HAWE Hydraulik CDK Series Operator's manual

Pressure-reducing valve type CDK

Product documentation

D 7745

09-2019-1.9

Screw-in valve

Operating pressure pmax:

Volumetric ow rate Qmax:

500 bar

22 l/min

2/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

© by HAWE Hydraulik SE.

The reproduction and distribution of this document as well as the use and communication of its contents to others without explicit

authorisation is prohibited.

Offenders will be held liable for the payment of damages.

All rights reserved in the event of patent or utility model applications.

Brand names, product names and trademarks are not specifically indicated. In particular with regard to registered and protected names

and trademarks, usage is subject to legal provisions.

HAWE Hydraulik respects these legal provisions in all cases.

Printing date / document generated on: 11.11.2019

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 3/25

Contents

1 Overview pressure control valve type CDK............................................................................................................ 4

2 Available versions, main data............................................................................................................................. 5

2.1 Screw-in valve..................................................................................................................................................... 5

2.2 Versions with individual connection block for pipeline connection..............................................................................6

2.3 Versions with individual connection block for plate mounting....................................................................................7

3 Parameters......................................................................................................................................................... 8

3.1 General............................................................................................................................................................... 8

4 Dimensions...................................................................................................................................................... 12

4.1 Screw-in valve................................................................................................................................................... 12

4.2 Mounting hole................................................................................................................................................... 13

4.3 Version with single connection block for pipe connection........................................................................................14

4.4 Version with connection block for manifold mounting............................................................................................. 17

4.5 Base plate hole pattern...................................................................................................................................... 18

4.6 Tapped plugs..................................................................................................................................................... 18

5 Assembly, operation and maintenance recommendations.....................................................................................19

5.1 Intended use..................................................................................................................................................... 19

5.2 Assembly information......................................................................................................................................... 19

5.2.1 Screwing in the screw-in valve.............................................................................................................................20

5.2.2 Setting the pressure........................................................................................................................................... 20

5.2.3 Creating the mounting hole.................................................................................................................................21

5.2.4 Making base plate.............................................................................................................................................. 21

5.3 Operating instructions.........................................................................................................................................22

5.4 Maintenance information..................................................................................................................................... 22

6 Other information.............................................................................................................................................23

6.1 Planning information.......................................................................................................................................... 23

6.2 Application examples.......................................................................................................................................... 24

