HAWQ MINI MEDIAM SPEED DOME CAMERA User manual

MINI MEDIAM SPEED DOME CAMERA

User Manual

Power Supply DC 12V

Factory Configuration: PELCO-D protocol, Baud rate 2400, Address code 1

Please read carefully before using this manual※

1

Catalogue

Chapter 1 Product S u mmarize………..………….…………….………….………….………….………….……………2

1 . 1 Te c hnical Paramet e rs………………. … … …….…… … …….………….……… … . …………. … ……….… … ……….2

1 . 2 Function descr i p tion………………………………………………….………….………….…………. … …….………. 3

C h a p ter 2 Equipmen t installation…………….…….…………………….………….………….………….…..…………6

2.1 DIP switch settings……………….........................................……….………….………….………….….................6

2.2 Dome camera s t ructure diagram…………………..…..……………………….………….………….………….……8

2.3 Bracket installation diagram...……..…………….……..…………………….………….…………. … … …….… … ...9

C h apt e r 3 S ystem O SD menu setting s ....…………………………………….………….………….…………. … … … 1 0

3 . 1 P o w e r - on self-te s t………….……………………………………………….………….………….………….………….1 0

3.2 Preset point setting and c alling……………………………………….………….………….………….…………….1 0

3.2.1 Set preset points ………….……………………………..…………….………….………….………….…………….10

3.2.2 Call preset points …….…………………………………….………….………….………….………….…………….10

3.3 Preset p o i n t f unction ta ble. ……………………………………………. … … …….………….………….…………….10

3.4 < M A I N MENU > … ……….………………………… … … ..…………….……… … . … ……….…… … … . … … … ……… . 11

3.5 <CAMERA >(Lens) settings menu.................................. ……….………….………….………….….....................11

Chapter 4 Simple Tr oubleshooting and M aintenance………………. ………….………….…… …….……… … .…. 1 2

4 . 1 S i mpl e Tr oubl es h ooting Ta b l e … …………………..………………….………….………….………….…….. … ……12

4 . 2 Af t e r S e r v i c e … … … …………………………………………. … … … … . … … … ….… … … … .…… … ….……...……..1 4

2

Chapter 1 Product Summarize

1.1 Technical Parameters (standard)

Model number 4 INCH MINI MEDIAM SPEED DOME CAMERA

Optical focus 10X 12X

Image sensor 1/3"CCD

Signal mode PAL / NTSC

Resolution 480TVL / 540TVL / 650TVL/ 700TVL

Optical focus Manual/Auto, adapt high performance DSP to realize full digital high continuous

focusing function.

Presets 256

Cruise scan 30 presets can join cruise

Other scan Support Horizontal scan

Rotation range Horizontal 360°unlimted rotation, Vertical 90°, auto reversal

Rotation speed Horizontal & Vertical Min 0.01° Max 60°/s.

Communications PELCO-D and PELCO-P

OSD Input 95 on the keyboard to call the module menu

Temperature control

system Optional

Power supply DC12V 2A

Resolution 480TVL / 540TVL / 600TVL/650TVL/ 700TVL

Ball cover dimension 4 inch optical glass cover

3

4. Set and call preset position

Preset function is the current state of the ball under the PTZ function of the horizontal angle, tilt angle and camera

Material Aluminum shell, waterproof IP66

Work environment -20℃~+50℃(select temperature control accessories), <95%RH

1.2 Function description

1. Set address coding, baud rate, control protocol

Any operation commands the camera has its own objectives address coding, baud rate, control protocol, a single

camera only to respond with its own address coding, baud rate, control agreement under the operation of the

command. Camera address coding, baud rate, control protocol specific settings please refer to the DIP settings.

2. Target tracking

Users can use the controls on the keyboard joystick control of the upper and lower turning left and right cameras

can be used to track moving targets or moving horizon, while the focal length can be adjusted to change the

perspective of the size or the target image size. In the auto-focus of the state, with the lens rotation, the camera will

automatically adjust according to a rapid scene changes, instantly get a clear picture.

3. Focal length / speed automatic matching technique

Manual adjustment, the longer the focal length of the case, a reflection of high-speed ball machine makes a slight

touch screen joystick may move back, resulting in data loss. Based on user-friendly design, ball according

to the proximity of the foca l length of the camera automatically adjusts the horizontal and vertical speed,so that

manual operation is more simple and easy to track targets.

lens focal length, etc. position parameters stored in memory, you need to call these parameters can be quickly and

PTZ cameras will be adjusted to that location. The operator can quickly and easily by controlling the keyboard,

4

infrared controller, control equipment such as storage and call the preset point, the ball machine to support 256

preset points.

