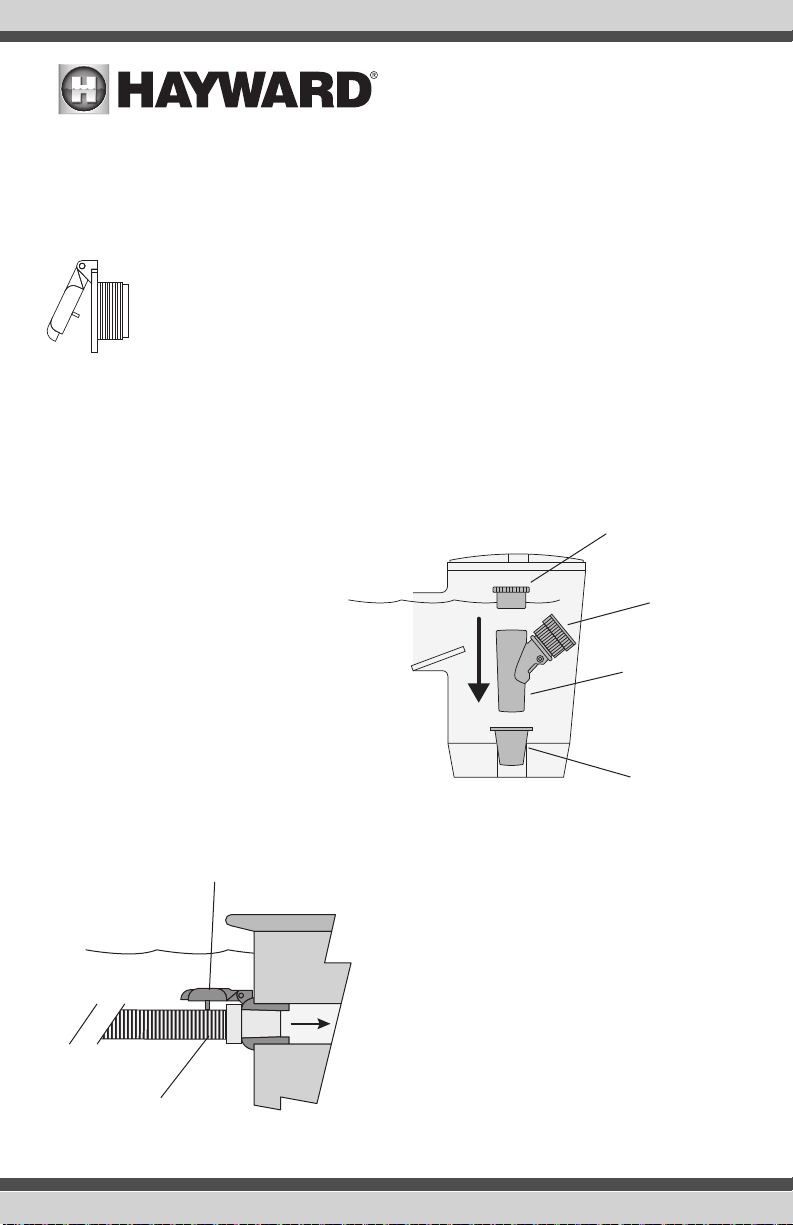

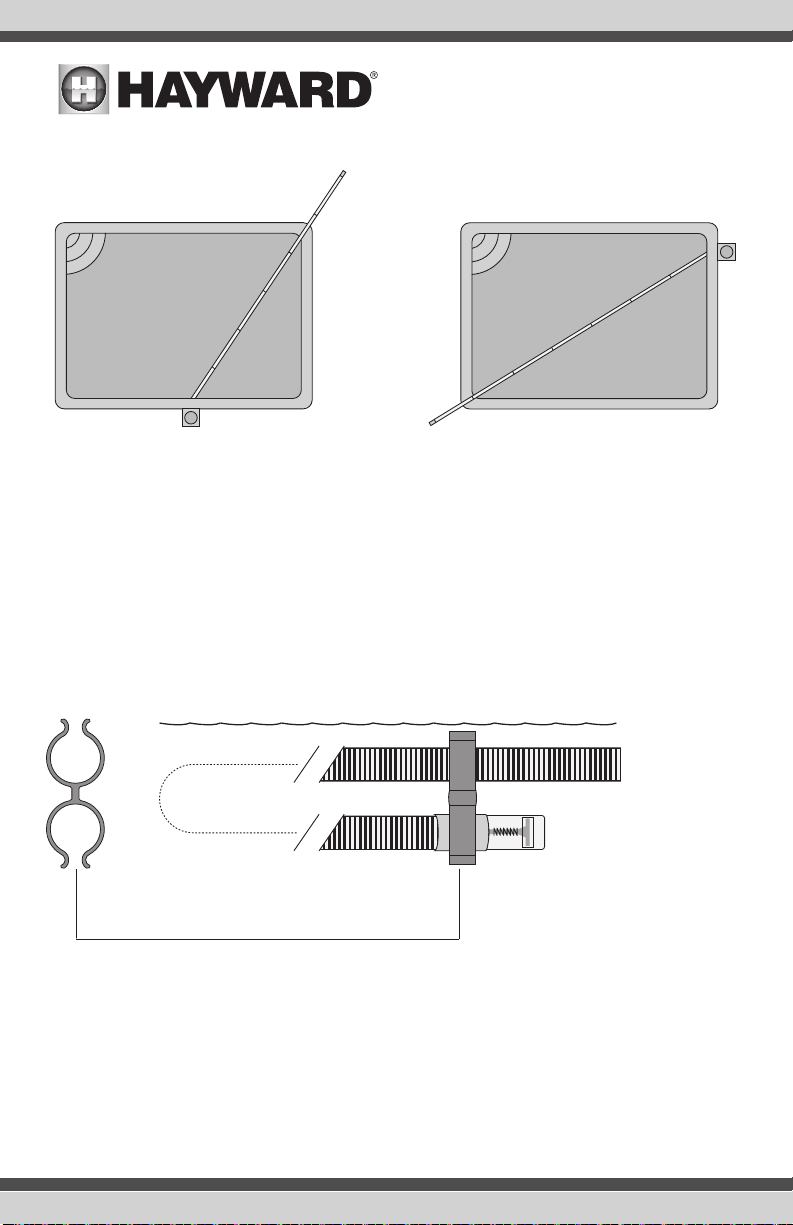

11. Lock the top cover onto the cleaner chassis with the locking buckle on the front of the

cleaner.

Troubleshooting

IMPORTANT: Always disconnect cleaner before servicing.

Problem Solution

Cleaner is not moving or is

moving too slowly.

• Check flow with Flow Gauge and if necessary, adjust the Flow Regu-

lator Valve.

• Check for debris inside the cleaner itself.

• Check that pump is running at desired speed and is fully primed. If

pump has lost prime, disconnect and wait for prime.

• Check if the pool filter needs cleaning or backwashing.

• Check to be sure that the main drain and all suction lines are

closed, except for the vacuum or suction line to which the cleaner

is attached.

• Check for leaks or obstructions in the system (e.g. debris in the

filter, pump basket or pump impeller).

Cleaner’s left track will not

turn when rotated by hand. • Check for obstructions inside the cleaner (see page 8).

Cleaner stays in one end

of the pool.