4/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

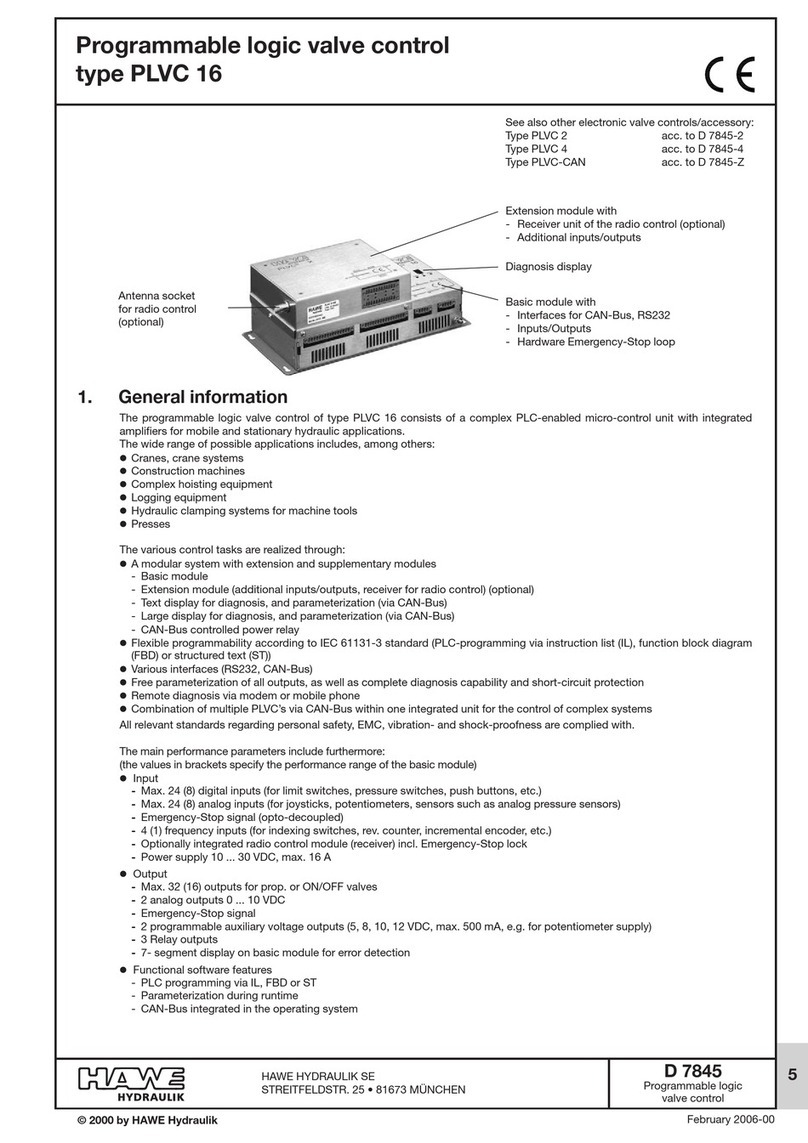

1Overview pressure control valve type CDK

Pressure reducing valves are a type of pressure control valve. They

maintain a largely constant outlet pressure even at a variable

(higher) inlet pressure.

Valve type CDK is a screw-in valve, and can be used in control

blocks. The bore-holes required for mounting are easy to create. All

versions oil-tight when closed.

Features and benets:

■Zero leakage in closed state

Intended applications:

■General hydraulic systems

■Jigs

■Test benches

Design:

■Type CDK 3 - standard version, can be used for all applications.

■Type CDK 32 - version with low pressure dependence on

changing pump inlet pressure and for usage at low pressure

settings.

■Type CDK 35 - version with low ow resistance, however with

higher pressure dependence on changing pump inlet pressures.

Version with connection blocks:

■For pipe connection (without/with pressure-limiting valve)

■For manifold mounting (without/with pressure-limiting valve)

■For manifold mounting (without/with pressure-limiting valve)

with adapter plate for pipe connection

Screw-in valve

Version with connection block for direct pipe connection

Version with connection block for manifold mounting

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 5/25

2Available versions, main data

2.1 Screw-in valve

Circuit symbol:

NOTE

Flow direction A d P not shown, see "Flow direction" section in Chapter 3.1, "General"

Sample order:

CDK 3 -2 R -200

Pressure setting (bar) Pressure control valve *

Adjustment Table 2 Adjustment

Basic type and pressure range Table 1 Basic type and pressure range

* If there is no specied pressure setting, the valve will be set at the factory to the maximum value in the pressure range in question

Table 1 Basic type and pressure range

Pressure range pA from ... to (bar)Type Volumetric

ow rate

Qmax (lpm) -08 -081 -1 -11 -2 -21 -5 -51

CDK 3 50 ... 450 50 ... 500 30 ... 300 30 ... 380 20 ... 200 20 ... 250 15 ... 130 15 ... 165

CDK 3K*12 55 ... 310 - 30 ... 200 - 20 ... 140 - 15 ... 90 -

CDK 32 6 30 ... 450 30 ... 500 18 ... 300 18 ... 380 12 ... 200 12 ... 250 8 ... 130 8 ... 165

CDK 32K*6 30 ... 310 - 18 ... 200 - 12 ... 140 - 8 ... 90 -

CDK 35 22 110 ... 450 110 ... 500 70 ... 300 70 ... 380 50 ... 200 50 ... 250 30 ... 130 30 ... 165

CDK 35K*22 110 ... 310 - 70 ... 200 - 50 ... 140 - 30 ... 90 -

*Short version, available "xed" only

Table 2 Adjustment

Identifier Description Circuit symbol

No designation Fixed, can be adjusted using tool

RCan be adjusted by hand, with lock nut

(not for type CDK 3.K)

HRotating grip with lock

(not for type CDK 3.K)

6/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

2.2 Versions with individual connection block for pipeline connection

Sample order:

CDK 3 -5 R

CDK 35 -2

-1/4

-1/4 SR

- DG 365 -100

-200 /250

Pressure setting (bar) Pressure relief valve

Version with pressure switch Table 4 Version with pressure switch

Versions with individual connection block Table 3 Versions with individual connection block

Table 3 Versions with individual connection block

Identifier Description Connection Circuit symbol

-1/4 G 1/4 (BSPP)

-9/16-18 UNF 9/16-18 UNF

-1/4-18 NPTF 1/4-18 NPTF

-1/2

Pipe connection

G 1/2 (BSPP)

-1/4 - DG.. G 1/4 (BSPP)

-9/16-18 UNF - DG.. 9/16-18 UNF

-1/4-18 NPTF - DG..

