Please file this Instruction Sheet in an accessible location: the Instruction Sheet must be read and familiar

to anyone who is using Southpaw Enterprises Equipment. AS THIS PRODUCT IS AN ITEGRAL PART OF

THE SUSPENSION SYSTEM OF YOUR EQUIPMENT, IT IS IMPERATIVE THAT YOU TAKE TIME TO

FAMILIARIZE YOURSELF WITH THE USE AND MAINTENANCE OF THIS EQUIPMENT BEFORE US-

ING, AND THAT YOU ADHERE STRICTLY TO THE MAINTENANCE AND INSPECTION PROGRAM.

Instruction Sheet

Safety Rotational Device 2000

Store these instructions in a safe place or

with the enclosed maintenance checklist

IMPORTANT: Please check equipment immediately for any damage

that may have resulted during shipping. If any damage has occurred,

please contact Southpaw Enterprises, Inc. immediately.

MATERIALS LIST

1 - Safety Rotational Device 1 - Maintenance Checklist

1 - Safety Snap - Attached 1 - Safety Snap Instruction Sheet

1 - Instruction Sheet

MINIMUM HEIGHT REQUIREMENTS AND SPACE NEEDED

Minimum Height: All hanging equipment should be hung at 8 ft.

Space Needed: Assure a clear distance of 6 ft. from walls and other

obstacles.

WORKING LOAD: 1,000 lbs.

HANGING INSTRUCTIONS

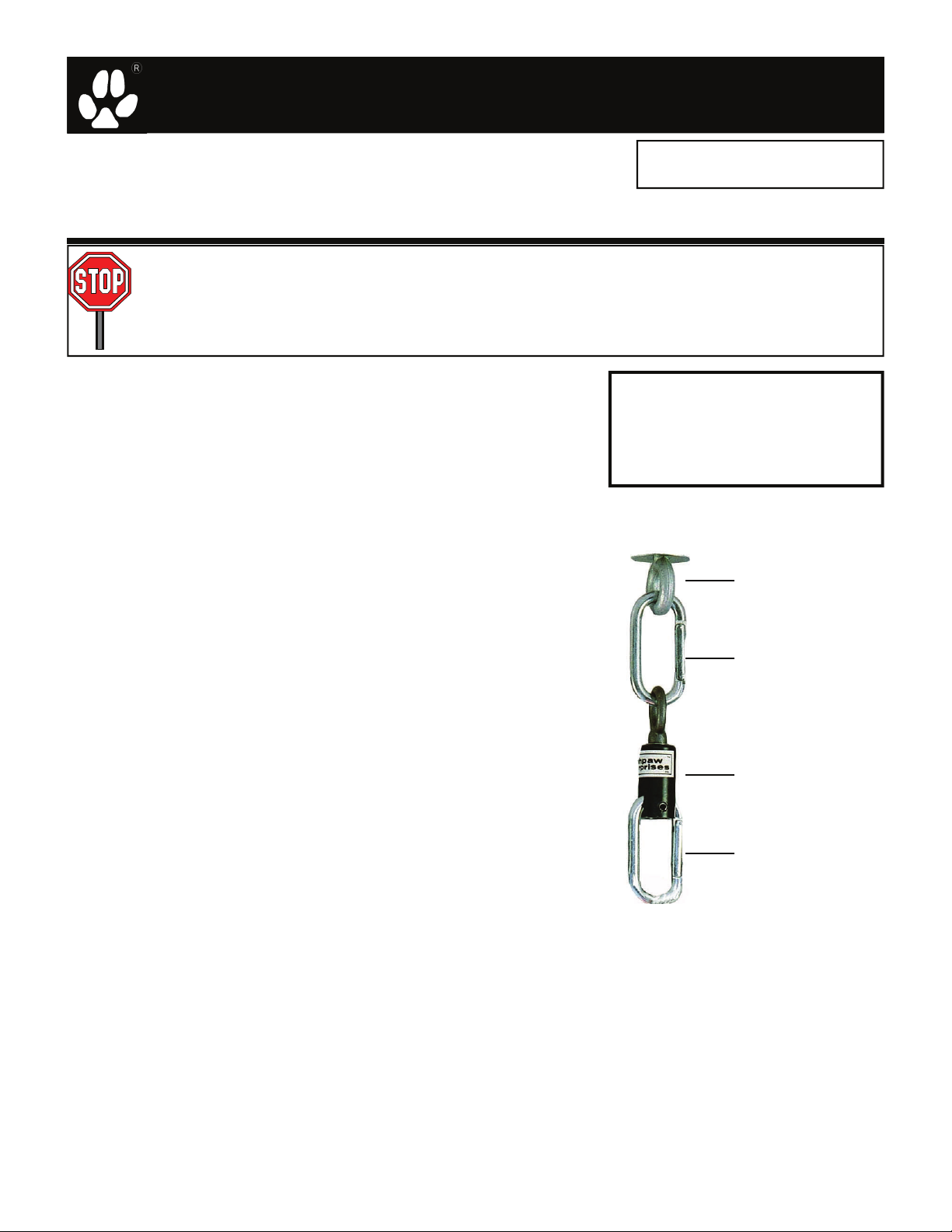

• Clip the Safety Rotational Device to your suspension system with a

Southpaw Safety Snap (# 2000) through the eye bolt on the top of the

Safety Rotational Device. The Southpaw Label should be facing in a

readable position when used in a permanent location. The Safety

Rotational Device must be hung in this manner to prevent dust, dirt,

and debris from entering the bearing area.

• Hang your suspended equipment from the Safety Snap attached to the

Safety Rotational Device.

• When using equipment with a Southpaw Safety Rotational Device

permanently attached, such as the Southpaw Bolster or Twirler, use the

Rotational Device as attached.

MAINTENANCE CHECKLIST

All of the following wear points should be checked on a monthly basis and recorded on the checklist enclosed. If re-

placement is necessary, contact Southpaw for replacement immediately.

• Remove the Rotational Device from the equipment and/or eyebolts. Remove the Southpaw Safety Snap from the

Rotational Device.

• You may use an aerosol dust remover or very clean compressed air to blow out any dust from inside the rotational

housing.

• Visually inspect the "eye" of the eyebolt. If the "eye" has a worn through 30% of the thickness of the steel, discon-

tinue use and replace.

• Visually inspect the round "pin" which goes through the housing of the rotational on the side opposite from the

"eye". If it is bent at all, discontinue use and replace. Note: This pin is made of hardened steel, and it is unlikely

that it will be worn. If it is worn, it will bend before it breaks. So a bent "pin" is worn. (Continued on back)

Warning: Failure to properly install a forged

steel eyebolt (1/2” or 5/8”) may result in serious

injury or death. If you have any questions

about the installation of the forged steel

eyebolt, please contact Southpaw Enterprises

Customer Service at 1-800-228-1698.

Suspension Point

Safety Snap

Rotational Body

Safety Snap

southpaw enterprises, inc.®