5. Lens Control

(1) Zoom control

Users can control the keyboard or through the ball machine to adjust the focus of the distance matrix of the host,

receive the necessary panoramic images, or is a fine view.

(2) Focus Control

System default auto-focus, zoom, the camera lens will be the center of the screen features auto-focus, to maintain a

clear picture; in exceptional circumstances, the user can manually focus, achieve the desired image effect.

When in manual focus state, to restore the auto-focus, as long as the sway bar can be restored remotely auto-focus.

There is also a dedicated control commands can be issued or to call an arbitrary way of restoring a preset bit

auto-focus.

The camera lens in the following situations will not autofocus on the camera objectives:

a. Target is not to screen center;

b. Targets the same time in the far and near the place;

c. Target light objects, such as neon lighting, spotlights and other luminous objects;

d. Target with droplets or dust behind the glass;

e. Targets moving too fast;

f. Large area targets, such as walls;

g. Objectives are too dark or inherently ambiguous.

6. Aperture Control

Users can control the keyboard to manually adjust the aperture size to get the required picture brightness.

5

7. Auto Backlight Compensation

When the backlight compensation function is open, the camera lens in the light background can be automatically

targets the more the dark luminance compensation. On the bright background light adjustment, to avoid the

background brightness caused by a mass of light throughout the picture, goals and not identifiable because of the

darkness to gain a clear image.

8. Auto White Balance

According to the changes in ambient light, automatic adjustment, the true color reproduction.

9. Night vision function (color / monochrome conversion)

Cameras with night vision function, automatic color / monochrome conversion mode, in accordance with changes in

ambient light automatic conversion CCD illumination. Such as: adequate lighting during the day due to the use of

general illumination to ensure colorful images. In the night illumination can be automatically changed to black and

white images show a clear interest.

10. Cruise

Can be pre-set cruise preset point, certain preset points, organized in the order required to auto-cruise in the queue,

only an external command can be in an indoor speed ball set automatically according to preset points in order to

provide the time interval constant movement back and forth.

11. Continuous scan

Just an external command or through a power-on action, free movement, alarm linkage, etc. to call, can make the

ball machine horizontal direction to a certain speed the cycle of continuous scanning.

6

ON OFF PELCO-D

Chapter 2 Equipment installation

2.1 DIP switch setting

Four DIP switch is the baud rate and the control protocol switch.

Eight DIP switch is the address code setting switch

DIP switch to “ON” means to “1”, DIP switch to "OFF" means "0".

The baud rate and control protocol as the following table:

NO. 1 2 3 4

Control protocol

Baud rate

(BPS)

OFF OFF 9600

ON ON 9600

OFF ON 4800

ON OFF 2400

8-bit DIP switch is used to set the dome camera address coding. Address set binary mode can be set to a total

of 256 different dome camera address coding, see coding table address.

