HAWS®P/N 0580001083 Rev.2 11/21 Model 8730 Page 3 of 20

TABLE OF CONTENTS

DISCLAIMER................................................................................................................................................2

TABLE OF CONTENTS ...............................................................................................................................3

DESCRIPTION OF PRODUCT.....................................................................................................................4

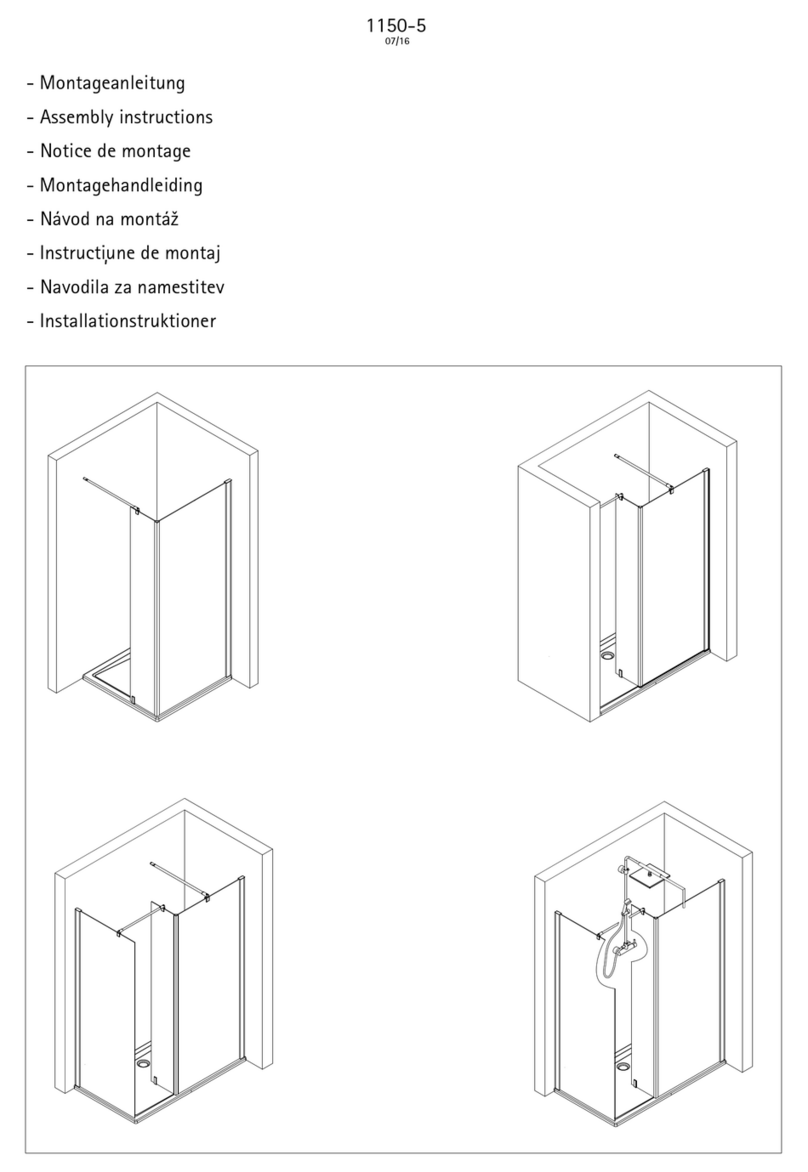

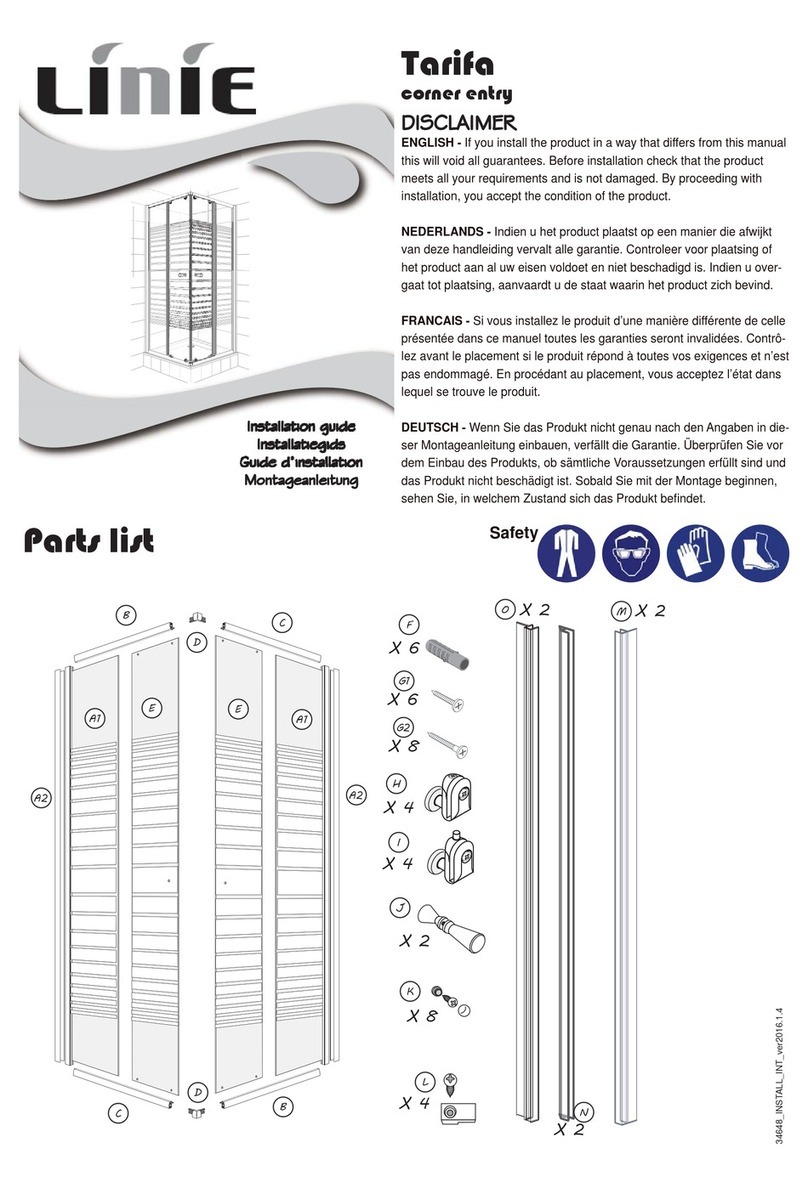

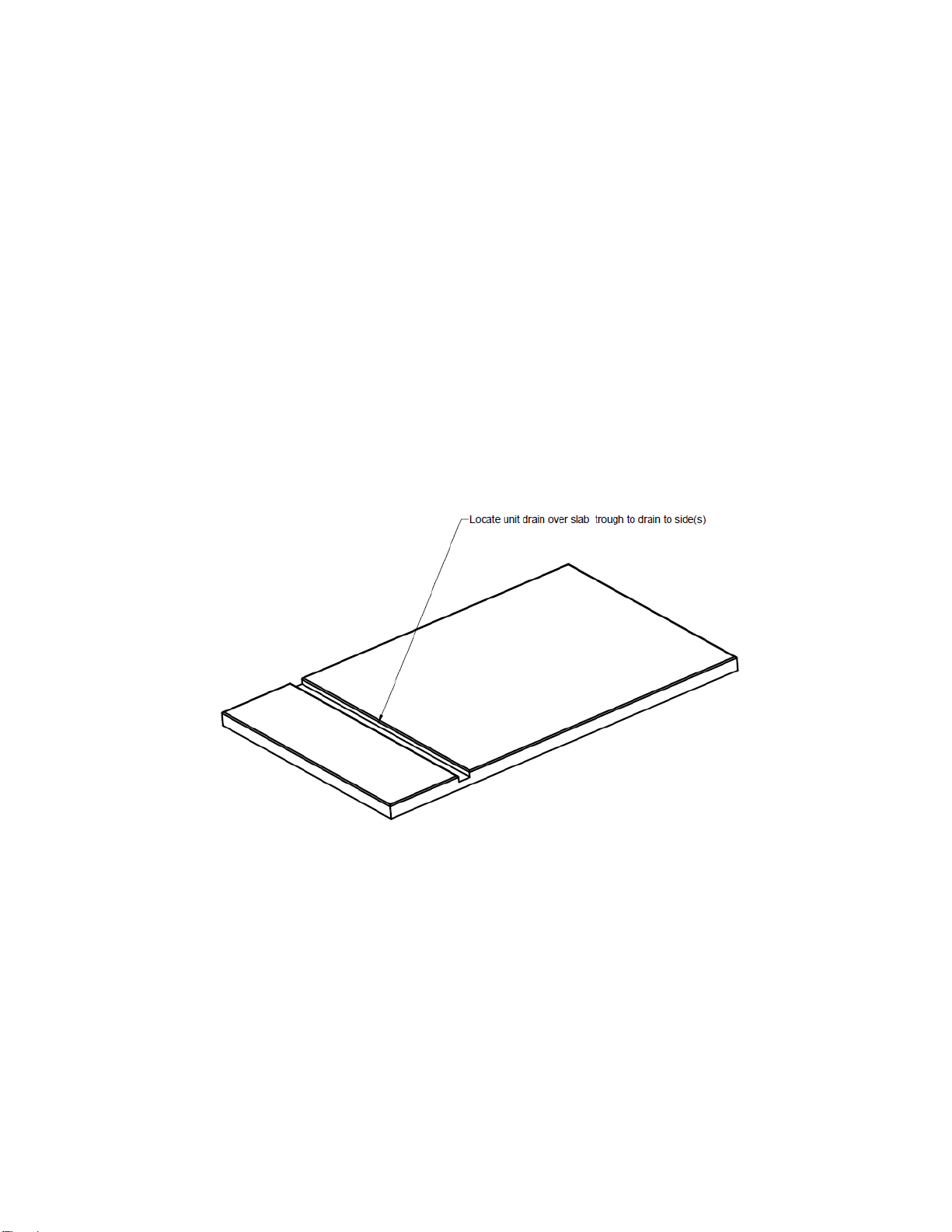

INSTALLATION PROCEDURE....................................................................................................................6

Checklist for start-up ..............................................................................................................................8

PROGRAMMABLE CONTROLLER ............................................................................................................9

PREVENTIVE MAINTENANCE..................................................................................................................10

Weekly ....................................................................................................................................................10

Monthly...................................................................................................................................................10

Quarterly.................................................................................................................................................10

Annually..................................................................................................................................................10

MAINTENANCE, TESTING, REPAIR ........................................................................................................11

Booth...................................................................................................................................................11

Double Swinging Doors ....................................................................................................................11

Combination Shower/Eyewash ........................................................................................................11

Freeze and Scald Valve.....................................................................................................................11

Y-Strainers..........................................................................................................................................11

TROUBLESHOOTING................................................................................................................................12

SPARE PARTS...........................................................................................................................................13

DRAWINGS ................................................................................................................................................14

General Arrangement Drawing (0580001083.D-GA)...........................................................................14

Electrical Schematic (0580001083.D-EL).............................................................................................16

Piping and Instrumentation Diagram (0580001083.D-PID)................................................................18

LIMITED WARRANTY................................................................................................................................20