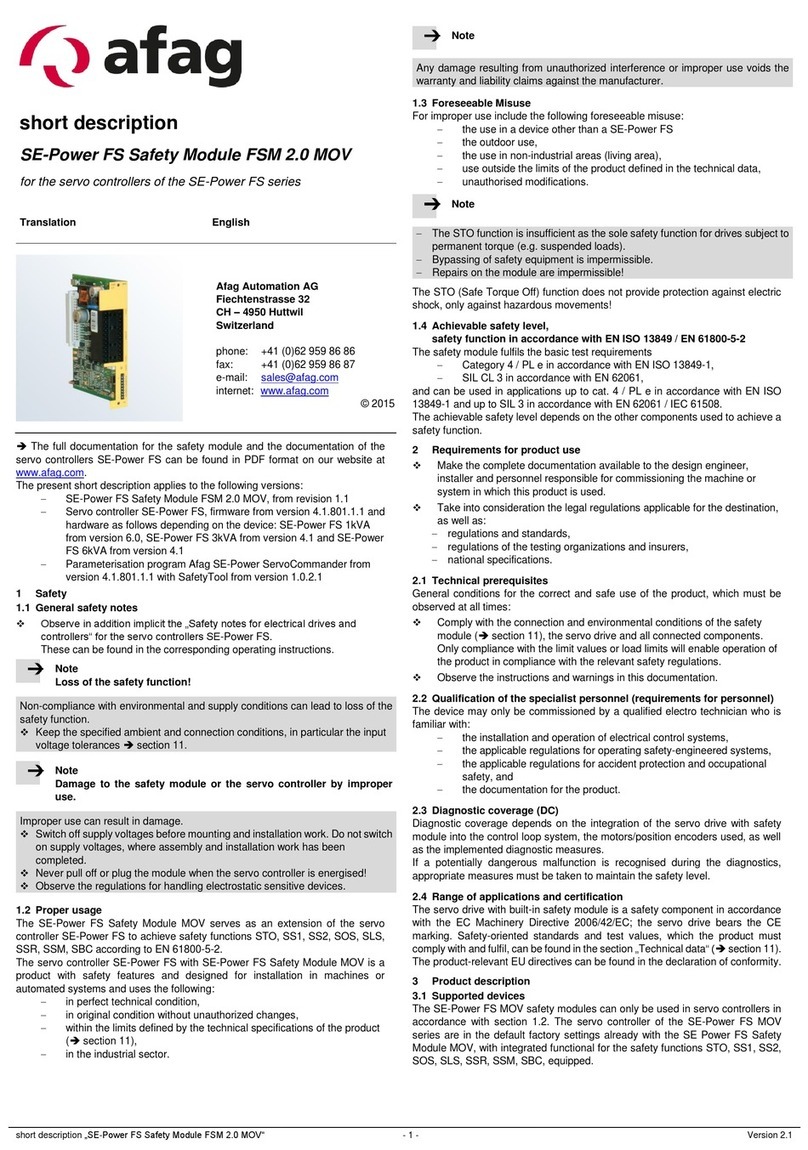

5Design and description .......................................................................................27

