Troubleshooting Guide

No fluid flow

•If valve operating air pressure is too low,

the valve will not open. Increase air

pressure to 70 psi (4.8 bar) minimum.

•The reservoir air pressure may not be

high enough. Increase pressure.

•The dispensing tip may be clogged.

Replace tip.

•The stroke adjustment may be closed.

Open stroke adjustment.

•Fluid may have solidified in the valve.

Clean the fluid body.

Fluid drools after the valve

closes, eventually stopping

•This is caused when air is trapped in

the outlet section of the fluid body or

the fluid has entrapped air. The air will

expand after the valve closes, causing

extrusion until the air reaches

atmospheric pressure.

Purge the valve by dispensing at a steady

flow until clear. If a small tip is used, it

may be necessary to remove the tip while

purging to obtain sufficient flow to carry

the air down through the tip adapter.

•If the fluid has entrapped air, the material

must be degassed before dispensing.

Fluid drips at a steady rate after

the valve closes

•A steady drip can be caused by excessive

reservoir pressure. Check to be sure

the reservoir pressure is not above 70

psi (4.8 bar).

•A steady drip also indicates failure of

the diaphragm to close fully due to

particle build-up or wear. In either case,

replace the sealing head in accordance

with the maintenance instructions.

Fluid leaks out between fluid

body and diaphragm

•Fluid leakage between the fluid body and

diaphragm indicates the annular sealing

ridge on the fluid body is damaged or the

fluid body is distorted due to excessive

torque on the retaining screws. In either

case, replace the fluid body.

Fluid flows out of the drain hole

•Fluid flowing out of the drain hole

indicates a ruptured diaphragm.

Replace in accordance with the

maintenance instructions.

Valve responds slowly when

opening and closing

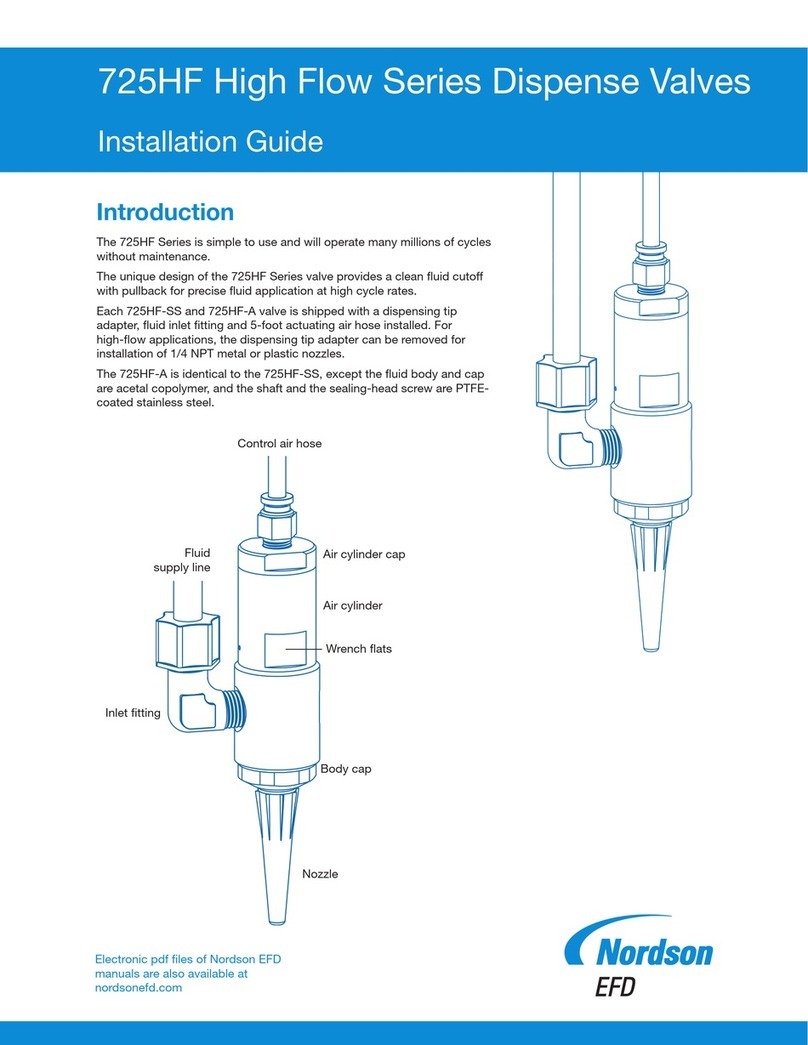

•Valve response is related to control air

hose length and size. The valve is

supplied with 5-feet of 3/32” ID tubing

attached. Any additional length or size

change will affect response time. Check

to be sure the length and size have not

been changed.

Inconsistent deposits

•Inconsistent deposits can result if the

air pressure controlling the valve and/or

supplying the reservoir is fluctuating or if

the valve operating pressure is less than

70 psi (4.8 bar). Check to be sure air

pressures are constant and the valve

operating pressure is 70 psi (4.8 bar).

•The time the valve is open must be

constant. Check to be sure the valve

controller is providing a consistent

output.