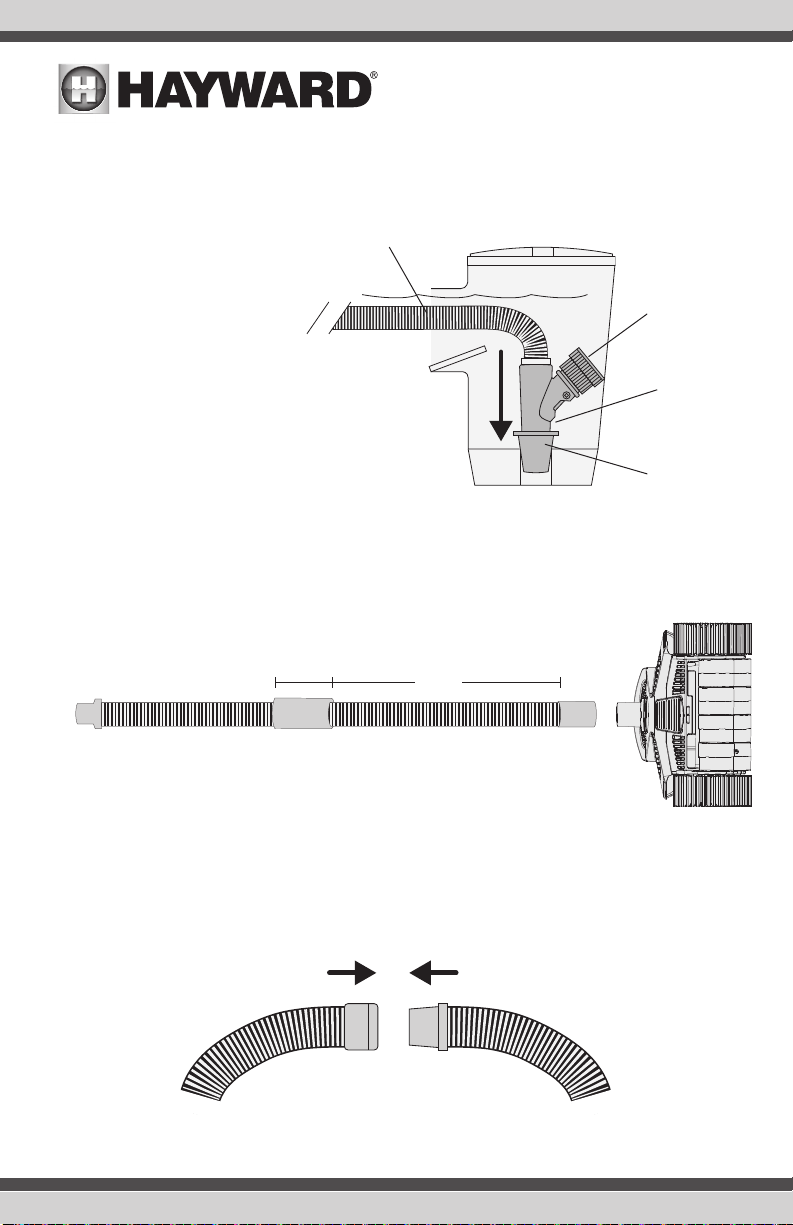

• Hose may be limiting movement. Adjust the hose and remove any

loops or coils.

• Check that hose is long enough (see page 5-6).

• Check flow with Flow Gauge and if necessary, adjust the Flow Regu-

lator Valve (see page 6).

• Check the direction of the return line water flow. If it is interfering

with the path of the cleaner, redirect to a different direction.

• Check the Leader Hose for float placement. The float may be in the

wrong position.

• Be sure that the swivel assembly (at top of cleaner) rotates

smoothly. If not, clean the area as described on page 8.

Cleaner climbs the wall

too much or climbs out

of pool.

• Check flow with Flow Gauge. You may need to decrease the flow

using the Flow Regulator Valve.

Cleaner won’t climb the

pool walls.

• Check to be sure that the cleaner tracks are not excessively worn.

Excessively worn tracks will not provide the grip necessary for your

cleaner to climb pool walls.

• Check flow with Flow Gauge. You may need to increase the flow

using the Flow Regulator Valve - do not exceed the maximum Flow

Gauge setting.

• Check the Leader Hose for float placement. The float may be in the

wrong position.

Cleaner stays on the main

drain.

• Check to be sure that main drain is closed. May need assistance

from a pool professional.

• Check to be sure a main drain grate is installed.

9

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS