ATR 421 - User manual 3

Summary

1 Model identication.......................................................................................................................... 7

2 Technical data .................................................................................................................................... 7

2.1 Main features ............................................................................................................................7

2.2 Hardware features ................................................................................................................... 8

2.3 Software features.....................................................................................................................8

3 Size and installation.......................................................................................................................... 9

4 Electrical wirings..............................................................................................................................10

4.1 Wiring diagram ......................................................................................................................10

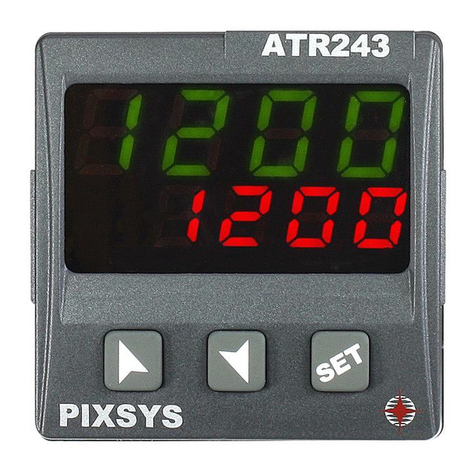

5 Display and keys functions............................................................................................................14

5.1 Numeric indicators (display) ...............................................................................................15

5.2 Meaning of Status Lights (led) ............................................................................................15

5.3 Keys .........................................................................................................................................15

6 Programming and conguration ................................................................................................16

6.1 Programming (or modifying) cycle data..........................................................................16

6.1.1 Programming of starting setpoint (if enabled) ...................................................17

6.1.2 Programming of the step .........................................................................................17

6.1.3 Programming of the auxiliary output (if congured) ........................................18

6.1.4 Fine programmazione...............................................................................................18

7 Cycle start .........................................................................................................................................18

7.1 Start of a cycle and setting of delayed start ....................................................................18

7.2 Fast advancement during the cycle .................................................................................19

7.3 Simple controller function ...................................................................................................20

7.4 Output manual control.........................................................................................................20

8 Programmer functions ..................................................................................................................21

8.1 Hold function ..........................................................................................................................21

8.2 Automatic tuning ..................................................................................................................21

8.3 Manual tuning........................................................................................................................22

8.4 Recovery of interrupted cycle .............................................................................................22

8.4.1 Recovery with automatic gradient.........................................................................22

8.4.2 Recovery with recovery gradient ............................................................................23