• Start moving the load along the beam only after it has

been attached correctly and all personnel are clear of

the danger zone.

• Be aware of hazards when setting up/folding down,

eg. hands/fingers trapped in rotating parts.

• It is essential for safety that the P O R TA -GANTRY is

withdrawn from use immediately should:

1) any doubt arise about its condition for safe use or;

2) it has been used to arrest a fall and not be used

again until confirmed in writing by a competent

person that it is acceptable to do so.

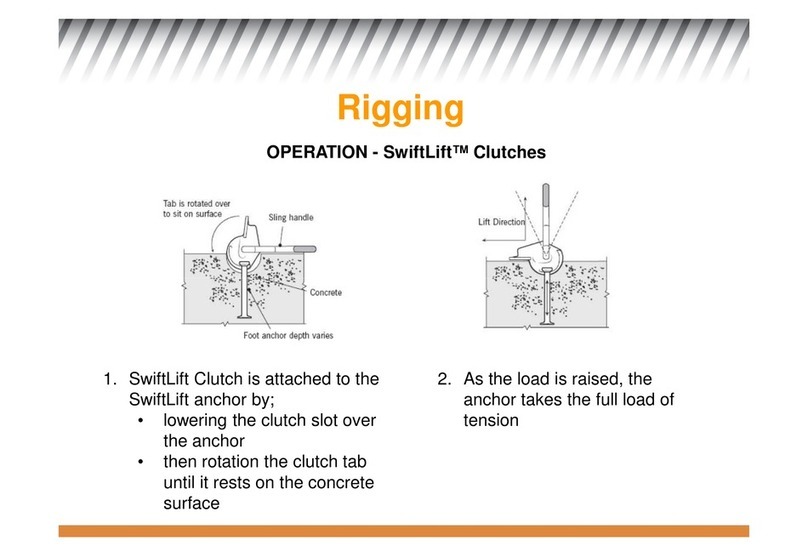

Attaching the load

The operator must ensure that the hoist is attached in

a manner that does not expose him or other personnel

to danger by the hoist, chain(s) or the load.

Temperature range

The

P O RTA -GANTRY

can be operated in ambient dry

temperatures between -20° and +55°C (-4°F to 131°F).

Consult your supplier in case of extreme working conditions.

If used in sub-zero and wet conditions, fall arrest

appliances characteristics may change.

Regulations

The

P O RTA -GANTRY

complies with the following

regulations:

PPE Directive 89/686/EEC, Machinery Directive

2006/42/EC, The Provision and Use of Work Equipment

Regulations 1998 (S.I. 1998 No. 2306), The Lifting

Operations and Lifting Equipment Regulations 1998

(S.I. 1998 No. 2307), and/or safety regulations of the

respective country for using manual lifting equipment

must be strictly adhered to. EN795:1997, ANSI Z359.1-

2007 and CSA Z259.16-04 certified.

INSPECTION/MAINTENANCE

Regular inspections

To ensure that the gantry frame remains in safe

working order it must be subjected to thorough periodic

inspections by a competent person. Inspections are to be

6 monthly for personnel lifting and 12 monthly for goods

only unless adverse working conditions or profile of use

dictate shorter periods. The components of the gantry

frame are to be inspected for damage, wear, corrosion

or other irregularities. To check for worn parts it may be

necessary to disassemble the gantry frame.

Repairs should only be carried out by an approved

specialist workshop that uses original spare parts.

If using the Gantry in explosive atmospheres see

additional section titled ATEX.

Inspections are instigated by the user. If detailed

information is required on inspection and test criteria,

please refer to your supplier’s technical department.

Please refer to pg 19 for the equipment inspection log.

Maintenance/Repair

In order to ensure correct operation not only the

operations instructions, but also the conditions for

inspection and maintenance must be complied with.

If defects are found stop using the P O RTA -GANTRY

immediately.

No alterations or additions to the equipment should be

made without the written consent of the manufacturer.

Any repair shall only be carried out in accordance with

the manufacturer’s procedures.

It is recommended to maintain the equipment in a clean

and dry manner. Cleaning is suggested using a sponge

or cloth with warm, soapy water (using diluted domestic

washing up liquid), rinsing and allowing to dry.