Camera address coding form

Camera

address

1 2 3 4 5 6 7 8

0 OFF OFF OFF OFF OFF OFF OFF OFF

1 ON OFF OFF OFF OFF OFF OFF OFF

2 OFF ON OFF OFF OFF OFF OFF OFF

PELCO-P

OFFOFF

7

3 ON ON OFF OFF OFF OFF OFF OFF

4 OFF OFF ON OFF OFF OFF OFF OFF

5 ON OFF ON OFF OFF OFF OFF OFF

6 OFF ON ON OFF OFF OFF OFF OFF

7 ON ON ON OFF OFF OFF OFF OFF

8 OFF OFF OFF ON OFF OFF OFF OFF

9 ON OFF OFF ON OFF OFF OFF OFF

10 OFF ON OFF ON OFF OFF OFF OFF

11 ON ON OFF ON OFF OFF OFF OFF

12 OFF OFF ON ON OFF OFF OFF OFF

… … … … … … … … …

246 OFF ON ON OFF ON ON ON ON

247 ON ON ON OFF ON ON ON ON

248 OFF OFF OFF ON ON ON ON ON

249 ON OFF OFF ON ON ON ON ON

250 OFF ON OFF ON ON ON ON ON

251 ON ON OFF ON ON ON ON ON

252 OFF OFF ON ON ON ON ON ON

253 ON OFF ON ON ON ON ON ON

254 OFF ON ON ON ON ON ON ON

255 ON ON ON ON ON ON ON ON

8

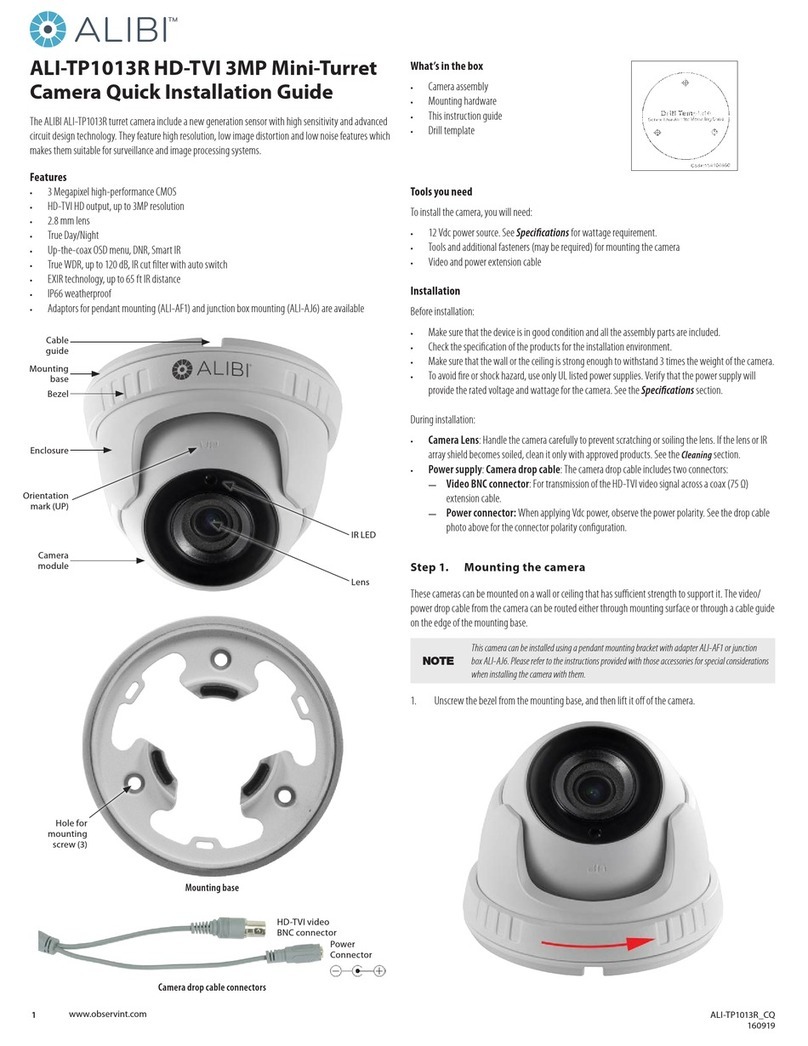

2.2 Dome camera structure diagram

Figure 1 Figure 2 Figure 3

Figure 4 Figure 5 Figure 6

2.3 Bracket installation diagram

9

Figure 7 Figure 8

Figure 9

10

Chapter 3 System OSD menu settings

3.1 Power-On Self-Test

When power is connected to the dome camera, the camera in horizontal and vertical direction movement, the

screen will appear system-related information, the dome camera self-test to complete the following diagram.

PELCO-D-2400-001

Display: PELCO-D protocol、Baud Rate 2400、Address code 1

3.2 Preset point setting and calling

3.2.1 Set Preset points:

(1) selected camera (see manual control of the keyboard);

(2) operation Rocker, zoom button, focus button, buttons adjust the camera aperture screen;

(3) Press the number keys + PRESET (input designated preset) to preserve the scene preset parameters.

3.2.2 Call preset points:

(1) Selected camera;

(2) Press the number keys (inputs the designated preset) + PREVIEW button, the camera immediately move to the

preset position, the lens zoom, focus and Iris is also automatically change to the preset parameters; if the input is a

special function preset point (see "Preset Point menu"), the dome camera will perform with special features preset

point of the corresponding functions (such as: Enter the 80th presets, the camera will perform auto-tracking feature).

3.3 Preset point function table:

11

Dial the 95th Presets Enter module menu

Dial the 83th Presets clear all presets

Dial the 98th Presets presets cruise

Dial the 99th Presets 360 degree continuing scan

3.4 <MAIN MENU>

The dome camera power on and working properly, call the 95 preset points into the module menu, screen display

as shown in the Table 3-1.

