Table of contents

Table of contents

1 Introduction.....................................................................................................................................................4

1.1 Information about these instructions.........................................................................................................4

1.2 Explanation of symbols.............................................................................................................................4

1.3 Disclaimer .................................................................................................................................................5

1.4 Terms of warranty.....................................................................................................................................5

1.5 Customer service and product monitoring ................................................................................................5

2 Safety...............................................................................................................................................................6

3 Description......................................................................................................................................................7

3.1 Intended use .............................................................................................................................................7

3.2 Type plate .................................................................................................................................................7

3.3 Technical Data..........................................................................................................................................8

3.4 Dimensions and space requirements .......................................................................................................9

3.5 Control elements.....................................................................................................................................11

4 Installation.....................................................................................................................................................12

4.1 Requirements .........................................................................................................................................12

4.1.1 Personnel requirements.............................................................................................................. 12

4.1.2 Necessary material ..................................................................................................................... 12

4.1.3 Place of installation ..................................................................................................................... 12

4.2 Assembly ................................................................................................................................................13

4.3 Checks after installation / annual check .................................................................................................14

4.3.1 Leaks .......................................................................................................................................... 14

4.3.2 Functioning of the control valve .................................................................................................. 14

4.3.3 Flow rate measurement .............................................................................................................. 14

4.3.4 Determining jet height and jet pattern of the eye / face wash station ......................................... 14

4.3.5 Determining the water temperature ............................................................................................ 15

4.4 Final work ...............................................................................................................................................15

4.5 Instructing the personnel and organizing maintenance ..........................................................................15

4.5.1 Personnel requirements.............................................................................................................. 15

4.5.2 Instructing the personnel............................................................................................................. 15

4.5.3 Organizing the maintenance ....................................................................................................... 15

5 Operation.......................................................................................................................................................16

6 Maintenance..................................................................................................................................................17

6.1 Personnel requirements..........................................................................................................................17

6.2 Maintenance schedule............................................................................................................................17

6.3 Maintenance log .....................................................................................................................................18

7 Disassembly and disposal...........................................................................................................................20

8 Spare parts....................................................................................................................................................21

9 Declaration of Performance.........................................................................................................................22

Haws AG

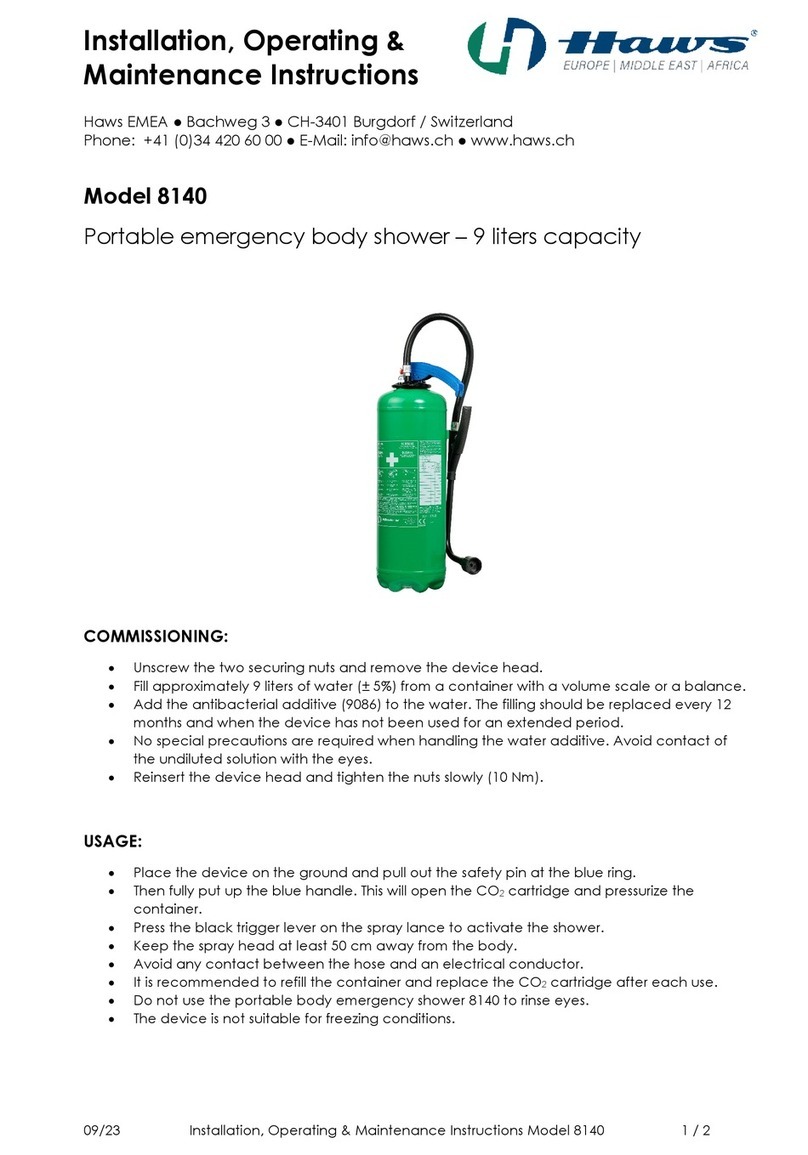

Delta™ 2203 Eye / Face Wash Station

iii / 22