Pipe connection, pressure switch in the load line

1/4-18 NPTF

-1/4 S Pipe connection, pressure-limiting valve, xed, tool adjustable G 1/4 (BSPP)

-1/4 SR Pipe connection, pressure-limiting valve, manually adjustable, with

lock nut

G 1/4 (BSPP)

NOTE

Connection M with reduced ow.

Table 4 Versions with pressure switch

Coding Setting range (bar)

- DG 33 200 ... 700

- DG 34 100 ... 400

- DG 35 40 ... 210

- DG 36 4 ... 12

- DG 364 4 ... 50

- DG 365 12 ... 170

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 7/25

2.3 Versions with individual connection block for plate mounting

Sample order:

CDK 35 -5 R - SP -100/300 - 1/4

Adapter plate Table 5 Connection block version

Connection block Table 5 Connection block version

Table 5 Connection block version

Identifier Description Circuit symbol

PPlate mounting

SP Plate mounting, pressure relief valve, xed, can be adjusted using tool

P - ... - 1/4 Plate mounting

SP - ... /... - 1/4 Plate mounting, pressure relief valve, xed, can be adjusted using tool, with adapter plate

for pipeline connection

8/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

3Parameters

3.1 General

General information

Designation Directly piloted 2-way pressure control valve

Design Ball seated valve

Model Screw-in valve, valve for pipe connection, manifold mounting valve

Material Steel; nitrided valve housing, electrogalvanised or ZiNi sealing nuts and connection block,

hardened and ground functional inner parts

Balls made of rolling bearing steel

Tightening torque See Chapter 4, "Dimensions"

Installation position As desired

Ports ■P = input (pump side or primary side)

■A = Load (secondary side)

■M = pressure gauge connection

■R = Tank connection

Markings apply to hydraulic schematics and assembly plans only. The markings are not

stamped onto the valve housing.

The ports are stamped on the versions for pipe connection and versions for manifold

mounting.

The coding can be found in the schematic overviews or the dimension diagrams in Chapter 4,

"Dimensions".

Flow direction P → A: Pressure control function

A → P: Only possible if the pressure on the pump side is lower than the load pressure.

NOTE

In the case of ow rates of A d P with more than QP d A max or if pressure surges

or pressure pulsations are to be expected, a separate bypass check valve is to be

provided.

Hydraulic uid Hydraulic oil: according to part 1 to 3;

ISO VG 10 to 68 according to DIN ISO 3448

Viscosity limits: min. approx. 4, max. approx. 1500 mm2/s

opt. operation approx. 10... 500 mm2/s.

Also suitable for biologically degradable hydraulic uids type HEPG (polyalkylene glycol)

and HEES (synthetic ester) at operating temperatures up to approx. +70°C.

Cleanliness level ISO 4406

21/18/15...19/17/13

Temperatures Ambient: approx. -40 ... +80°C, Fluid: -25 ... +80°C, Note the viscosity range!

Permissible temperature during start: -40°C (observe start-viscosity!), as long as the service

temperature is at least 20K higher for the following operation.

Biologically degradable pressure uids: Observe manufacturer's specifications. By considera-

tion of the compatibility with seal material not over +70°C.

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 9/25

Pressure and ow rate

Operating pressure ■On the pump side pP max = 500 bar

■Load side pA max, see Table for basic version in Chapter 2, "Available versions, main data"

■Return pR ≤ 20 bar

Pressure dependence The pressure ratio as designed causes a slight change to the actual pressure pA in conjunction

with a variable pump pressure pP.

Pressure range (bar)Type

-08

-081

-1

-11

-2

-21

-5

-51

CDK 3 ± 1.3 ± 0.9 ± 0.6 ±0.4

CDK 32 ± 0.7 ± 0.45 ± 0.3 ± 0.23

CDK 35 ± 2.7 ± 1.7 ± 1.2 ± 0.8

pp ± 10 bar results in a pressure change for A of pA

Flow rate QP→A max = 6 lpm (CDK 32)

= 12 lpm (CDK 3)

= 22 lpm (CDK 35)

QA→P max = 25 lpm See note in Chapter 3, "Parameters"

10/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

Characteristics

Oil viscosity approx. 60 mm2/s

pA - QP→A - characteristics

The pressure setting applies for QP→A→0 lpm. If Q > 0, i.e. the connected consumer is

moving, the secondary pressure pA drops slightly.

The pressure pA is set according to the information in the order at pP ≈ 1.1 pA.

CAUTION

Risk of injury on overloading components due to incorrect pressure settings!

Risk of minor injury.

■Pay attention to the maximum operating pressure of the pump and the valves.

■Always monitor the pressure gauge when setting and changing the pressure.

QA ow rate (lpm); pA outlet pressure (bar)

Δp - Q - Characteristic curve P→A or A→P

QA Volumetric ow rate (lpm); Δp Flow resistance (bar)

NOTE

For this purpose, please observe the additional information under the point "Flow

direction".

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 11/25

Weight

Screw-in valve Type

CDK.. = 0.7 kg

Version with single connection block Identifier

- 1/4 = 1.3 kg

- 9/16-18 UNF = 1.3 kg

- 1/4-18 NPTF = 1.3 kg

- 1/4 - DG.. = 1.6 kg

- 1/4 S(SR) = 1.6 kg

- P = 1.1 kg

- SP = 1.6 kg

- P-../..-1/4 = 1.5 kg

- SP-../..-1/4 = 2.0 kg

12/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

4Dimensions

All dimensions in mm, subject to change.

4.1 Screw-in valve

CDK 3..

1Sealing option

2Stop

3KANTSEAL DKAR00021-N90 NBR 90 Sh 23.52x26.88x1.68

4Seal edge

5Sealing nut

6O-ring 21.95x1.78 (21.89x2.62) AU 90 S

7Valve housing

CDK 3.K

1Stopper

2KANTSEAL DKAR00021-N90 NBR 90 Sh 23.52x26.88x1.68

3Sealing edge

4Sealing nut

5O-ring 21.95x1.78 (21.89x2.62) AU 90 S

6Valve housing

7Adjusting screw

NOTE

For this purpose, please also observe the information on threads and on producing requirements in Chapter 5.2, "Assembly

information"!

Type CDK 3.K: Do not turn set screw 8 beyond the red marker ring!

Adjustment

No designation Coding RCoding H

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 13/25

4.2 Mounting hole

Location for sealing (inlet to outlet): at the contact area between the facial sealing edge of the tapped journal of the valve housing and

the stepped shoulder of the tapping hole of the location thread.

The stepped shoulder is depicted with the normal 118° drill tip angle for steel.

Therefore reaming of the hole and bevels to help the seals slip in are not necessary.

The sealing of the attached valve and its xing at the manifold body are made by a sealing nut with a tting seal and an O-ring.

Additionally the passage between port A and T is sealed at the screwin port and the internal piston.

Counterbore 0.5+0.2 (max. #30+0.1), exclusively required for pressures at A in excess of 100 bar.

14/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

4.3 Version with single connection block for pipe connection

CDK 3..- 1/4

CDK 3..- 1/4 - DG..

Coding Connections P, A, M

- 1/4

- 1/4 - DG.. G 1/4 (BSPP) ISO 228-1

CDK 3..- 9/16-18 UNF

CDK 3..- 9/16-18 UNF - DG..

Coding Connections P, A, M

- 9/16-18 UNF

- 9/16-18 UNF-DG.. 9/16-18 UNF ANSI B1.1, SAE-6

1Screw-in valve, as per Chapter 4.1, "Screw-in valve"

2Pressure switch DG 3.. as per D 5440

3Without DG 3.. (can be retrofitted here)

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 15/25

CDK 3..- 1/4-18 NPTF

CDK 3..- 1/4-18 NPTF - DG..

Coding Connections P, A, M

- 1/4-18 NPTF

- 1/4-18 NPTF-DG.. 1/4-18 NPTF ANSI B1.20.3

1Screw-in valve, as per Chapter 4.1, "Screw-in valve"

2Pressure switch DG 3.. as per D 5440

3Without DG 3.. (can be retrofitted here)

CDK 3..- 1/2

Coding Connections P, A

- 1/2 G 1/2 (BSPP) ISO 228-1

1Screw-in valve, as per Chapter 4.1, "Screw-in valve"

16/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

CDK 3..- 1/4 S

CDK 3..- 1/4 SR

1Fixed

2Adjustable

Coding Connections P, A, R

- 1/4 S

- 1/4 SR G 1/4 (BSPP) ISO 228-1

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 17/25

4.4 Version with connection block for manifold mounting

CDK 3 - .. - P CDK 3 - .. - SP

1Sealing with O-rings 7.65x1.78 NBR 90 Sh

For this purpose, please observe the hole pattern in Chapter 4.5, "Base plate hole pattern".