3.5<CAMERA> (Lens settings)

LANGUAGE Chinese/English

CAMERA ID

ZOOM DISPLAY

BLC

AGC

DAY/NIGHT

FOCUS

001

ON/OFF

MIDDLE/MAX/MIN

AGC/AUTO/COLOUR/ B/W

AUTO/MANU/KAUTO

BAUD RATE 9600

BRIGHTNESS 02

SHARPNESS 07

MIRROR OFF

Cancel module menuRedial the 95th

Presets

ON/OFF

12

HLM OFF

HLM LEVEL 1F

TABLE 3-1 CAMERA SETTINGS

Chapter 4 Simple troubleshooting and maintenance

4.1 Simple Troubleshooting Table

snoituloSesuaCelbissoPeruliaF

Connected the wrong power

cord Corrections

ecalperdegamadsiylppusrewoP

ecalperesufdaB

Electricity without

action, no images, light

does not shine.

noisulcxEdabsinoitcennocdrocrewoP

IR uniform dome camera

address code, the baud rate

setting does not

To re-set the high-speed dome address code and

baud rate

snoitcerroclocotorpgnorW

Power are self-test,

there are images, not

control

RS485 line reversed or open Check wiring RS485 control line

13

ecnanetniaMeruliaflacinahceM

denethgiartStliTaremaC

Unable to complete

self-test, there are

images associated with

motor tweet sound Power is not enough

Replacement to meet the requirements of the power

supply, it is best to power the camera on the

near-infrared uniform

Image instability Video line c noisulcxEdabsinoitcenno

ecalpeRhguonetonsirewoP

Blur Manual focus on the state Operation of any infrared high speed dome camera or

call a preset point

Power is not enough high-speed

Dome

Replacement to meet the requirements of the power

supply, it is best to power on the high-speed dome

camera in the vicinity

Check control of the most

distant high-speed dome

camera match whether to join

the resistance

The most far away from the control of the ball-type

cameras by adding matching resistor

Far from 485 the signal

attenuation Bold Line of Control

IR control of a

high-speed dome

camera non-stop or

delay

Converter 485 is not enough

driving force Replacement of a source converter

14

4.2 After Service

Dear users, in order to ensure the full enjoyment of your camera services, please read the following products and

services charter.

(A): IR dome camera company limited warranty and lifetime maintenance services

1. The limited warranty period from the date of sale for 12 months, in the limited warranty period, you will enjoy

the products fault free service, delivered or sent by the user's maintenance (improper use of man-made causes of

failure or an irresistible. The fault does not belong to the scope of the warranty).

2. In more than 12 months limited warranty from the date of the product life-long failure of the implementation of

paid maintenance services.

(B): The dome camera repair response time

1. Users will be sent to the company from the date of product, 24-hour response service.

2. Customers return products to our company, please advance with my company-related contact, and then

returned to our company products. Otherwise, the situation appears not timely maintenance by the user themselves.

Product Warranty Cards

Under this warranty cards note that every case of normal use the product itself due to quality problems caused by

failures in the warranty period will be given free maintenance.

Warranty Description:

1. This product is free of charge warranty period of one year, during the warranty period any product quality problems

occur, so doing the warranty card for free (non-human damage), life-long maintenance.

15

2. A result of improper use or other reasons as well as the failure of products outside the warranty period can be so

doing card repair, free of maintenance, only the income component costs.

3. Product required maintenance should be a copy of this card and the invoice with the product delivery of the

Company or the local special maintenance department.

4. Secretly open the dome camera casing, tearing up letters labeling, according to the provisions of collecting

maintenance fees and components and other expenses.

5. Does not accept any modification or installation of other functions due to failure after the dome camera.

The following conditions will not be free of charge Warranty:

1. Due to normal wear and tear caused by periodic inspection, maintenance, repair or replacement parts.

2. As the fall, extrusion, soaking, damp, and other man-made damage.

3. Because of flood, fire, lightning and other natural disasters or force majeure of the factors that damage.

4. By non-authorized repair centers repair the machine off.

5. Listed above, if changes to the relevant provisions shall prevail.

Model Number

Factory Number

Date of manufacture

Customer Unit

Name

Address

Telephone

Maintenance date Failure condition Maintenance site Maintenance result

Remark: ___________________________________________________

___________________________________________________

16

Table of contents