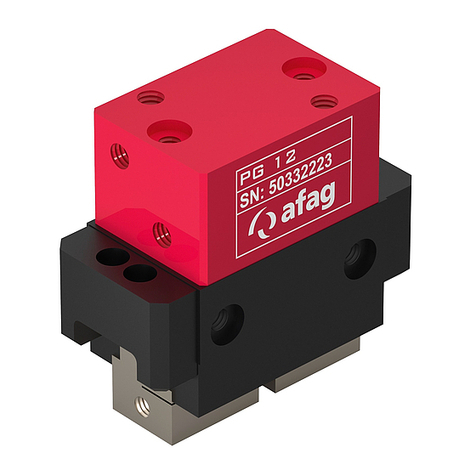

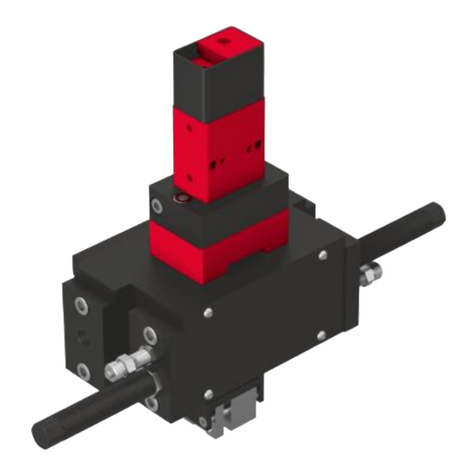

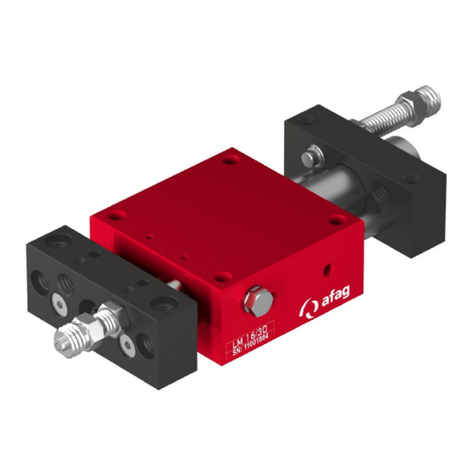

5.1 Design of module GMQ 32........................................................................27

5.2 Product description GMQ 32......................................................................28

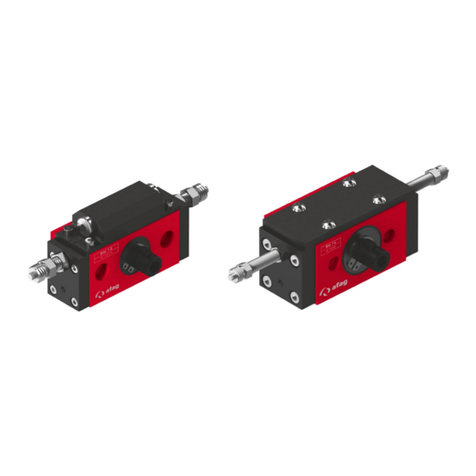

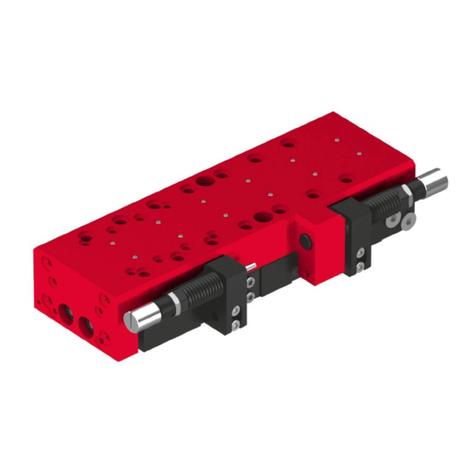

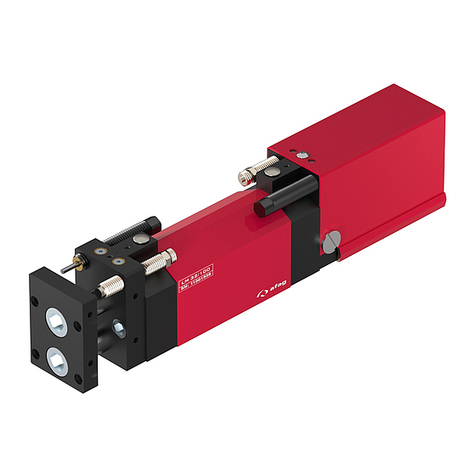

5.3 Design GMQ 32/RM 16 - GMQ 32/RM 25..................................................29

5.4 Product description.....................................................................................29

5.5 Accessories ................................................................................................30

5.5.1 Accessories GMQ 32 ...........................................................................30

5.5.2 Accessories RM 16 ..............................................................................30

5.5.3 Accessories RM 25 ..............................................................................30

6Installation, assembly and setting .....................................................................31

6.1 Safety instructions for installation and assembly .......................................31

6.2 Installation & Assembly ..............................................................................32

6.2.1 Mounting position and fastening ..........................................................32

6.2.2 Module centering..................................................................................32

6.2.3 Tightening torques for screws..............................................................34

6.2.4 Connection to the pneumatic system...................................................34

6.2.5 Mounting the initiators..........................................................................36

6.2.6 Assembly of the gripping jaws..............................................................39

6.2.7 Manufacture of the gripper fingers.......................................................39

6.3 Settings.......................................................................................................40

6.3.1 Safety notes for settings.......................................................................40

6.3.2 Adjusting the stop screw and stop pin..................................................41

6.3.3 Stroke adjustment of the GMQ 32 grippers .........................................42

6.4 Conversion of the GMQ module.................................................................43

6.4.1 Conversion of the GMQ 32 to internal clamping..................................44

6.4.2 Conversion of the GMQ 32 to double-acting........................................45

7Commissioning ....................................................................................................46

7.1 Safety instructions for commissioning........................................................46

7.2 Commissioning of the modules ..................................................................46

8Fault elimination...................................................................................................47

8.1 General Notes ............................................................................................47

8.2 Safety instructions for troubleshooting .......................................................47

8.3 Table Fault causes and remedy GMQ 32, GMQ 32/RM16, GMQ 32/RM25

....................................................................................................................48

9Maintenance and repair.......................................................................................49

9.1 General notes.............................................................................................49

9.2 Safety instructions for Maintenance and Repair ........................................49

9.3 Maintenance activities and maintenance intervals.....................................50

9.3.1 Overview of the maintenance points....................................................50