CDK 3(32, 35) - .. - P - .. - 1/4 CDK 3(32, 35) - .. - SP - .. - 1/4

1Adapter plate (connection block for pipe connection)

2Sealing with O-rings 7.65x1.78 NBR 90 Sh

Identifier Connections P, A, R

- P ..

- SP .. G 1/4 (BSPP) ISO 228-1

18/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

4.5 Base plate hole pattern

The hole pattern corresponds to that of type ADM 11 P as per D 7120. The O-ring

counterbore for the drain port R (or L) is present but is only required for type

CDK..-SP.

4.6 Tapped plugs

The mounting holes can be sealed with tapped plugs if necessary; for example, if the assembly of standardised basic bodies is to be

carried out with or without screw-in valves as required.

Passage open

1Tapped plug M24x1.5 DIN 910

2Sealing ring A25x30x2 DIN 7603-Cu

Passage closed

1O-ring 21.95x1.78 AU 90 Sh

2KANTSEAL DKAR00021-N90 NBR 90 Sh 23.52 x 26.88 x 1.68

3Tapped plug and locking tapped plug complete order no.. 7710 029

© HAWE Hydraulik SE D 7745 - 09-2019-1.9 19/25

5Assembly, operation and maintenance recommendations

5.1 Intended use

This valveis intended exclusively for hydraulic applications (uid technology).

The user must observe the safety measures and warnings in this documentation.

Essential requirements for the product to function correctly and safely:

– All information in this documentation must be observed. This applies in particular to all safety measures and warnings.

– The product must only be assembled and put into operation by qualied personnel.

– The product must only be operated within the specied technical parameters. The technical parameters are described in detail in this

documentation.

– All components must be suitable for the operating conditions in the event of application in an assembly.

– The operating and maintenance manual of the components, assemblies and the specic complete system must also always be

observed.

If the product can no longer be operated safely:

1. Remove the product from operation and mark it accordingly.

✓It is then not permitted to continue using or operating the product.

5.2 Assembly information

The product must only be installed in the complete system with standard and compliant connection components (screw ttings, hoses,

pipes, xtures etc.).

The product must be shut down correctly prior to dismounting (in particular in combination with hydraulic accumulators).

DANGER

Risk to life caused by sudden movement of the hydraulic drives when dismantled incorrectly!

Risk of serious injury or death.

■Depressurise the hydraulic system.

■Perform safety measures in preparation for maintenance.

20/25 D 7745 - 09-2019-1.9 © HAWE Hydraulik SE

5.2.1 Screwing in the screw-in valve

1Valve housing *

2Lock nut and sealing nut *

3Basic body

4Sealing edge

5Locking

6Stopper

7Sealing option

1. Before screwing in the valve, loosen the lock nut and sealing nut until the travel stop.

2. Screw in the valve and tighten with the specied torque. The metallic sealing of the

inlet to the outlet is formed between the facial sealing edge of the valve and the

shoulder of the stepped hole in the basic body.

3. Tighten lock nut and sealing nut with specied torque.

* Values in brackets apply to pressure ranges of type CDK 3.-08 (-81)

5.2.2 Setting the pressure

If there is no specied pressure setting, the valve will be set at the factory to the maximum value in the pressure range in question.

Guideline values for pressure adjustment

Pressure adjustment

Pressure control valve

Identifier Δp/revolution

(bar/R)

08 37

1 25

2 16

5 10

Pressure adjustment

Pressure control valve

Identifier Δp/revolution

(bar/R)

081 46

11 31

21 20

51 12

Pressure adjustment

Pressure relief valve

Pressure range

(bar)

Δp/revolution

(bar/R)

... 500 100

... 315 55

... 160 19

... 80 9.5

CAUTION

Risk of injury on overloading components due to incorrect pressure settings!

Risk of minor injury.

■Pay attention to the maximum operating pressure of the pump and the valves.

■Always monitor the pressure gauge when setting and changing the pressure.

This manual suits for next models

3

Table of contents

Other HAWE Hydraulik Control Unit manuals